LR2RC500 Bundle

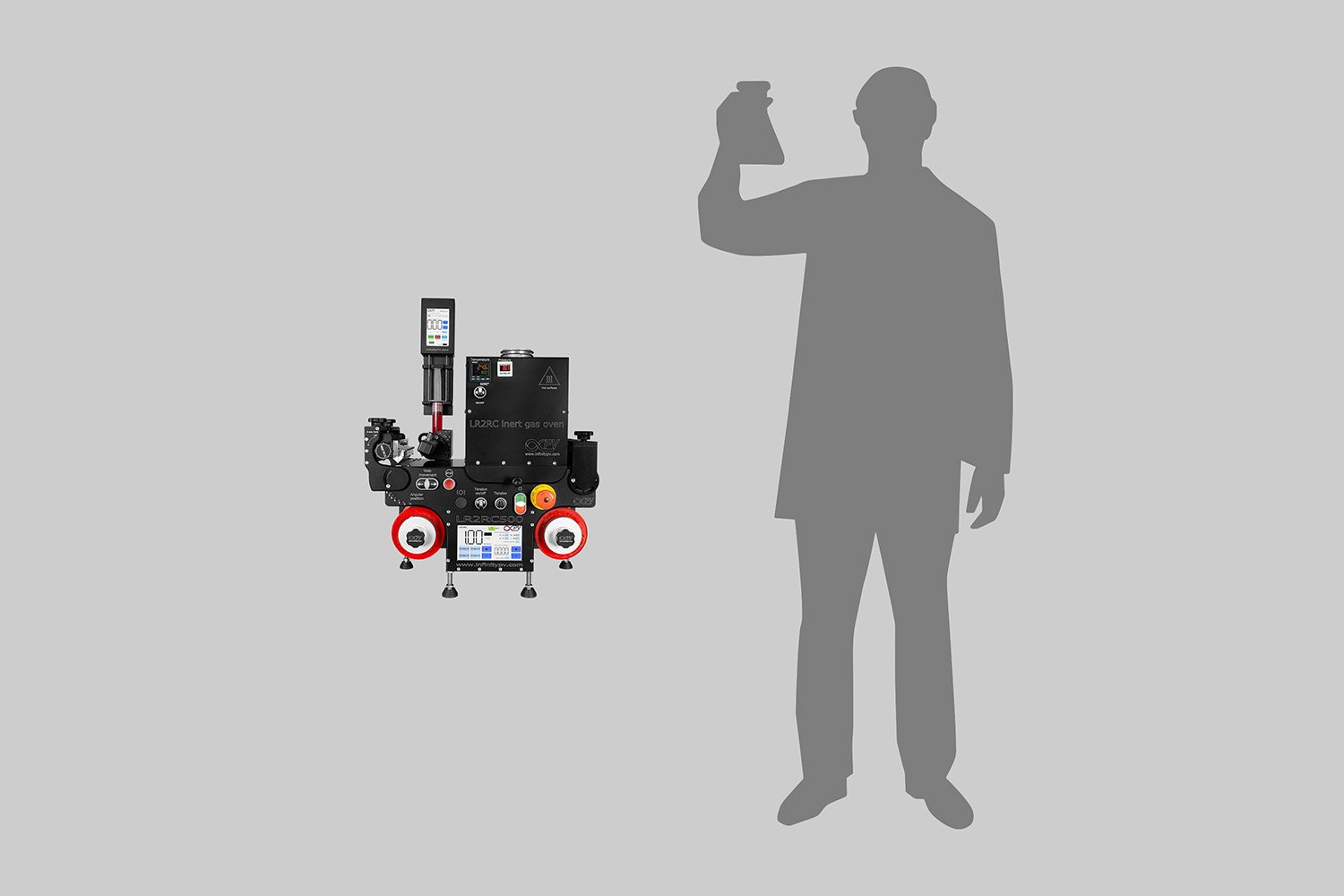

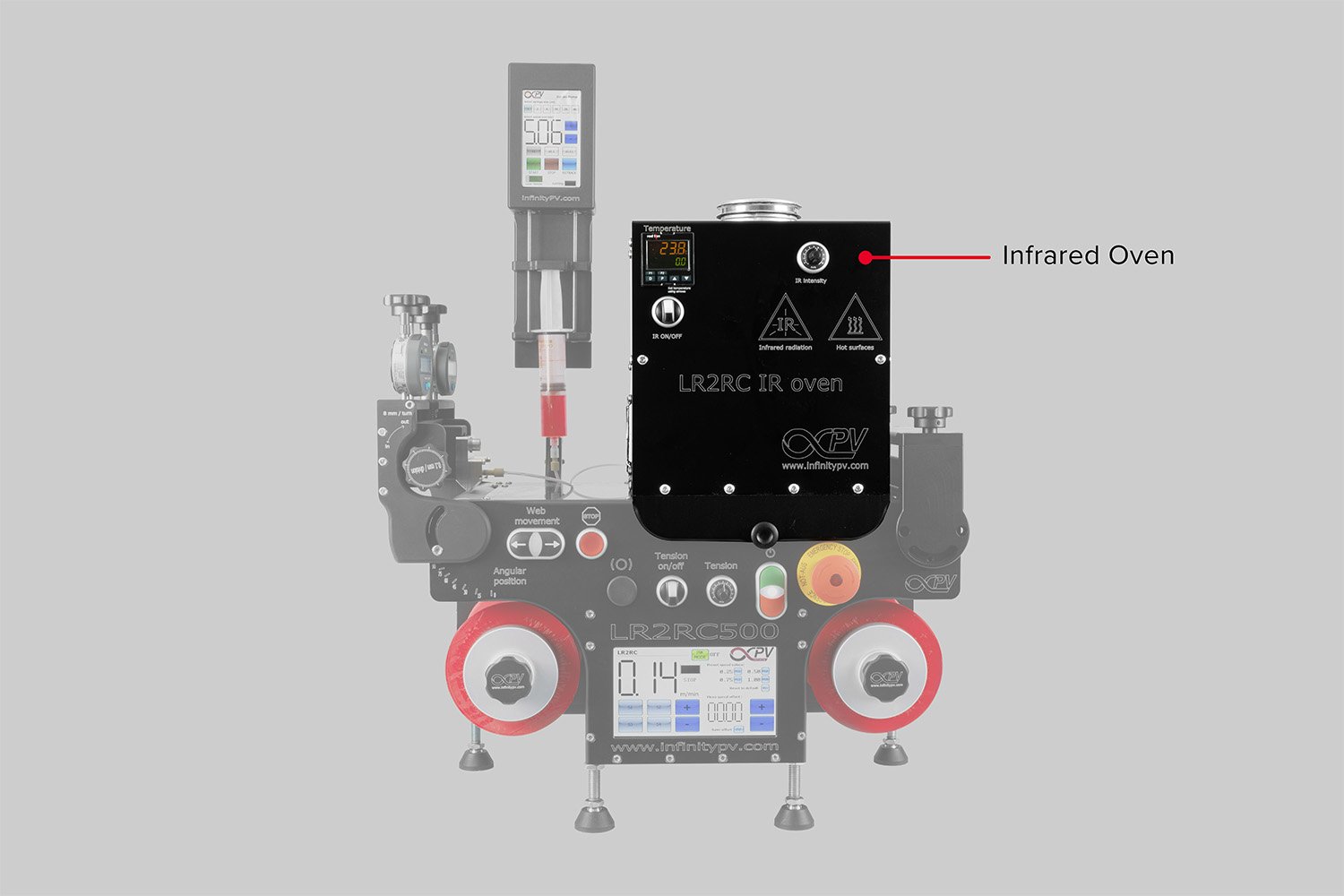

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.

Probably the World’s Most Compact R2R Slot-die Coater

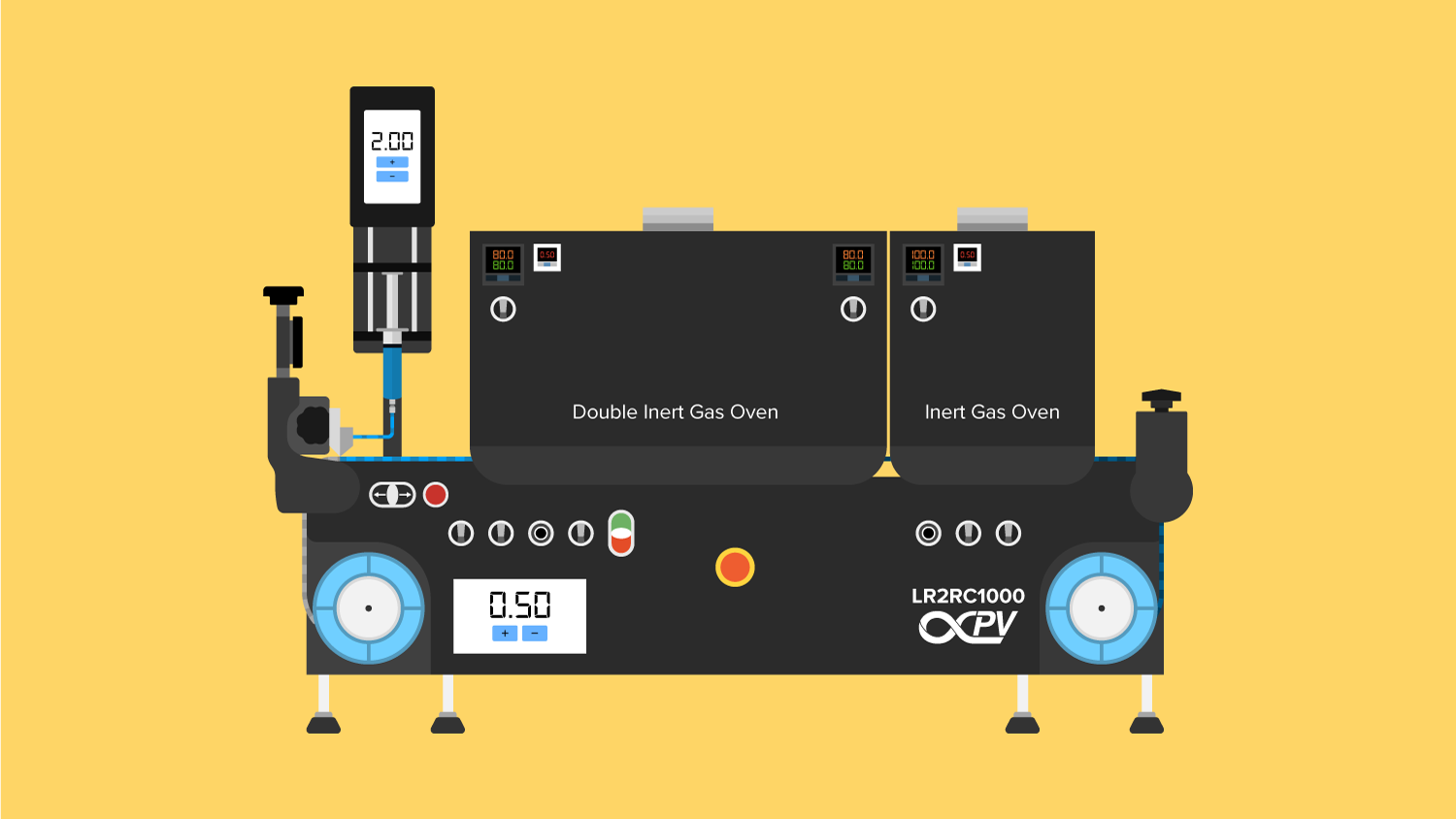

New to roll-to-roll processing or want to start exploring slot-die coating in your research? We at infinityPV have selected the most essential components for roll-to-roll slot-die coating and added it to our most compact Laboratory Roll-to-Roll Coater the LR2RC500.

This comprehensive solution integrates roll-to-roll web handling, slot-die coating technology, syringe pump and an optimized infrared oven system on a laboratory scale never seen before.

With the LR2RC500, you can achieve higher throughput, improved material utilization, and unparalleled control in your research. Don’t miss this opportunity to transform your research into scalable success—invest in the LR2RC500 and watch your innovations take flight!

What’s Included:

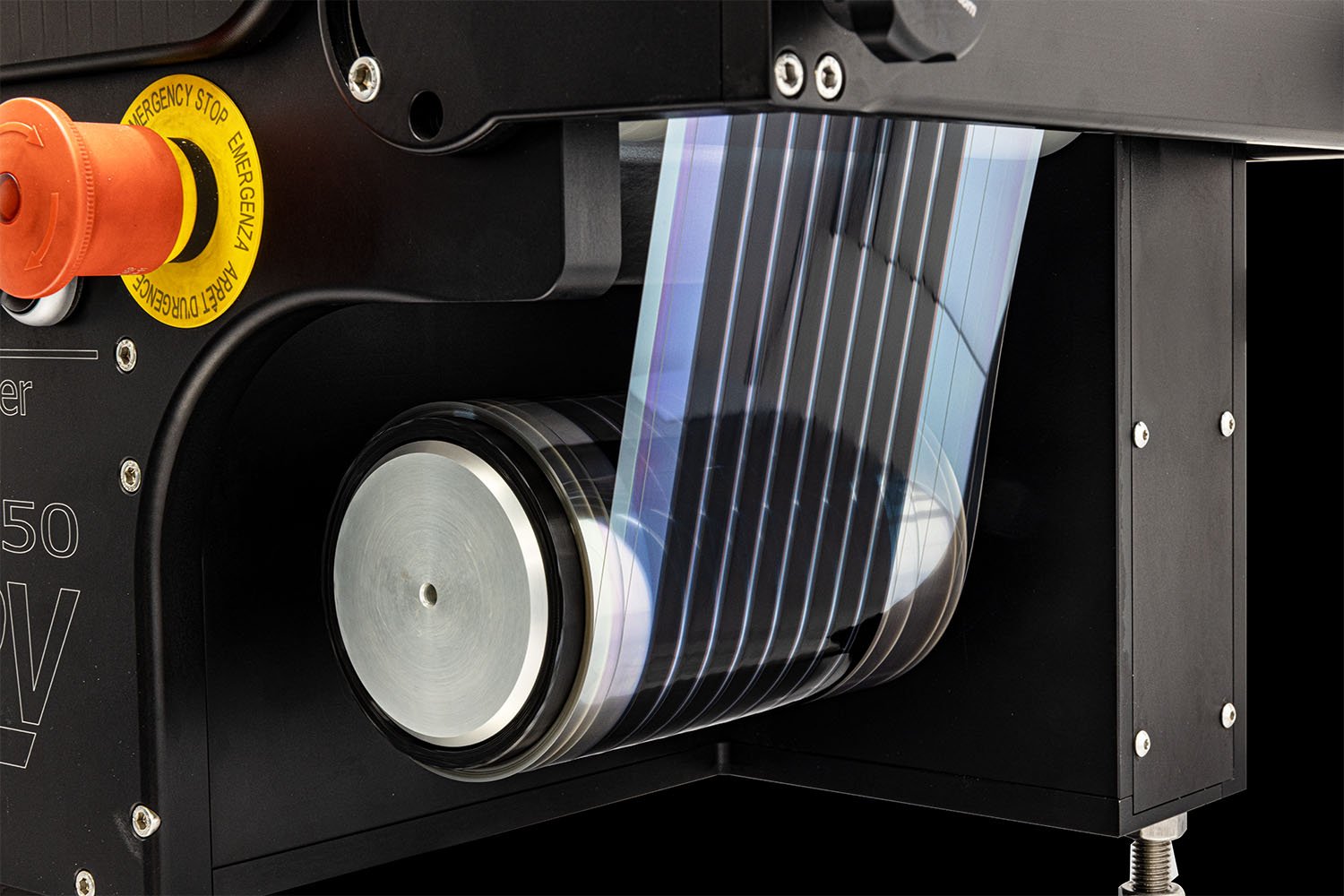

LR2RC500 Platform: Featuring anodized aluminum rollers, web tension control, spindles with adjustable conical bobbin holders, touch screen interface, and easy-to-use operation buttons.

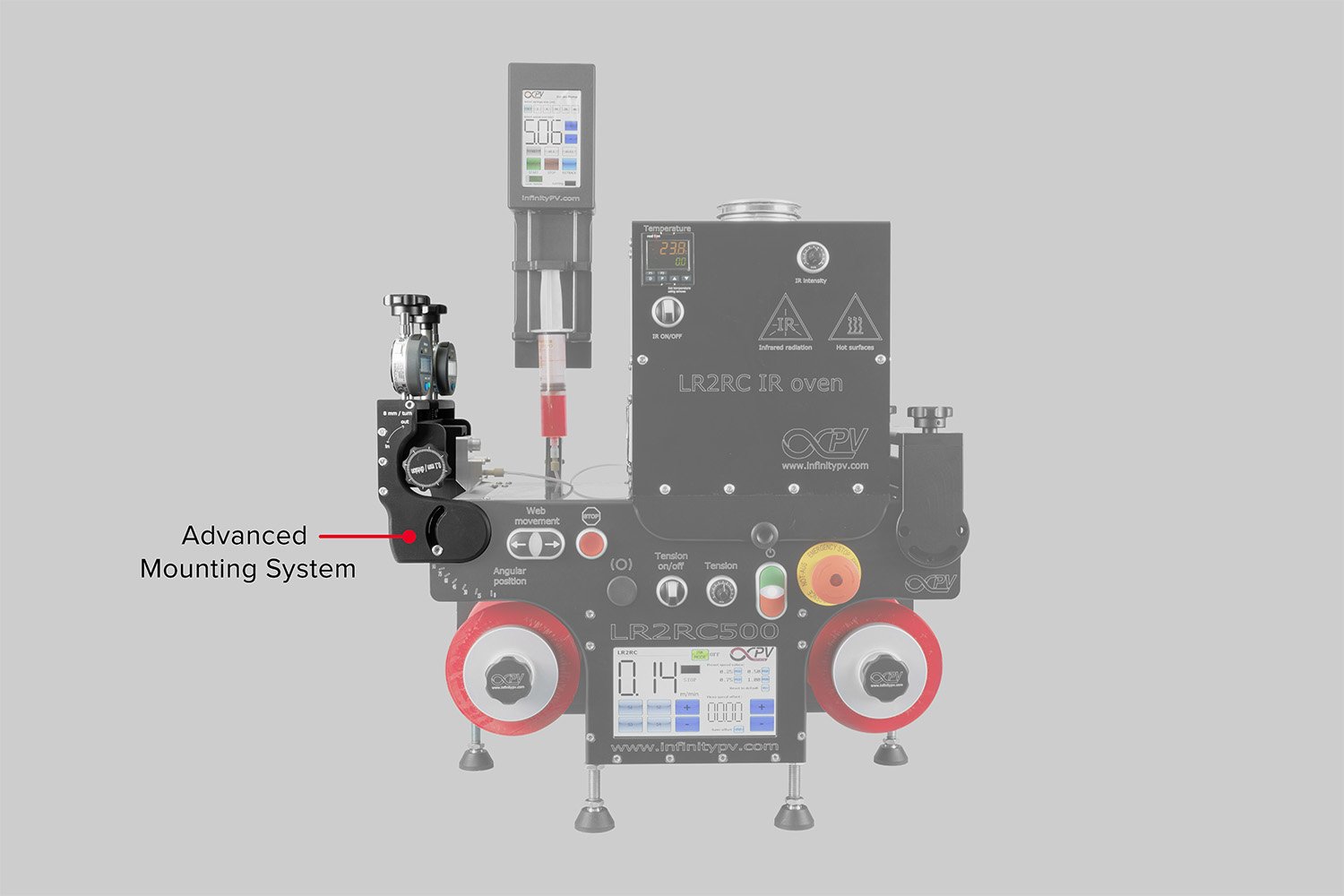

Advanced Mounting System: Manual adjustment with digital micrometers units for two-point head to substrate distance readout.

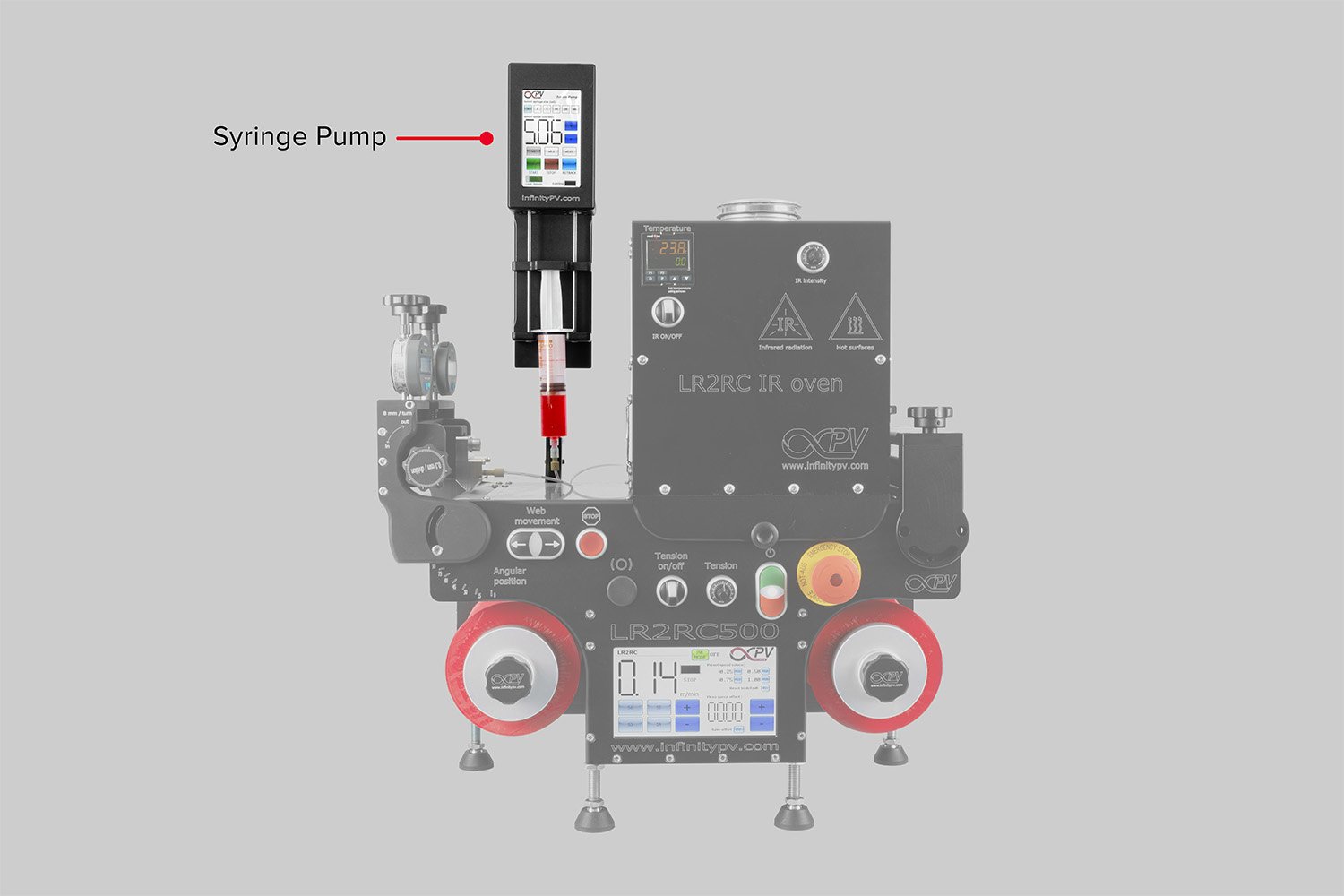

Jumbo Syringe Pump: Provides precise and consistent ink delivery, ideal for research applications.

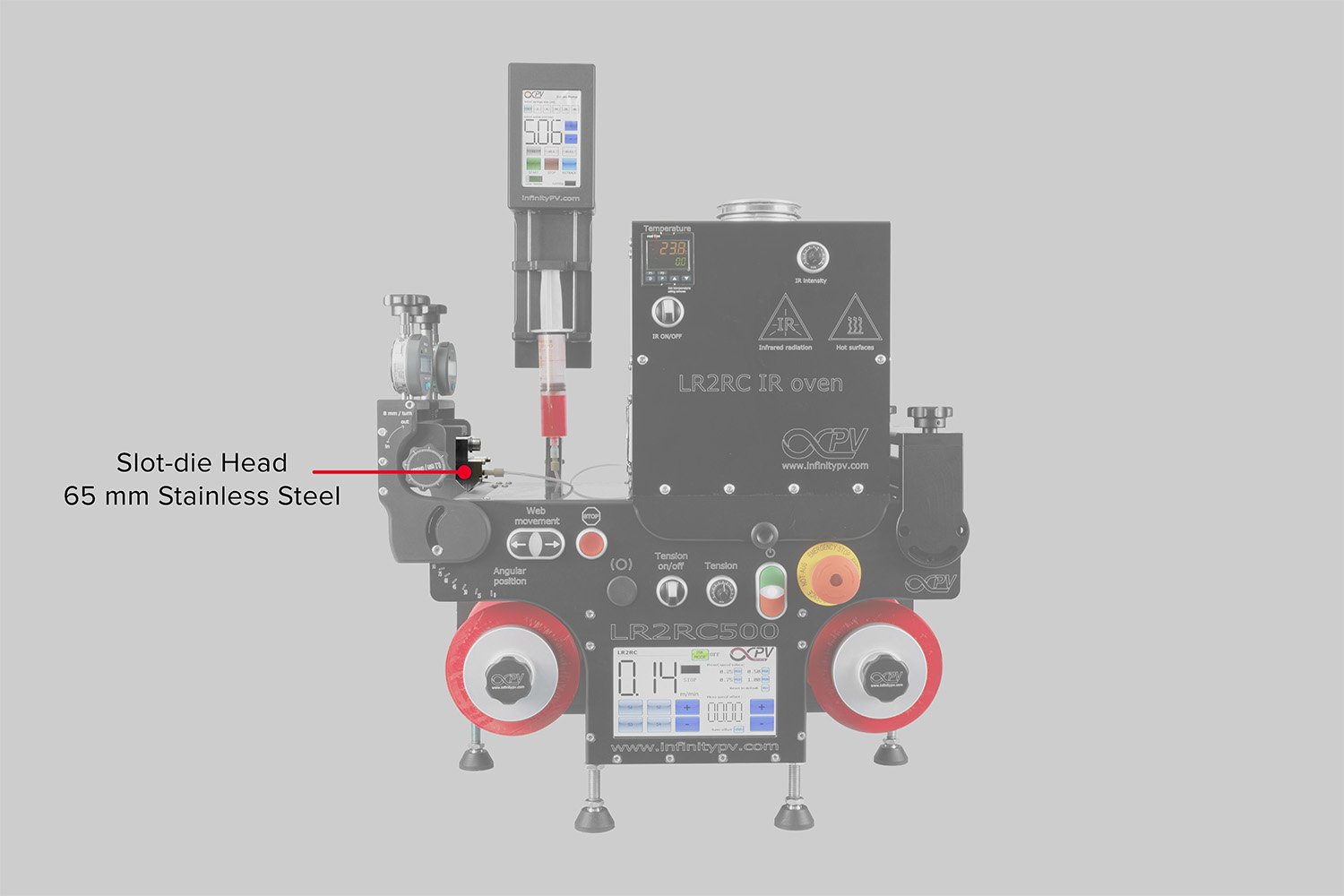

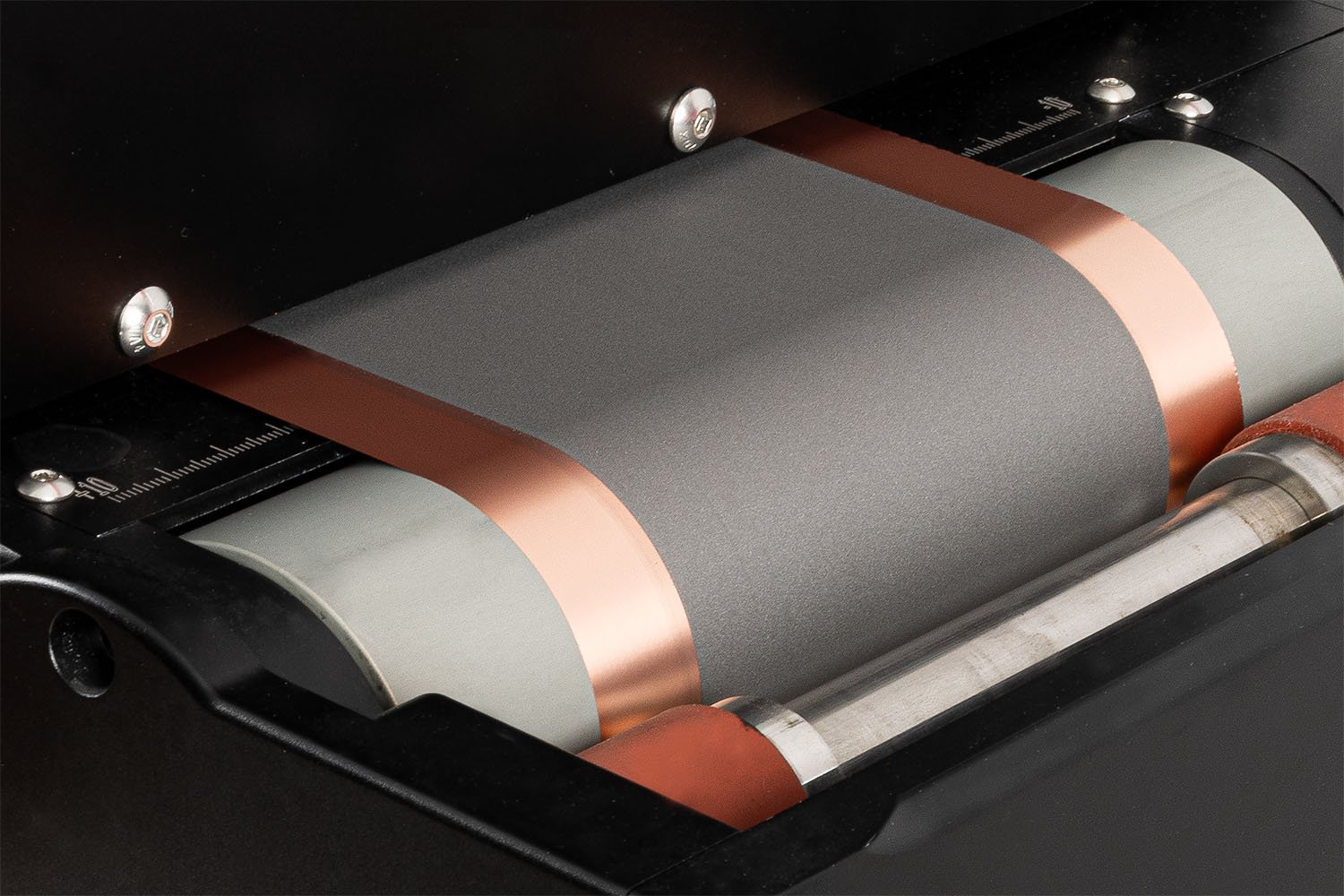

65 mm Stainless Slot-Die Head (50 mm working width): Ensures uniform and high-quality coating results.

Shim Kit and Fitting Kit: Optimized for 50 mm coating width, enhancing flexibility and precision in your experiments.

Infrared Oven System: For effective drying and curing at a lab scale, enabling quick setup and adjustments to meet your specific needs.

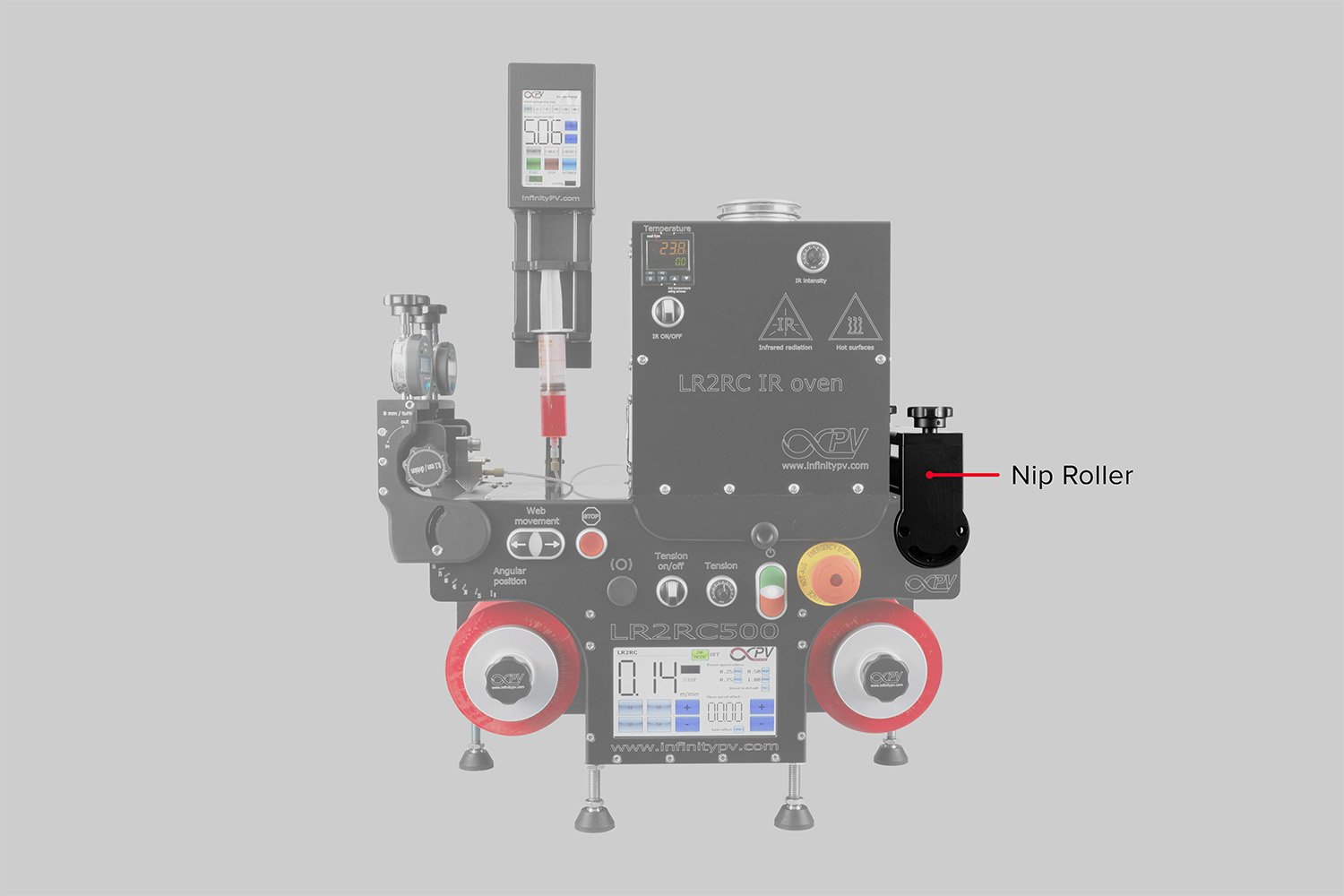

Full and Manual Nip Rollers: Tailor your setup for various substrate handling requirements.

Why Choose the LR2RC500 Bundle?

Compact and Scalable: Perfect for small laboratory spaces, gloveboxes, or fume hoods without needing additional infrastructure.

Integrated Solution: Includes essential components for R2R slot-die coating, streamlining your workflow from research to pilot-scale production.

Enhanced Control and Efficiency: Achieve higher throughput, improved material utilization, and unparalleled control over your coating processes.

Customizable and Modular: With modular components, the LR2RC500 can be easily adapted to fit your specific requirements, making it the ideal platform for diverse applications such as batteries, printed solar cells, LEDs, sensors, and more.

Modular Customization with the Roll-to-Roll Coater Laboratory

The Laboratory Roll-to-Roll Coater is a high-precision, compact solution for processing thin functional films in both lab and small pilot-scale environments. Its versatile modular design supports slot-die coating, slurry coating, and flexographic printing, and accommodates various coating components including slot-die heads, laminators, air knives, edge guides, plasma and corona treatment systems, and drying and curing ovens. The Laboratory Roll-to-Roll Coater can fit seamlessly into existing lab spaces, gloveboxes, or fume hoods without additional infrastructure. Capable of handling hundreds of meters of foil, it provides scalability and efficiency for applications such as thin film batteries, fuel cells, printed solar cells, OLEDs, sensors, adhesives. Designed for user convenience and built to international safety standards, the Laboratory Roll-to-Roll Coater is a flexible and economical choice for advancing thin-film technology. Customize your system today to meet your specific needs.

Key Features

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Choose from a variety of lengths and widths, with numerous components available.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

Modular Drying/Curing System: Accommodates various drying and curing methods.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

Technical Specifications

Operating Power: Single phase (240VAC) for smaller models; three-phase (400VAC) for larger models.

Drying/Curing Length: 250 mm

Web Width: Up to 200 mm

Web Speed: 0.05-2.8 m/min (forward and reverse).

Spindles: Adjustable cones for smaller cores in LR2RC500.

Applications

Printed Solar Cells (OPV, Perovskite, DSSC, Tandem)

Adhesives and Sealants

Medical Devices (Biocompatible and Drug-eluting Layers)

Packaging Materials