The infinityPV Roll-to-Roll Academy empowers researchers to innovate with slot-die coating and roll-to-roll processing, speeding development and smoothing the path to commercialization across electronics, energy, and pharma.

Batteries

Whether you’re new to the field or an experienced professional, this page provides a comprehensive overview of battery technology. From the fundamental principles of energy storage to the latest innovations in materials and manufacturing processes, we cover the advancements shaping the future of batteries. Explore emerging technologies, such as solid-state batteries, and learn how these innovations are driving improvements in energy efficiency, sustainability, and applications in various industries, including electric vehicles and renewable energy storage. Stay informed on the trends transforming the battery industry and its role in the transition to a sustainable energy future.

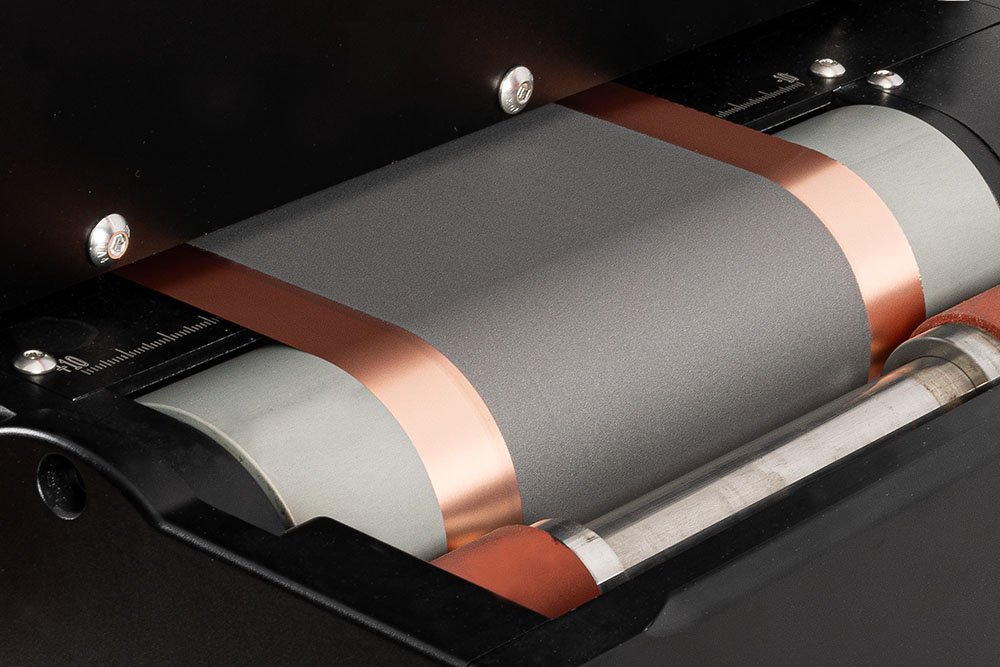

Slurry Coater for Uniform Lab-Scale Wet Film Coating

The Slurry Coater is a precision tool designed for wet film deposition in laboratory-scale R&D, ideal for coating functional materials like battery slurries, perovskite inks, conductive pastes, and sensor formulations. Seamlessly integrating with the Laboratory Roll-to-Roll Coater, it ensures uniform, repeatable coatings with micro-precision control over the wet film thickness.

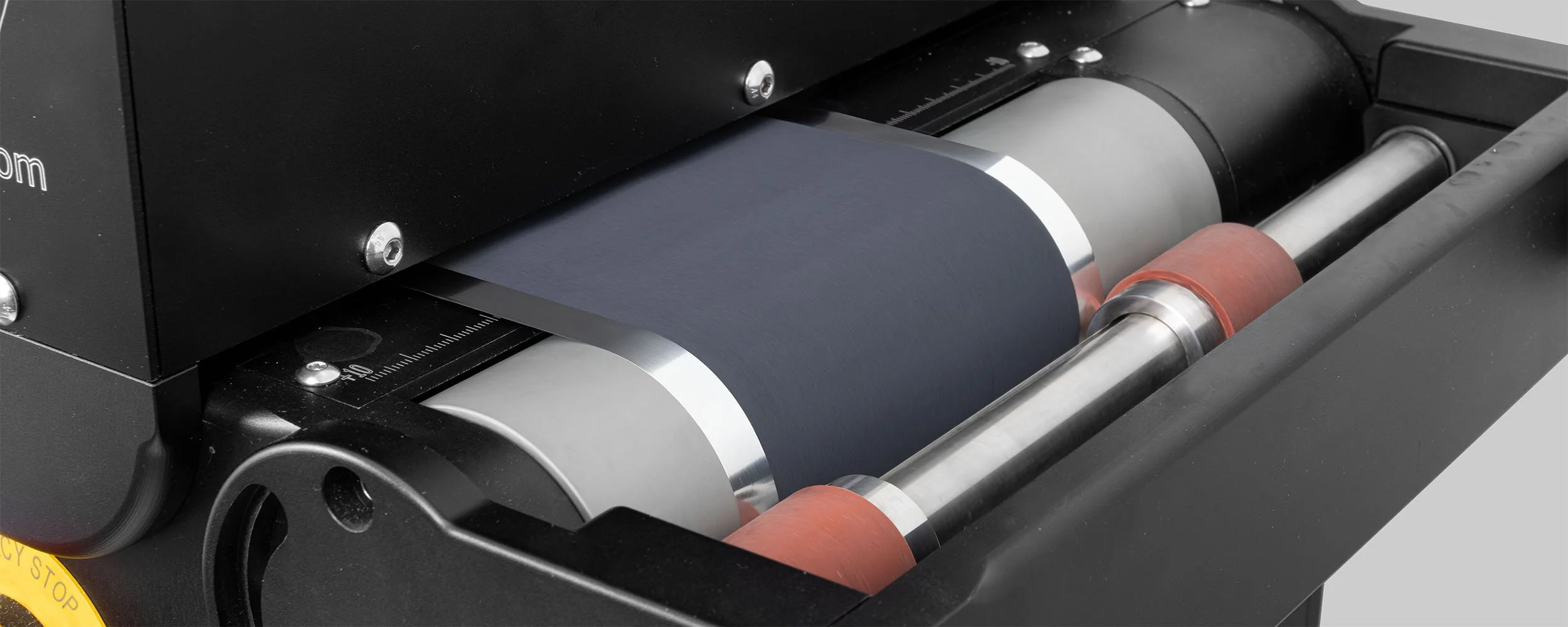

Probably the World’s Most Compact R2R Slot-die Coater

The LR2RC500 Bundle is a compact, fully integrated roll-to-roll coating platform for laboratories, complete with an advanced mounting system, anodized rollers, a jumbo syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Build Your Own R2R Slot-die Coater

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, knife cutters, laminators, laser systems and more.