Laboratory Roll-to-Roll Coater

A compact and modular roll-to-roll lab coater that transforms the way functional thin films are printed and coated.

Compact Roll-to-Roll Processing

The Laboratory Roll-to-Roll Coater (LR2RC) is a compact, high-precision R2R lab scale coater that transforms the way thin functional films are processed. This versatile system caters to various needs, from laboratory to small pilot-scale production, processing hundreds of meters of foil efficiently.

Modular Customization

The Laboratory Roll-to-Roll Coater's modular design allows users to customize the system according to their specific requirements. Options include selecting the length and width of the unit and choosing from a wide array of components, such as printing and coating units, drying and curing systems, foil pretreatment modules, and advanced laminators. This flexibility ensures the Laboratory Roll-to-Roll Coater can fit within existing lab spaces, gloveboxes, or fume hoods without additional infrastructure.

Scalable Efficiency With Numerous Applications

Providing a complete, turnkey system, the Laboratory Roll-to-Roll Coater bridges the gap between laboratory research and small-scale pilot production. It handles hundreds of meters of foil, making it an economical choice for scaling up production. Advanced slot-die heads, web tension control, and software options guarantee consistent, high-quality results across applications like batteries, fuel cells, printed solar cells, transistors, LEDs, and sensors.

User-Friendly Design

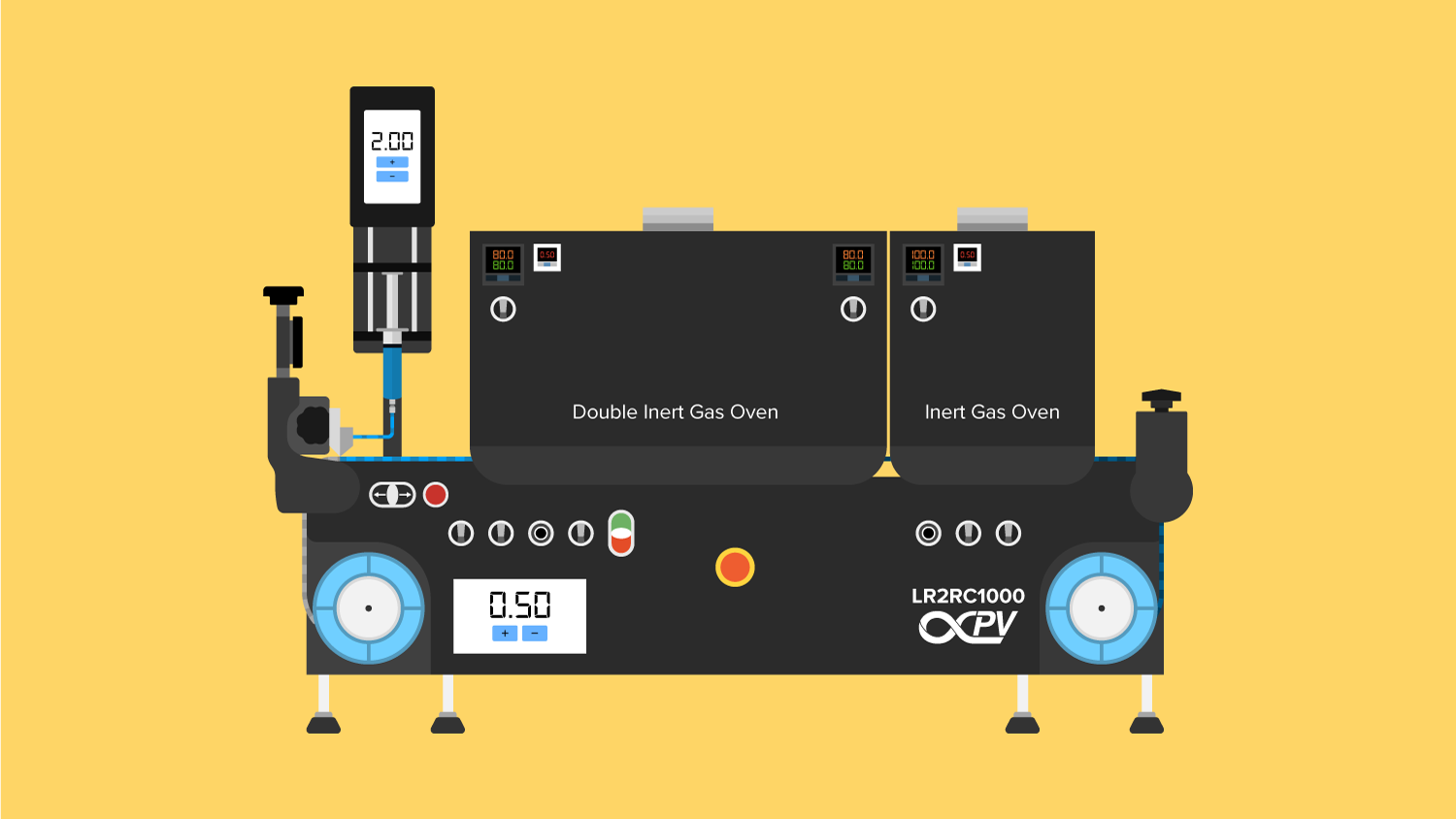

Designed for convenience, the Laboratory Roll-to-Roll Coater features easy-to-remove and reattach components, such as hot air, inert gas, IR and UV ovens, enhancing operational efficiency. The system's CE certification and CSA/UL compliance underscore its reliability and adherence to international safety standards.

Build Your Own System Today

Start building your custom thin-film production system today with the Laboratory Roll-to-Roll Coater Customizer. Choose the right platform size and enhance it with a range of components like printing units, drying systems, and laminators.

Key Features

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Choose from a variety of lengths and widths, with numerous components available.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

Modular Drying/Curing System: Accommodates various drying and curing methods.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

Technical Specifications

Operating Power: Single phase (240VAC) for smaller models; three-phase (400VAC) for larger models.

Coating Width: Up to 180 mm (standard models), up to 280 mm (wide models).

Drying/Curing Length: From 250 mm (LR2RC500) to 1250 mm (LR2RC1500).

Web Width: Up to 200 mm (standard models), up to 310 mm (wide models).

Web Speed: 0.05-2.8 m/min (forward and reverse).

Spindles: Automatic compressed air spindles for 3-inch core diameters, adjustable cones for smaller cores in LR2RC500.

Numerous Applications

The Laboratory Roll-to-Roll Coater’s advanced slot-die heads, web tension control, and software options guarantee consistent, high-quality results across applications like batteries, fuel cells, printed solar cells, transistors, LEDs, sensors, and more.

A Size for Everyone

The Laboratory Roll-to-Roll Coater offers you multiple platform sizes to meet your diverse needs. You can choose from platform lengths of 500 mm, 750 mm, 1000 mm, and 1500 mm, and widths of 350 mm and 460 mm. This variety allows you to select the size that best fits your specific requirements, whether you have a compact lab space or need a larger configuration for extensive operations.

Choose Your Own Components

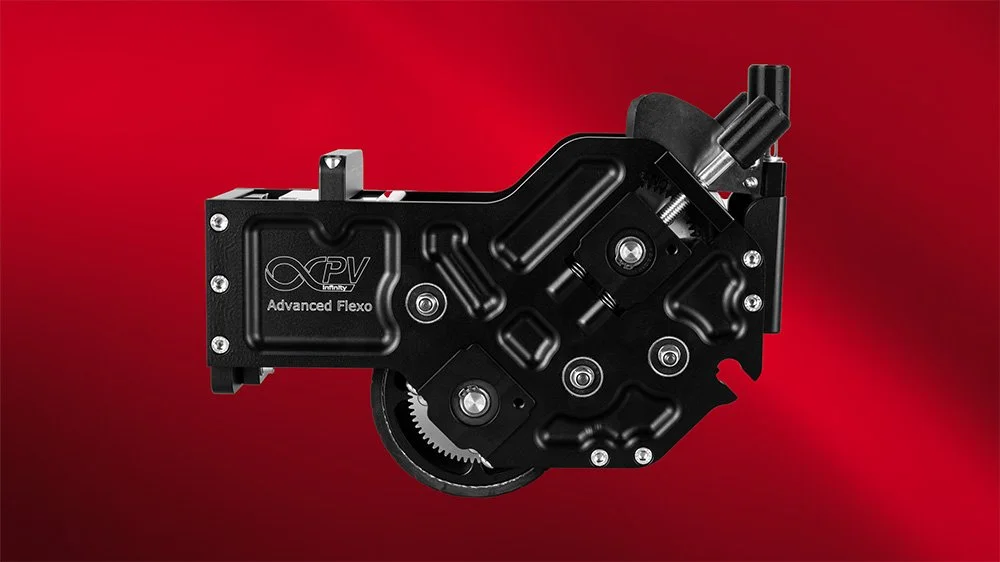

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, knife cutters, laminators, laser systems and more.

Fits in Your Laboratory

Designed with you in mind, the Laboratory Roll-to-Roll Coater fits seamlessly into your existing laboratory environment requiring no additional infrastructure. Its compact size allows you to integrate it into laboratories, gloveboxes, or fume hoods without needing additional infrastructure.

Video: How Does the Laboratory Roll-to-Roll Coater Work?

Ready to Build Your Own Laboratory Roll-to-Roll Coater?

Platforms

The Laboratory Roll-to-Roll Coater platform is available in four lengths, ranging from 500 mm to 1500 mm, and two widths of 350 mm (coating width up to 180 mm) and 460 mm (coating width up to 280 mm). With a processing width of up to 180 mm, the standard platform presents an ideal solution for laboratories venturing into the realm of R2R processing. The wide platform revolutionizes processing with its capability to handle 12-inch / 305 mm wide substrates, making it the most compact Roll-to-Roll (R2R) platform globally for industrial-scale coating and printing. If you are uncertain about whether a standard or wide platform will best suit your needs, feel free to contact us.

LR2RC500

Standard: 500 x 350 x 300 mm (WxDxH)

The perfect platform for compact spaces and quick processing needs, the LR2RC500 offers a cost-effective solution without compromising on versatility. View price here.

LR2RC750

Standard: 750 x 350 x 300 mm | Wide: 750 x 460 x 300 mm (WxDxH)

Finding the ideal balance between size and functionality, the LR2RC750 seamlessly accommodates additional features while remaining a perfect fit for fume hoods or gloveboxes. View price here.

LR2RC1000

Standard: 1000 x 350 x 300 mm | Wide: 1000 x 460 x 300 mm (WxDxH)

For robust drying of thin films, look no further than the LR2RC1000. With three sections designed to host various oven systems, it streamlines coating and printing tasks efficiently. View price here.

LR2RC1500

Standard: 1500 x 350 x 300 mm | Wide: 1500 x 460 x 300 mm (WxDxH)

When ample laboratory space is available and integration of custom instruments is a priority, the LR2RC1500 delivers the necessary length for an expansive R2R line. View price here.

Components

After selecting your platform, it's time to choose from our array of components, ranging from slot-die heads to advanced laminators. Each component is engineered to enhance efficiency, consistency, and quality in your R2R system. Explore our offerings to tailor your coater platform precisely to your needs and unleash its full potential in revolutionizing thin-film production. Customize Your Machine and Get a Quotation here.

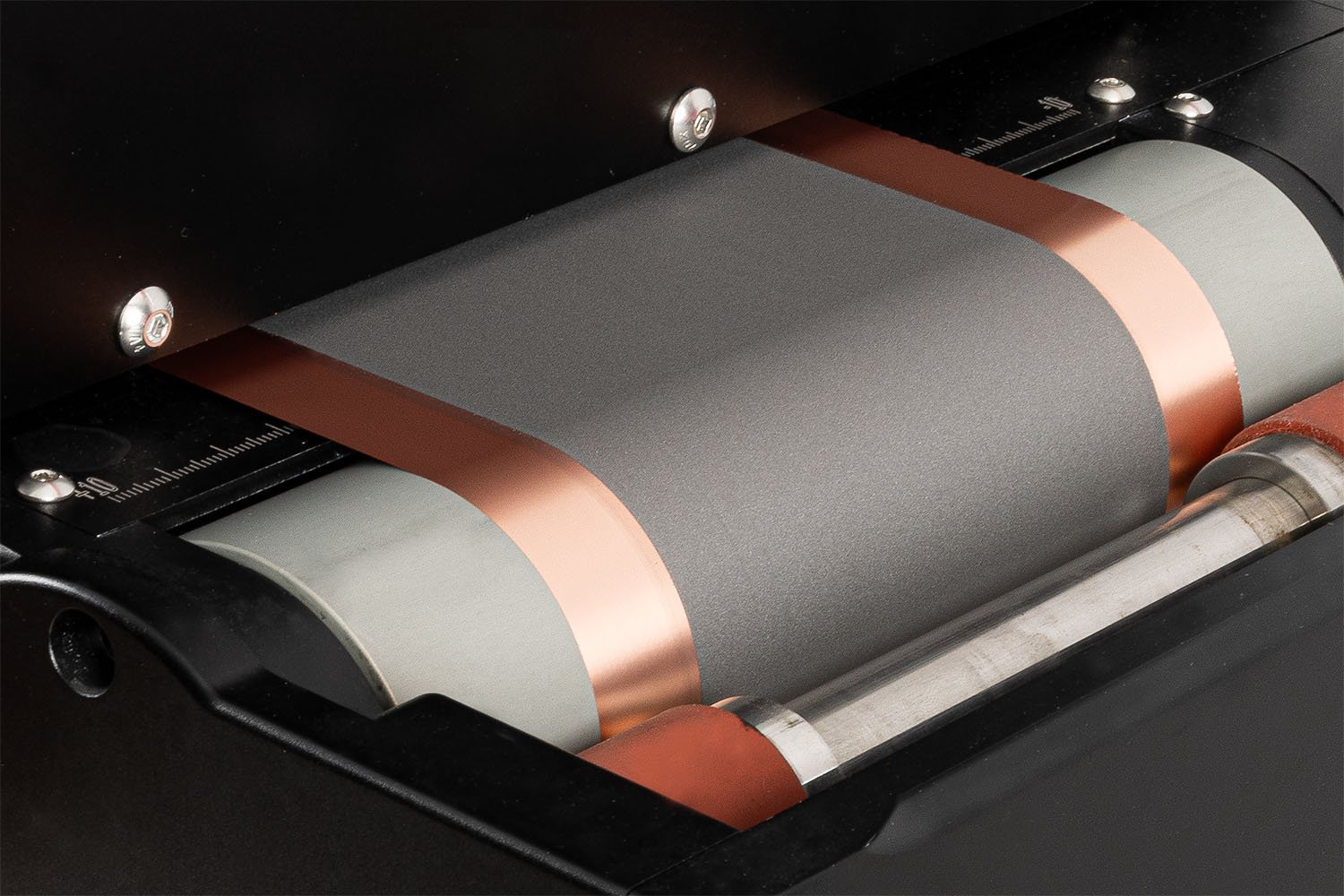

Slurry Coater

A vital tool for lab-scale production of advanced thin films, supporting critical applications like batteries, fuel cells, and printed solar cells. Watch video.

Air Knives

Air knives for all needs. The Standard Air Knife for efficient drying and quenching, and Air Knife Pro for controlled, repeatable results.

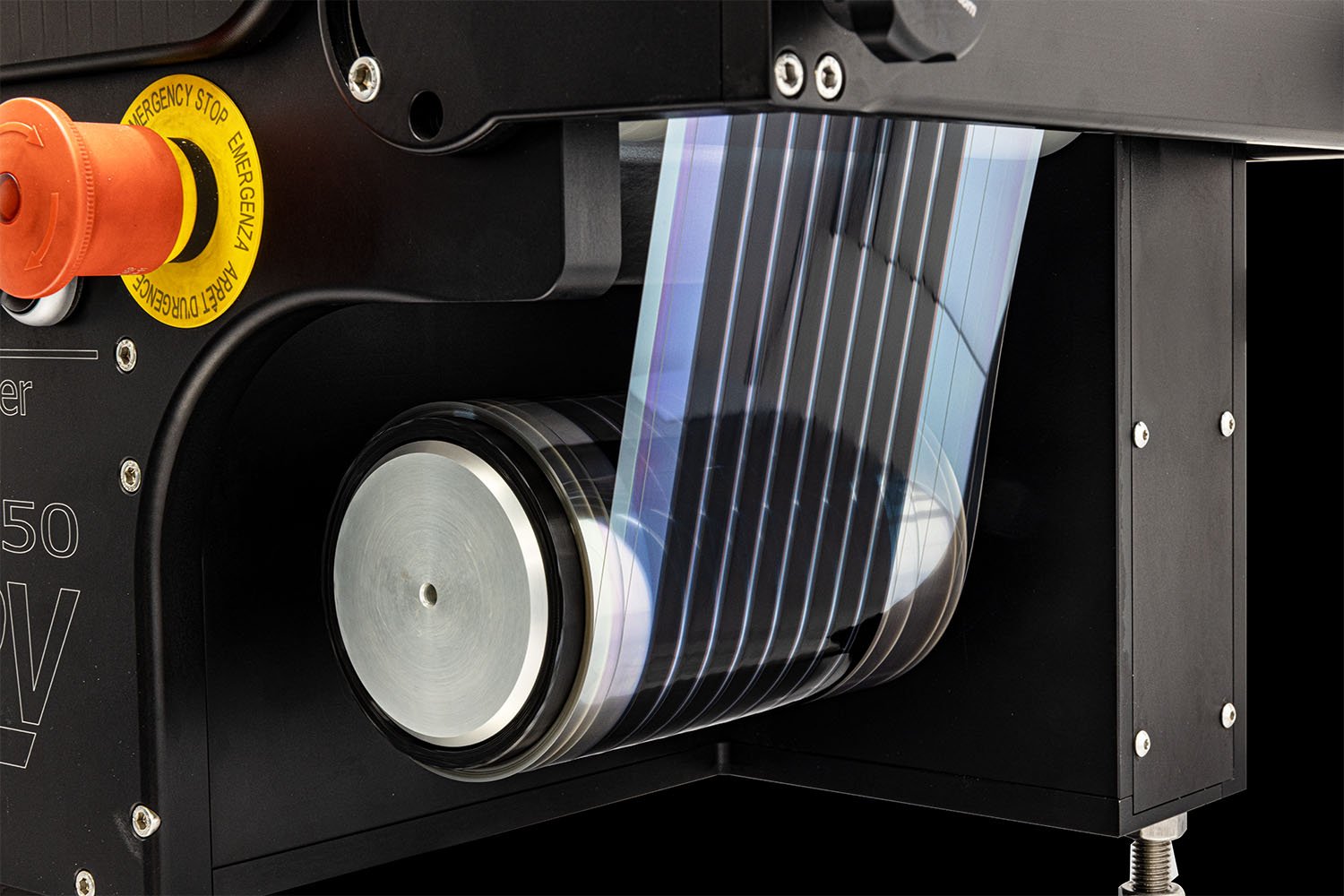

Roll-to-Roll Laminator

A laminator designed for thin-film encapsulation with various adhesives, featuring precise tension control and customizable web width. Watch video.

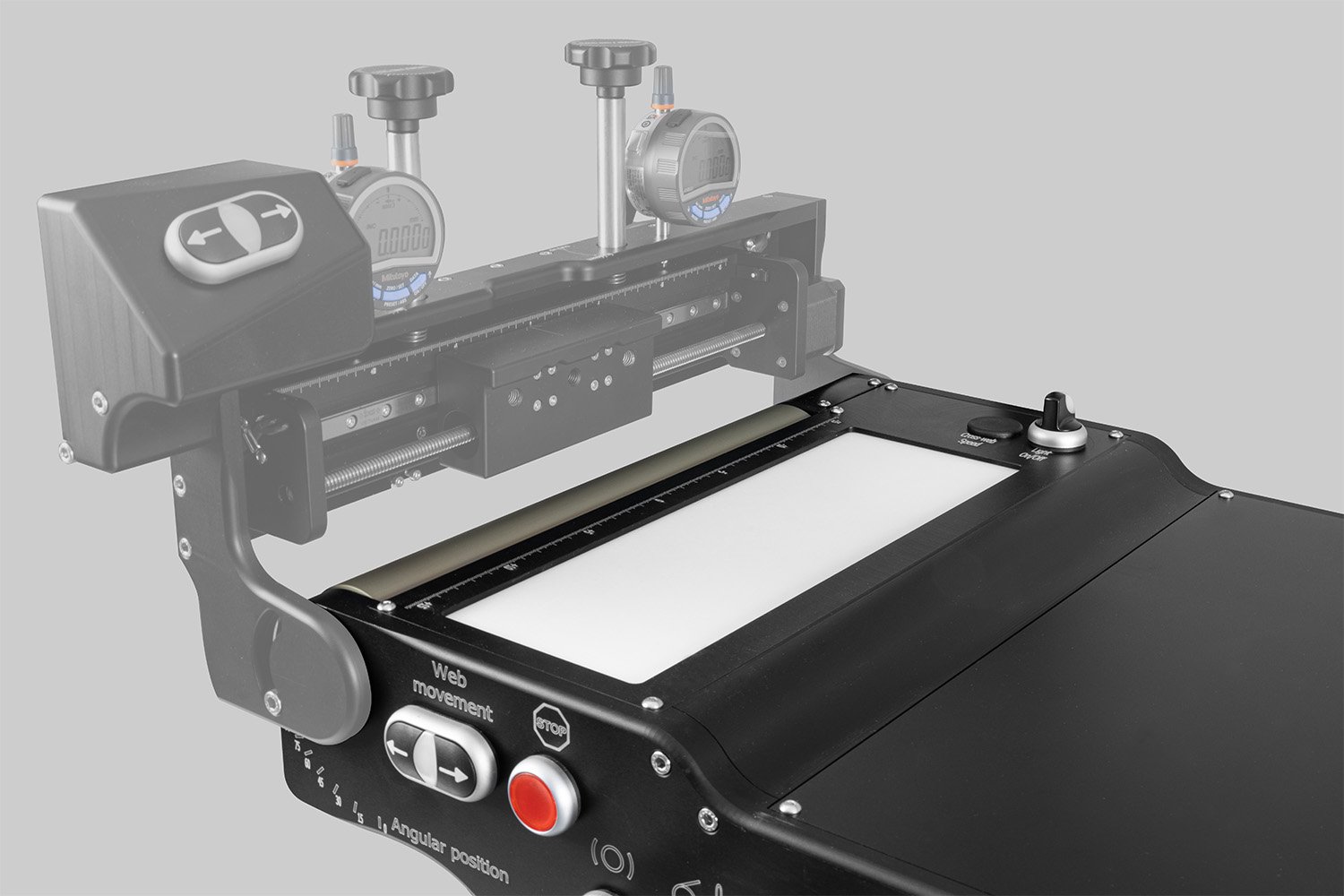

Mounting Systems

The precision angular mounting system is ideal for slot-die heads, knife coating setups, or flexographic printing units, with angle adjustment from 0 to 90 degrees. The Simple Mounting System offers manual tilt and cross-web adjustments, the Advanced Mounting System include digital micrometers and motorized adjustments, and the PC Controlled Mounting System offers PC control which is perfect when working in a glovebox or a fume hood.

Stripper Unit

The Stripper Unit allows for removal of a protective liner or other foil just before the coating or printing station. It comes with compressed air spindles, tension control and automation of nip engagement. Watch video.

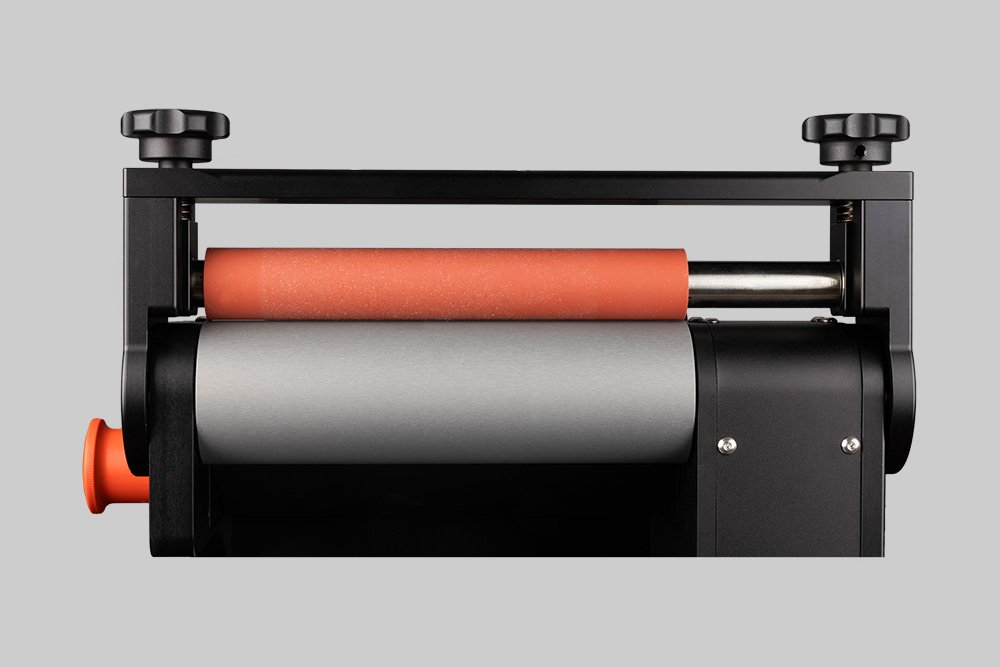

Rollers

The Laboratory Roll-to-Roll Coater features 60 mm anodized aluminum rollers, durable and cost-efficient for 95% of applications. With low runout, they ensure experimental success. For specific needs, we offer POM or PEEK rollers for insulation or chemical resistance and stainless steel for extreme corrosion resistance.

Inspection Table

Inspection Table that enables inspection on transparent substrates directly after coating or printing. Ideal for visual checks or camera systems, it fits LR2RC750, LR2RC1000, and LR2RC1500 platforms and can be added during purchase or retrofitted later. Watch video.

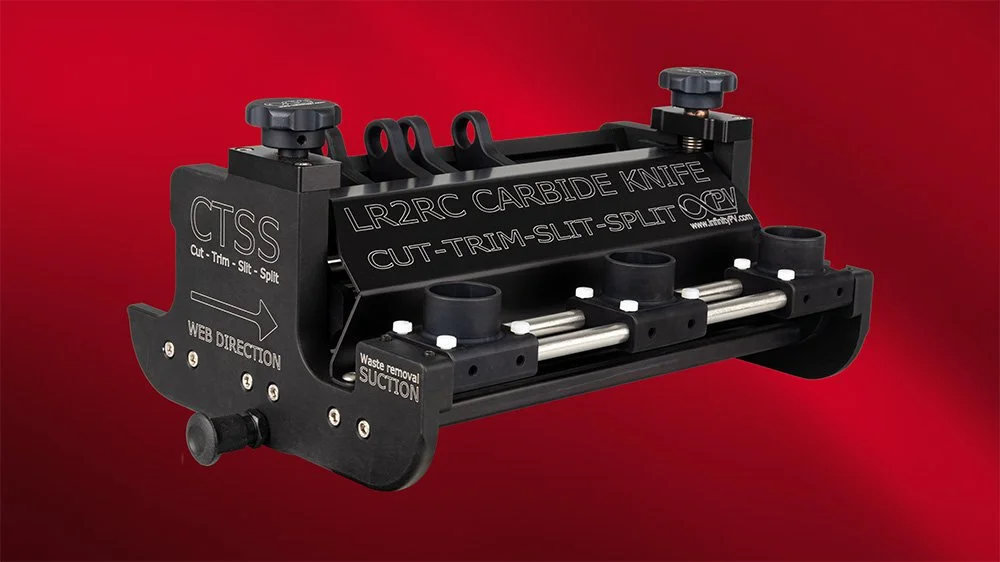

Knife Cutter

Knife Cutter for precise foil handling offers ultra-durable carbide cutters and adjustable cutting positions. Precision-ground stainless steel rollers ensure gentle handling and chemical resistance, making it safe and efficient. Watch video.

Foil Turner

Foil turner that enables seamless inline processing on both sides of the foil, ideal for double-sided slot-die coating in batteries, fuel cells, membranes, and more. Watch video.

Nip Rollers

The Nip Rollers offer flexibility with multiple configurations. The Manual Nip Roller features a full rubber roller with manual control of nip pressure and tilt, while the Adjustable Nip Roller include adjustable rollers, automated nip engagement, pressure, and pressure points. It's perfect for simple manual packaging with minimal effort.

Spindles

Spindle options include the LR2RC500 with adjustable cones for core width, diameter, and position (35 mm to 90 mm inner diameters), and the LR2RC750, LR2RC1000, and LR2RC1500 platforms with automatic compressed air spindles for 3-inch core diameters, ensuring efficient handling for larger setups.

Additional Options

The Laboratory Roll-to-Roll Coater is a flexible, customizable platform supporting stop-and-go and Forward-Reverse-Action cycles, with robotics integration for automation. It offers custom cabinets and glovebox systems for inert atmosphere work and is user-friendly for easy customization, making it a true "maker" platform.

Popular Setups

Customized for lab-scale research and development, this system facilitates the efficient application of battery electrode coatings.

The LR2RC750 Coater is a complete system that facilitates the coating of all layers within the solar cell device stack, as well as the encapsulation of solar cells using various lamination options.

With a substrate processing width of up to 305 mm, you are well-prepared to advance the R&D processing of fuel cells , enabling efficient pilot-scale production of fuel cell technology.

A pilot-scale production line that allows for high throughput production of OLEDs. With the 305 mm web width, corona system, edge guide, and advanced drying system, this setup is truly a slot-die coating workhorse.

Videos

Introducing the Slurry Coater

Making Scaling Perovskite Solar Cells

Battery Cell Fabrication

Laboratory Roll-to-Roll Coater

Advanced Laminator

Flexographic Printing

Knife Cutter

Stripper Unit

Foil Turner

Customer Success Stories

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Technical Specifications

| Item | Technical Parameter | Remarks |

|---|---|---|

| Dimensions (WxDxH) and Weight | LR2RC500: 500 x 350 x 300 mm | 30 kg LR2RC750: 750 x 350 x 300 mm | 40 kg LR2RC750 Wide: 750 x 460 x 300 mm | 50 kg LR2RC1000: 1000 x 350 x 300 mm | 50 kg LR2RC1000 Wide: 1000 x 460 x 300 mm | 60 kg LR2RC1500: 1500 x 350 x 300 mm | 80 kg LR2RC1500 Wide: 1500 x 460 x 300 mm | 100 kg | Total weight and dimensions depend on final configuration. |

| Operates From | LR2RC500: Single Phase (240VAC) LR2RC750: Single Phase (240VAC) LR2RC750 Wide: Single Phase (240VAC) LR2RC1000: 3 -phases (400 VAC) LR2RC1000 Wide: 3 -phases (400 VAC) LR2RC1500: 3 -phases (400 VAC) LR2RC1500 Wide: 3 -phases (400 VAC) | |

| Drying and Curing Section Length | LR2RC500: 250 mm LR2RC750: 500 mm LR2RC750 Wide: 500 mm LR2RC1000: 750 mm LR2RC1000 Wide: 750 mm LR2RC1500: 1250 mm LR2RC1500 Wide: 1250 mm | The drying and curing length depends on the selected oven systems. |

| System Control | Touch Screen Manual Adjustment Buttons PC Control | |

| Web Width | Up to 200 mm Up to 310 mm (Wide) | |

| Foil Length | Up to 100 m | Depending on subtrate thickness. |

| Web Speed | 0.05-2-8 m/min (Forward and Reverse) | Other web speeds are available upon request |

| Tension Control | Manually | Individual or collective control over rewinder and unwinder depending on configuration |

| Coating Width | Up to 180 mm (Standard) Up to 280 mm (Wide) | |

| Spindles | Automatic Compressed Air Spindles 3-inch Core Inner Diameters | The LR2R500 comes with adjustable cones that accept core inner diameters from 35 mm up to 90 mm |

Frequently Asked Questions

-

The Laboratory Roll-to-Roll Coater is a compact, high-precision machine designed to coat and print functional thin films in a roll-to-roll configuration. It is suitable for research and small pilot-scale production environments, offering flexibility and scalability in processing.

-

The Laboratory Roll-to-Roll Coater’s is versatile ands modular design allows for customization to meet specific research or production needs. It can be used for manufacture of various applications including:

Batteries

Fuel Cells

Printed Solar Cells

Transistors

LEDs

Sensors

-

Compact Size: Fits into laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Options for platform length, width, and a wide range of components like printing units, drying systems, and laminators.

Modular Design: Allows easy integration of components such as slot-die heads, syringe pumps, advanced laminators, and more.

User-friendly: Features easy-to-remove and reattach heat and UV stations, CE certification, and compliance with international safety standards.

-

Yes, the coater's compact size and modular design allow it to fit within existing lab spaces, gloveboxes, or fume hoods without requiring additional infrastructure.

-

The Laboratory Roll-to-Roll Coater allows for control of the tension of both unwinder and rewinder and high precision motors combined with the integrated screen software grant easy and accurate handling of the speed of the substrate. This ensures consistent coating thickness and quality across runs, critical for reliable research and production.

-

The Laboratory Roll-to-Roll Coater platform has been thoroughly tested under Argon atmosphere and is compatible with Argon gloveboxes.

-

Yes, the Laboratory Roll-to-Roll Coater can be used for slot-die coating. It can feature advanced slot-die heads that are specifically designed for high-precision, consistent, and uniform coating of thin films. The system is highly customizable, allowing you to integrate slot-die heads along with other components like web tension control and various drying/curing units, making it ideal for applications such as batteries, printed solar cells, OLEDs, sensors, and other thin-film technologies.

-

Technical specifications vary based on the model but generally include:

Operating Power: Single-phase or three-phase depending on the model (240 VAC or 400 VAC).

Drying/Curing Length: Ranges from 250 mm to 1250 mm.

Web Width: Up to 190 mm for standard models and up to 305 mm for wide models.

Web Speed: Adjustable from 0.05 to 2.8 m/min (forward and reverse). Lower gearing is available upon request.

Spindles: Automatic compressed air spindles or adjustable cones depending on the model.

-

Yes, the Laboratory Roll-to-Roll Coater offers extensive customization options through its modular design. Users can select platform size, components like slot-die heads and drying systems, and add-ons such as laminators or web guiding systems. This flexibility allows tailoring the coater to specific research or production requirements.

-

We provide comprehensive technical support and assistance for the Laboratory Roll-to-Roll Coater. Our team assists with installation, training, and ongoing support to ensure optimal performance and user satisfaction.

-

For detailed information about the Laboratory Roll-to-Roll Coater, its components like slot-die heads, syringe pumps, ovens, and more, visit our website or contact our support team. We also offer resources such as videos and customer success stories to showcase the capabilities of the Laboratory Roll-to-Roll Coater in various applications.

-

To get a quotation or start building your custom thin-film production system with the Laboratory Roll-to-Roll Coater, use the Laboratory Roll-to-Roll Coater Customizer. Choose your platform size and select from a range of components to build the ideal setup for your needs.

For more information, feel free to contact our team at info@infinityPV.com. We're here to support your journey in printed electronics and thin-film production.

Related Products

Slot-die Heads

Discover our versatile range of slot-die heads tailored to meet diverse application needs.

Ovens

The Laboratory Roll-to-Roll Coater accommodates various oven systems designed for the efficient drying and UV-curing of processed thin films.