Research Laboratory Coater

A versatile, compact system for producing high-quality films using multiple deposition techniques like slot-die coating and flexo.

State-of-the-Art Sheet Coater for Advanced Thin-Film Applications

Take your thin-film research to new heights with the Research Laboratory Coater from infinityPV. Tailored to the rigorous demands of R&D, this innovative sheet coater delivers precise and consistent results for applications including printed batteries, solar cells, fuel cells, OLEDs, and sensors. Designed to handle both organic and inorganic materials, the coater ensures superior film quality, enabling researchers to achieve breakthrough discoveries.

Why Research Laboratory Coating Excels in Thin Film Production

The Research Laboratory Coater is engineered for high uniformity and precise thickness control, making it ideal for nanometer- to micrometer-scale thin films. Its ability to handle diverse liquid formulations ensures consistent results for a variety of applications. Reliable and versatile, it is a valuable tool for researchers seeking accuracy, reproducibility, and efficiency.

Integrated Drying for Streamlined Processes

The Research Laboratory Coater simplifies your workflow with integrated drying capabilities. By combining coating and drying within a single, compact system, it ensures uniform film quality while optimizing laboratory space. With precise temperature control, this feature enhances drying consistency, making it an essential solution for thin-film processing.

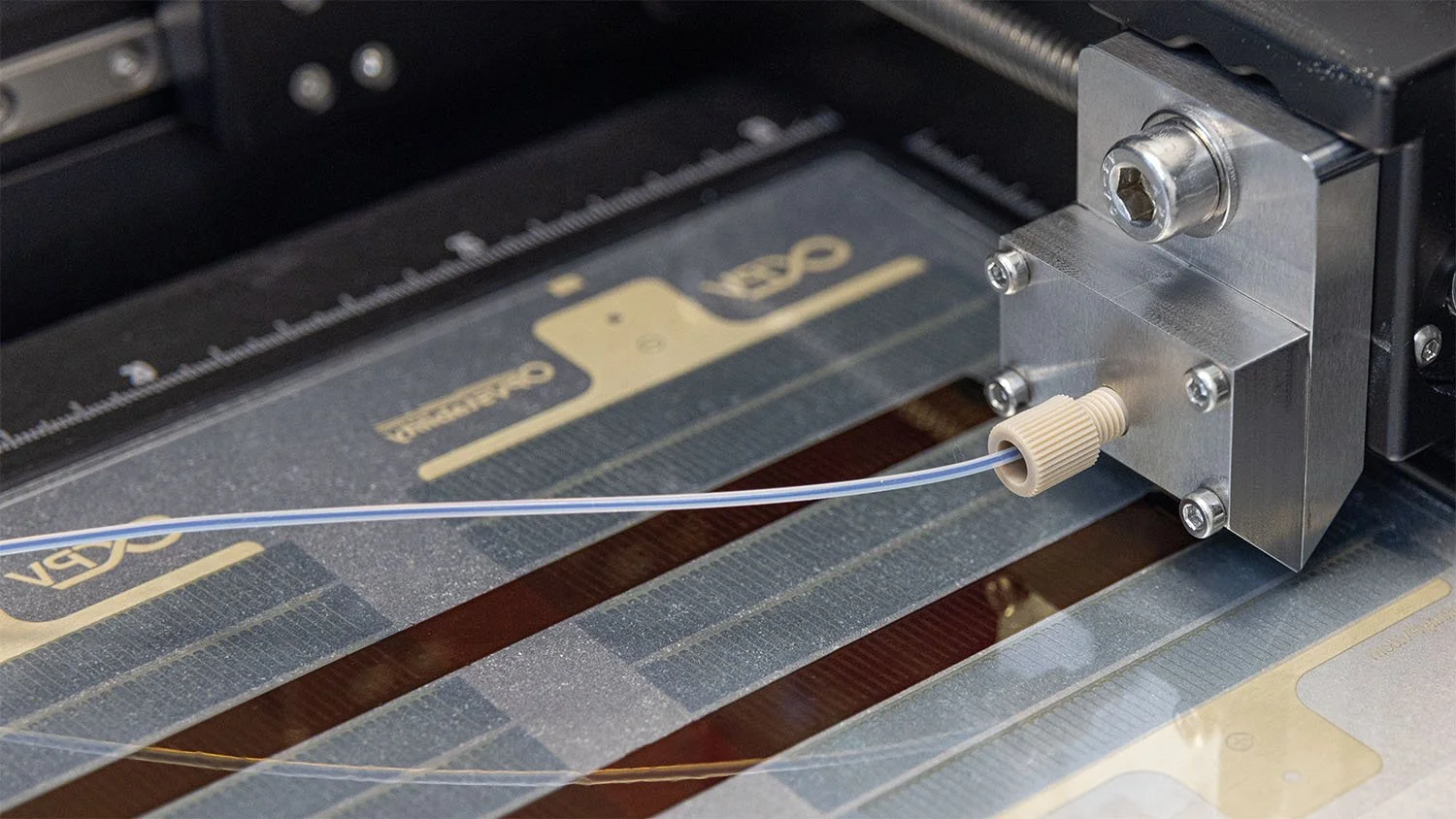

Precision Ink Delivery with Integrated Syringe Pump

Control your coating process with unparalleled accuracy using the infinityPV Syringe Pump. This component offers precise adjustments to flow rates, ensuring consistent ink delivery for both organic and inorganic formulations. Its adaptability makes it indispensable for customizing your setup to the specific needs of your research projects.

Key Features

Quick Setup and User-Friendly Operation

Modular Design with Swappable Components

Cantilever Structure for Easy Substrate Handling

Integrated Syringe Pump for Accurate Ink Flow

Versatile Coating/Printing Options: Slot-Die Coating, Bar Coating, Knife Coating, Pen, and Flexo Printing

Compact Size for Use in Gloveboxes and Fume Hoods

CE Certified and CSA/UL Compliant for Global Standards

Technical Specifications

Power Requirements: 110–240 VAC

Coating Area: 100 x 280 mm

Coating Speed: 1.2–33 mm/sec

Dimensions: 500 x 550 x 450 mm (W x D x H)

Weight: 20 kg

Height Adjustment Resolution: 1 μm

Control Interface: Touchscreen and Physical Buttons for Ease of Use

Optional Heated Slot-die Head

Applications

Video: How to Make Solar Cells Using the Slot-die Coater

Learn how to fabricate solar cells using slot-die coating and flexo printing on a Slot-die Coater. From preparing the ink and coating the active and hole-conducting layers to printing the silver back electrode. By combining slot-die coating with flexo printing, this method enables efficient and high-quality solar cell production.

Components

Customize your slot-die coater to meet your exact needs. Choose your base plate, integrate precision syringe pumps, and select from various coating tools, including slot-die heads for uniform thin films, bar coaters, knife coaters, and flexo printers. Build the perfect system for your applications with ease.

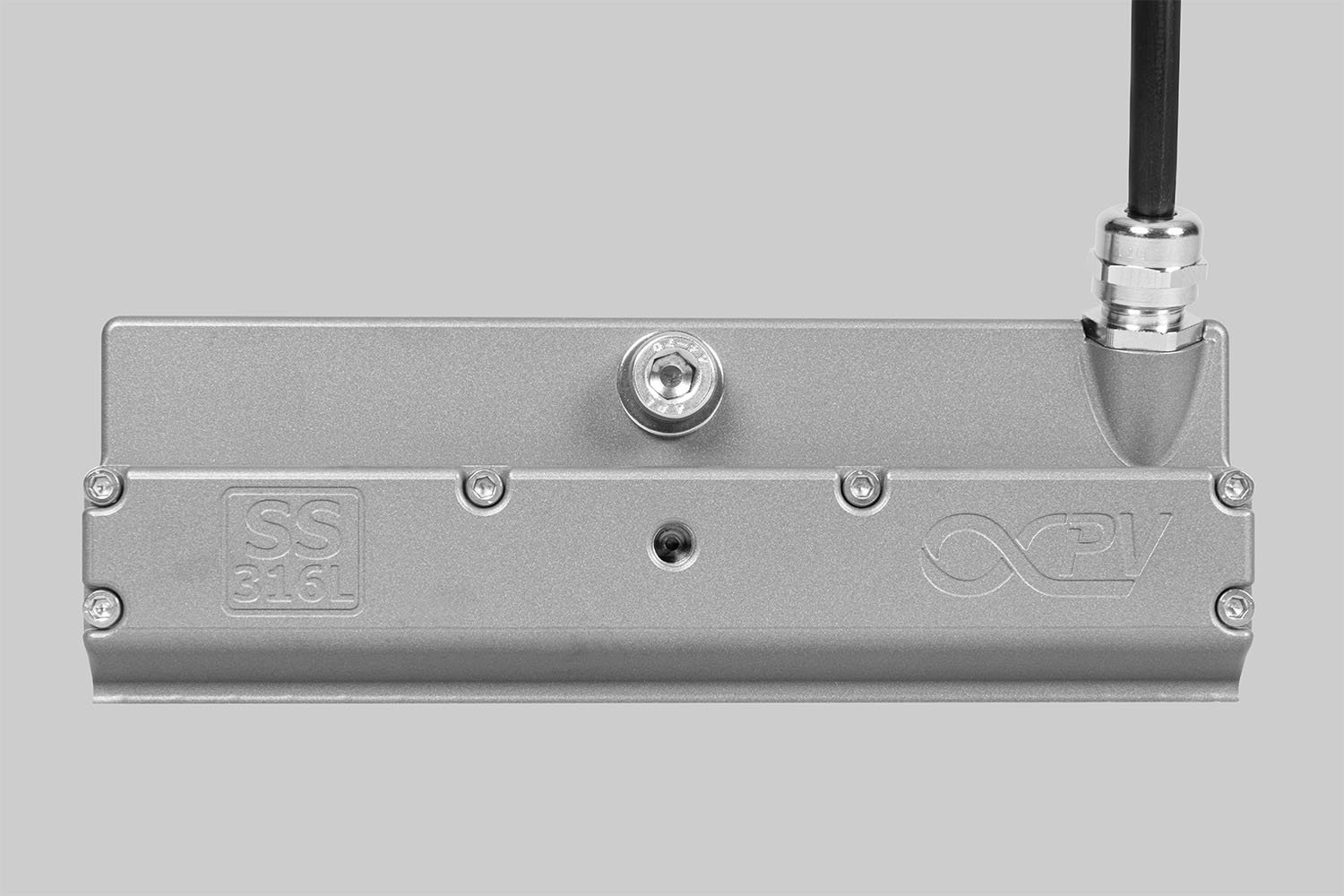

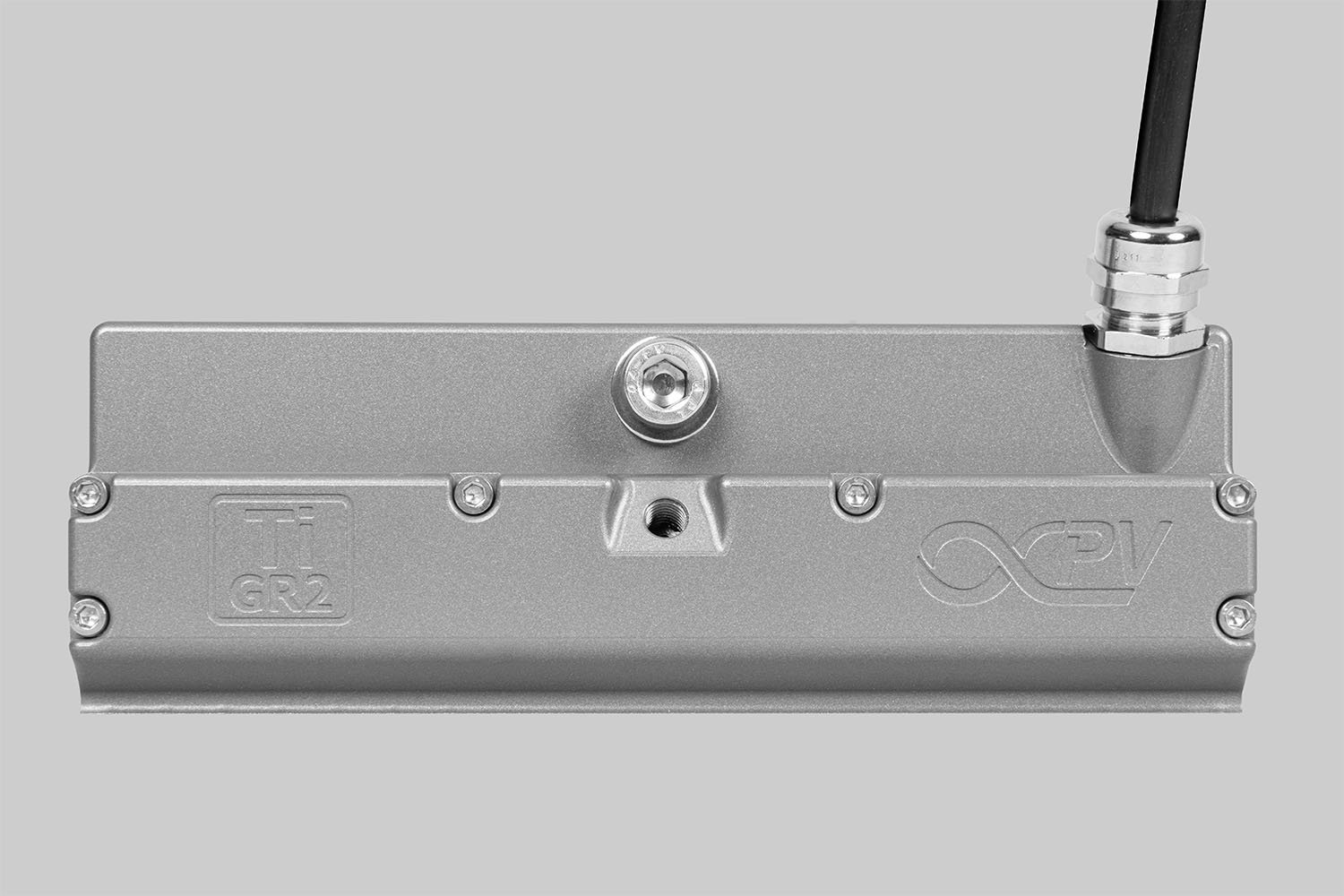

The infinityPV slot-die heads offer unparalleled performance across various materials and size. Available in PEEK, Stainless and Titanium in standard widths of 40 mm, 65 mm, 115 mm, 165 mm, 195 mm and 305 mm.

Engineered with precision and innovation in mind, our slot-die heads offer unparalleled performance across various materials and size. Available in Stainless Steel and Titanium in standard widths of 40 mm, 65 mm, 115 mm and 165 mm.

If you need a customized slot-die head tailored to your specific requirements, our expert team is ready to collaborate with you to design and manufacture a solution that meets your exact needs.

The Research Laboratory Coater includes an integrated hot plate for convenient drying of processed thin films directly on the unit. The system features a standard hot plate capable of reaching temperatures up to 90 °C, ensuring efficient drying during your coating process.

Upgrade from the standard hot plate, which reaches up to 90 °C, to the high-temperature hot plate capable of reaching 140 °C. This enhanced option provides greater flexibility, optimizing your thin-film coating applications.

The knife coater unit has a knife blade in anodized aluminum with a high precision ground edge, resulting in a coating width of 30 mm. Adjust the gap size between the substrate and the knife blade of the coating unit, using the micrometer screw on the knife coater unit.

The nominal thickness obtainable with each bar/rod: 10 micron, 25 micron, 50 micron, 100 micron and 250 micron.

The simple flexographic roller system can be used for printing many types of materials when preparing single devices among others the back silver for inverted geometry device.

The Air knife is a powerful piece of equipment for drying and rapid quenching of coated thin films with compressed air or inert gas (important for i.e. perovskites)

Manual positioning of the slot-die head, bar coater, knife coater or flexo roller. Watch video here.

Software control of the coating position with 3-axis motion control (side registration, up/down, fwd/rev). Watch video here.

Engineered for precise temperature regulation and superior slot-die coating performance, this advanced controller guarantees uniform film thickness and enhances product quality, ensuring optimal results with every use.

Videos

RLC 3DPrint - Slot-Die Coating

RLC 3DPrint with Heated Vacuum Chuck

Printed Batteries

How To Print Solar Cells With The Research Laboratory Coater (RLC)

Printing Perovskite on Flexible Substrate

Flexographic Printing with the Research Laboratory Coater

Technical Specifications

Research Laboratory Coater

| Item | Technical Parameters | Remarks |

|---|---|---|

| Weight | >20 kg | Depends on final configuration. |

| Dimensions (WxDxH) | 500 mm x 550 mm x 450 mm | |

| Power Supply | 120 V AC or 240 V AC | Depends on final configuration. |

| Coating Area | 100 mm x 280 mm | |

| Coating Speed | From 1.2 mm/sec to 33 mm/sec | |

| Base Plate Temperature | Standard Temperature up to 90◦C High Temperature Option up to 140◦C Heated Vaccum Chuck up to 90◦C | |

| Thin Film Processing Options | Slot-die Coating Heated Slot-die Coating Knife Coating Bar Coating Simple Flexo Printing |

Syringe Pumps

| undefined | Technical Parameters | Remarks |

|---|---|---|

| Pump Control | 0.01 ml - 9.99 ml | |

| Ink Volume | Standard Pump: Up to 20 ml Jumbo Pump: Up to 60 ml | |

| Options for Mixing and Gradient Experiments | Combine up to 4 Pump for Advanced Mixing and Gradients Experiments | |

| Power Supply | 24 V | Power from the Research Laboratory Coater |

Slot-die Coating

| Item | Technical Parameters | Remarks |

|---|---|---|

| Slot-die Coating Width | 5 mm - 150 mm | Patterned or Full Coating |

| Slot-die Head Position | 12 o'clock | |

| Height Adjustment (Head to Substrate) | 5 mm | |

| Sideways Travel Length | 160 mm | |

| Slot-die Head Material | Stainless Steel PEEK Titanium | |

| Tubing and Connector Material | PTFE (Tubing) and PEEK (Connector) |

Heated Slot-die Coating

| undefined | Technical Parameter | Remarks |

|---|---|---|

| Slot-die Coating Width | 10 mm - 150 mm | Patterned or Full Coating |

| Slot-die Head Material | Stainless Steel Titanium | |

| Temperature Range | RT-100◦C |

Probably the World’s Most Compact R2R Slot-die Coater

The LR2RC500 Bundle is a compact, fully integrated roll-to-roll coating platform for laboratories, complete with an advanced mounting system, anodized rollers, a jumbo syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.