LabelTEC Corona Surface Treater

Elevating Adhesion with Precision Corona Treatment for Narrow Web Applications.

Transform Your R2R Process With Corona Surface Treatment

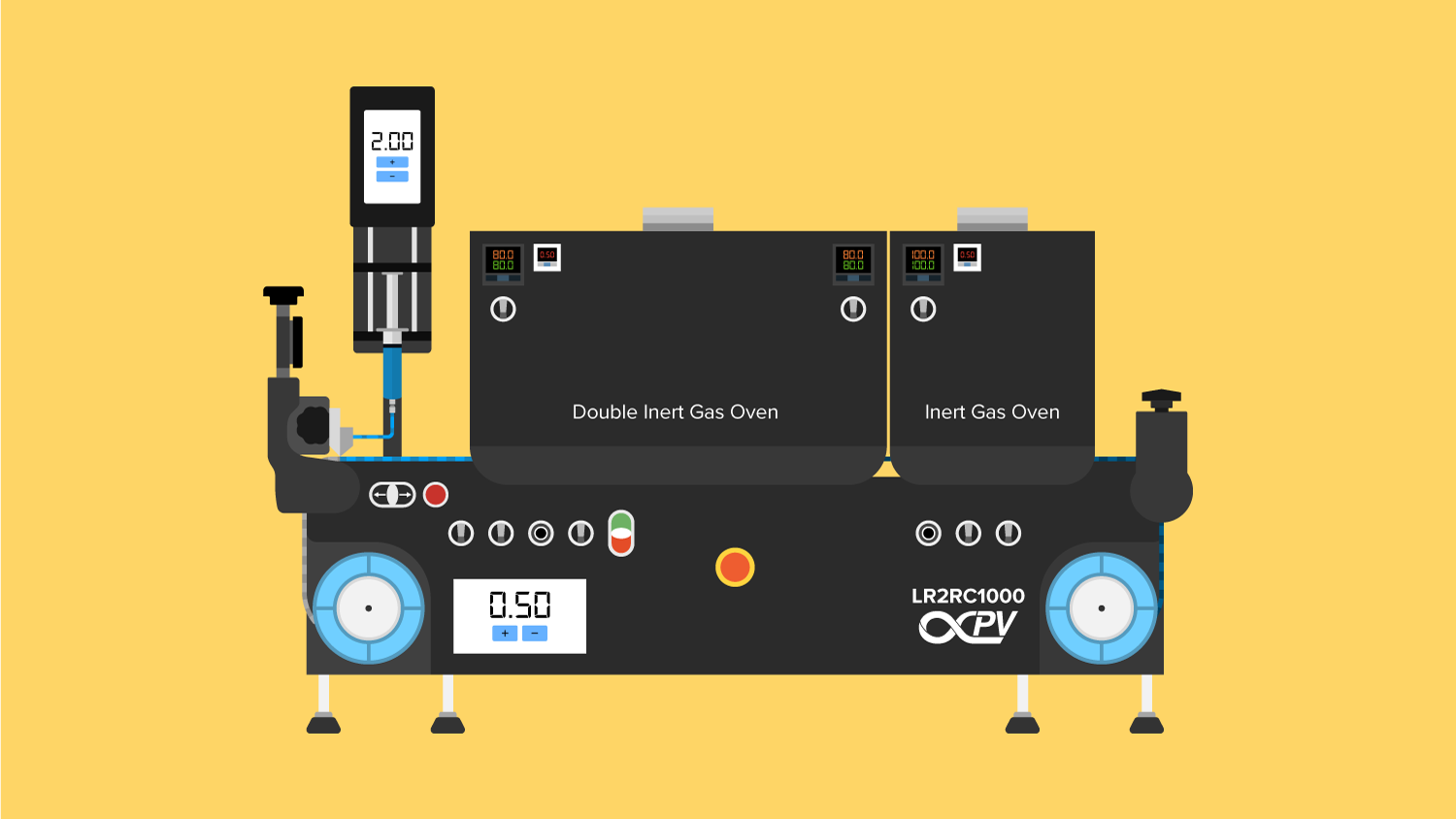

The LabelTEC Corona Surface Treater by Tantec for the Laboratory Roll-to-Roll Coater enables effective surface treatment of polymer-based materials, enhancing their wettability through electrical discharge. Polymer substrates, due to their naturally low surface energy, often suffer from poor adhesion to inks, glues, and coatings. For optimal adhesion, the surface energy of the substrate must be increased to just above that of the material being applied.

Corona surface treatment with LabelTEC effectively enhances surface adhesion properties, making it ideal for pretreating conductive and non-conductive narrow webs. This system can treat one or both sides of the web and accommodates widths from 100-500 mm, with production speeds reaching up to 150 m/min.

Technical Specifications

Mains Voltage and Frequency: 230 VAC 50/60 Hz

Output Voltage/Power: Choose from 200W / 1000W / 2000W

Output Frequency: Up to 30 kHz

Mains Cable: Supplied with connector

Control Interface: Connector supplied

Operator Display: HMI remote

Treatment Width (mm): From 100 – 500 mm

Side for Treatment: 1 or 2 sides

Speeds: Up to 150 m/min

Electrodes: Ceramic

What is Corona and Plasma Surface Treatment?

Explore the differences between corona and plasma surface treatment technologies, crucial for enhancing adhesion in industrial applications. Discover how these methods modify surface energy to combat dewetting, improve wettability, and ensure better bonding of inks, coatings, and adhesives on non-porous materials. Learn about their benefits, applications, and why surface treatment is essential for achieving optimal product quality and efficiency in manufacturing processes.

Download Brochure

Explore the capabilities of the Laboratory Roll-to-Roll Coater by downloading our detailed brochure. This document provides an in-depth overview of the coater’s customizable features, technical specifications, and broad range of applications. Discover how our advanced technology can enhance your research and production processes.

Video: What is the Laboratory Roll-to-Roll Coater?

The Laboratory Roll-to-Roll Coater is a compact, high-precision lab coater that transforms the way thin functional films are processed. It offers modular customization to fit different needs, scalable efficiency for small-scale production, and a user-friendly design with easy-to-remove components. Ideal for applications like batteries, fuel cells, and solar cells, it allows you to customize a system that’s perfect for your needs.