Laboratory Roll-to-Roll Coater

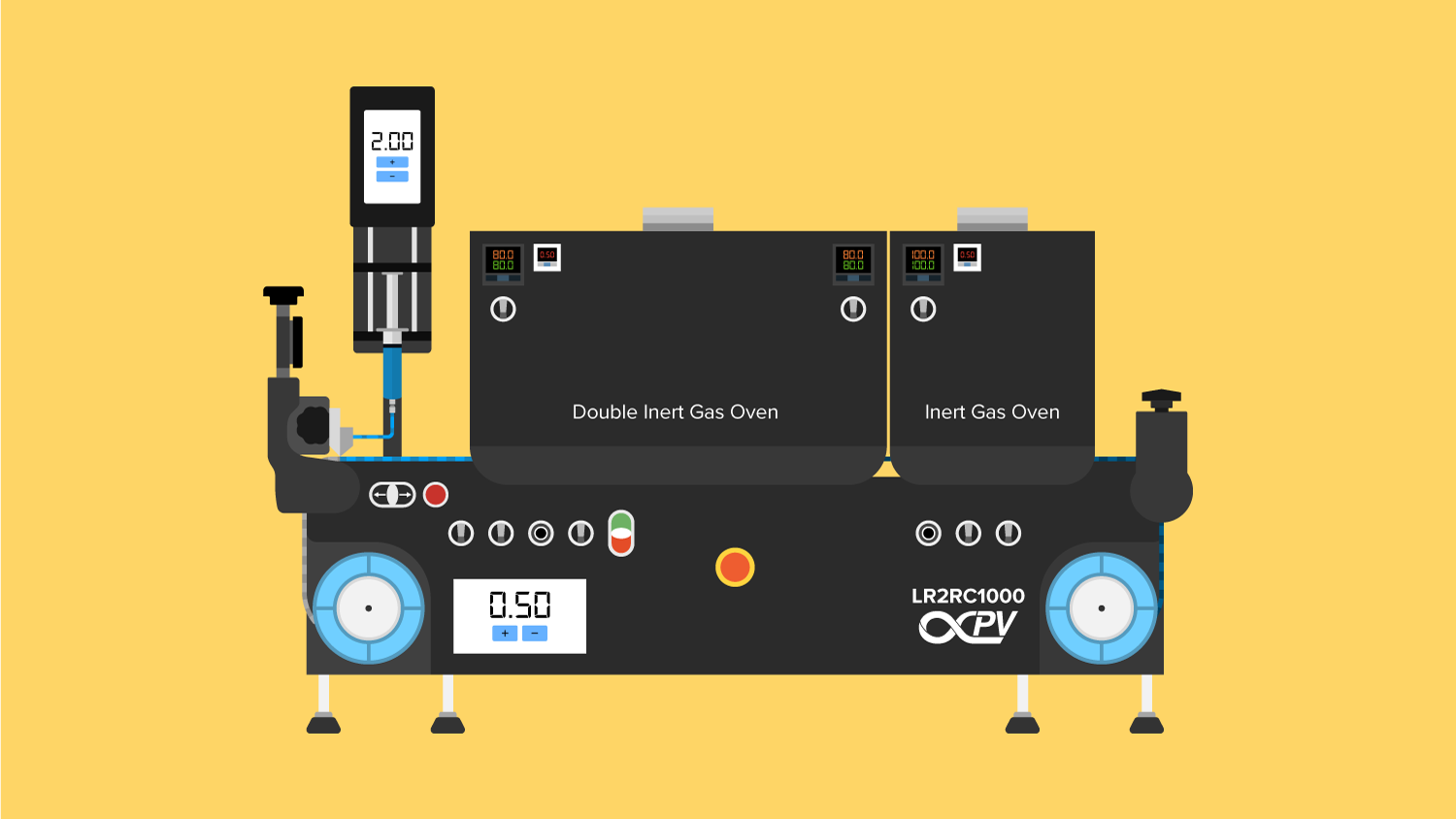

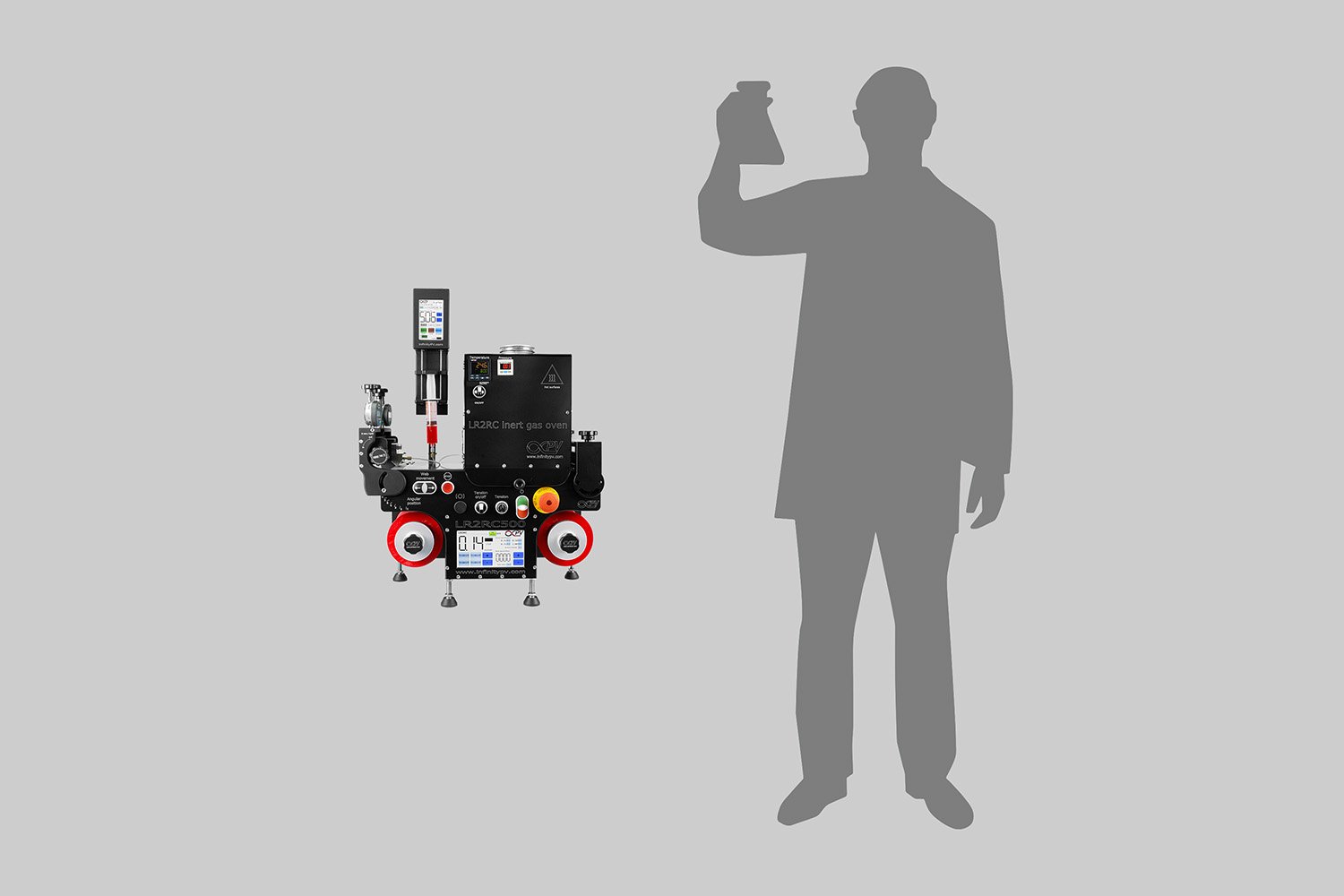

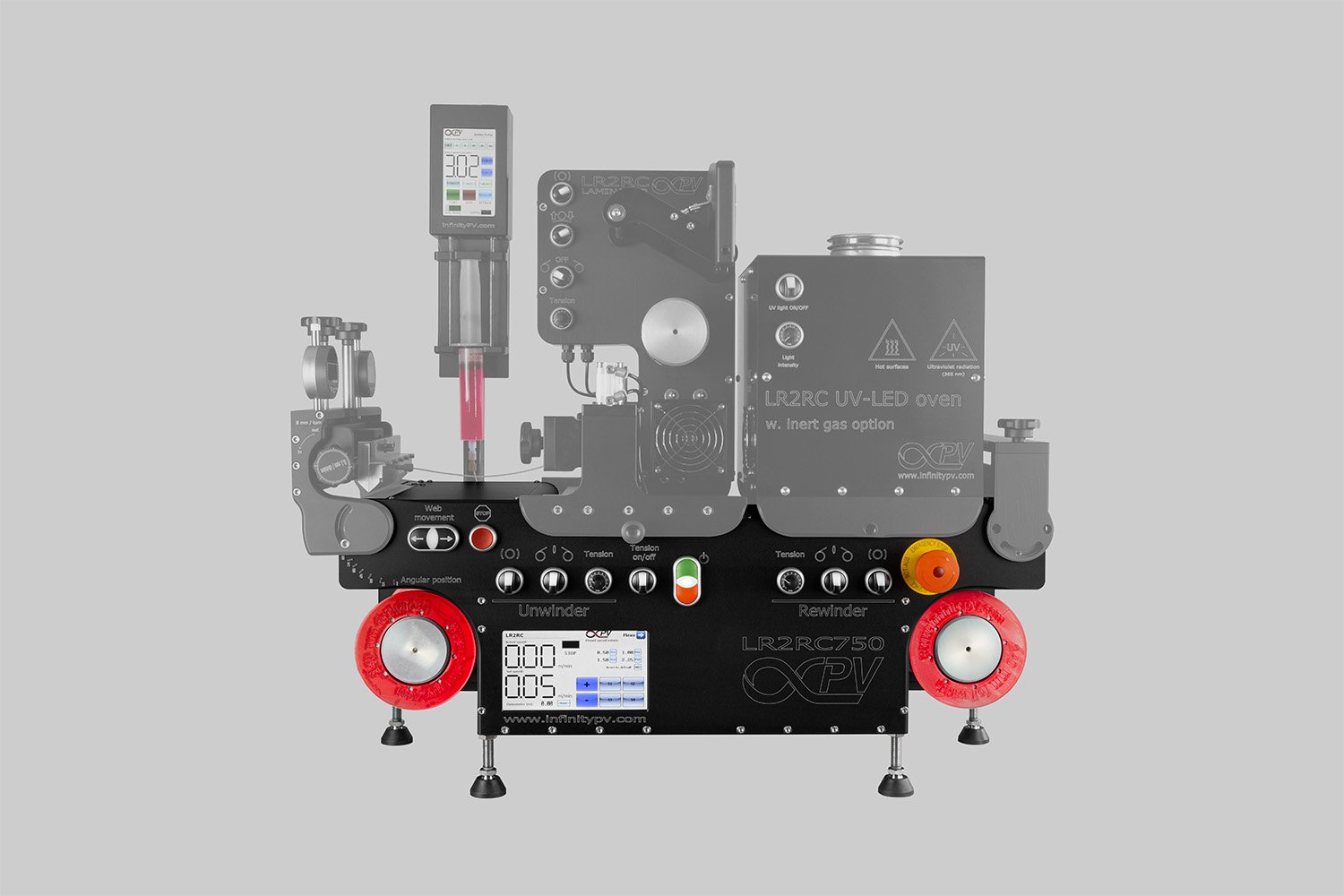

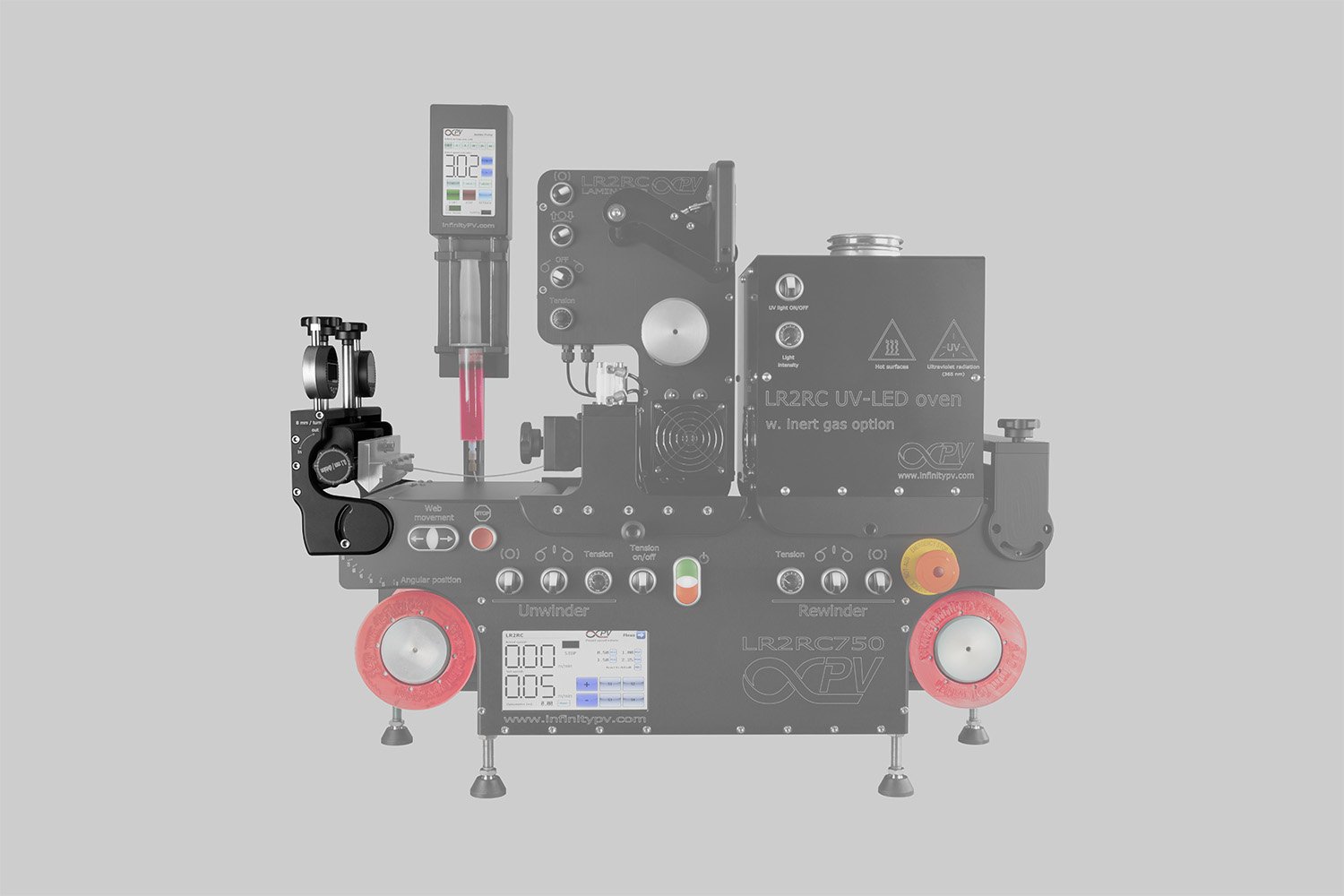

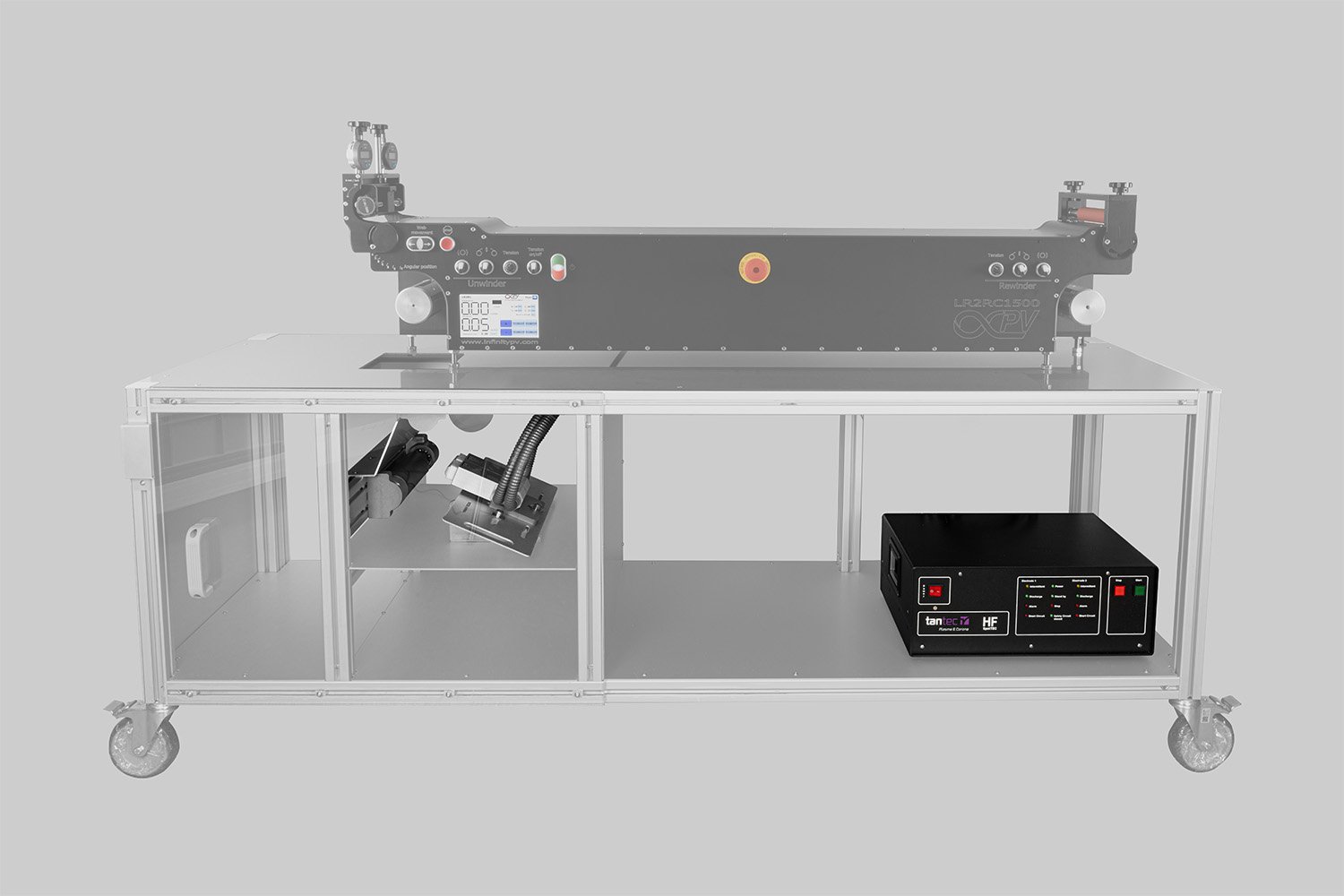

The Laboratory Roll-to-Roll Coater is a compact, high-precision lab coater that transforms the way thin functional films are processed. It offers modular customization to fit different needs, scalable efficiency for small-scale production, and a user-friendly design with easy-to-remove components.

Compact Roll-to-Roll Processing

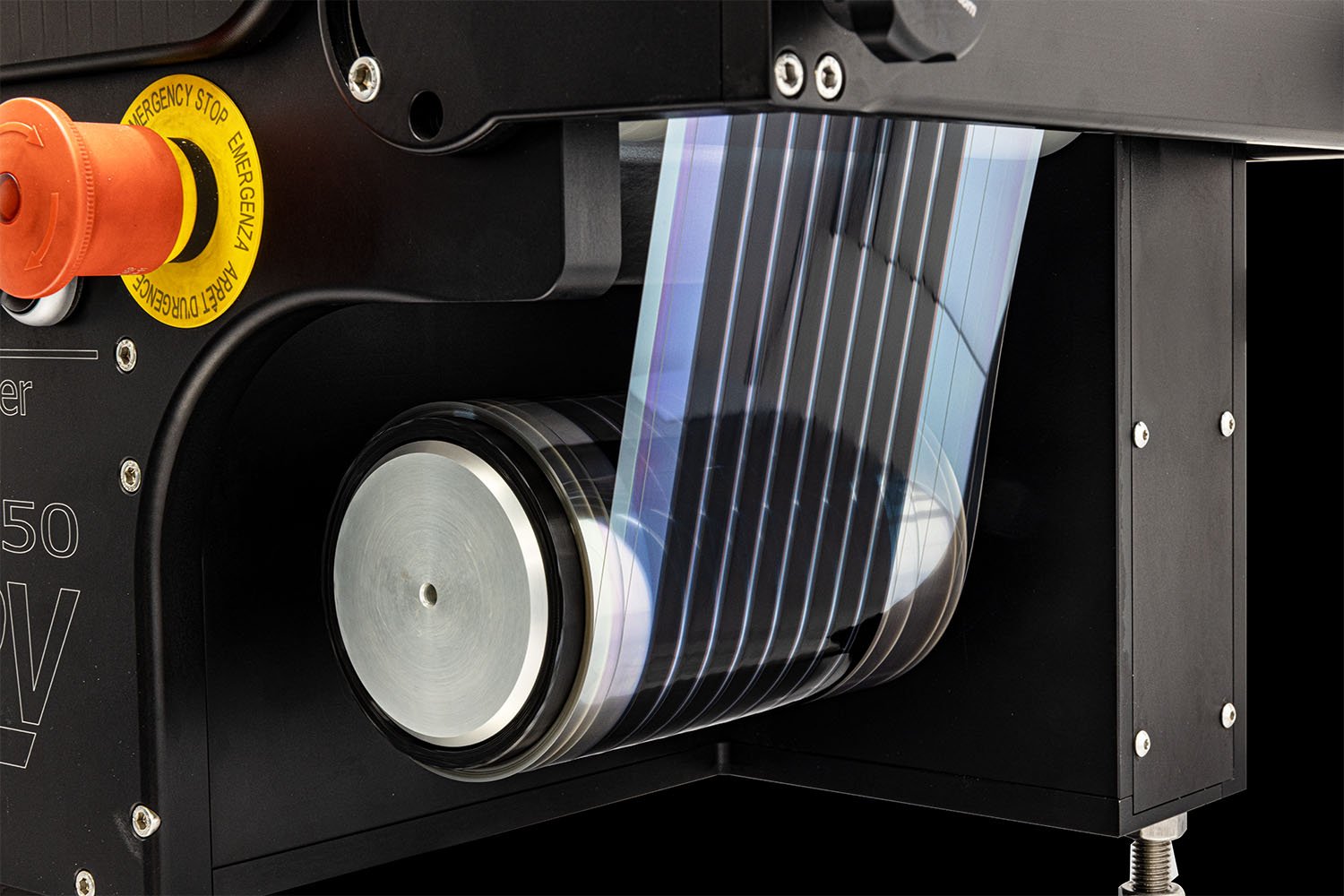

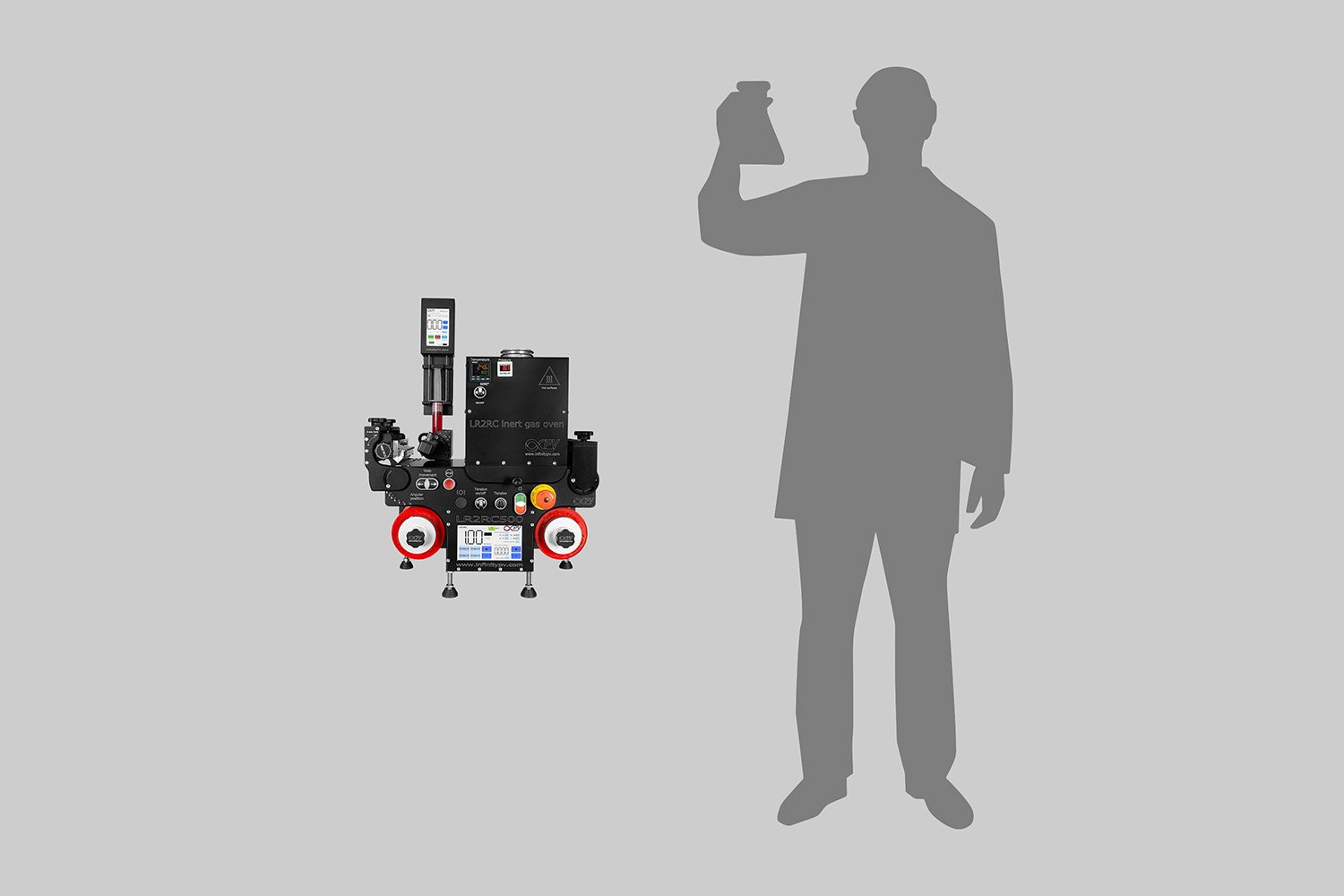

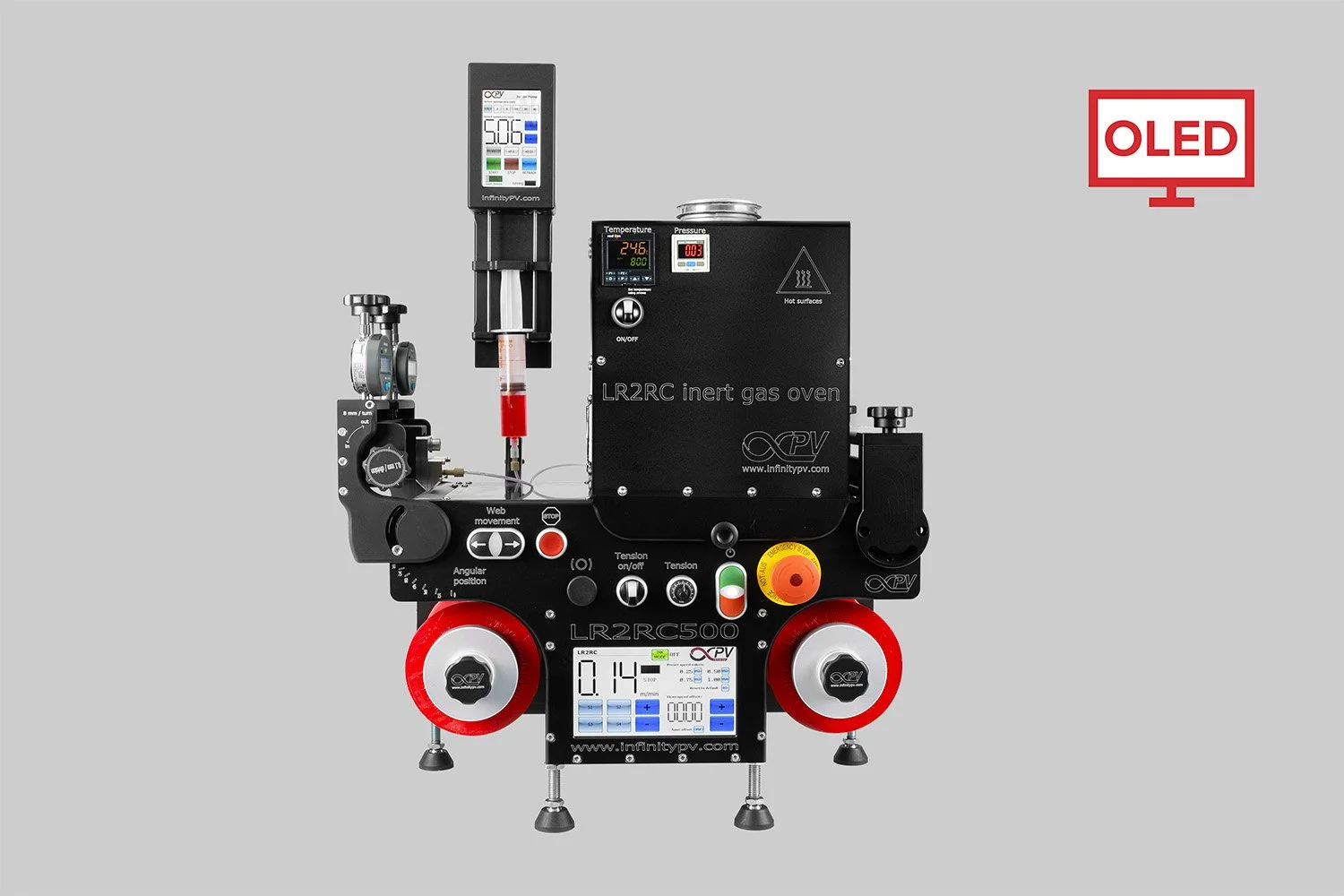

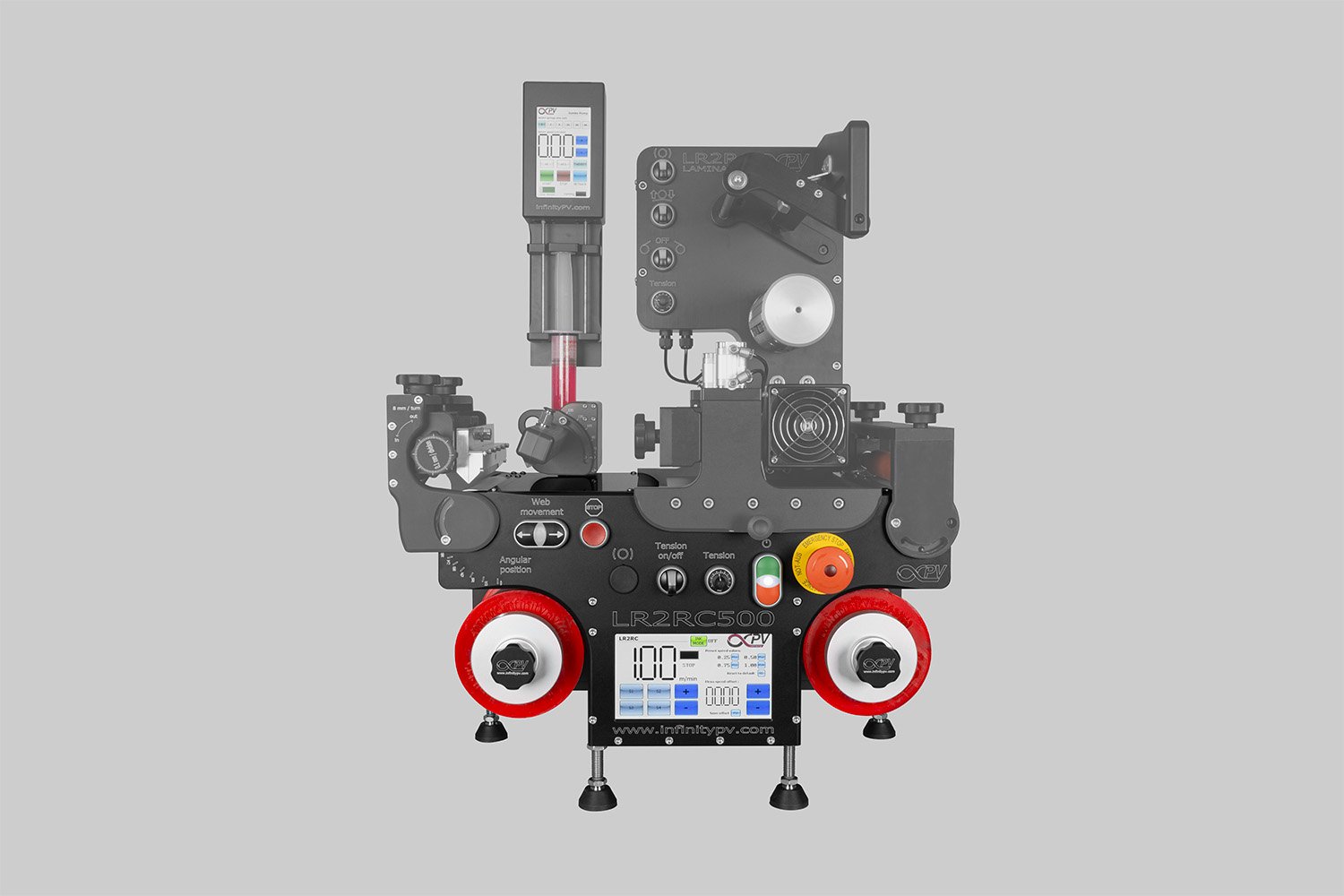

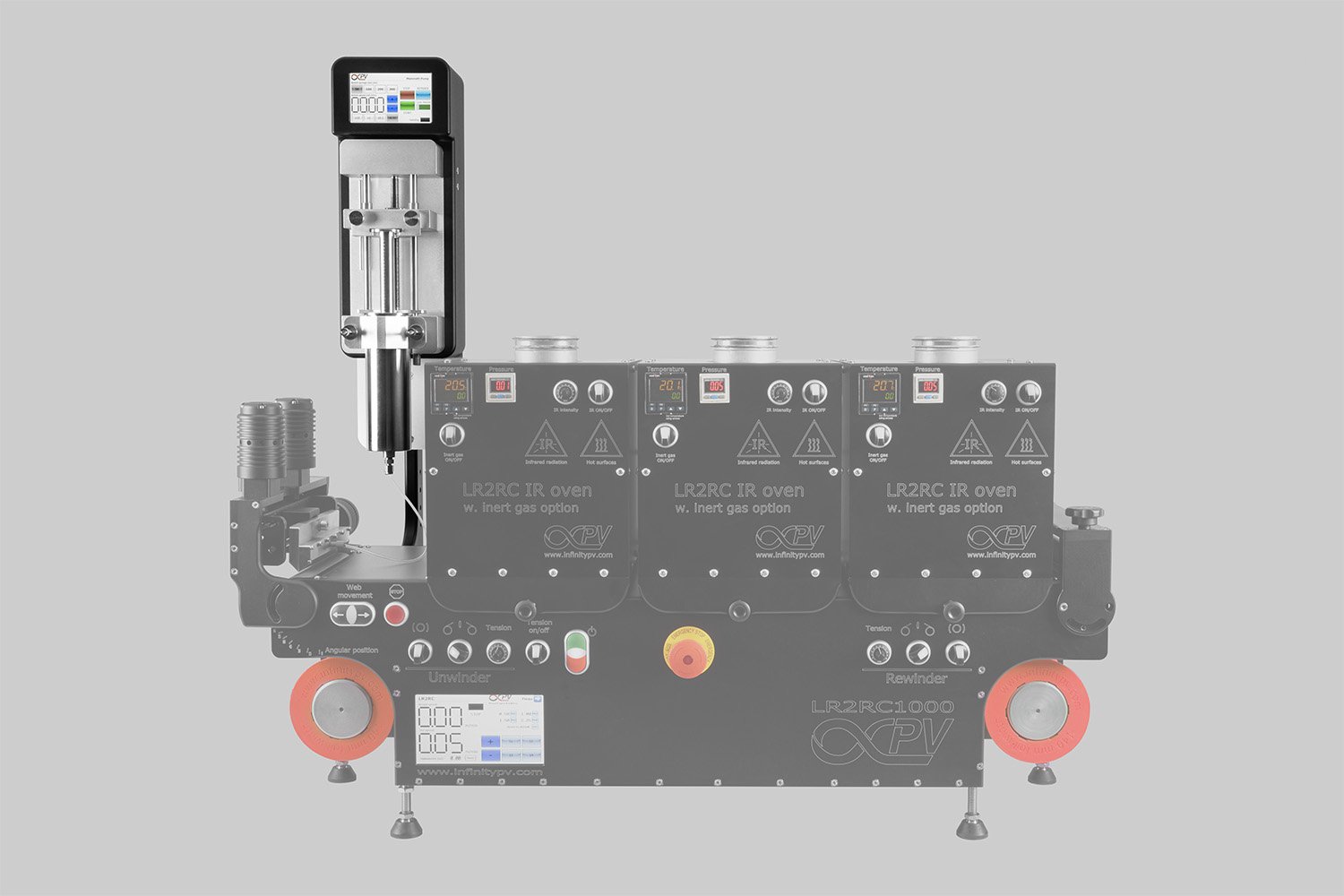

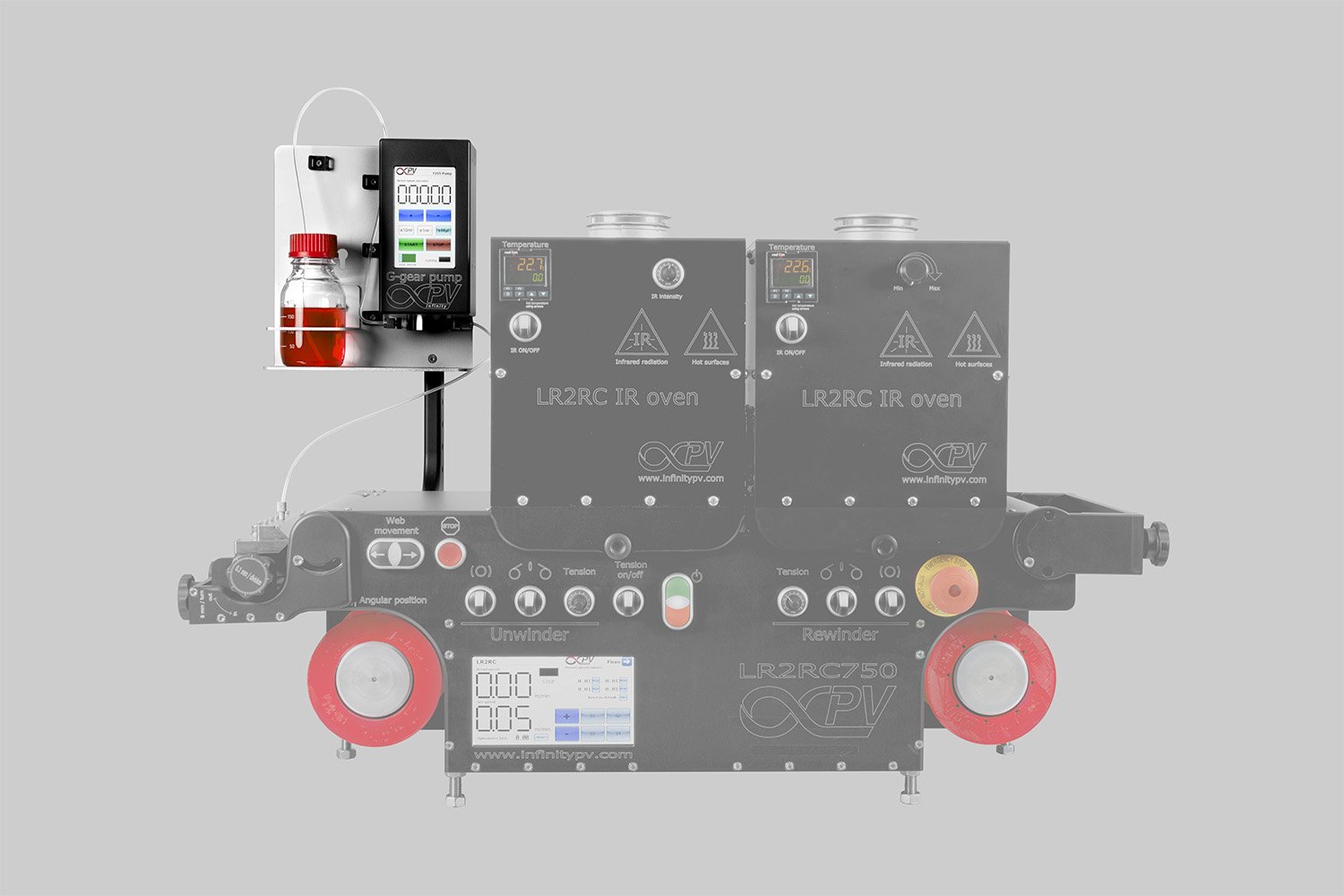

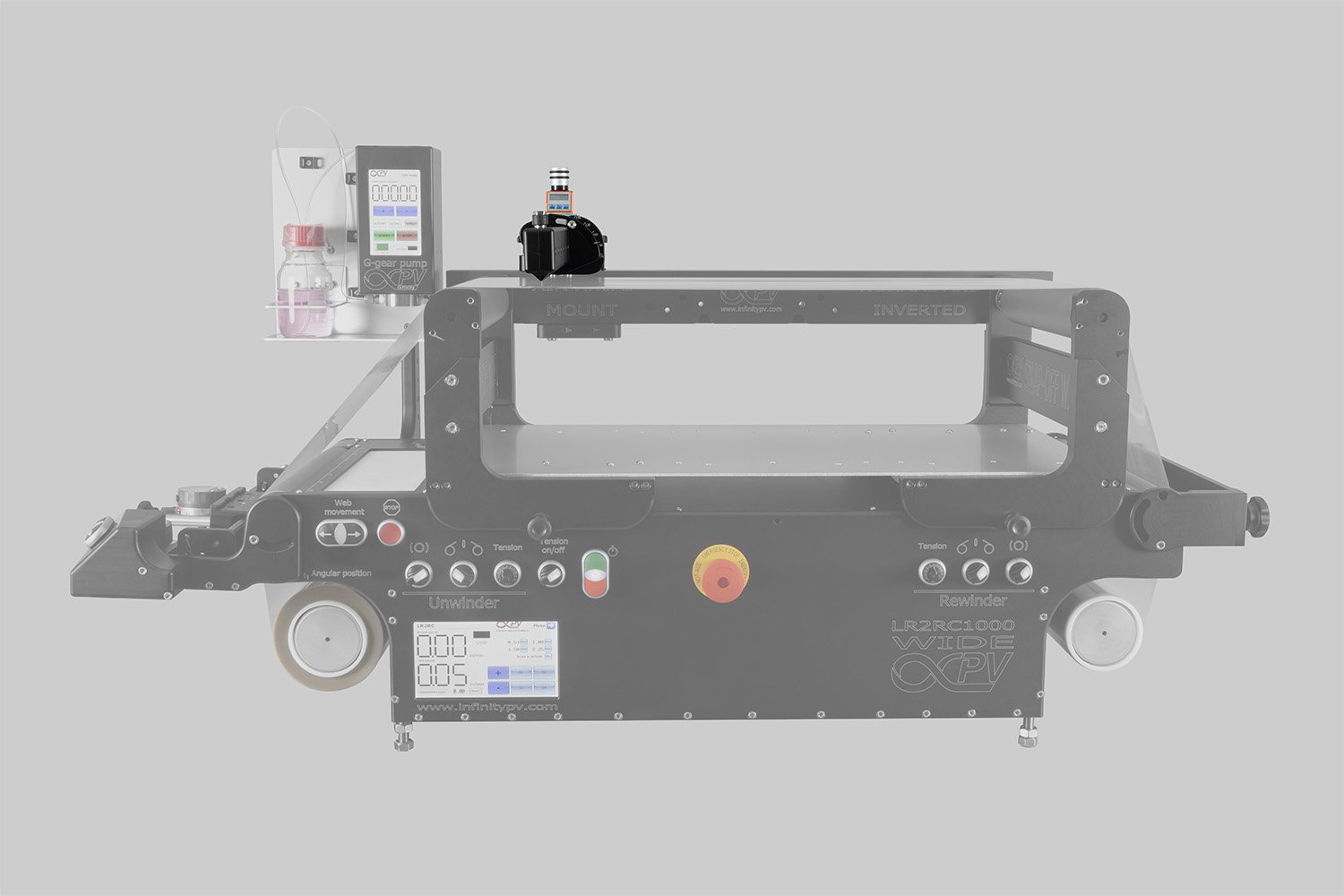

The Laboratory Roll-to-Roll Coater (LR2RC) is a compact, high-precision R2R lab scale coater that transforms the way thin functional films are processed. This versatile system caters to various needs, from laboratory to small pilot-scale production, processing hundreds of meters of foil efficiently.

Modular Customization

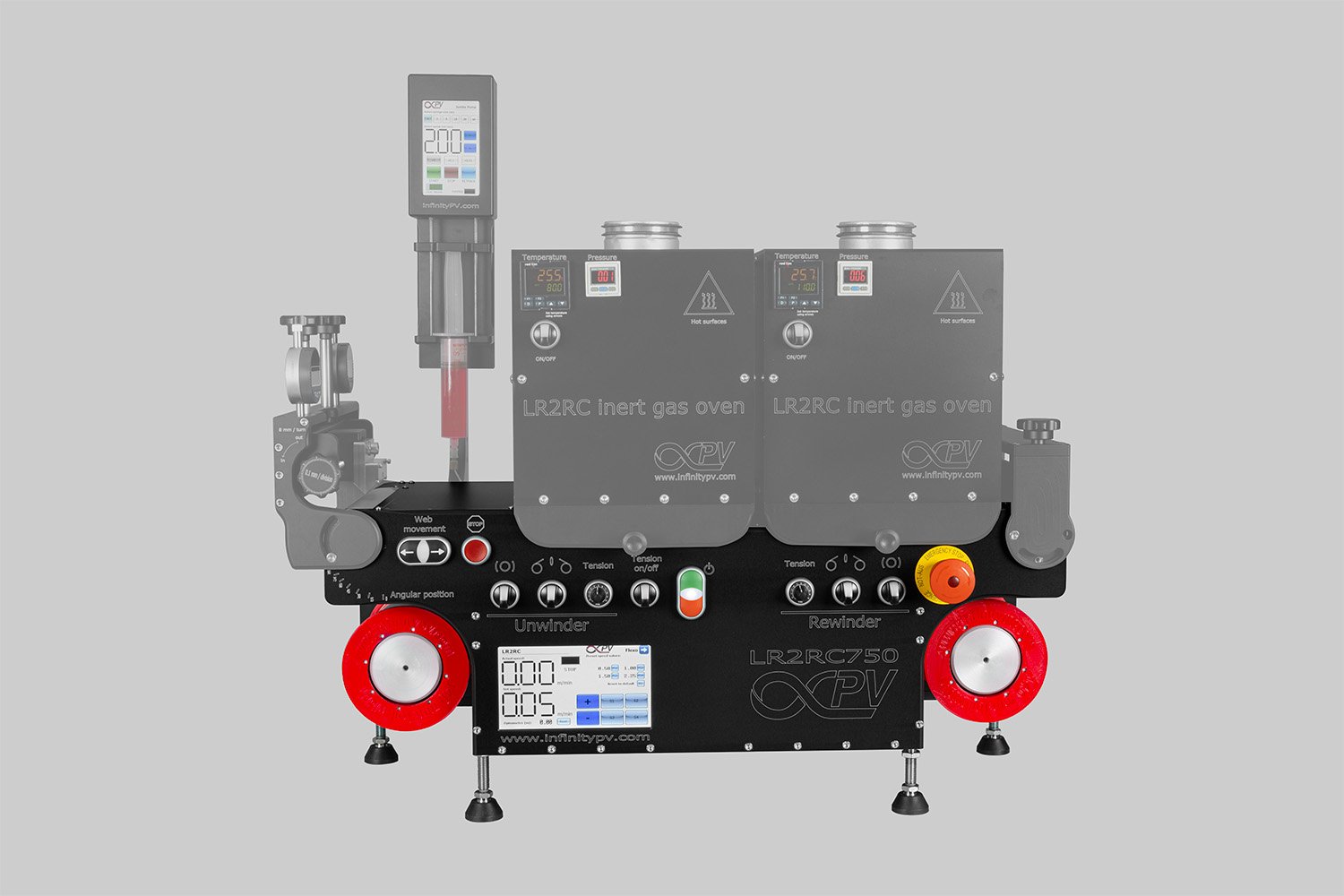

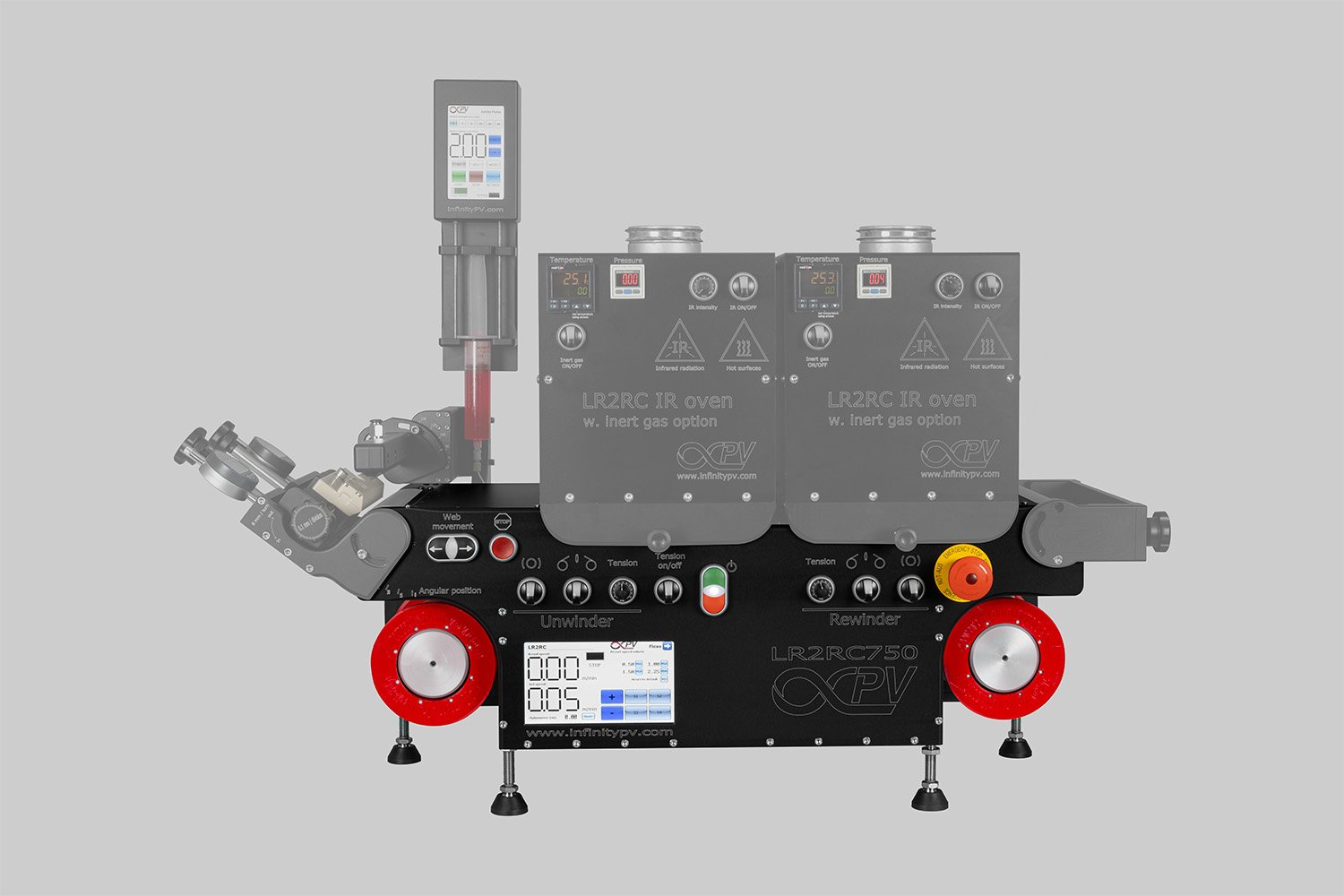

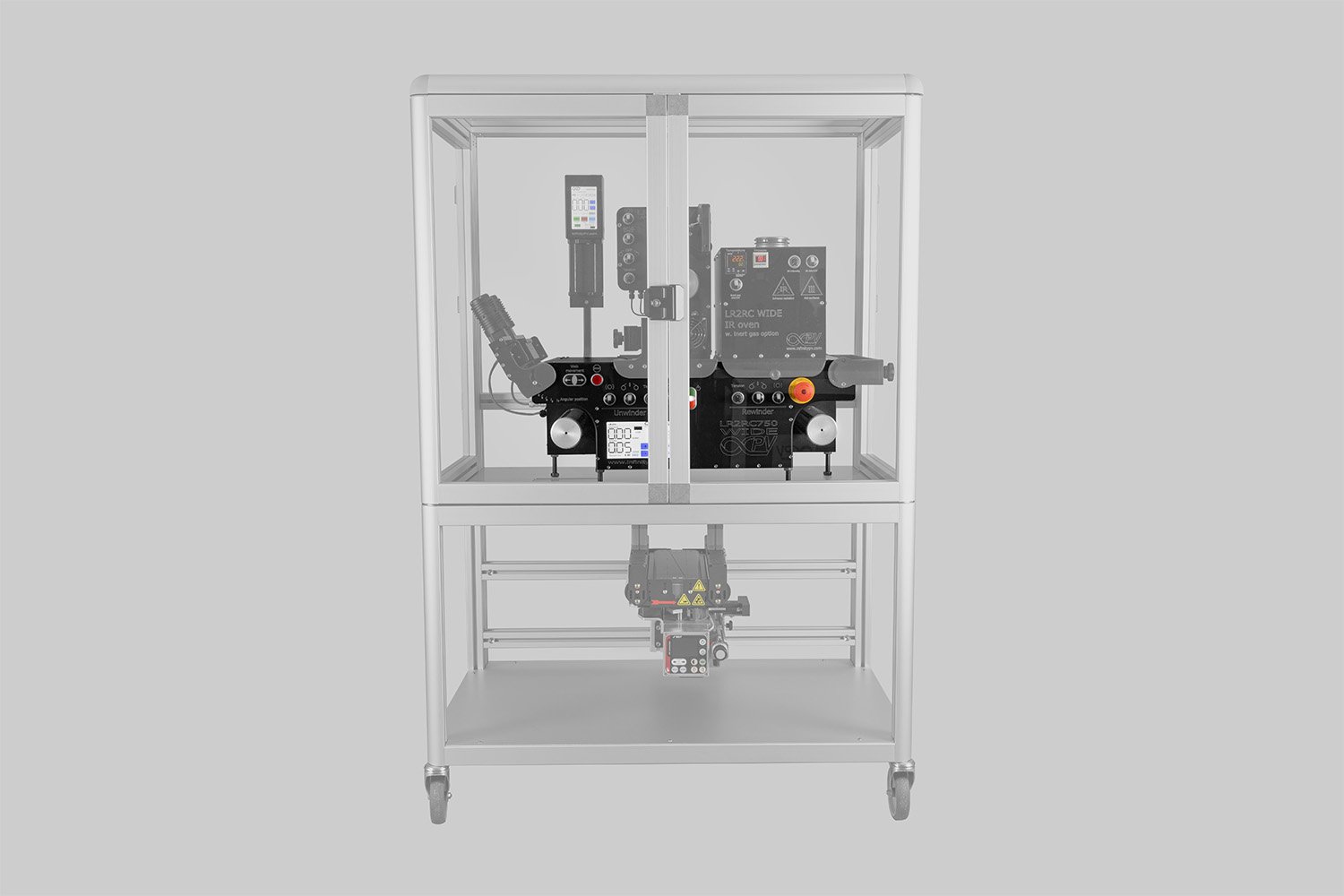

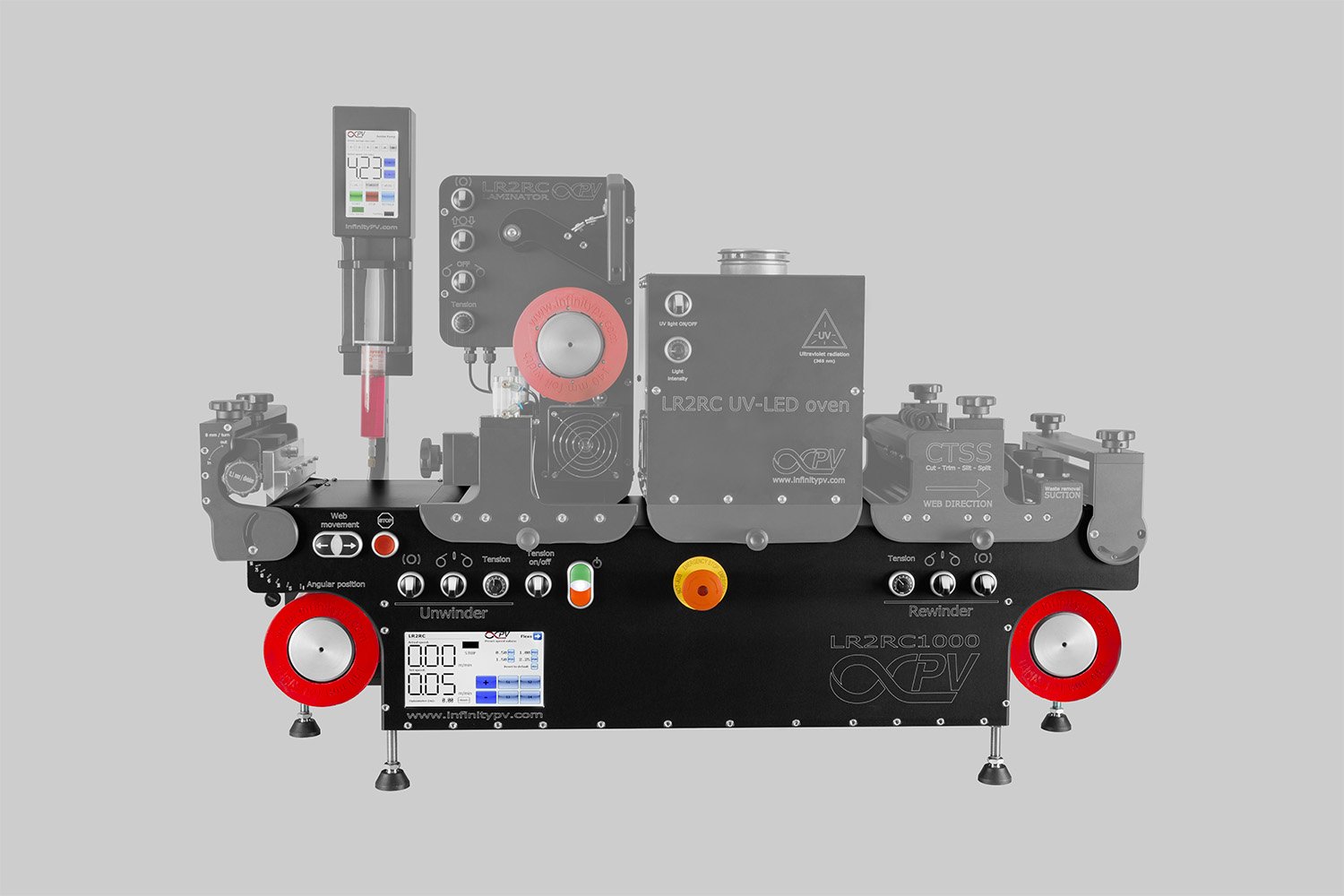

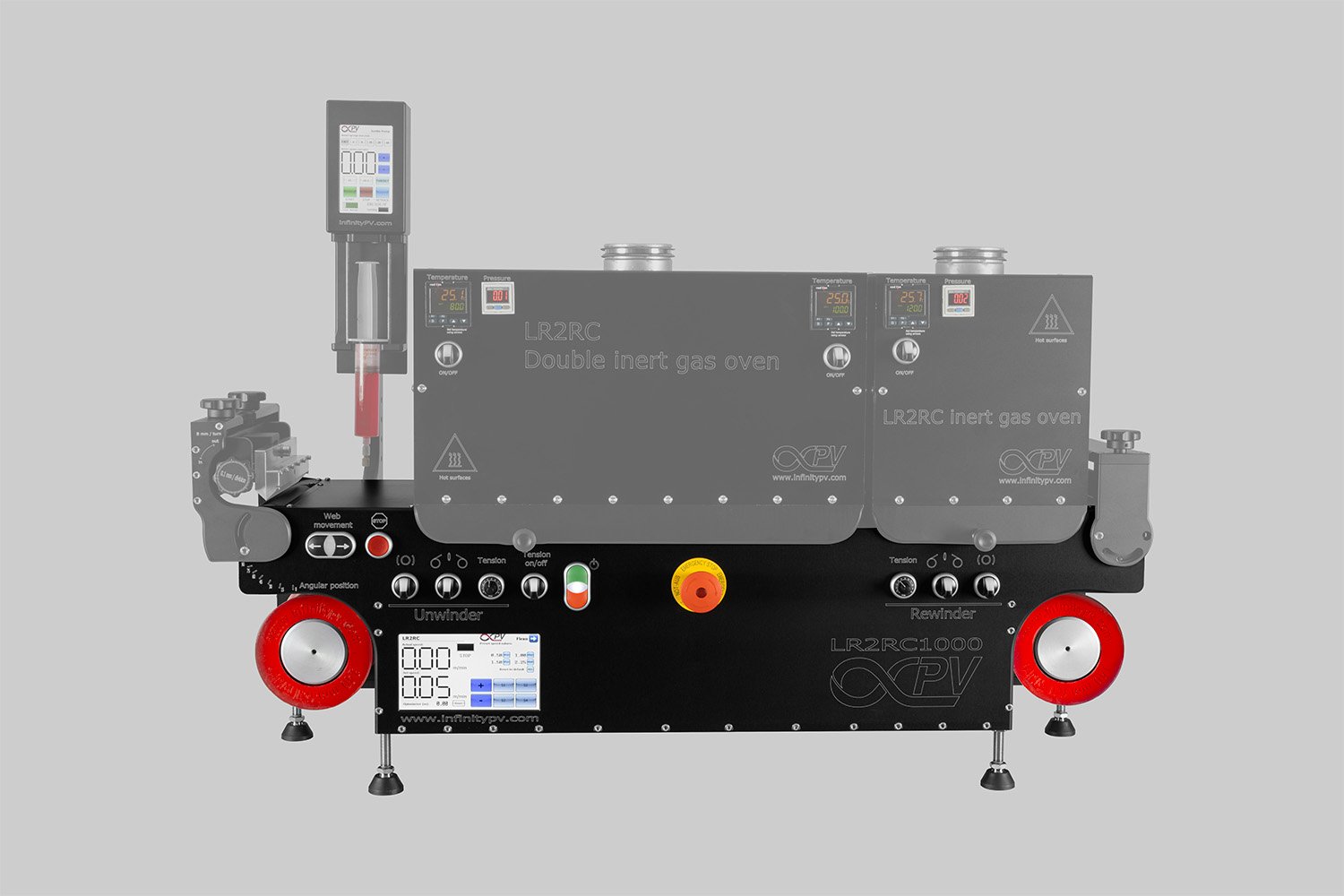

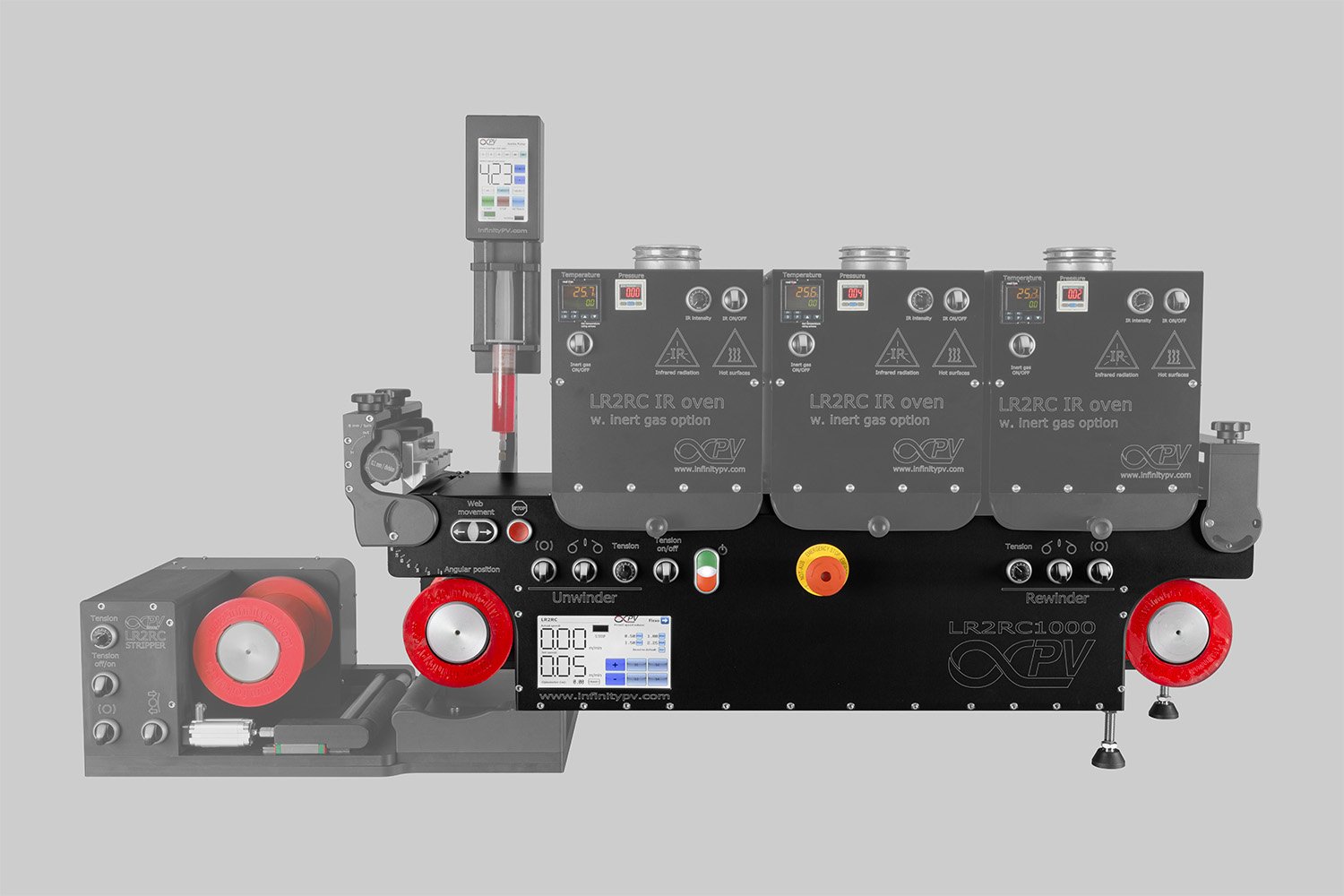

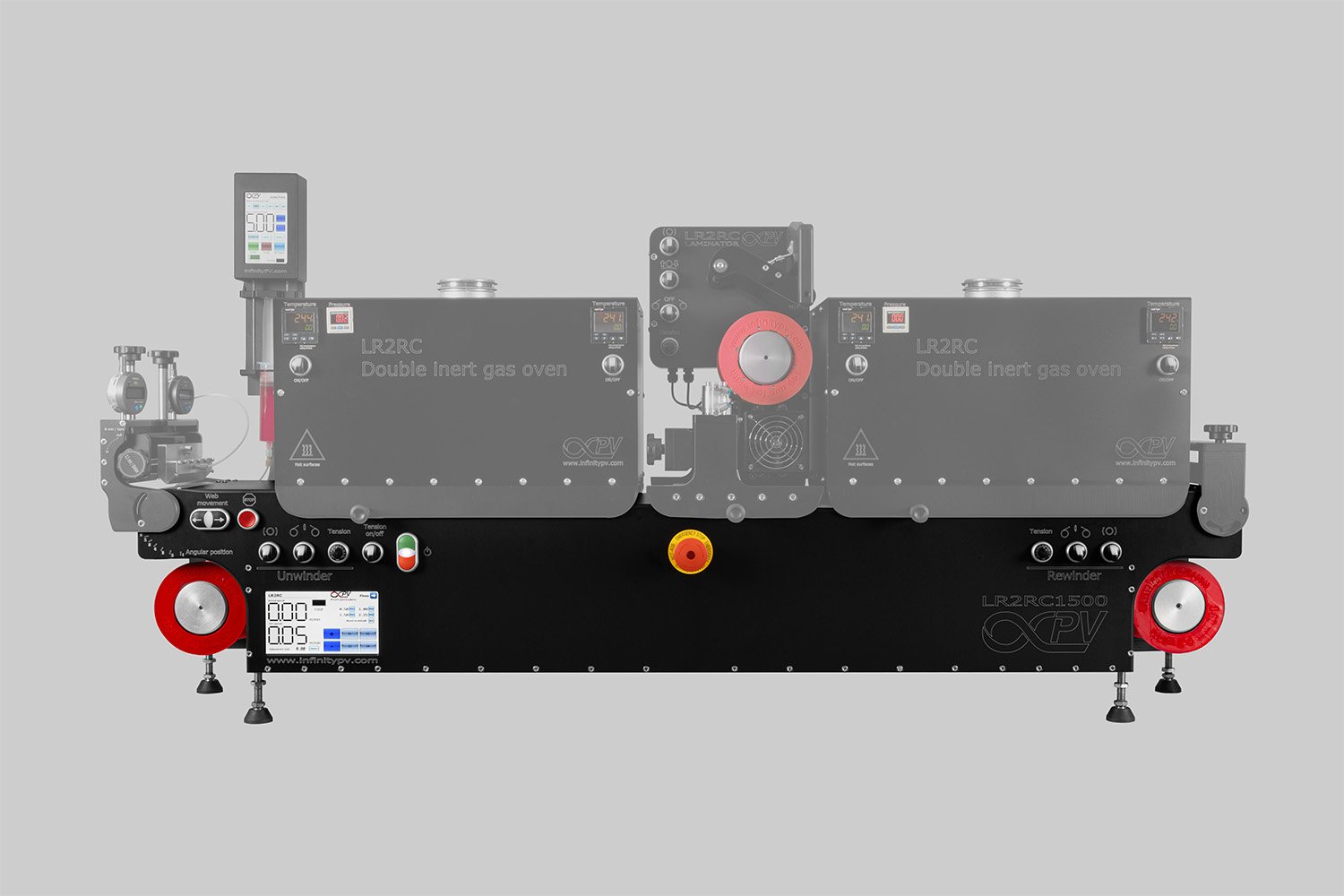

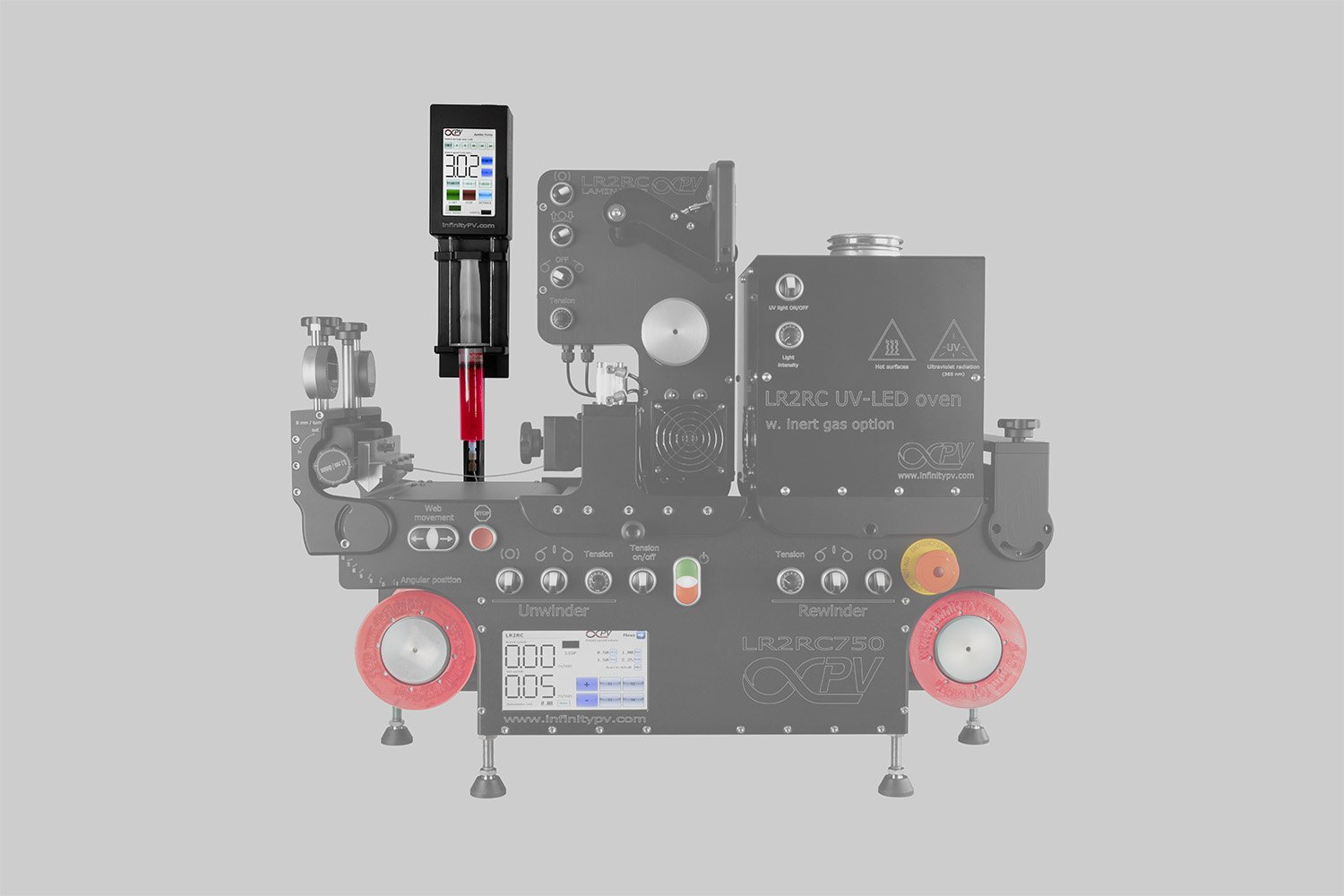

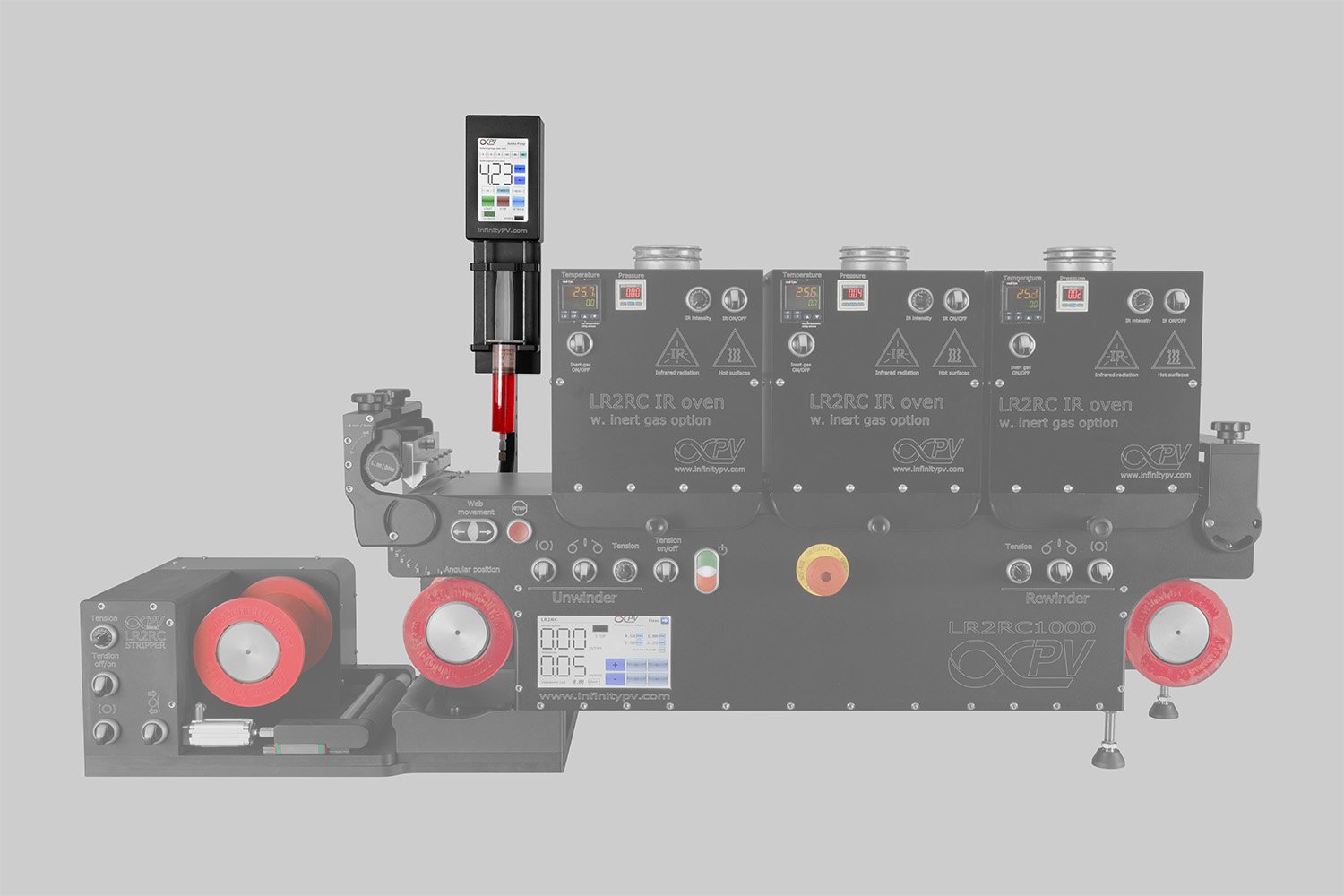

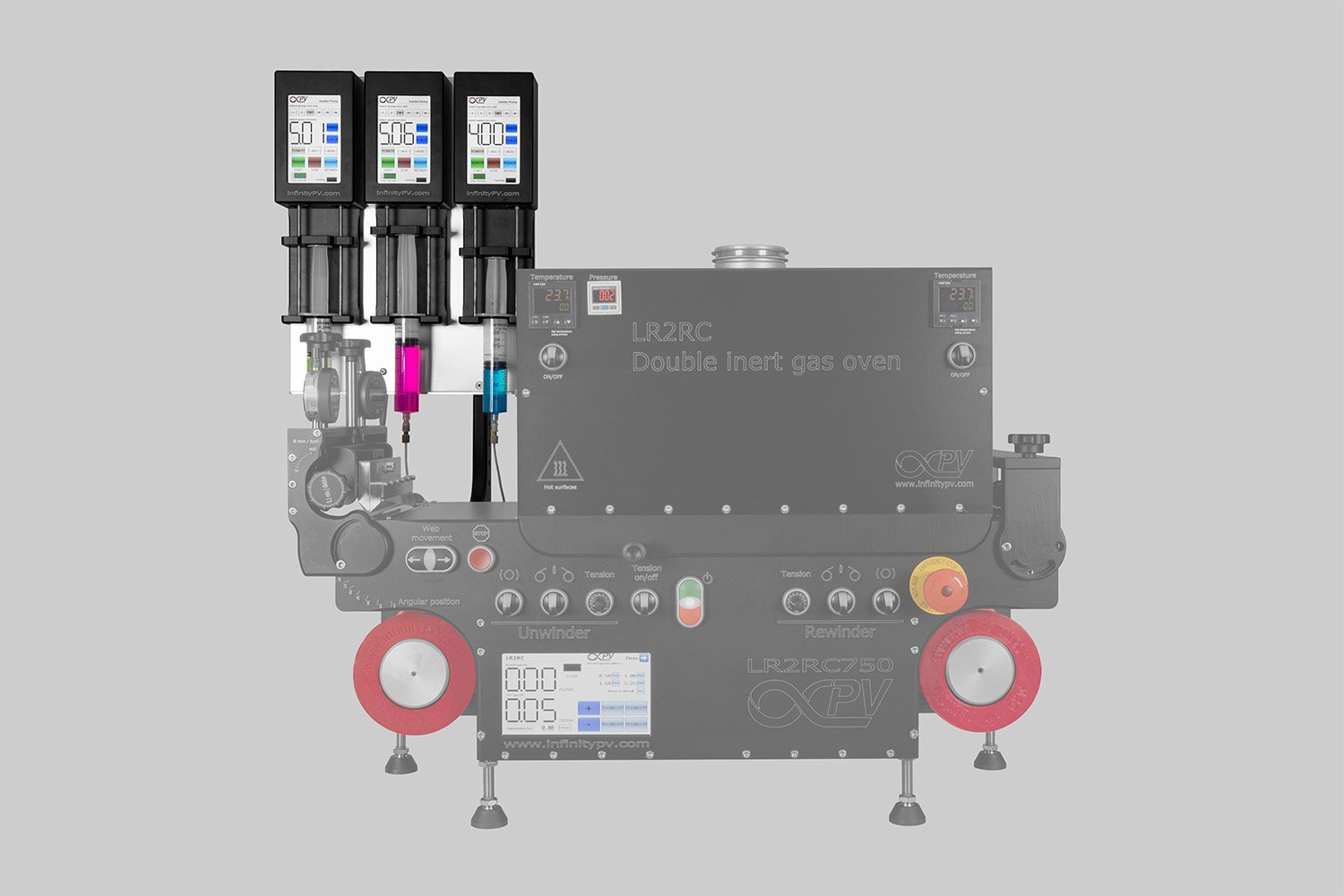

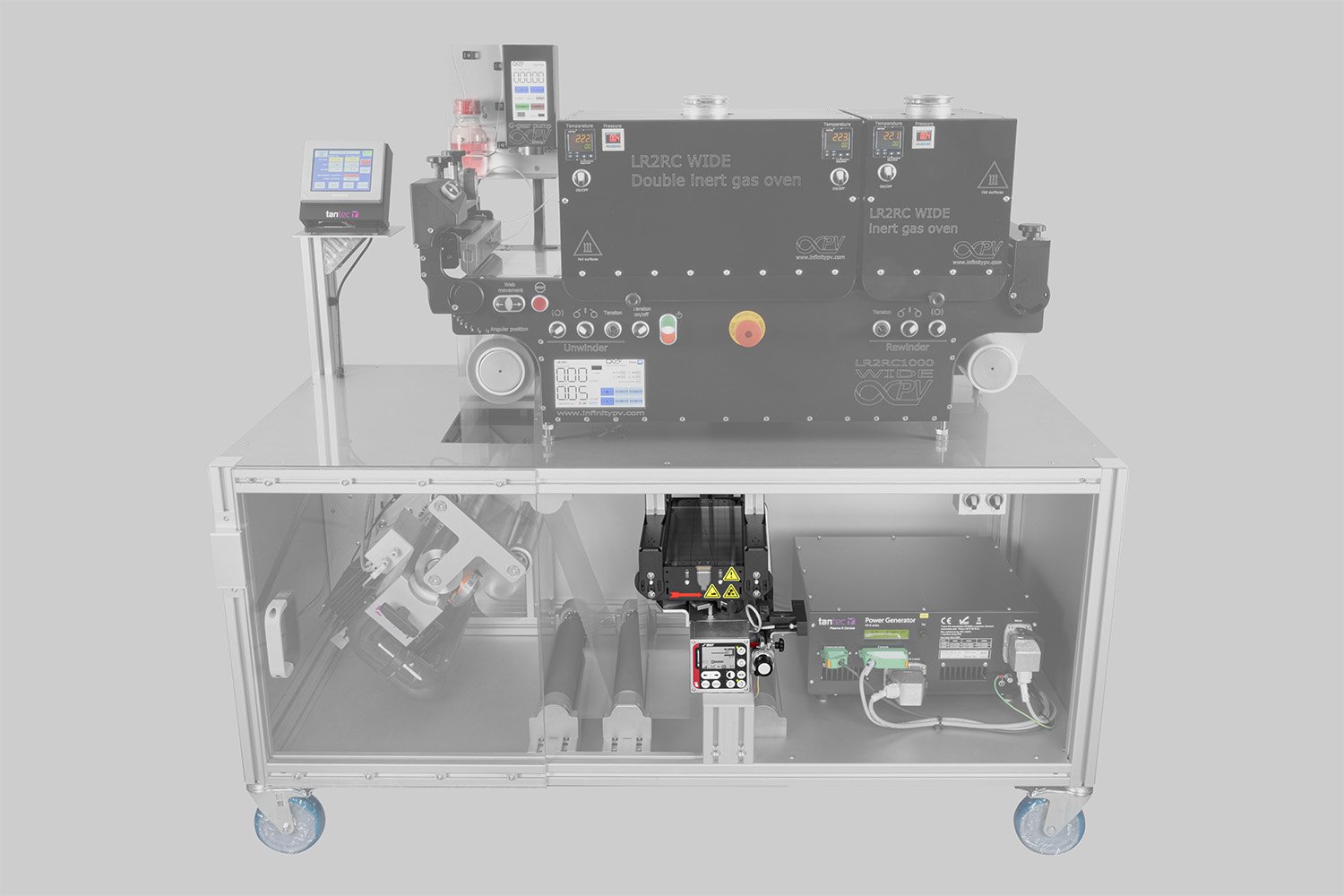

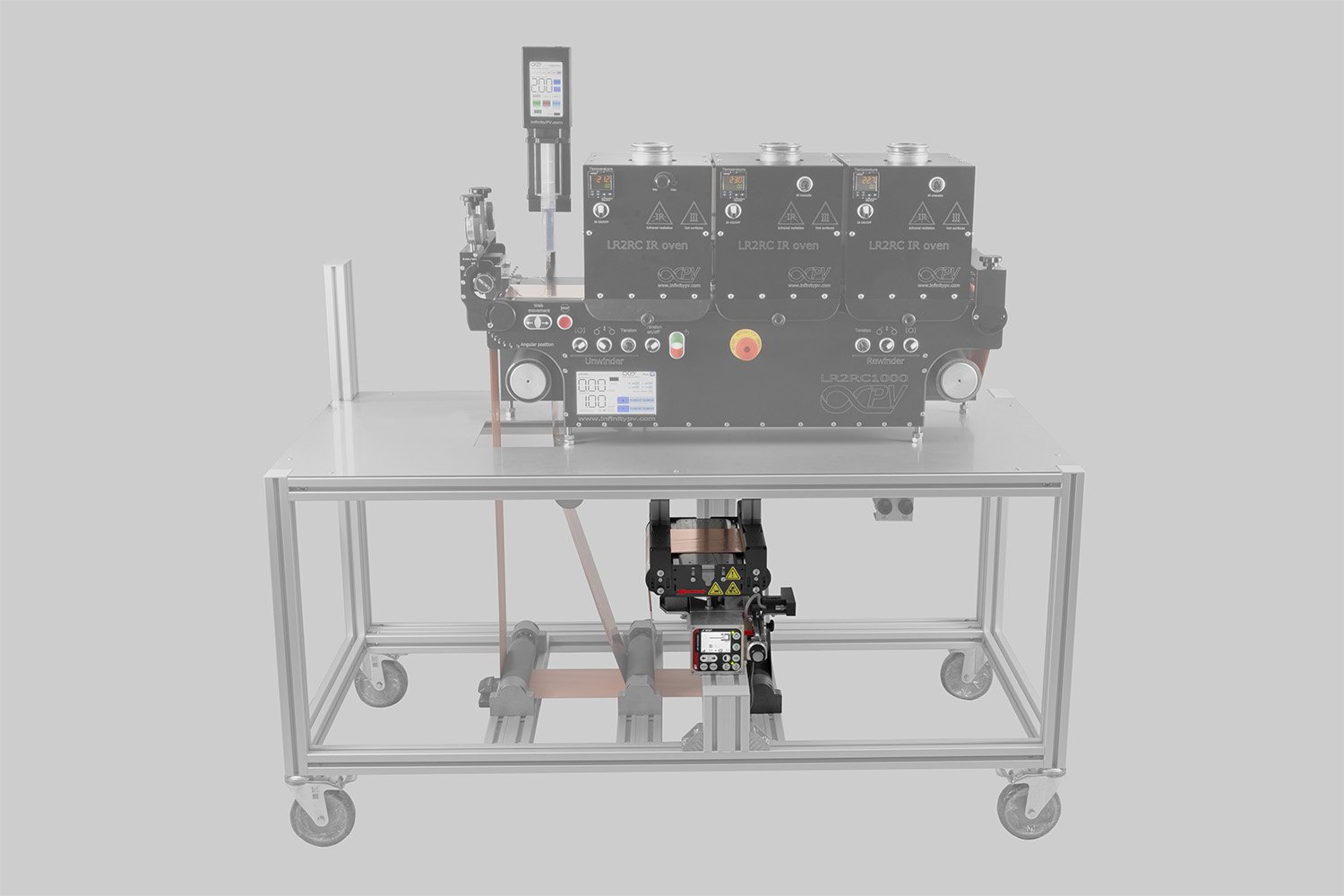

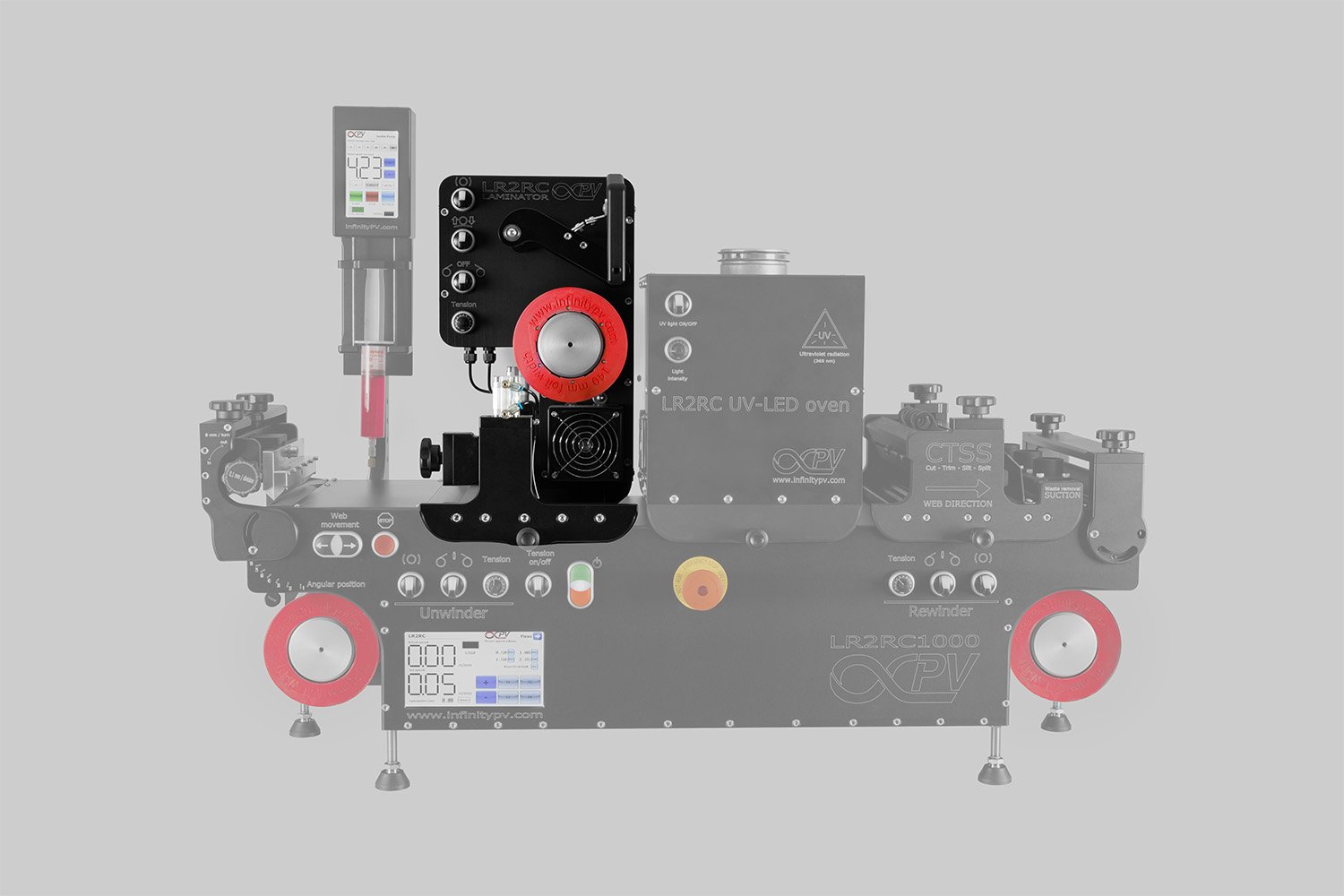

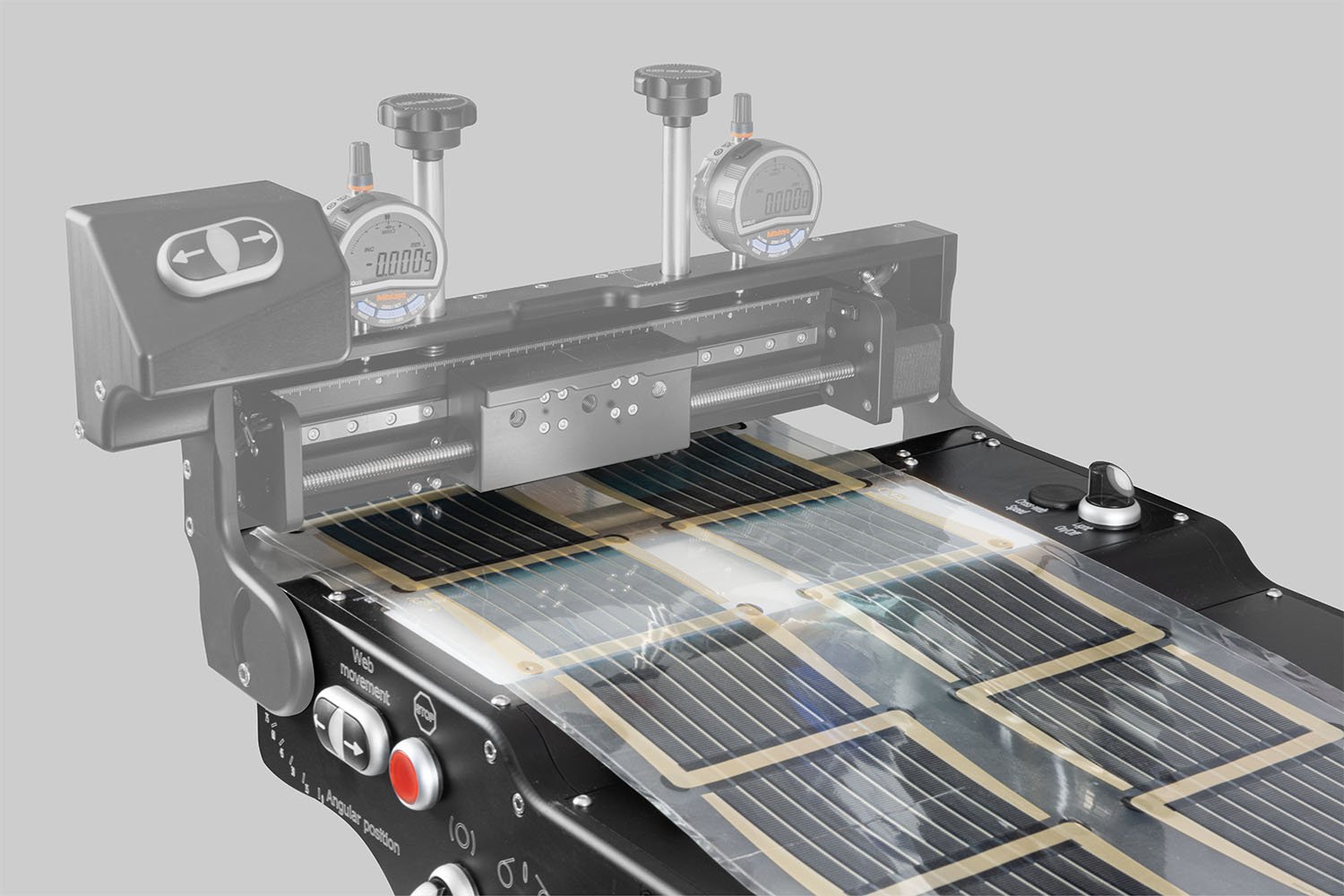

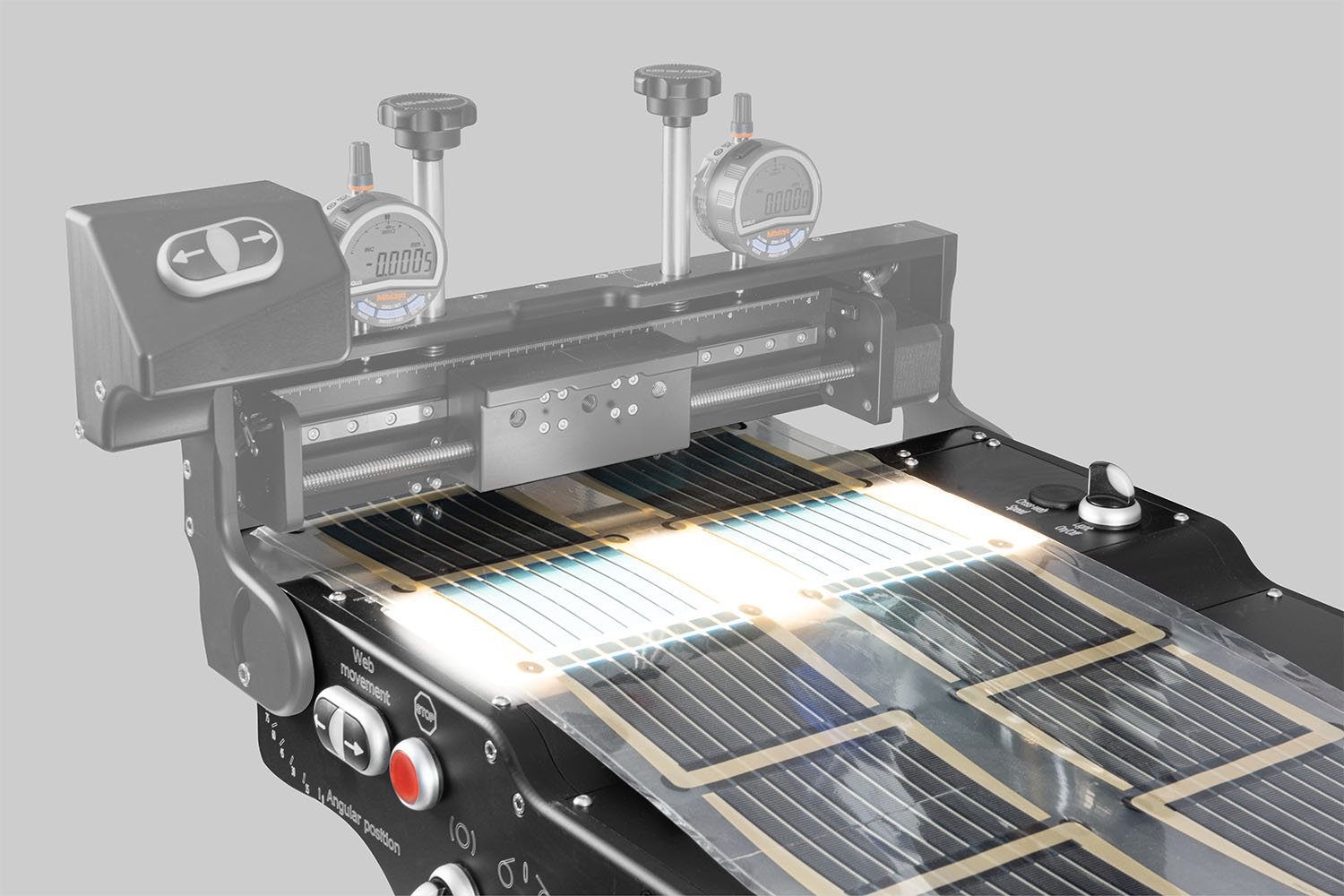

The Laboratory Roll-to-Roll Coater's modular design allows users to customize the system according to their specific requirements. Options include selecting the length and width of the unit and choosing from a wide array of components, such as printing and coating units, drying and curing systems, foil pretreatment modules, and advanced laminators. This flexibility ensures the Laboratory Roll-to-Roll Coater can fit within existing lab spaces, gloveboxes, or fume hoods without additional infrastructure.

Scalable Efficiency With Numerous Applications

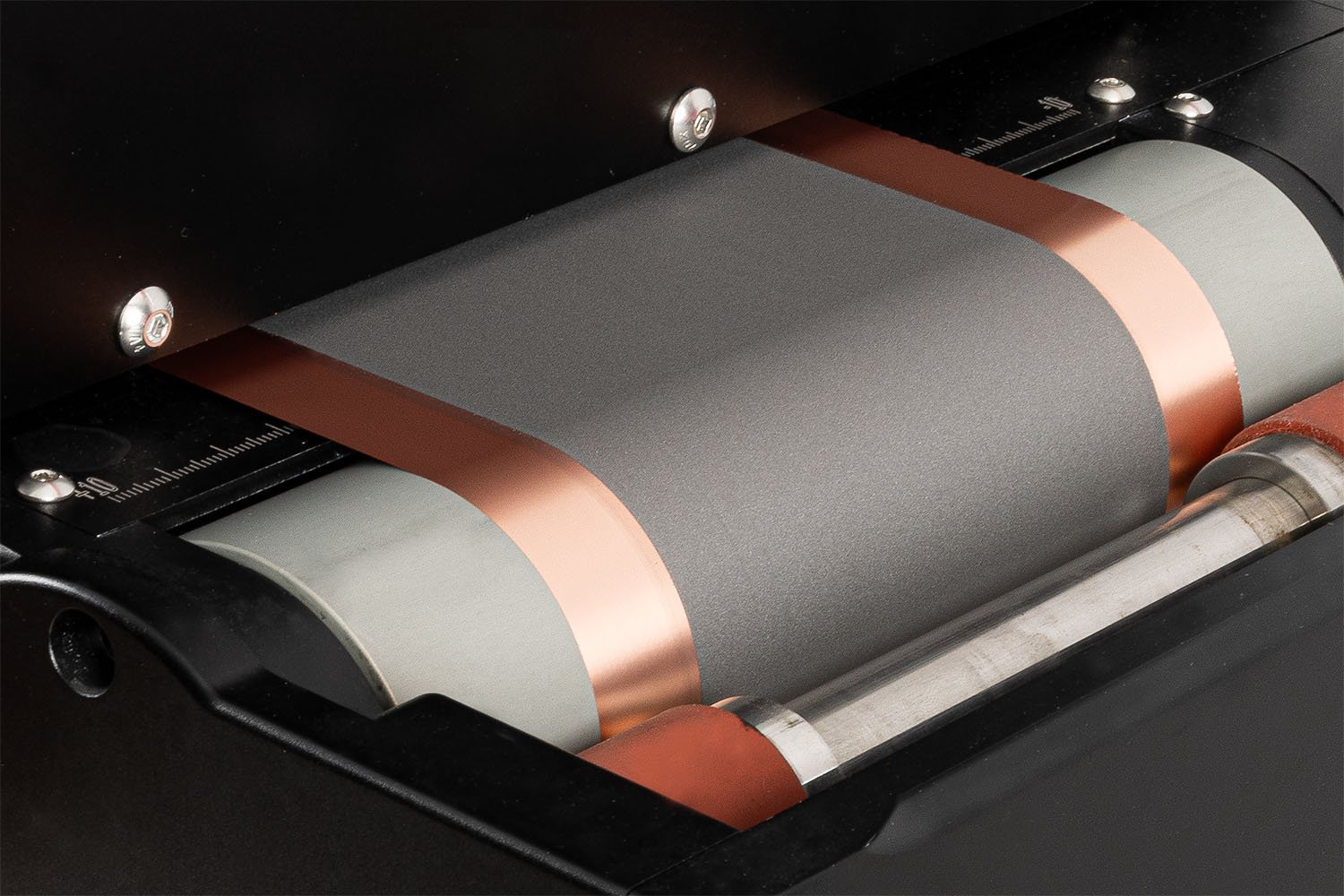

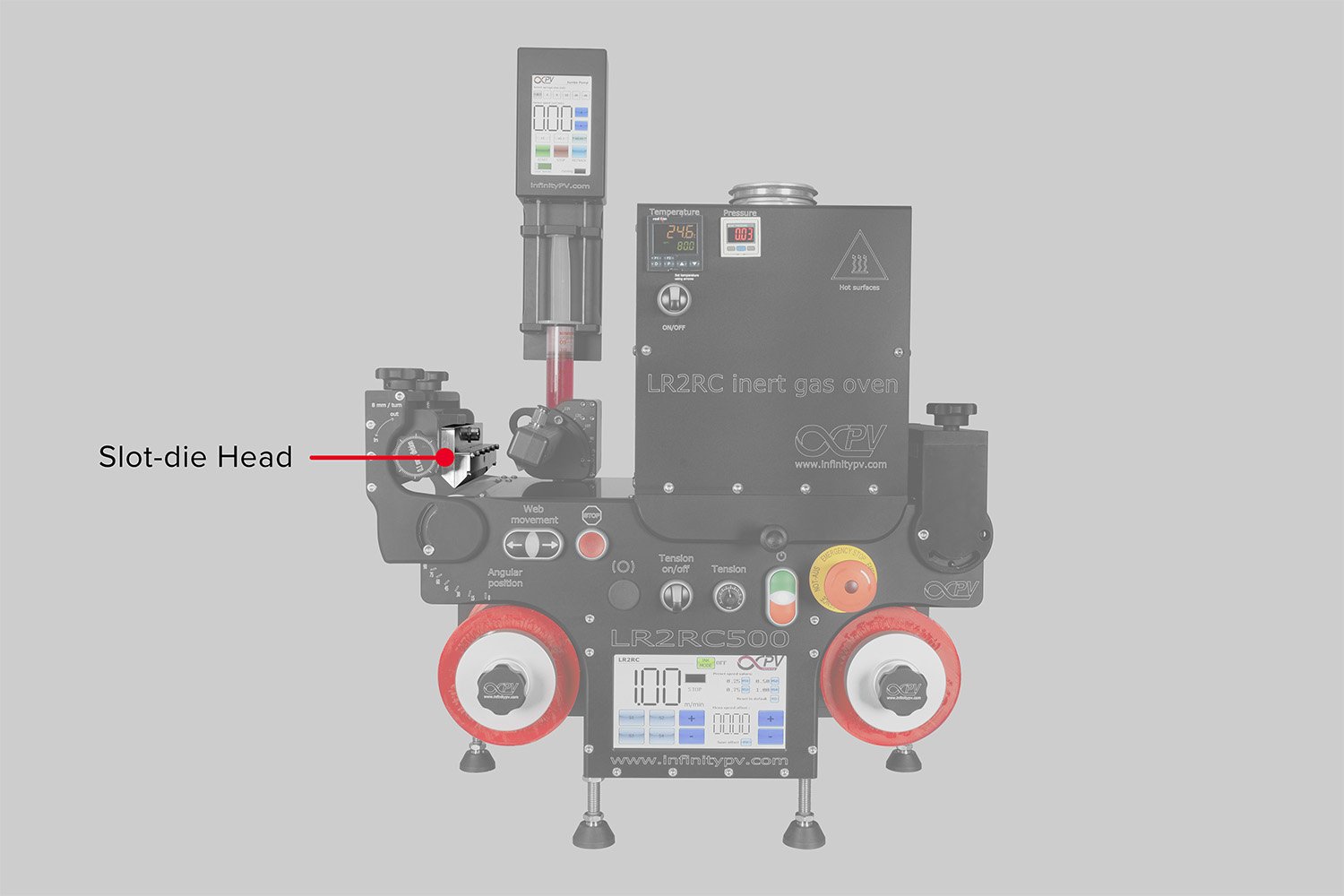

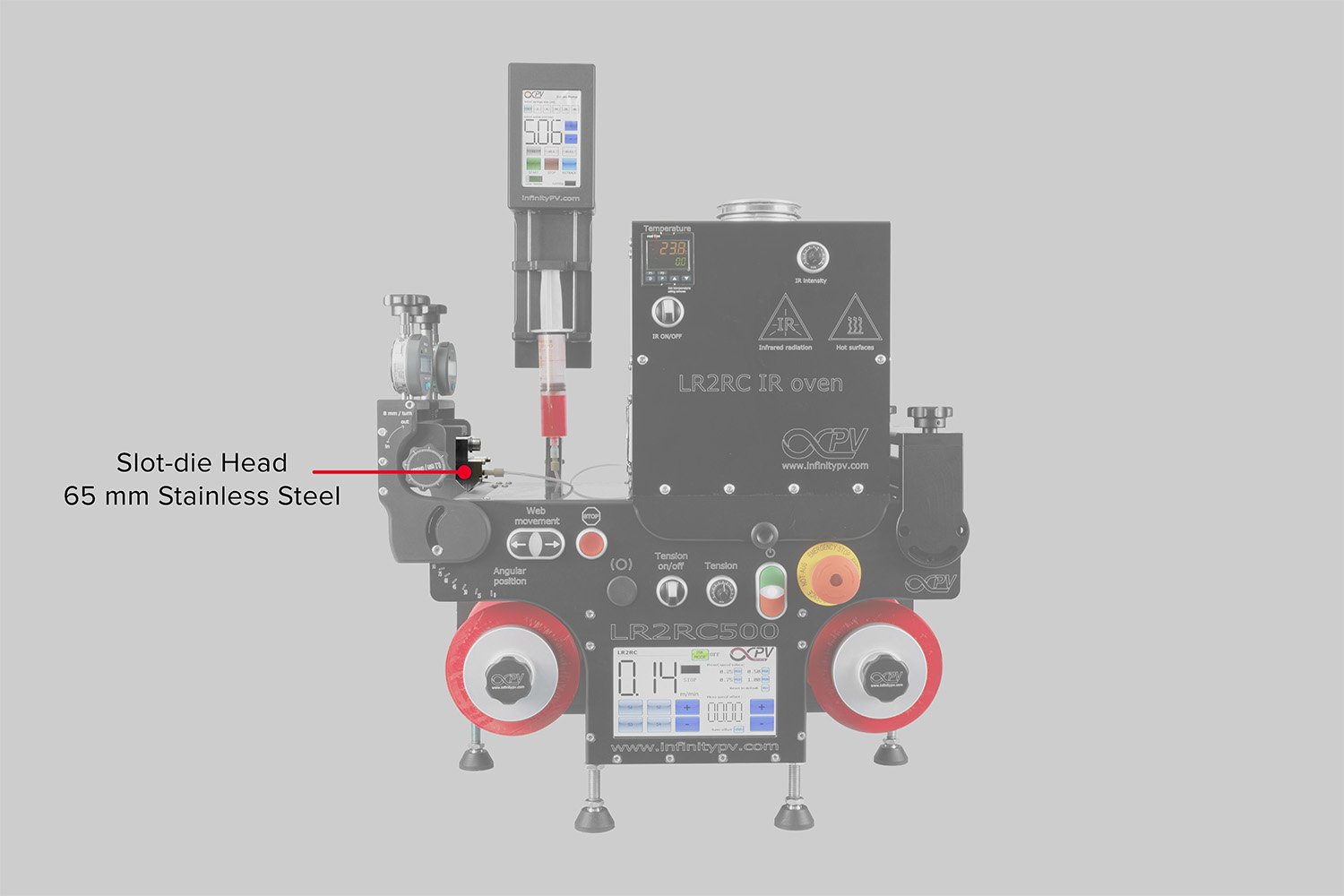

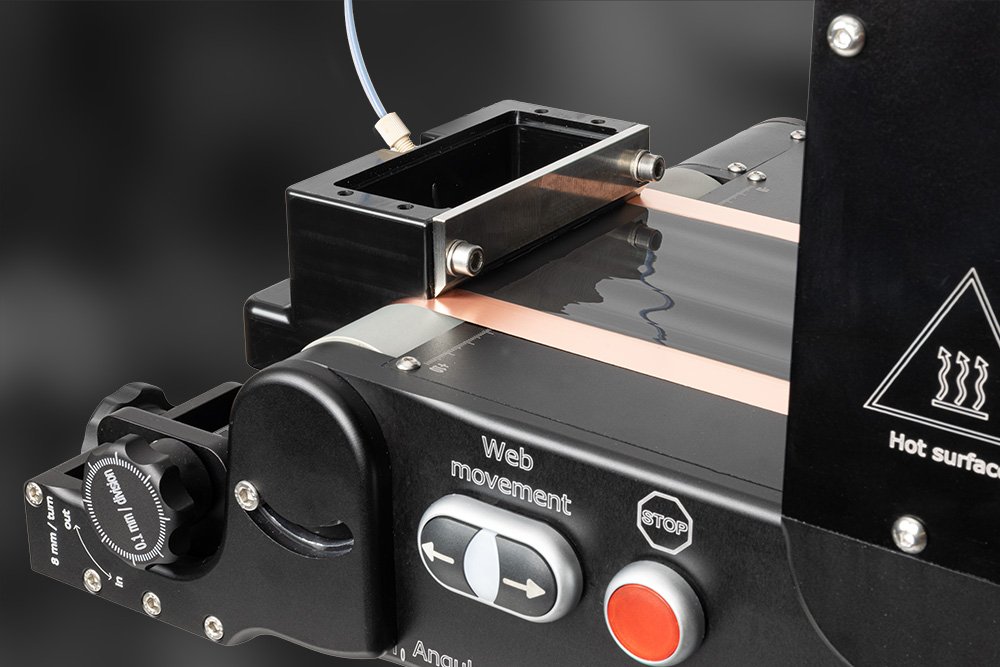

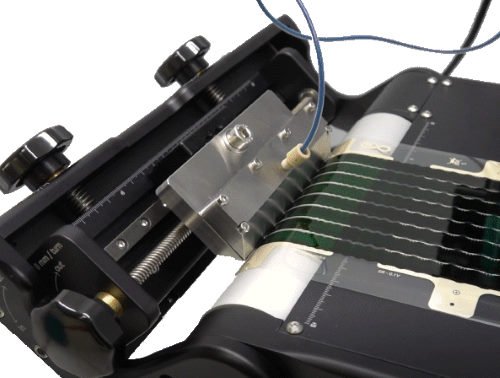

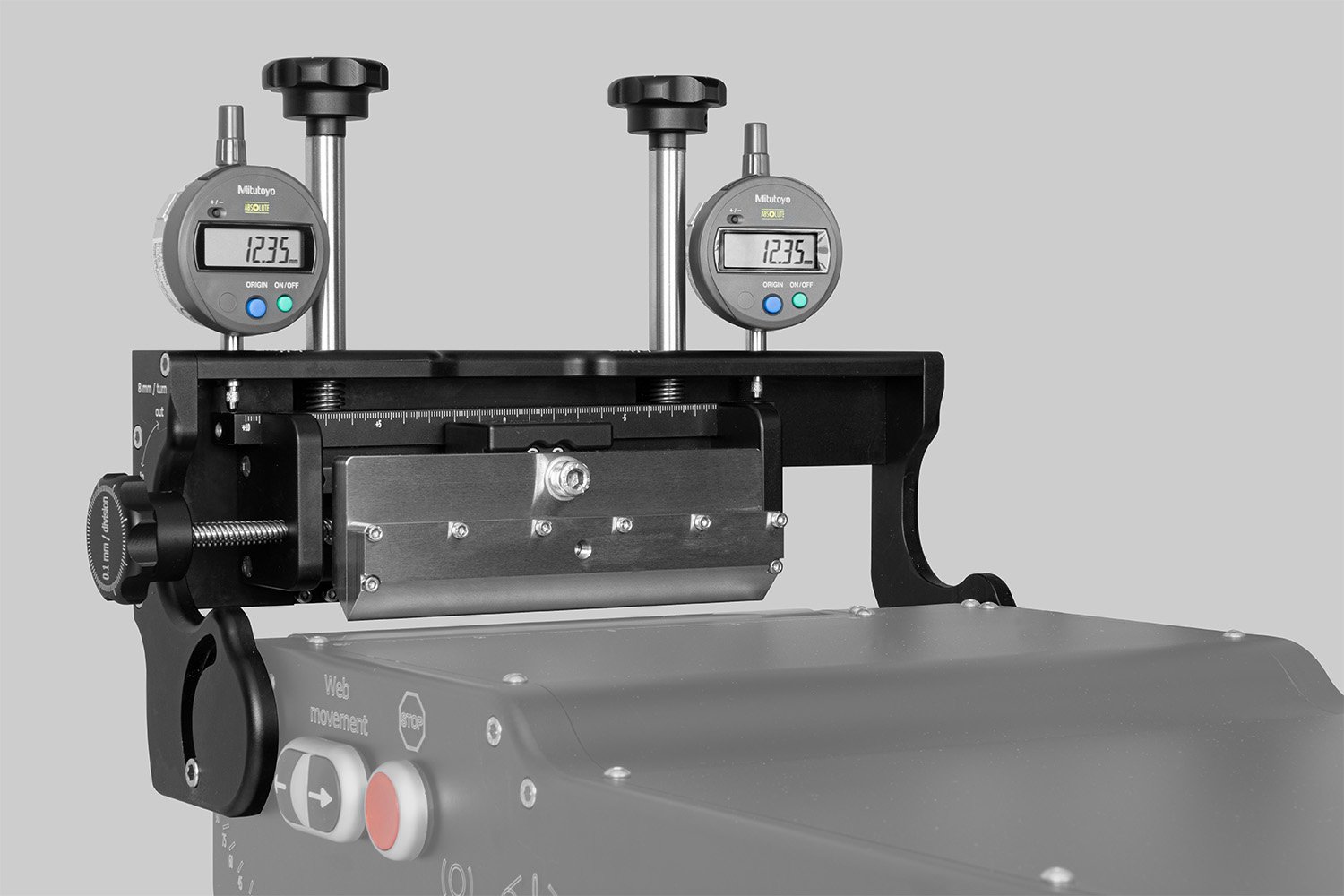

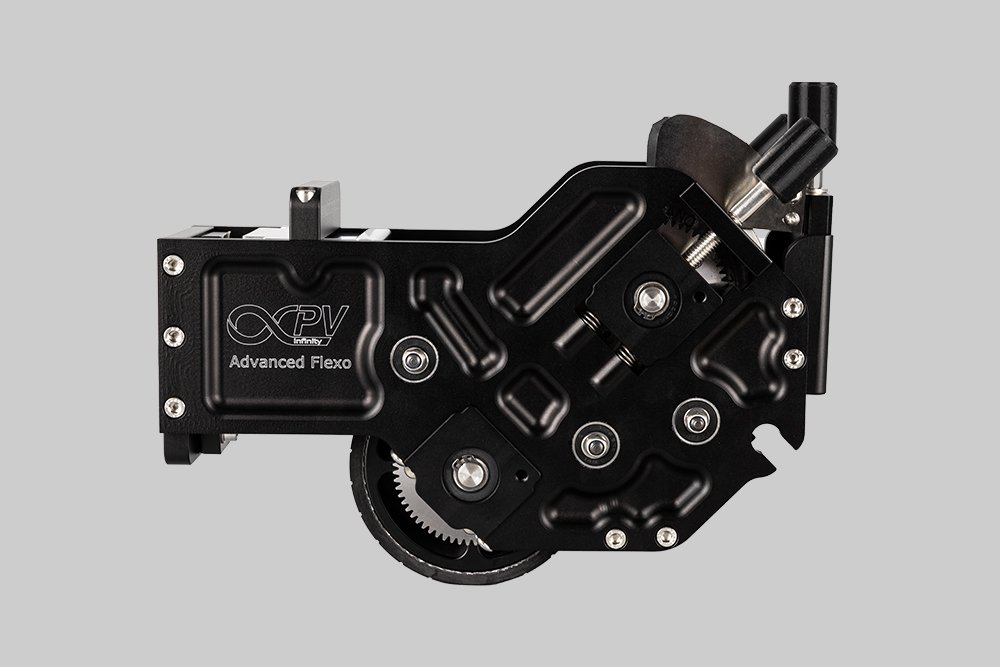

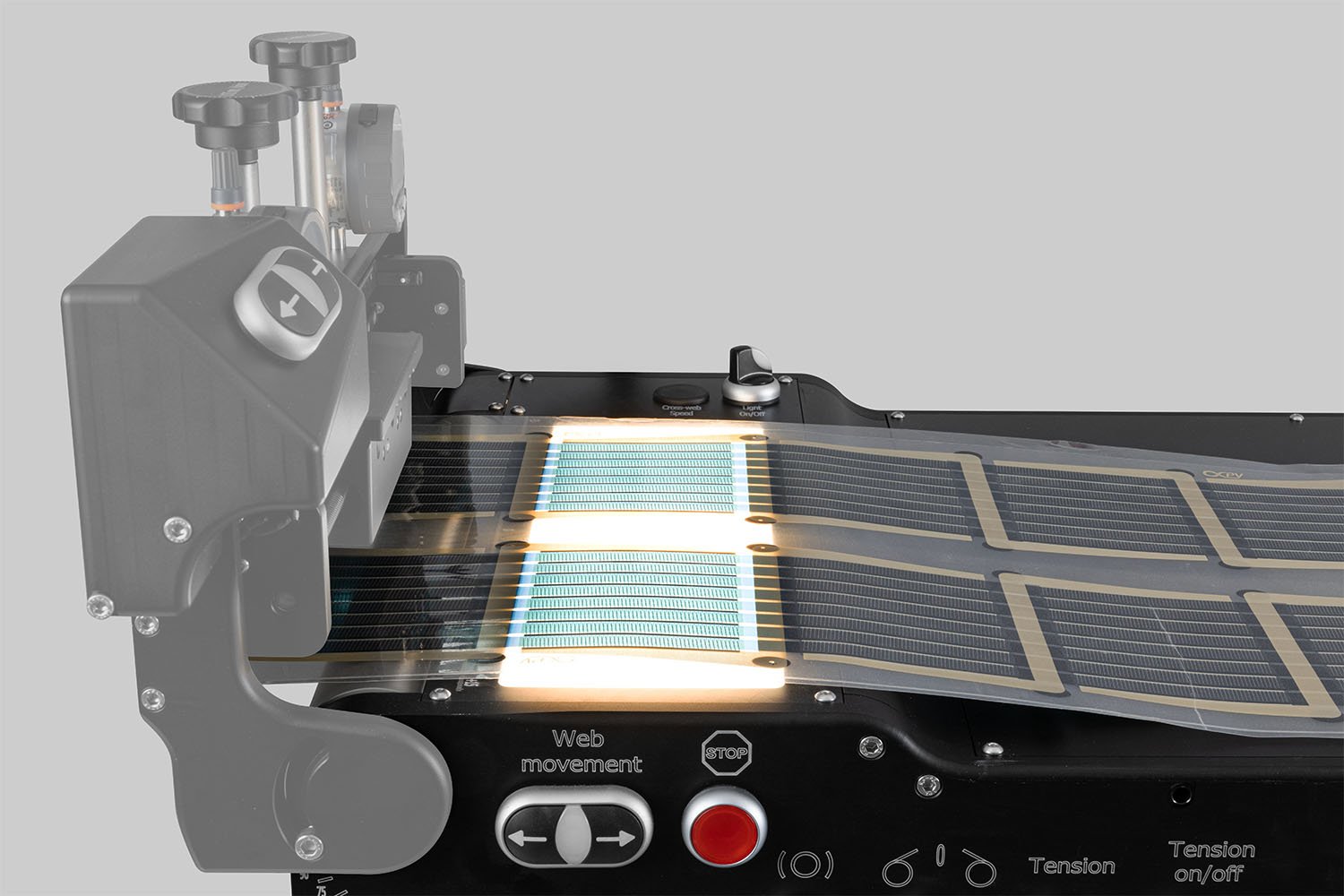

Providing a complete, turnkey system, the Laboratory Roll-to-Roll Coater bridges the gap between laboratory research and small-scale pilot production. It handles hundreds of meters of foil, making it an economical choice for scaling up production. Advanced slot-die heads, web tension control, and software options guarantee consistent, high-quality results across applications like batteries, fuel cells, printed solar cells, transistors, LEDs, and sensors.

User-Friendly Design

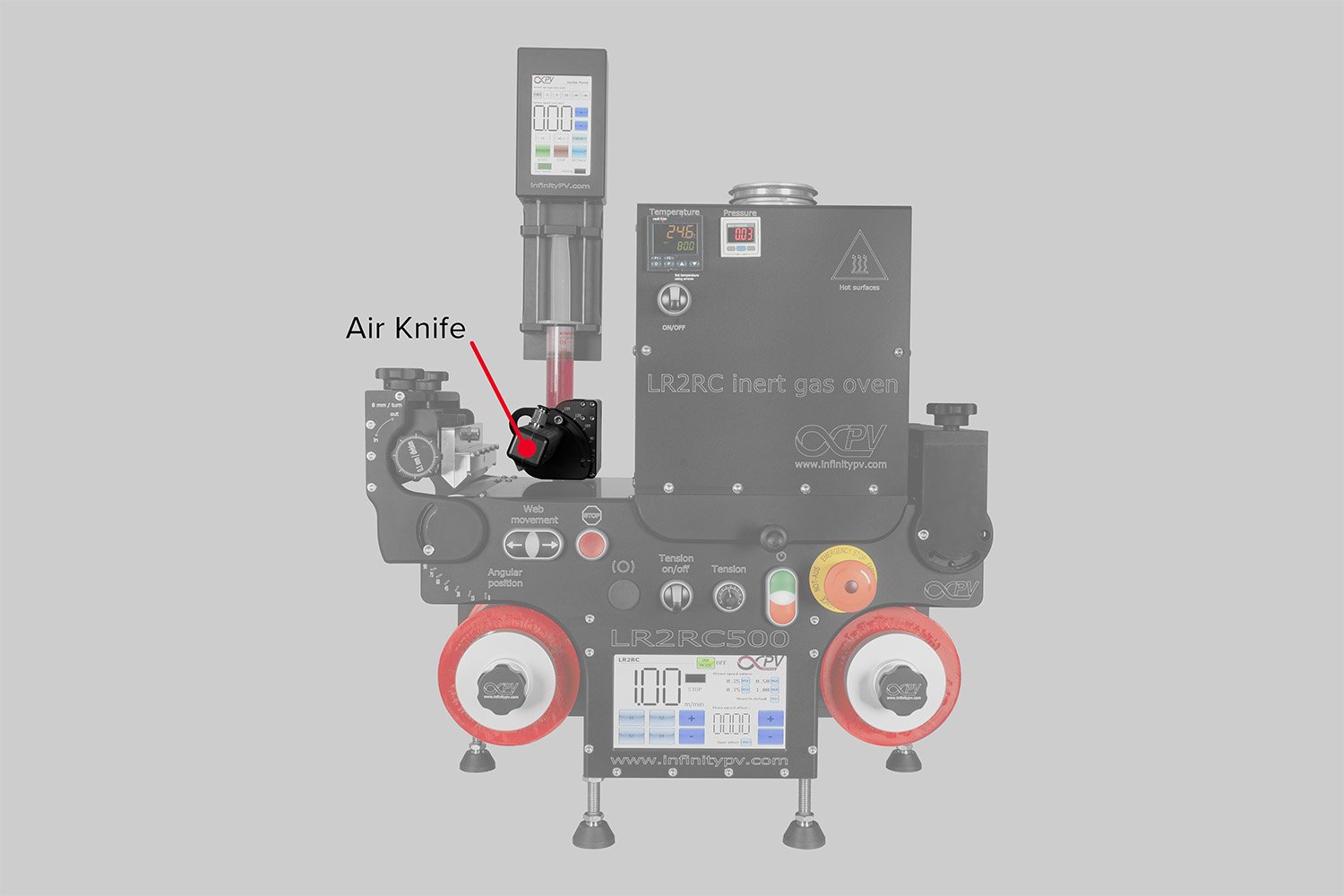

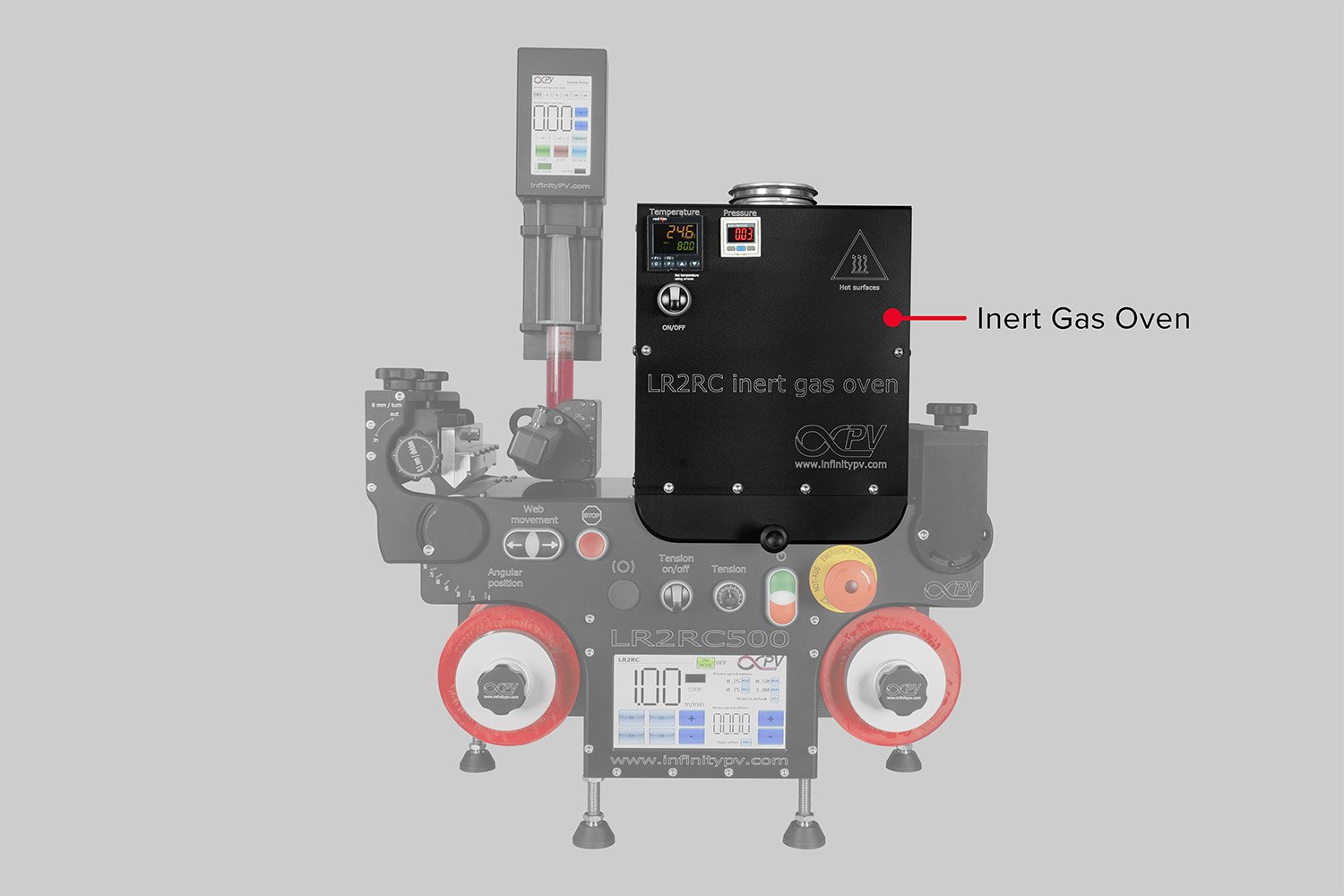

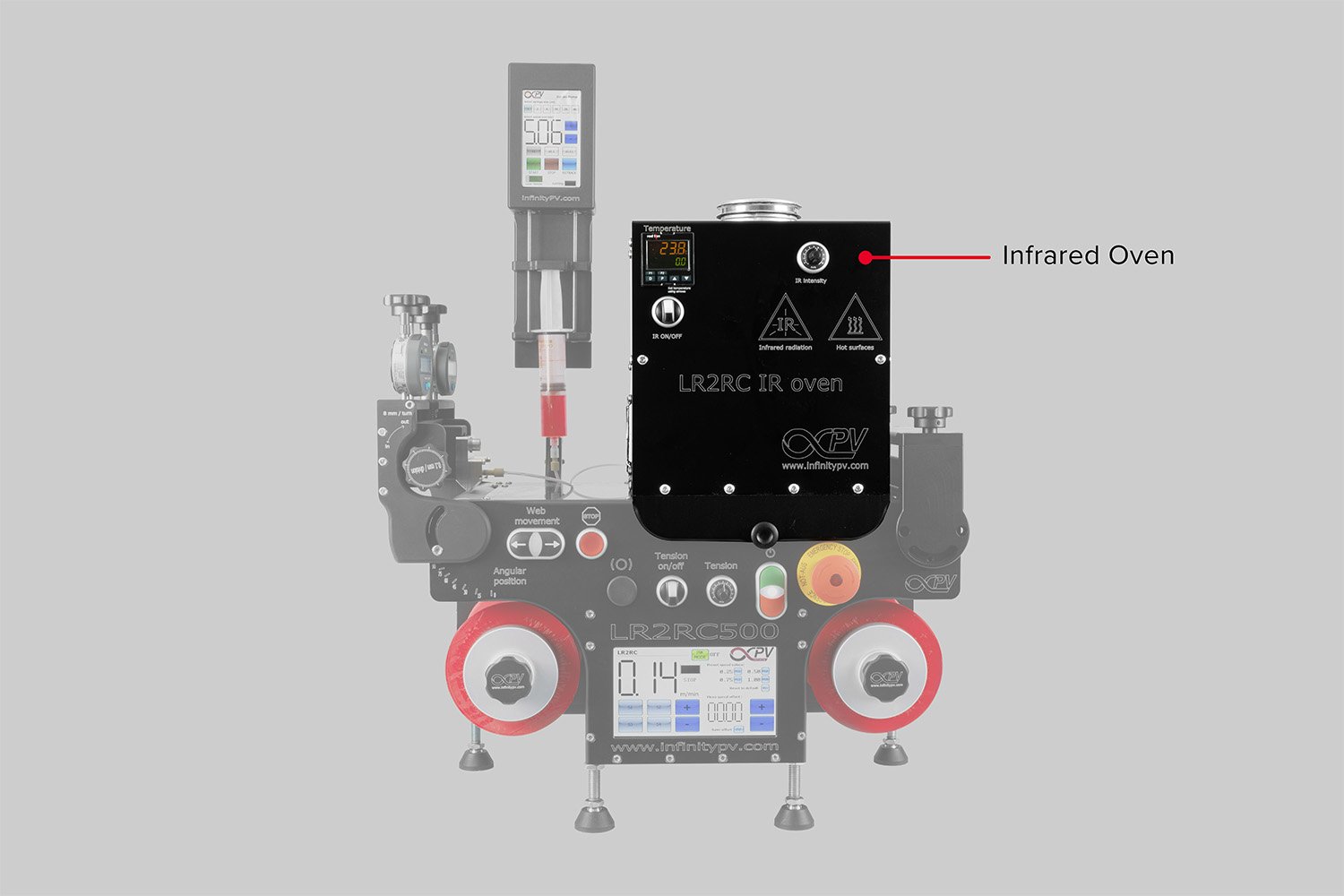

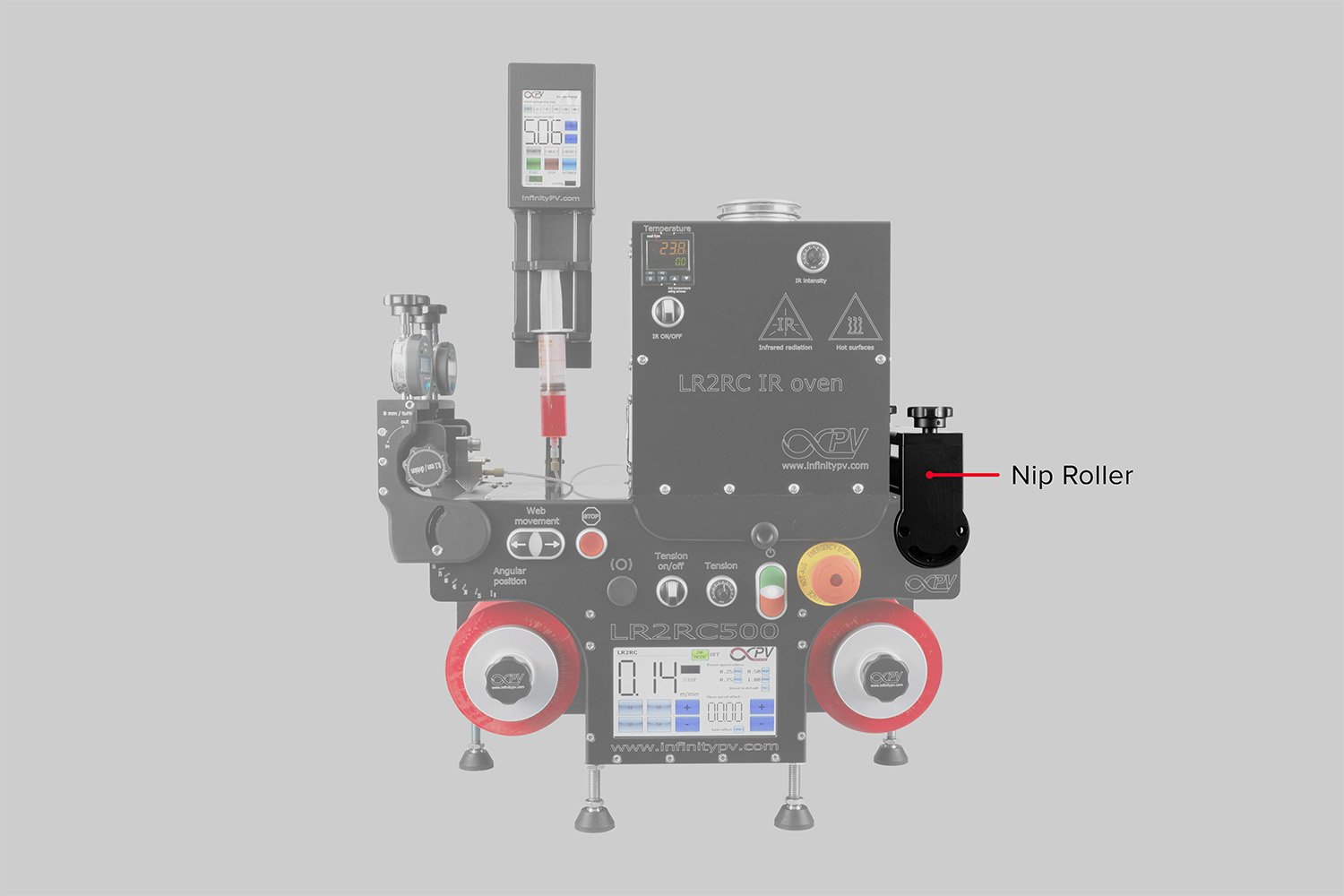

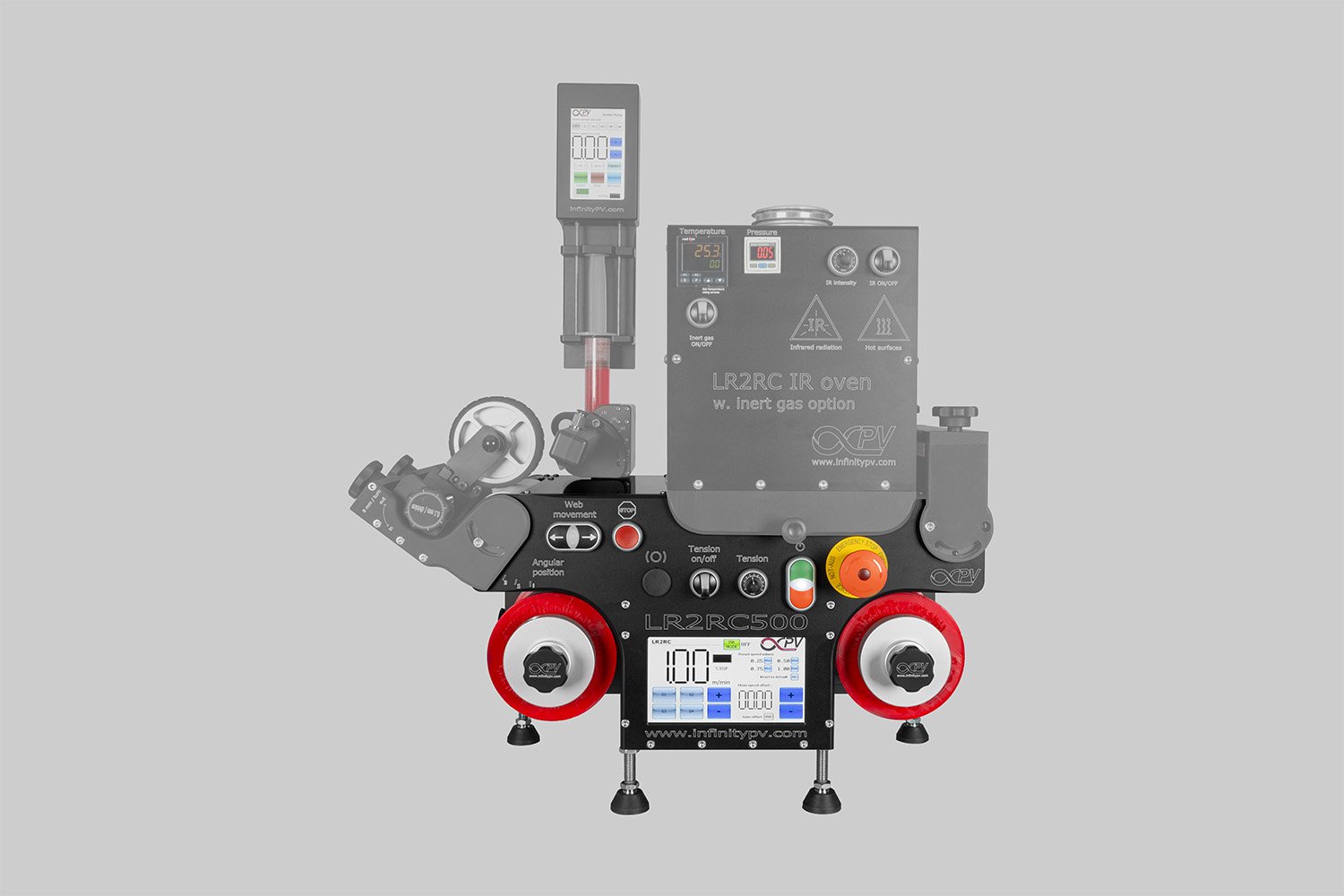

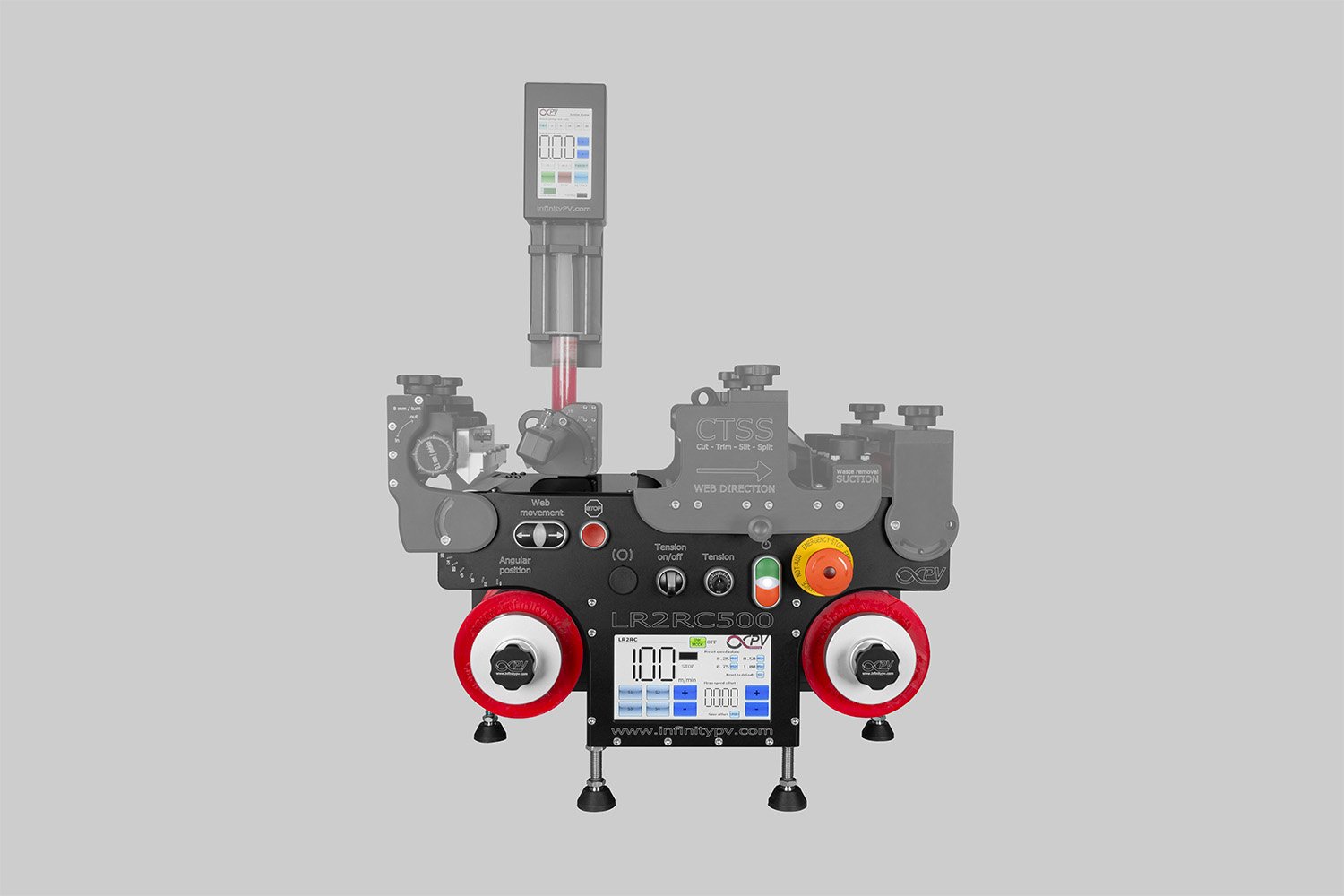

Designed for convenience, the Laboratory Roll-to-Roll Coater features easy-to-remove and reattach components, such as hot air, inert gas, IR and UV ovens, enhancing operational efficiency. The system's CE certification and CSA/UL compliance underscore its reliability and adherence to international safety standards.

Build Your Own System Today

Start building your custom thin-film production system today with the Laboratory Roll-to-Roll Coater Customizer. Choose the right platform size and enhance it with a range of components like printing units, drying systems, and laminators.

Key Features

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Choose from a variety of lengths and widths, with numerous components available.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

Modular Drying/Curing System: Accommodates various drying and curing methods.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

Technical Specifications

Operating Power: Single phase (240VAC) for smaller models; three-phase (400VAC) for larger models.

Drying/Curing Length: From 250 mm (LR2RC500) to 1250 mm (LR2RC1500).

Web Width: Up to 200 mm (standard), up to 310 mm (wide models).

Web Speed: 0.05-2.8 m/min (forward and reverse).

Spindles: Automatic compressed air spindles for 3-inch core diameters, adjustable cones for smaller cores in LR2RC500.

Video: What is the Laboratory Roll-to-Roll Coater?

The Laboratory Roll-to-Roll Coater is a compact, high-precision lab coater that transforms the way thin functional films are processed. It offers modular customization to fit different needs, scalable efficiency for small-scale production, and a user-friendly design with easy-to-remove components. Ideal for applications like batteries, fuel cells, and solar cells, it allows you to customize a system that’s perfect for your needs.

All Platforms and Components

Laboratory Roll-to-Roll Coater

Download Brochure

Explore the capabilities of the Laboratory Roll-to-Roll Coater by downloading our detailed brochure. This document provides an in-depth overview of the coater’s customizable features, technical specifications, and broad range of applications. Discover how our advanced technology can enhance your research and production processes.

Technical Specifications

| Item | Technical Parameter | Remarks |

|---|---|---|

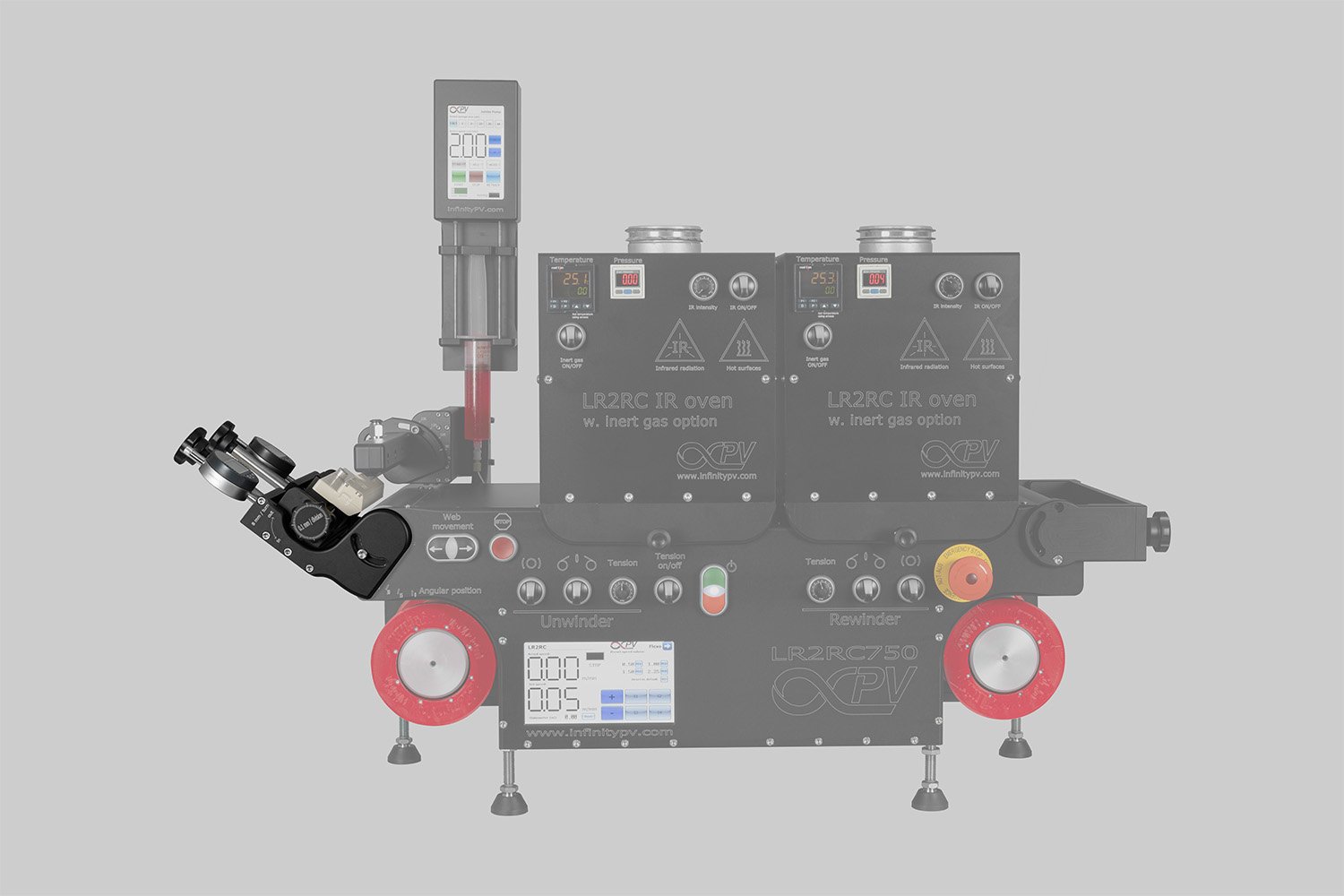

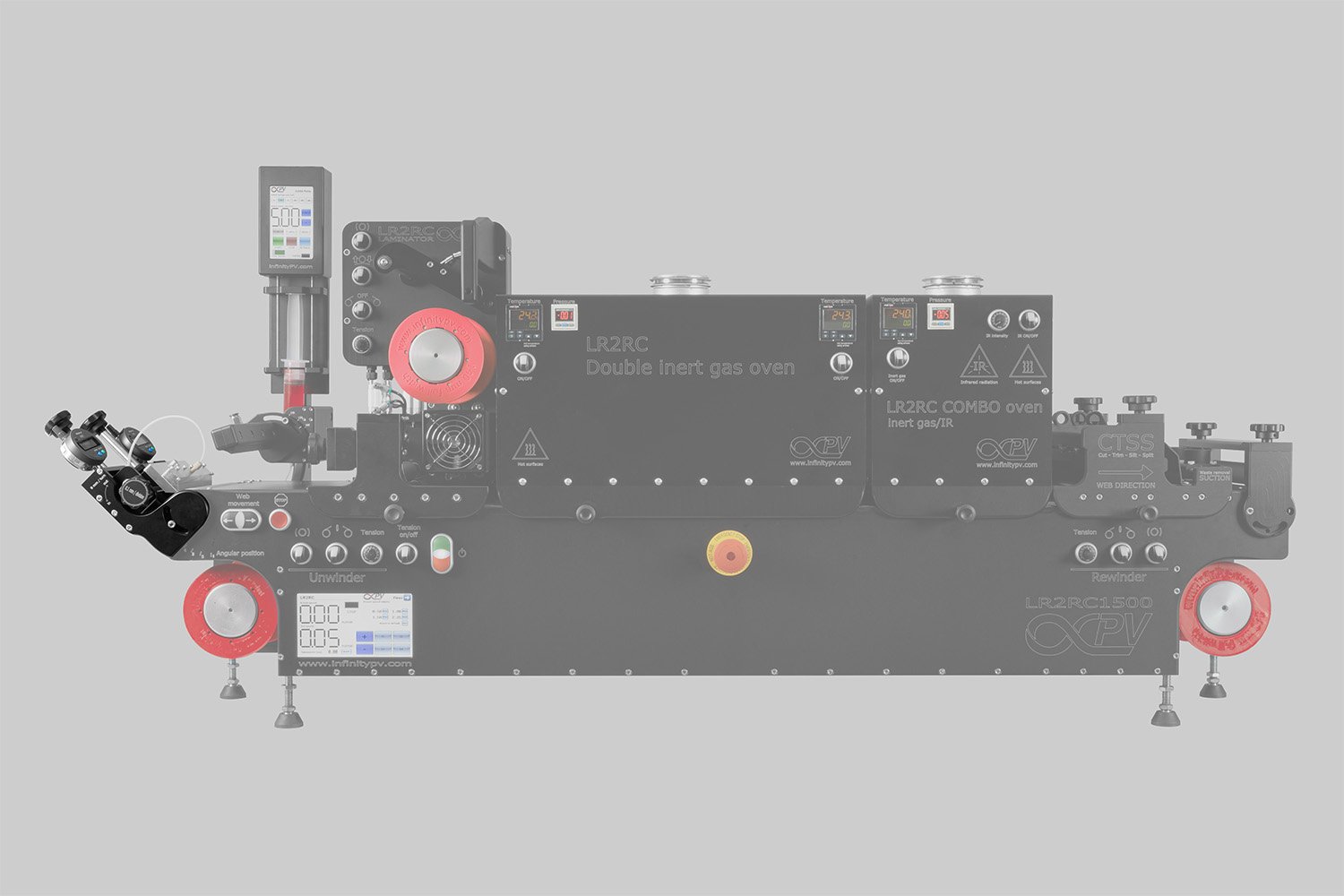

| Dimensions (WxDxH) and Weight | LR2RC500: 500 x 350 x 300 mm | 30 kg LR2RC750: 750 x 350 x 300 mm | 40 kg LR2RC750 Wide: 750 x 460 x 300 mm | 50 kg LR2RC1000: 1000 x 350 x 300 mm | 50 kg LR2RC1000 Wide: 1000 x 460 x 300 mm | 60 kg LR2RC1500: 1500 x 350 x 300 mm | 80 kg LR2RC1500 Wide: 1500 x 460 x 300 mm | 100 kg | Total weight and dimensions depend on final configuration. |

| Operates From | LR2RC500: Single Phase (240VAC) LR2RC750: Single Phase (240VAC) LR2RC750 Wide: Single Phase (240VAC) LR2RC1000: 3 -phases (400 VAC) LR2RC1000 Wide: 3 -phases (400 VAC) LR2RC1500: 3 -phases (400 VAC) LR2RC1500 Wide: 3 -phases (400 VAC) | |

| Drying and Curing Section Length | LR2RC500: 250 mm LR2RC750: 500 mm LR2RC750 Wide: 500 mm LR2RC1000: 750 mm LR2RC1000 Wide: 750 mm LR2RC1500: 1250 mm LR2RC1500 Wide: 1250 mm | The drying and curing length depends on the selected oven systems. |

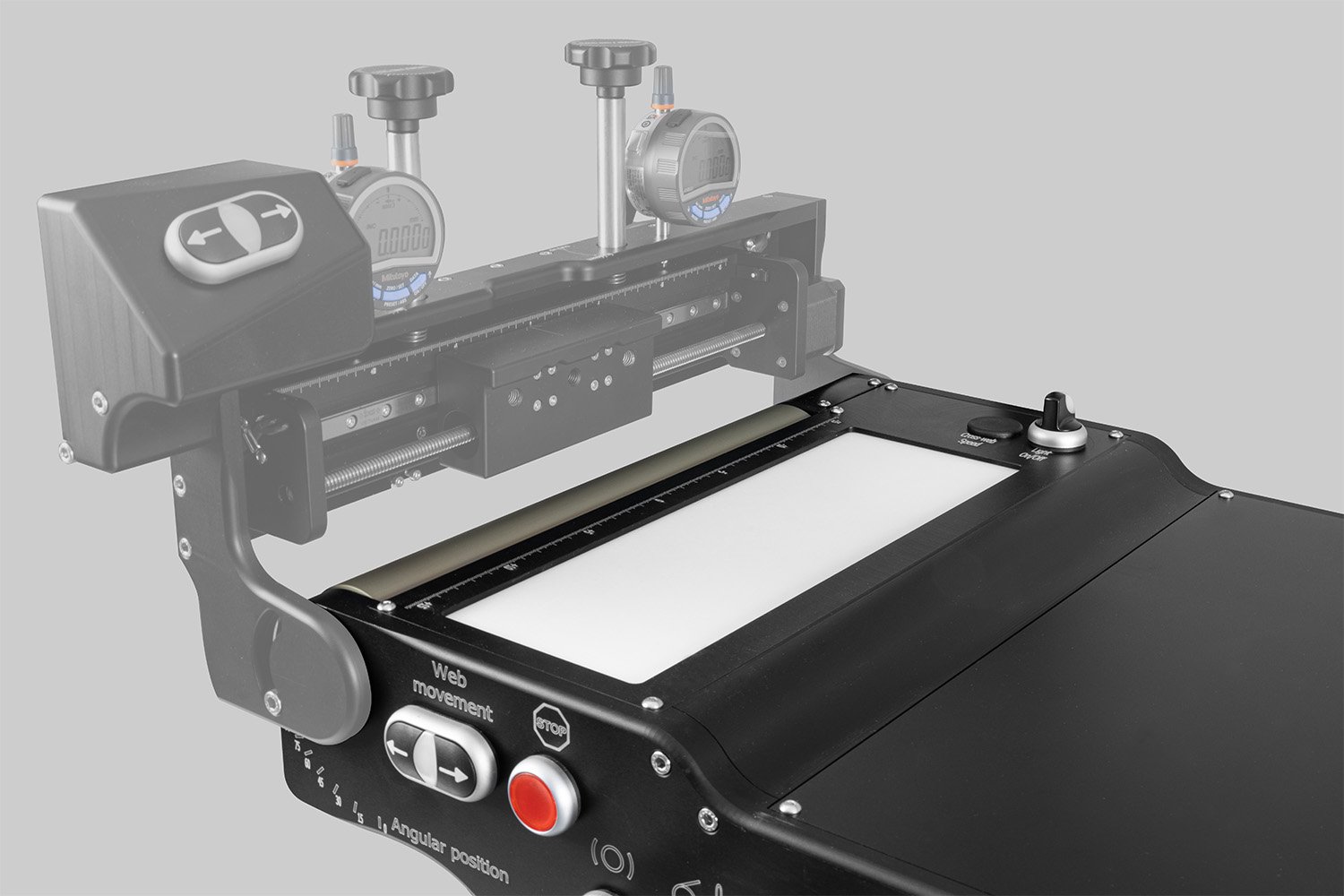

| System Control | Touch Screen Manual Adjustment Buttons PC Control | |

| Web Width | Up to 200 mm Up to 310 mm (Wide) | |

| Foil Length | Up to 100 m | Depending on subtrate thickness. |

| Web Speed | 0.05-2-8 m/min (Forward and Reverse) | Other web speeds are available upon request |

| Tension Control | Manually | Individual or collective control over rewinder and unwinder depending on configuration |

| Coating Width | Up to 180 mm (Standard) Up to 280 mm (Wide) | |

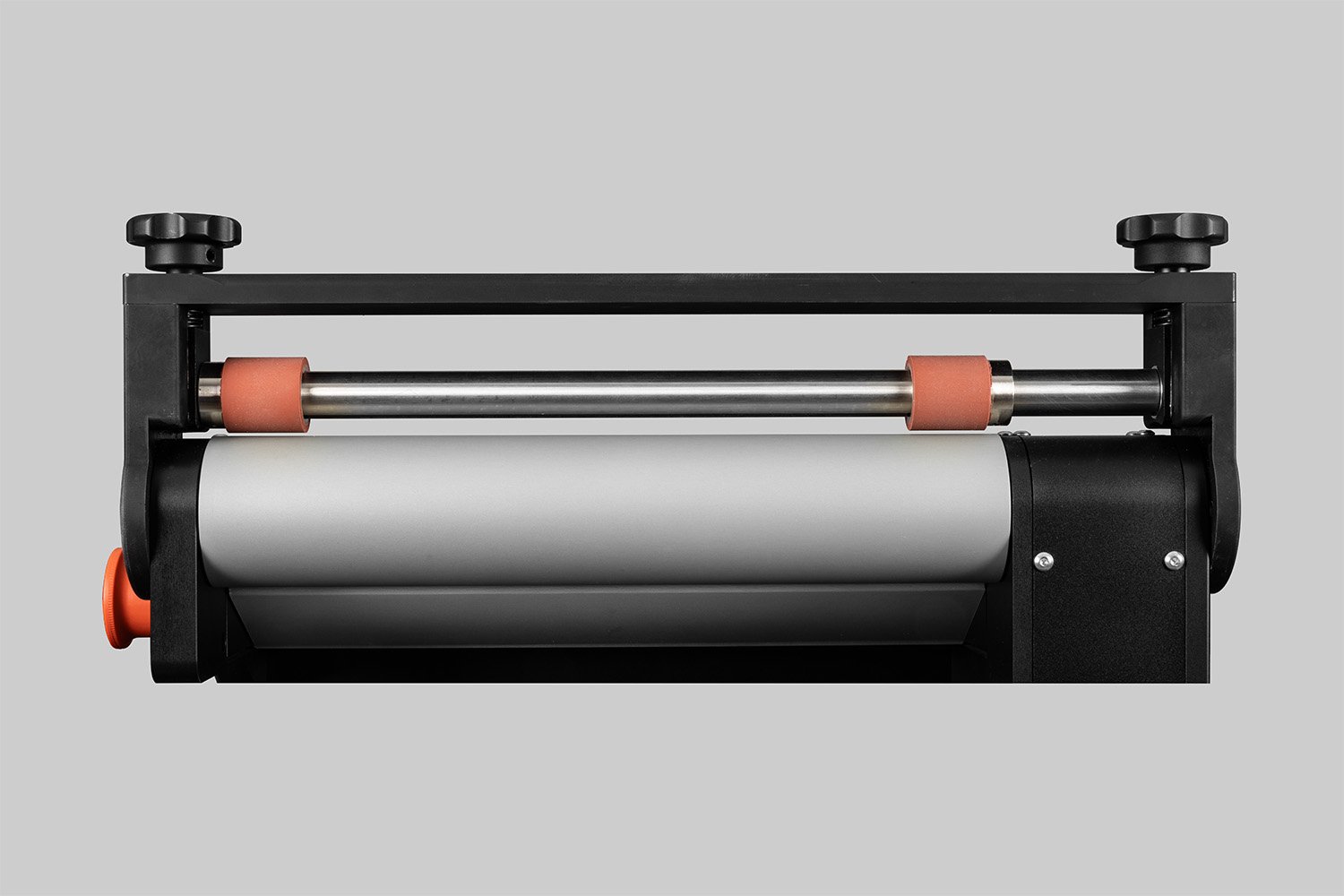

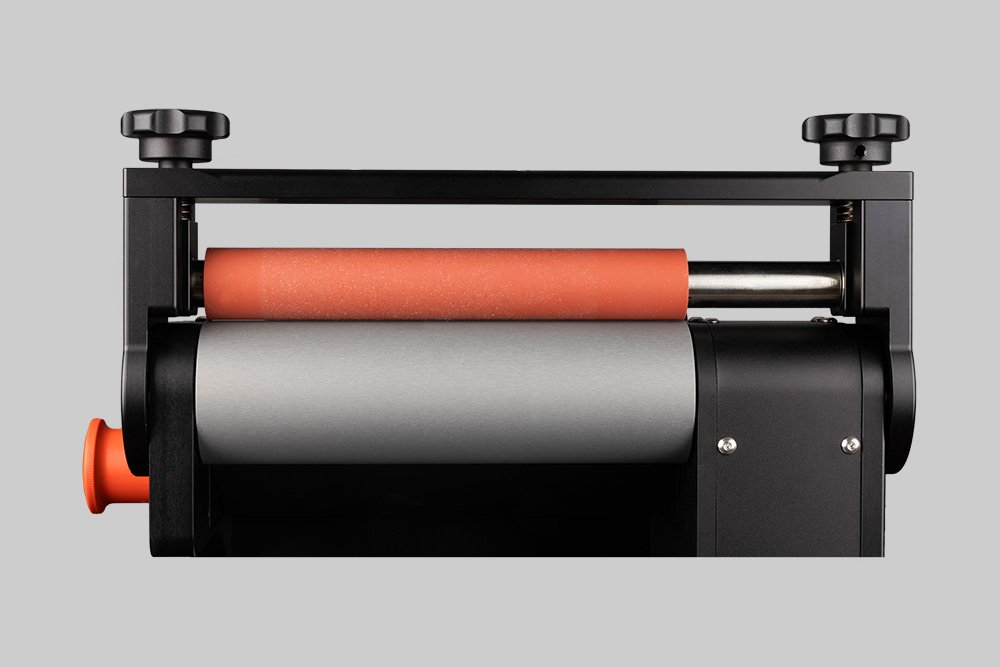

| Spindles | Automatic Compressed Air Spindles 3-inch Core Inner Diameters | The LR2R500 comes with adjustable cones that accept core inner diameters from 35 mm up to 90 mm |

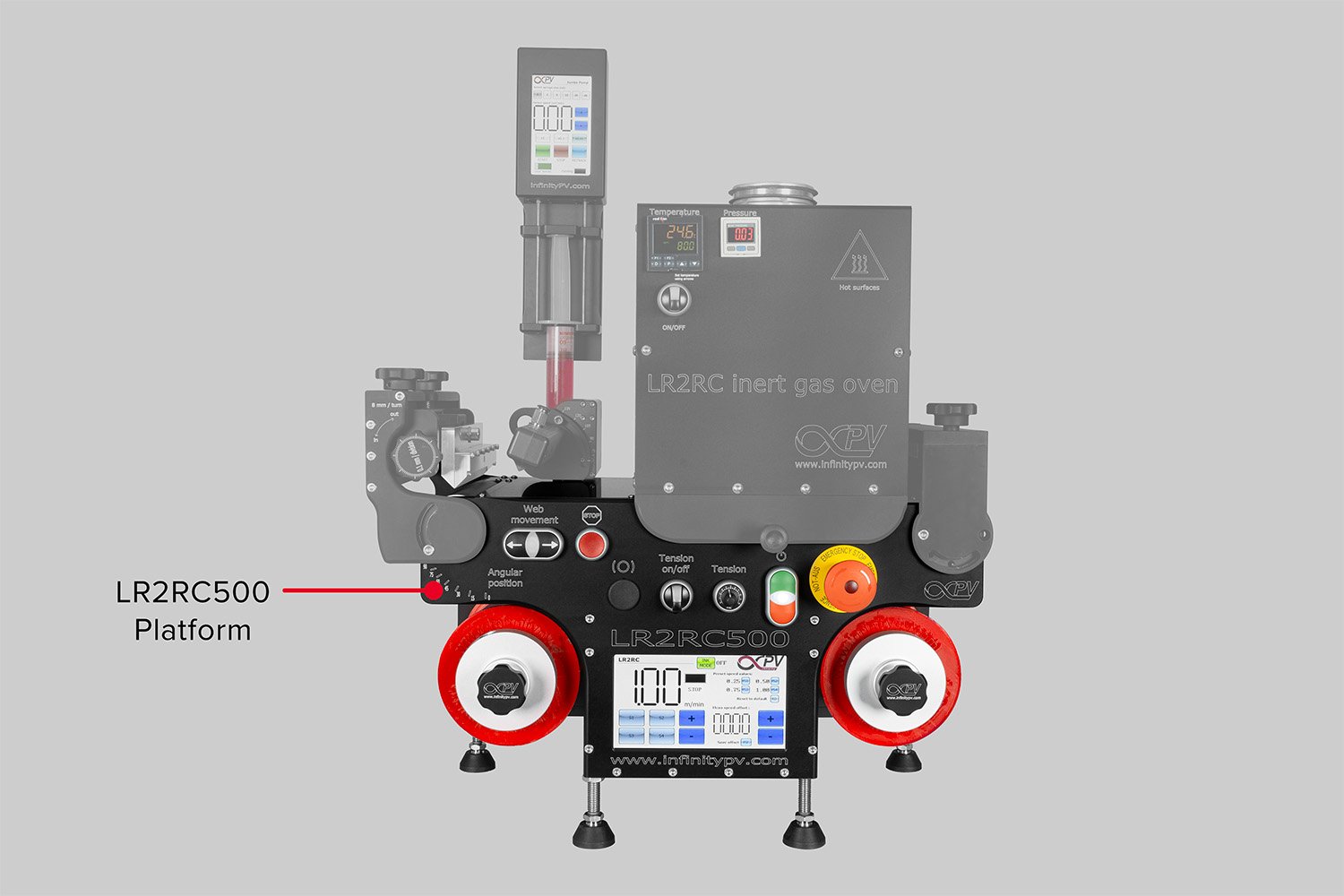

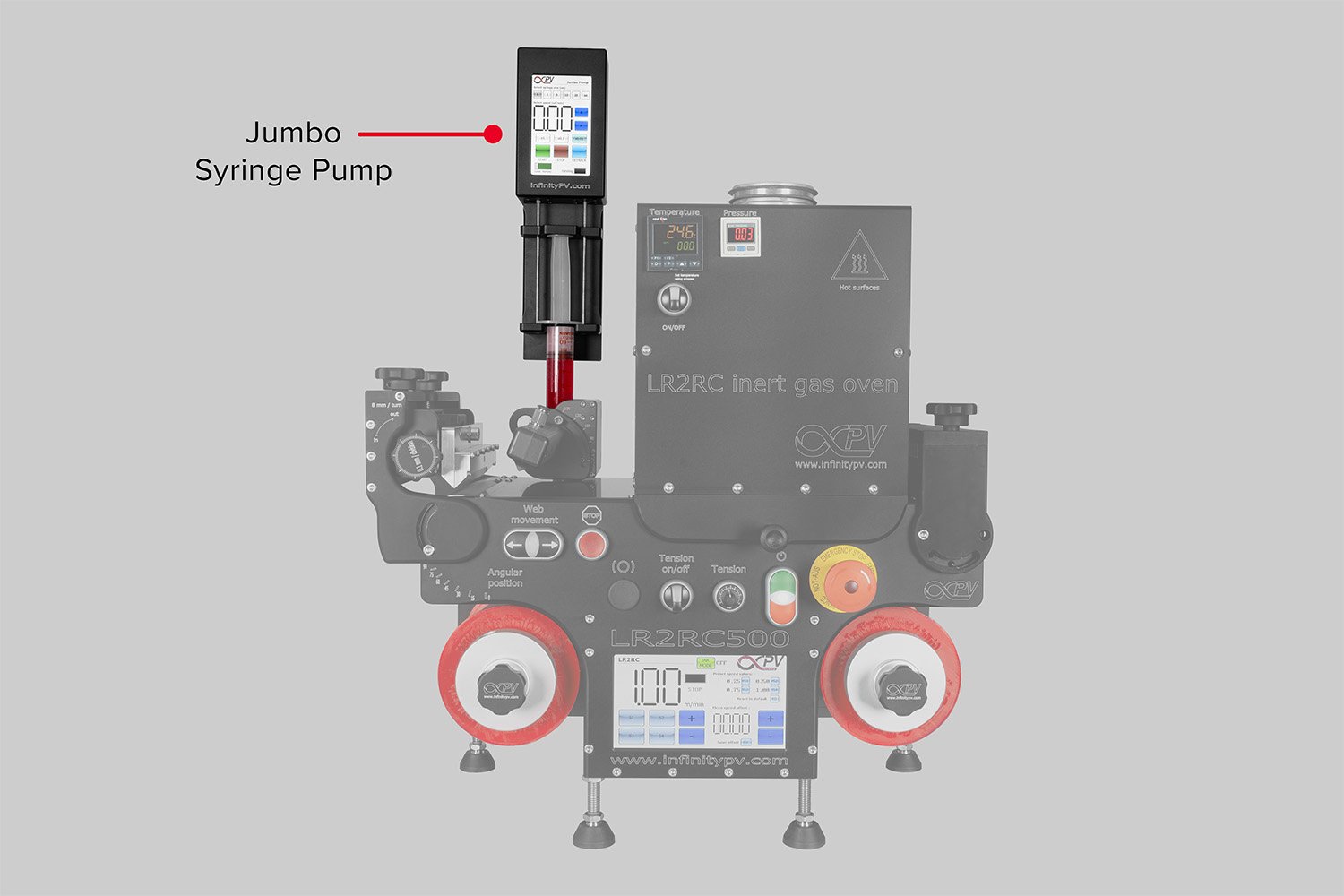

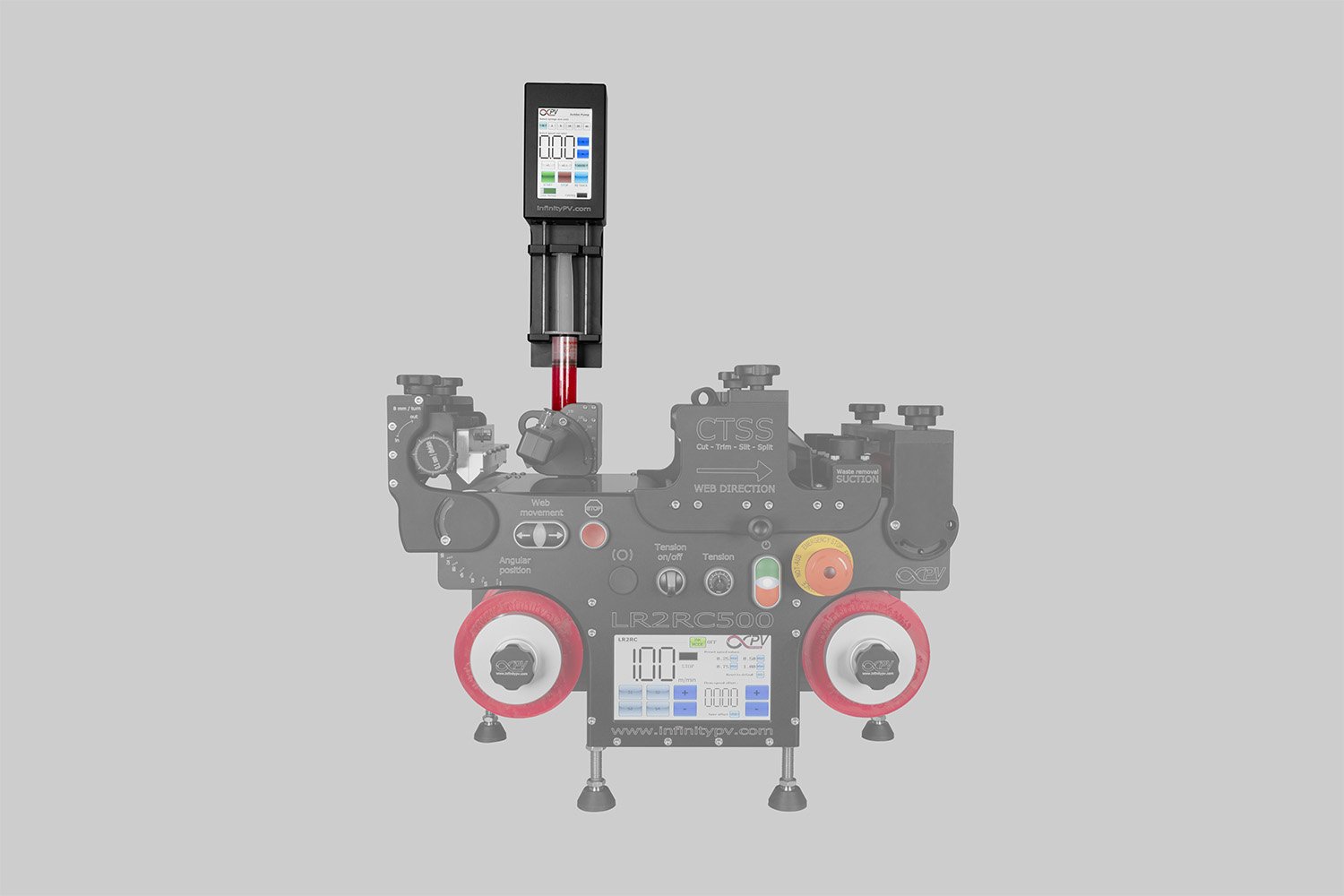

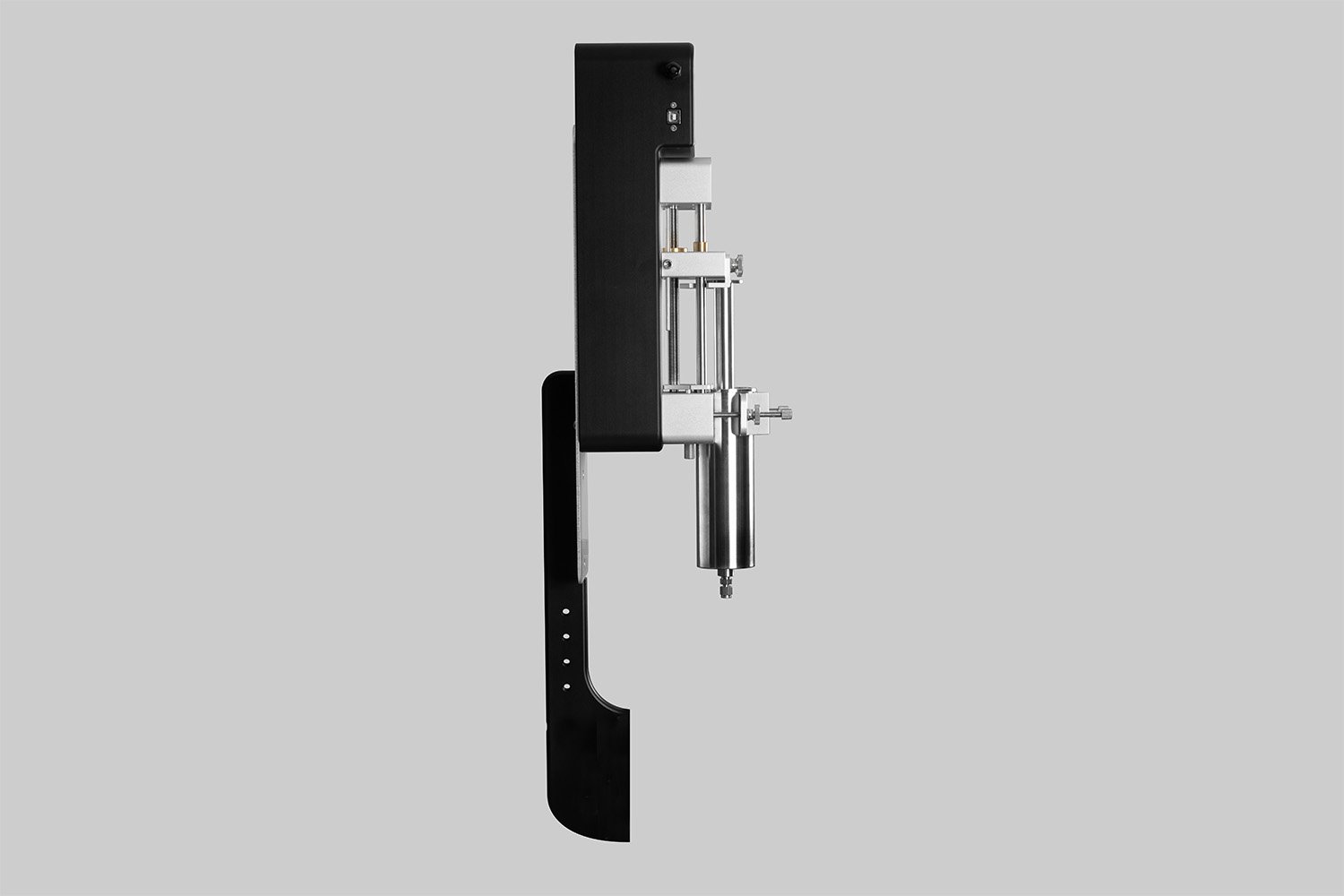

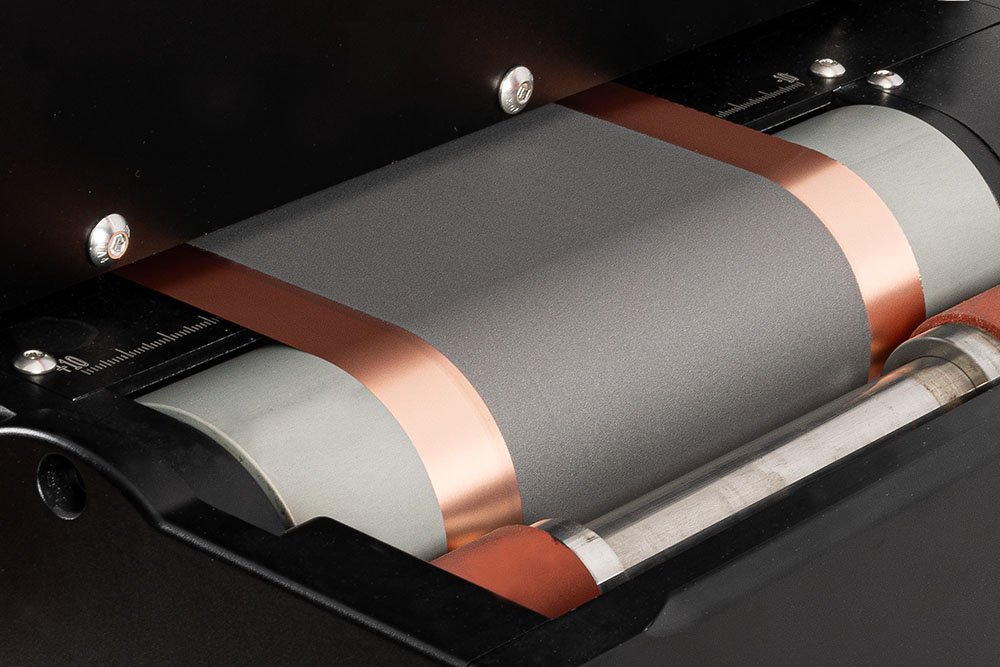

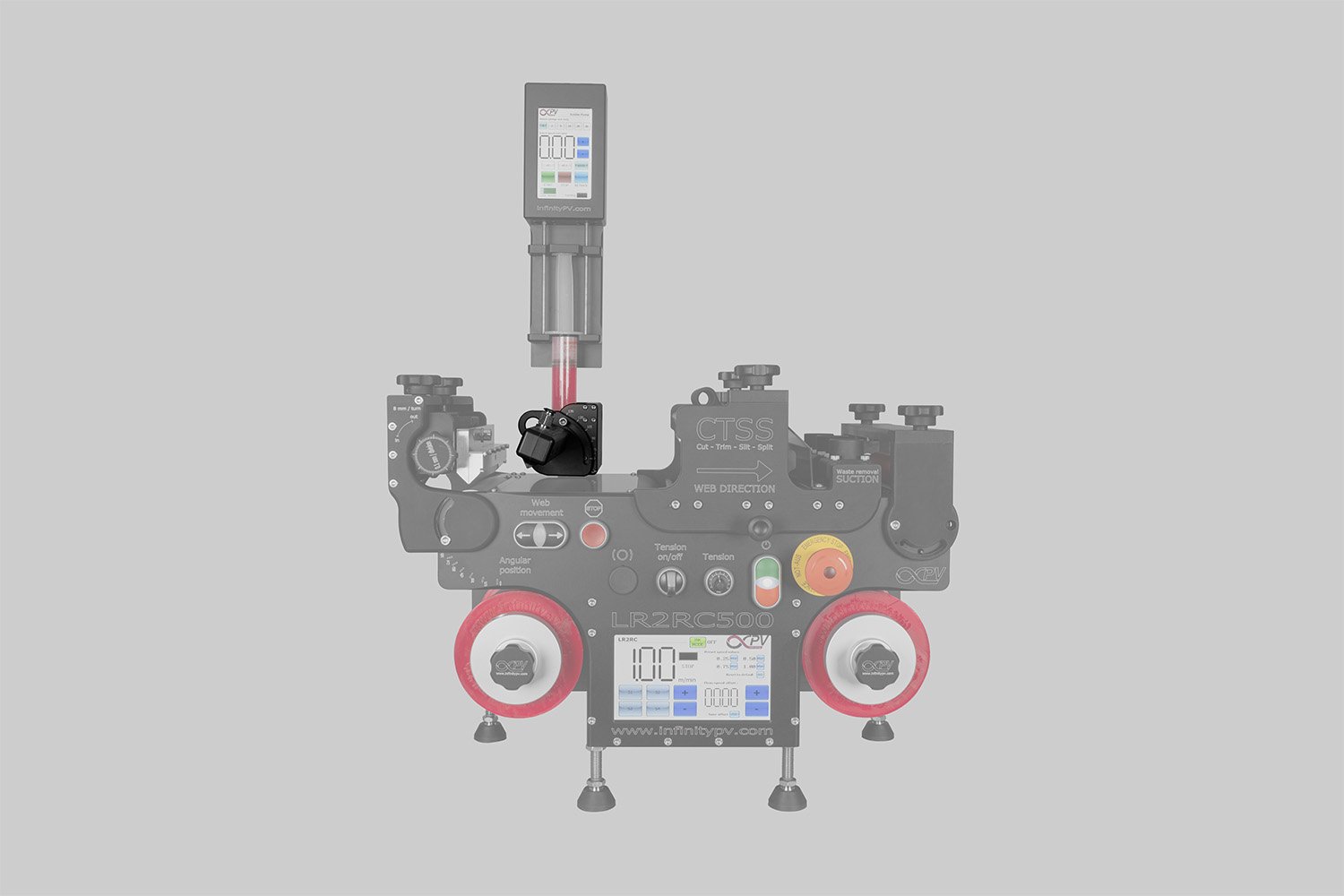

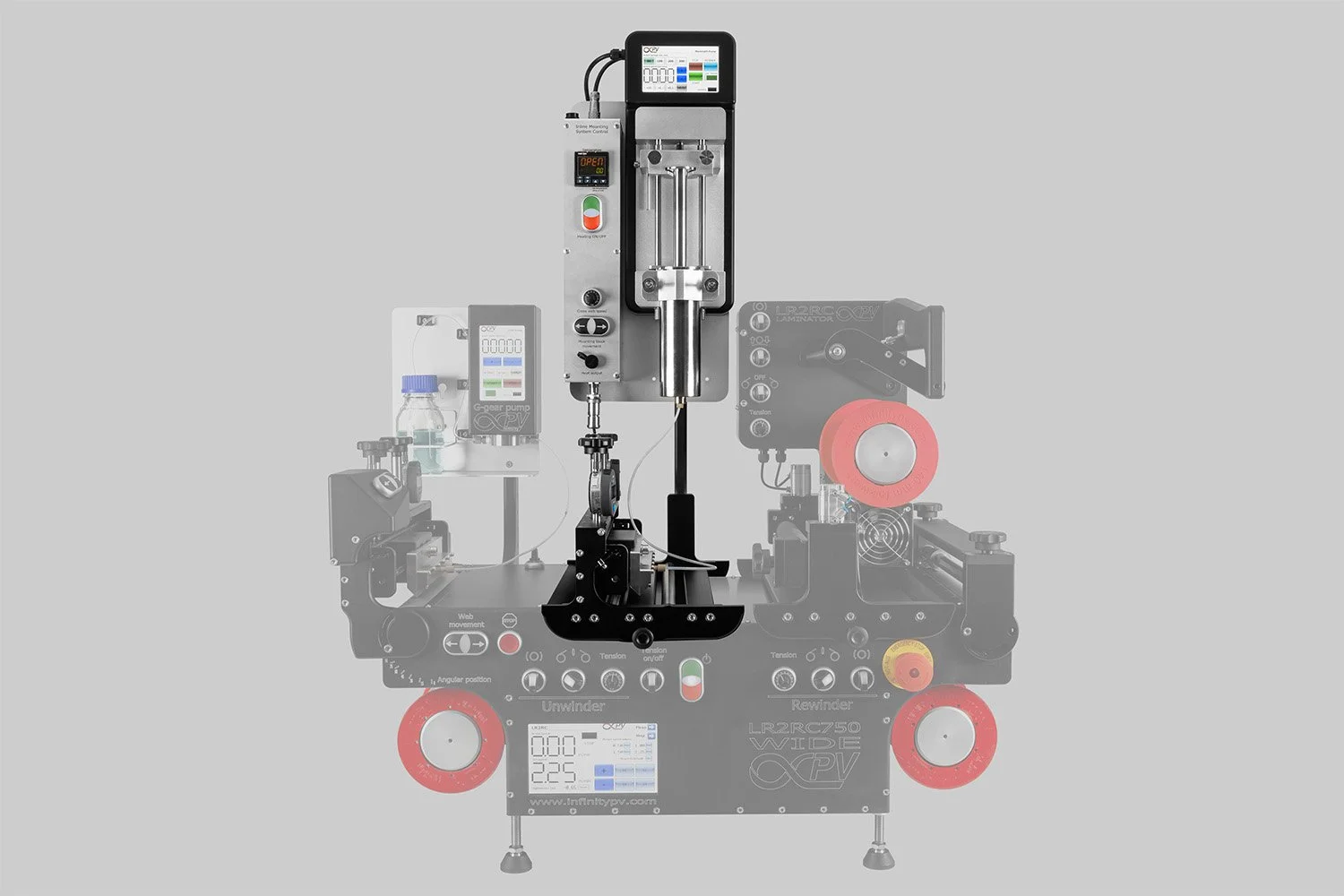

Probably the World’s Most Compact R2R Slot-die Coater

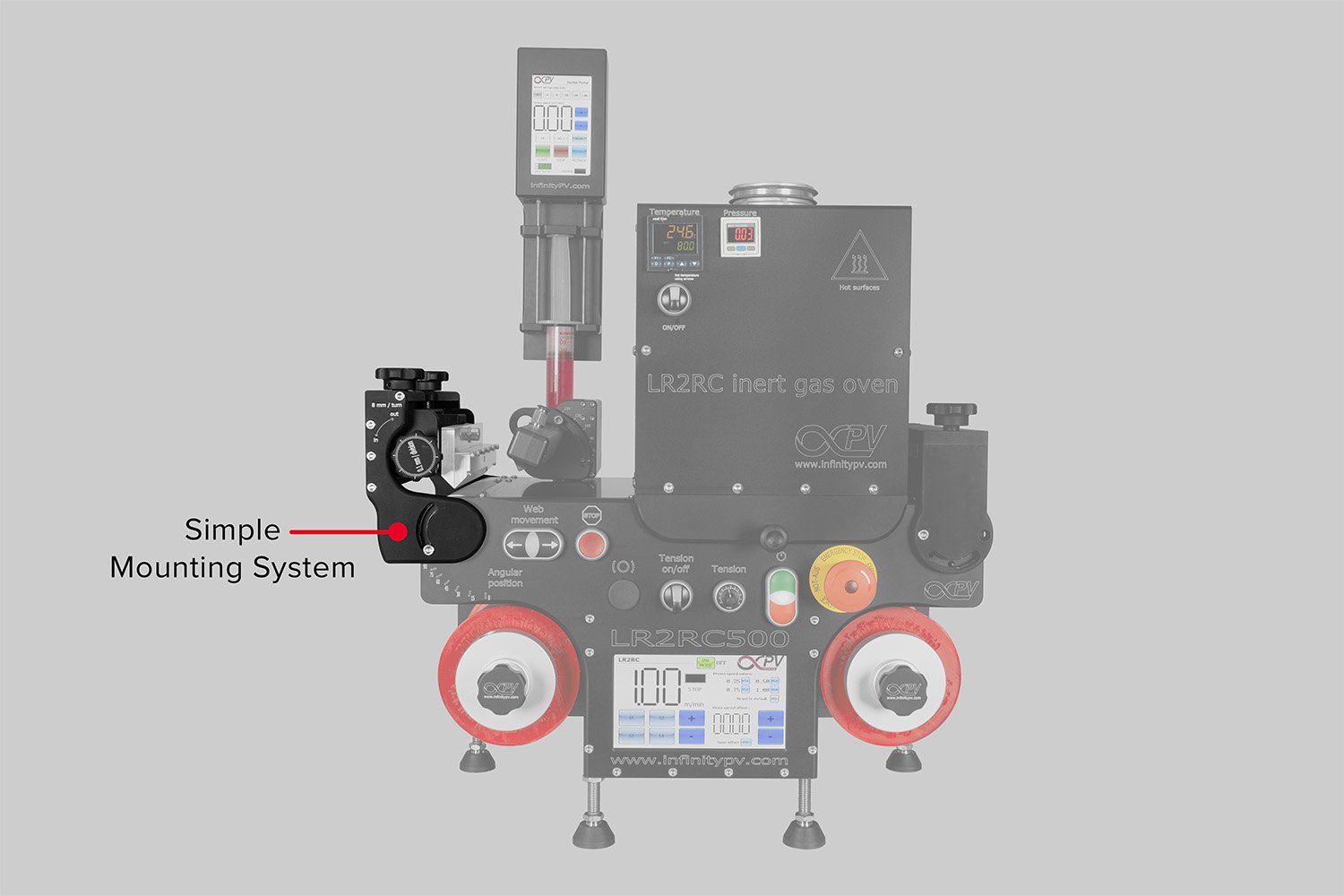

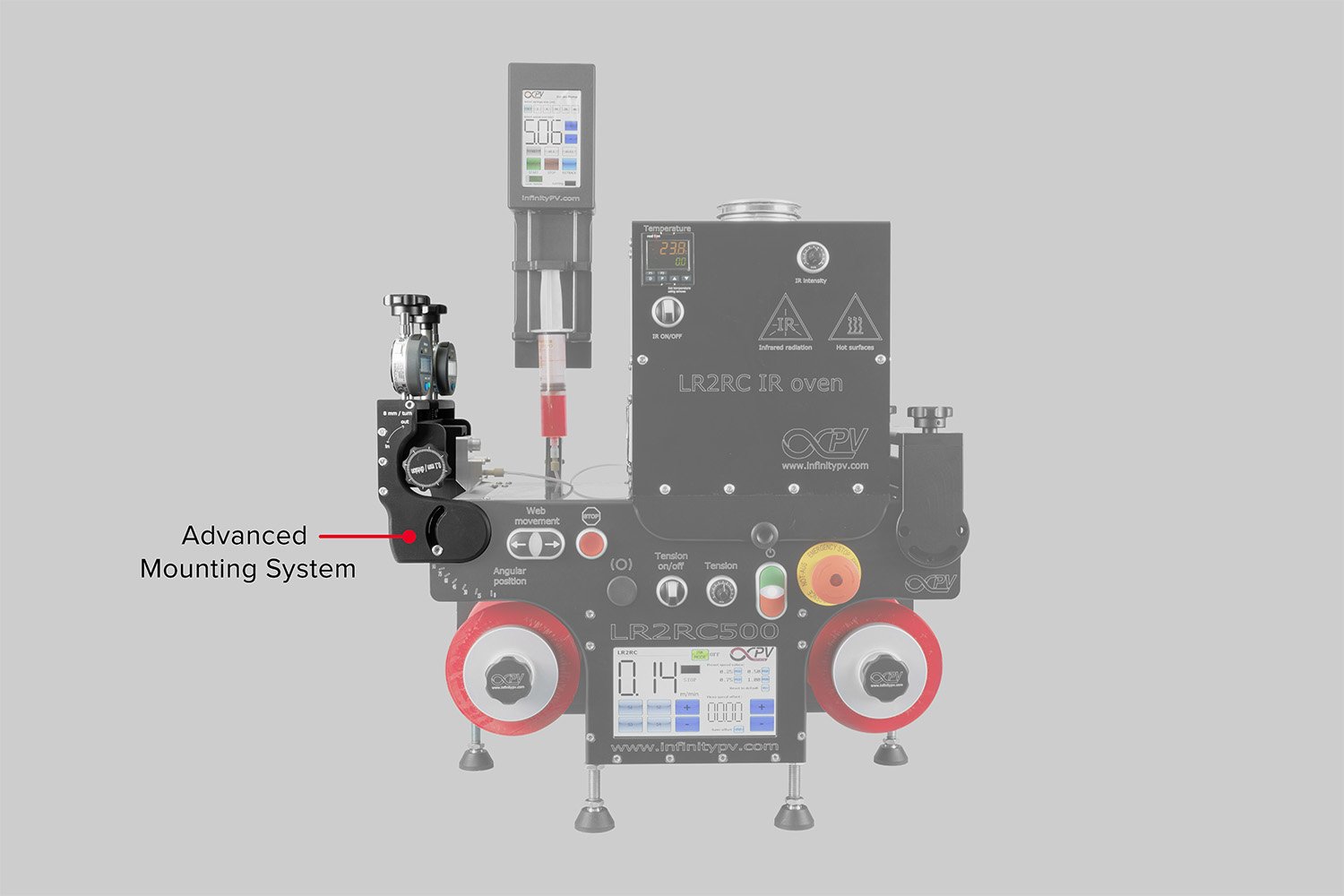

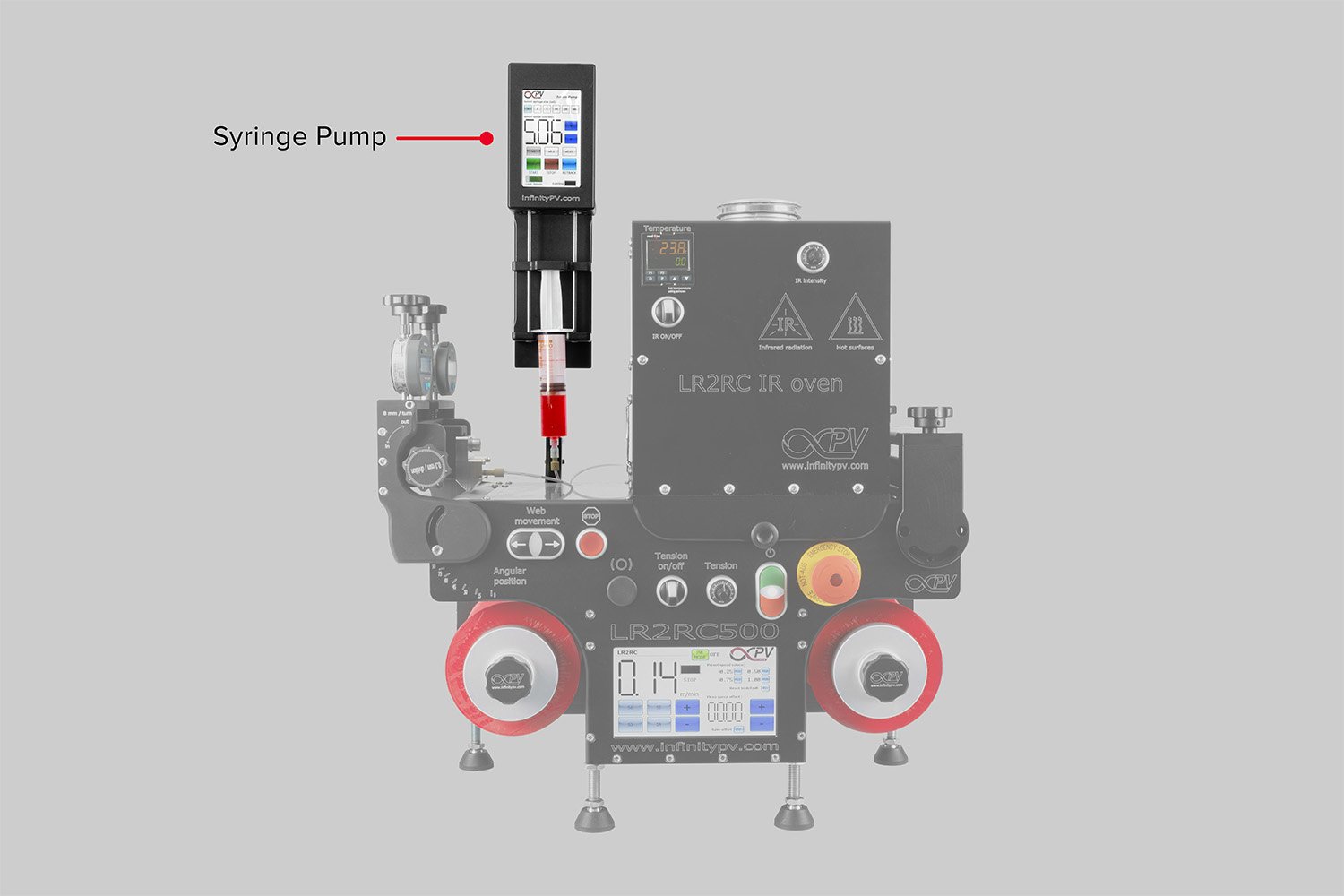

The LR2RC500 Bundle is a compact, fully integrated roll-to-roll coating platform for laboratories, complete with an advanced mounting system, anodized rollers, a jumbo syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.