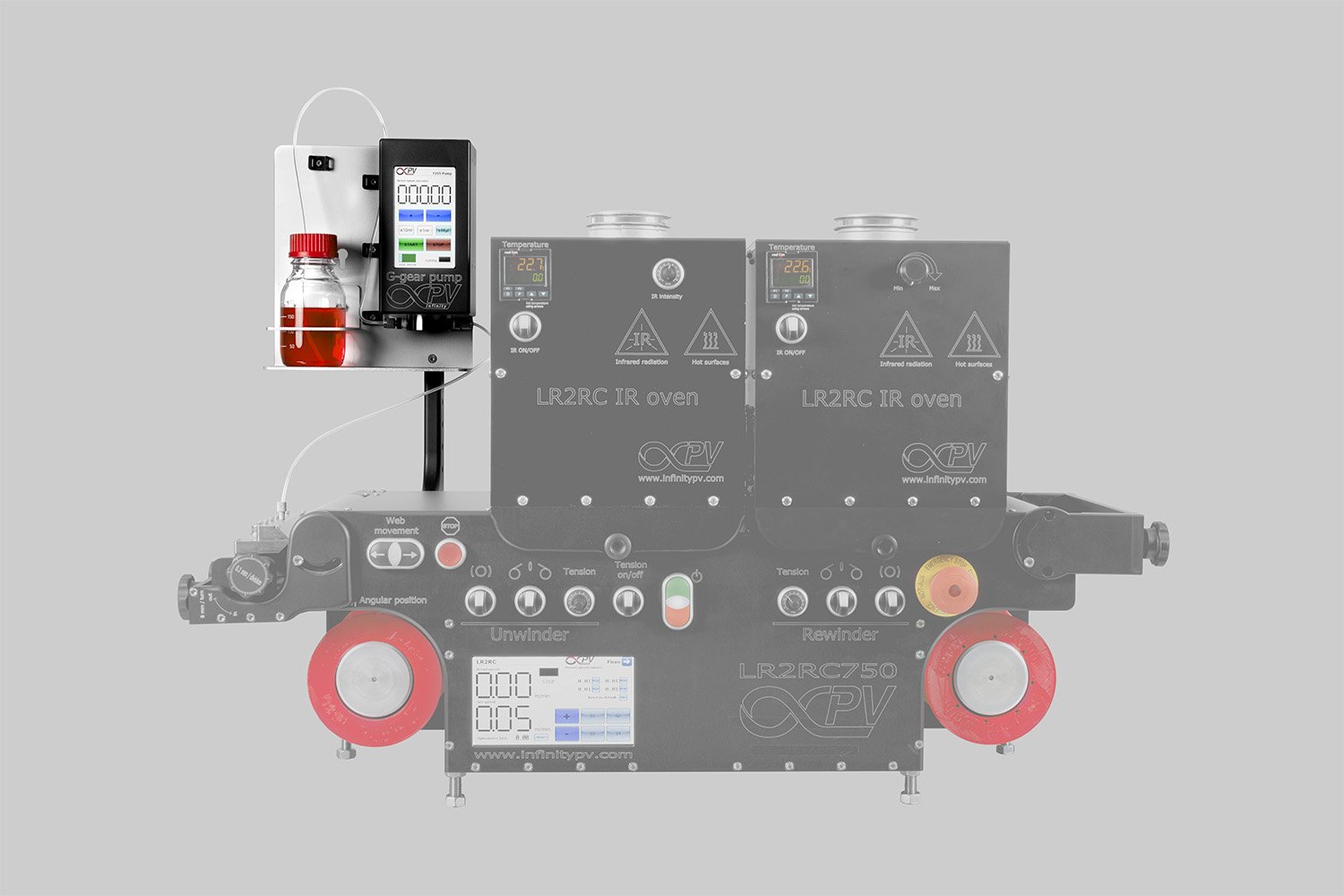

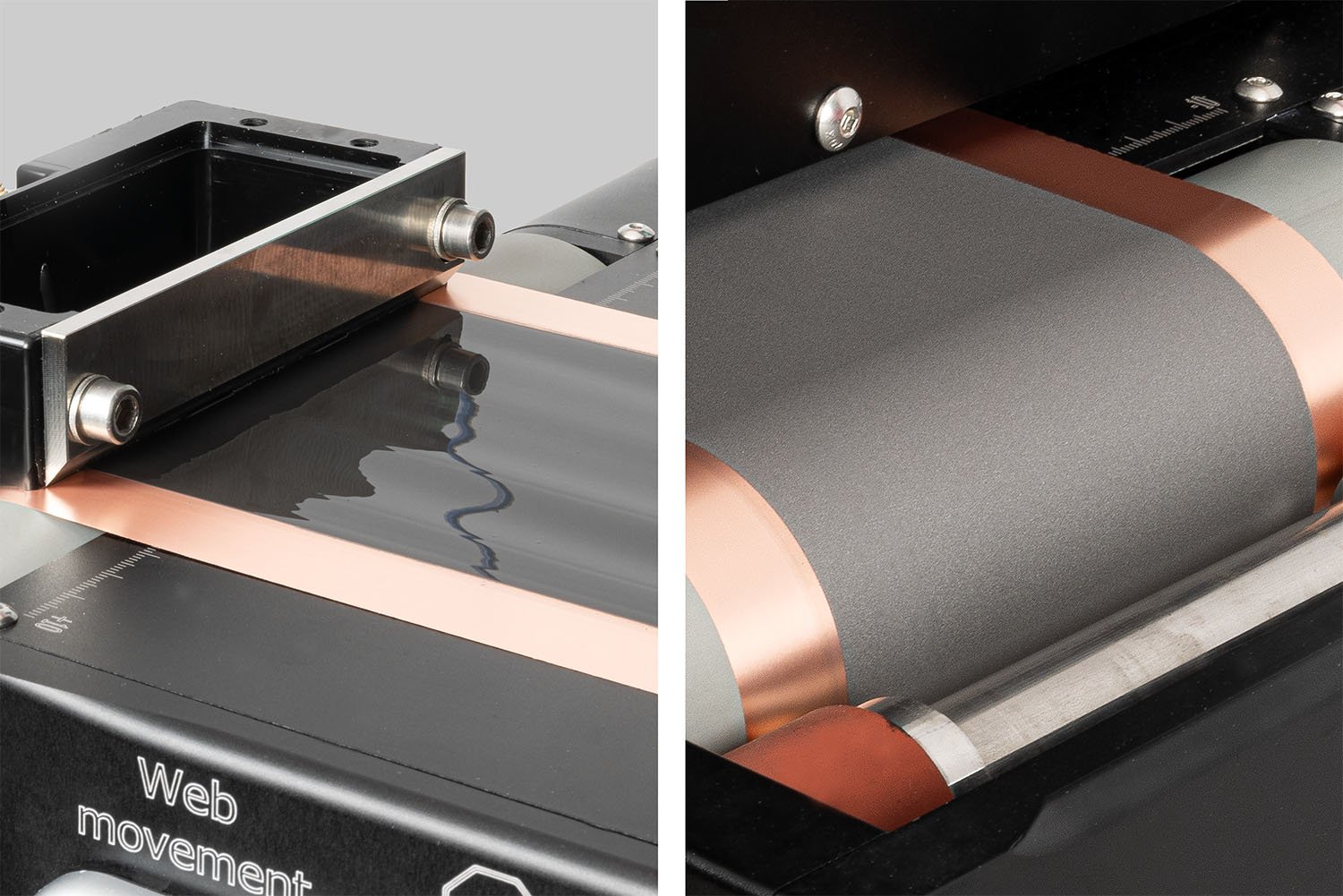

The Gear Pump is a positive displacement pump that uses gears to pump fluids by transferring mechanical energy from the motor to the fluid. The Gear pump is ideal for applications that require a steady fluid supply over extended periods. The pump can function across a wide range of flow rates, making it suitable for various industrial processes that demand both low and high flow rates. Additionally, its design allows for the pumping of non-Newtonian fluids without imposing strict limitations on the type of liquid being used.

An integrated 5-inch color touch screen makes setting the ink flow intuitive, allowing for real-time adjustments even while the pump is operating.

Applications

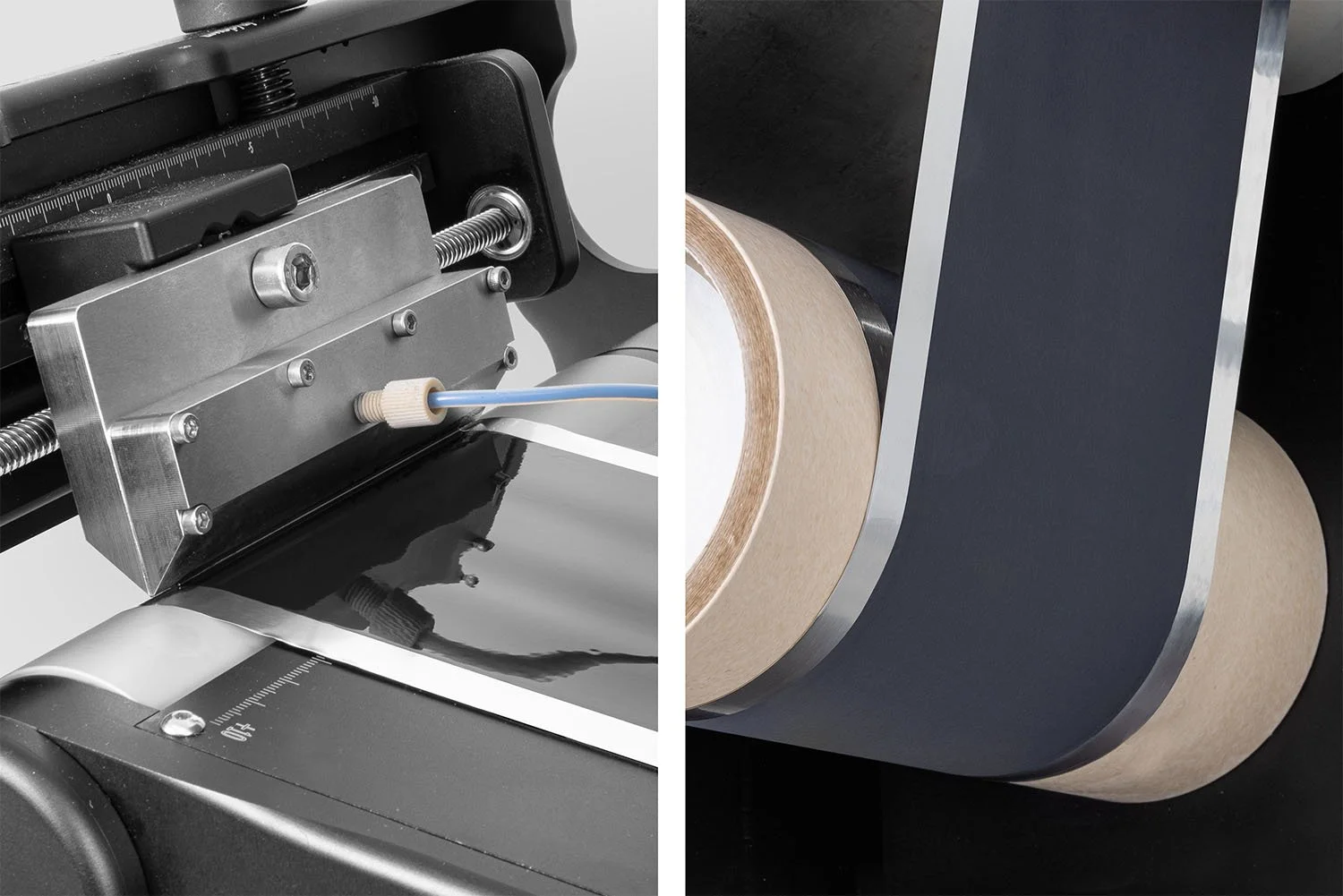

Ink dosage

Chemical processing

Medical and pharmaceutical industry

Dispensing of adhesives

Food and beverage industry

Specifications

Pump Type: Interal Gear Pump

Flow Rate: 0.05 - 288 ml/min

Max System Pressure: 8 bar (1160 psi)

Viscosity Range: 0.3 – 1000 mPas

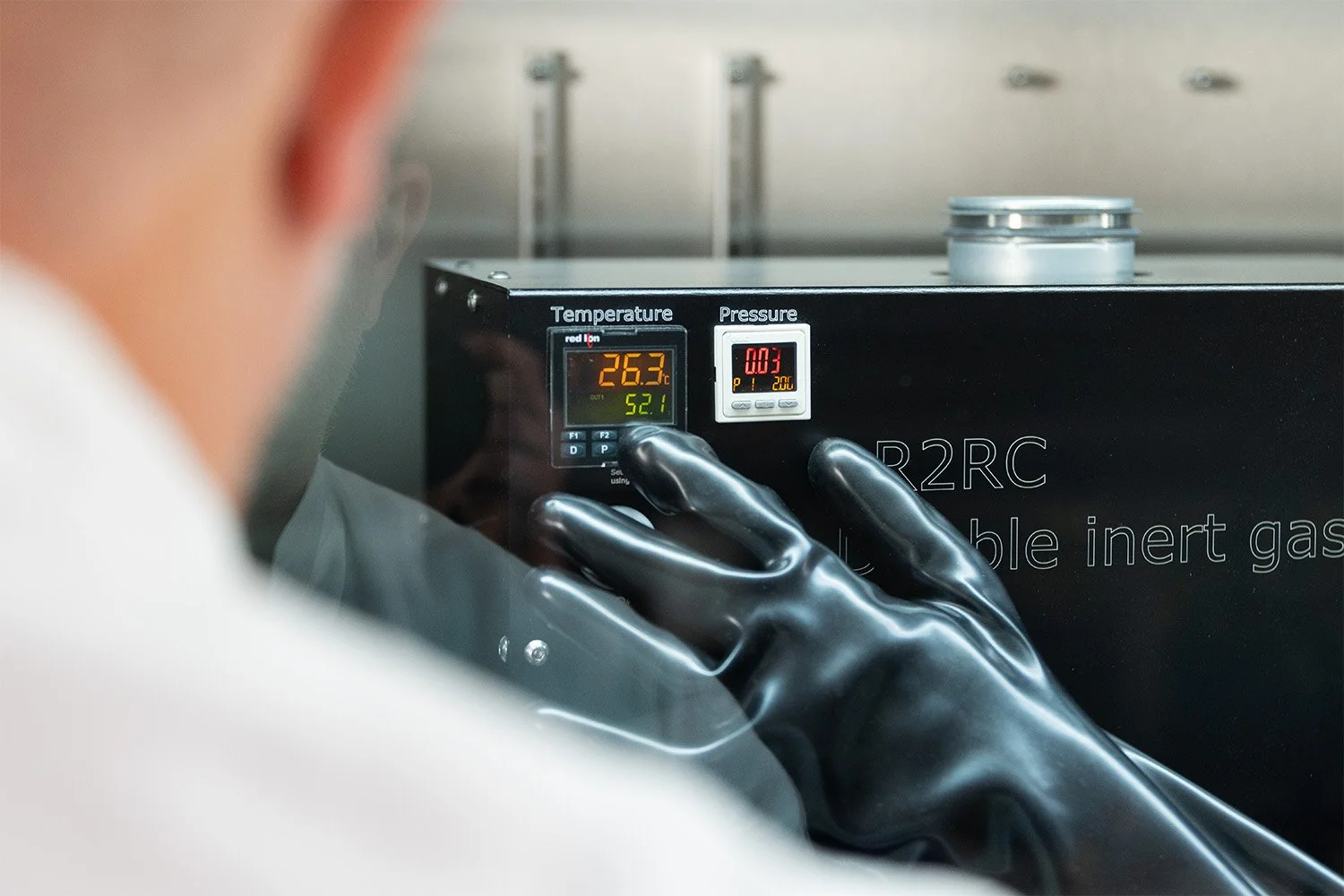

Liquid Temperature Range: -5°C to 60°C

Particles: <10 um

Features

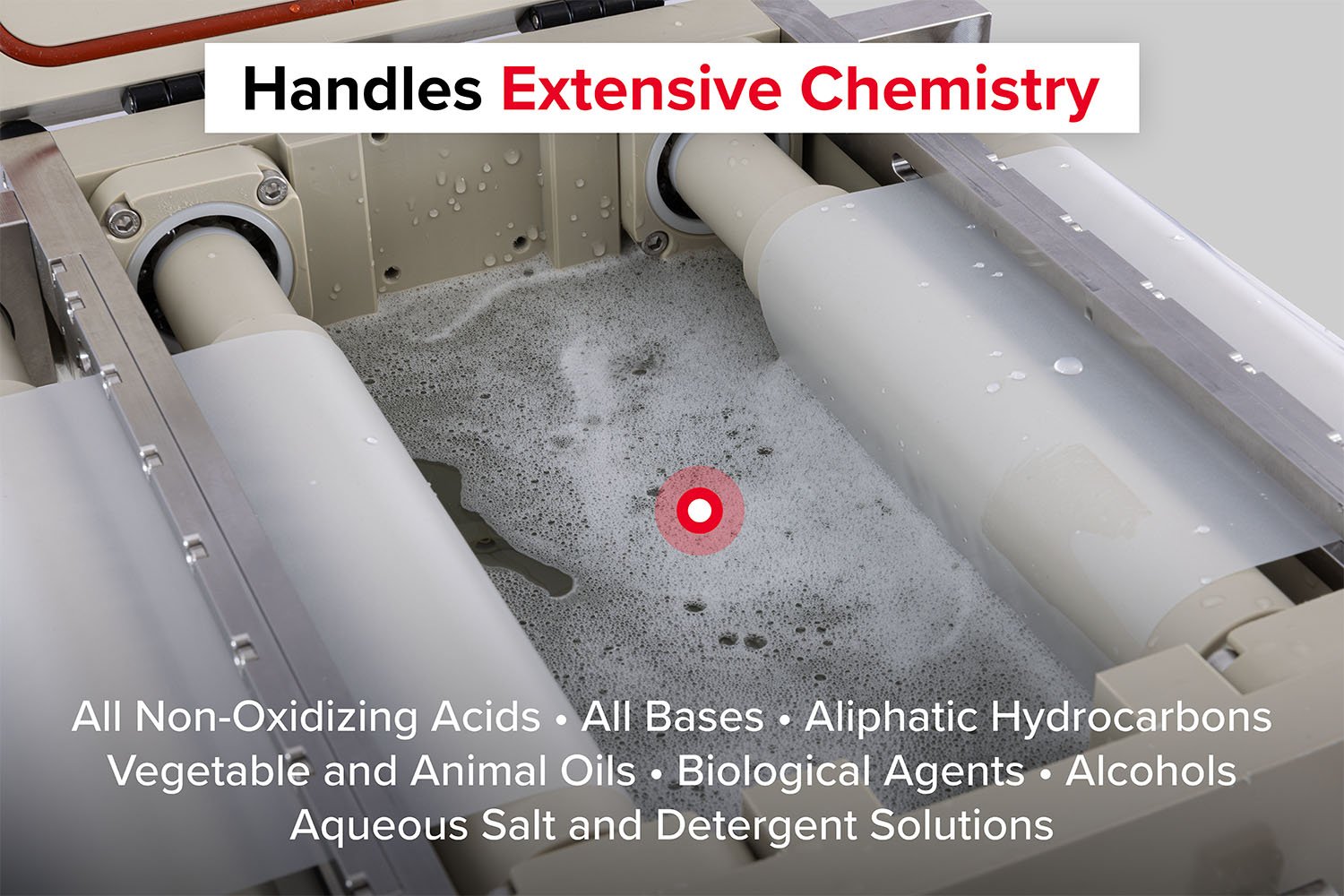

High resistance to corrosion oxidizing and reducing media, acids and bases

High dosage precision CV < 1 % at low volumes

Broad viscosity range

Low pulsation delivery, low shear stress rotary micro annular gear technology

High differential pressures achievable even for low viscosity liquids

Easy Maintenance

Adjustable flow rate by changing RPM

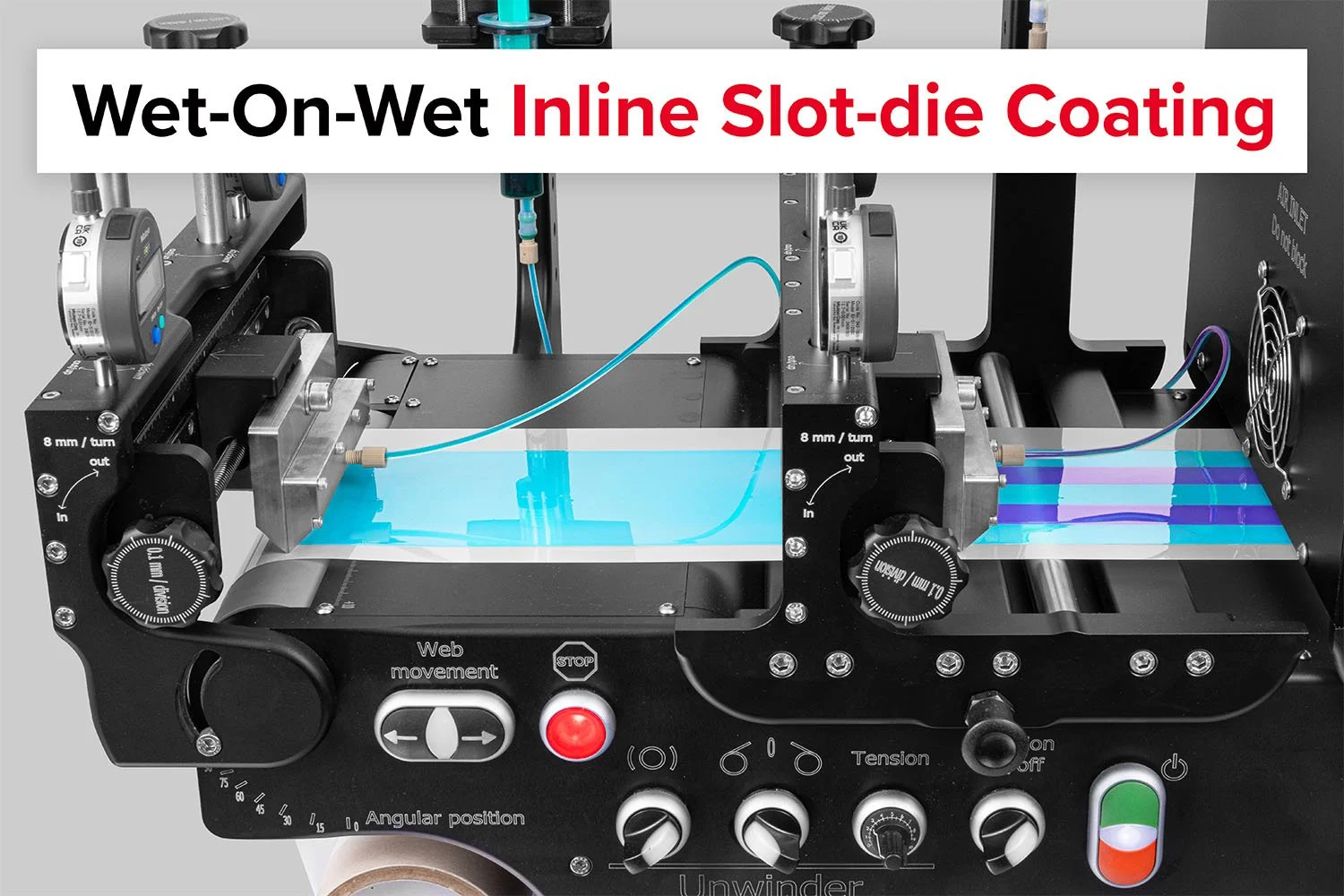

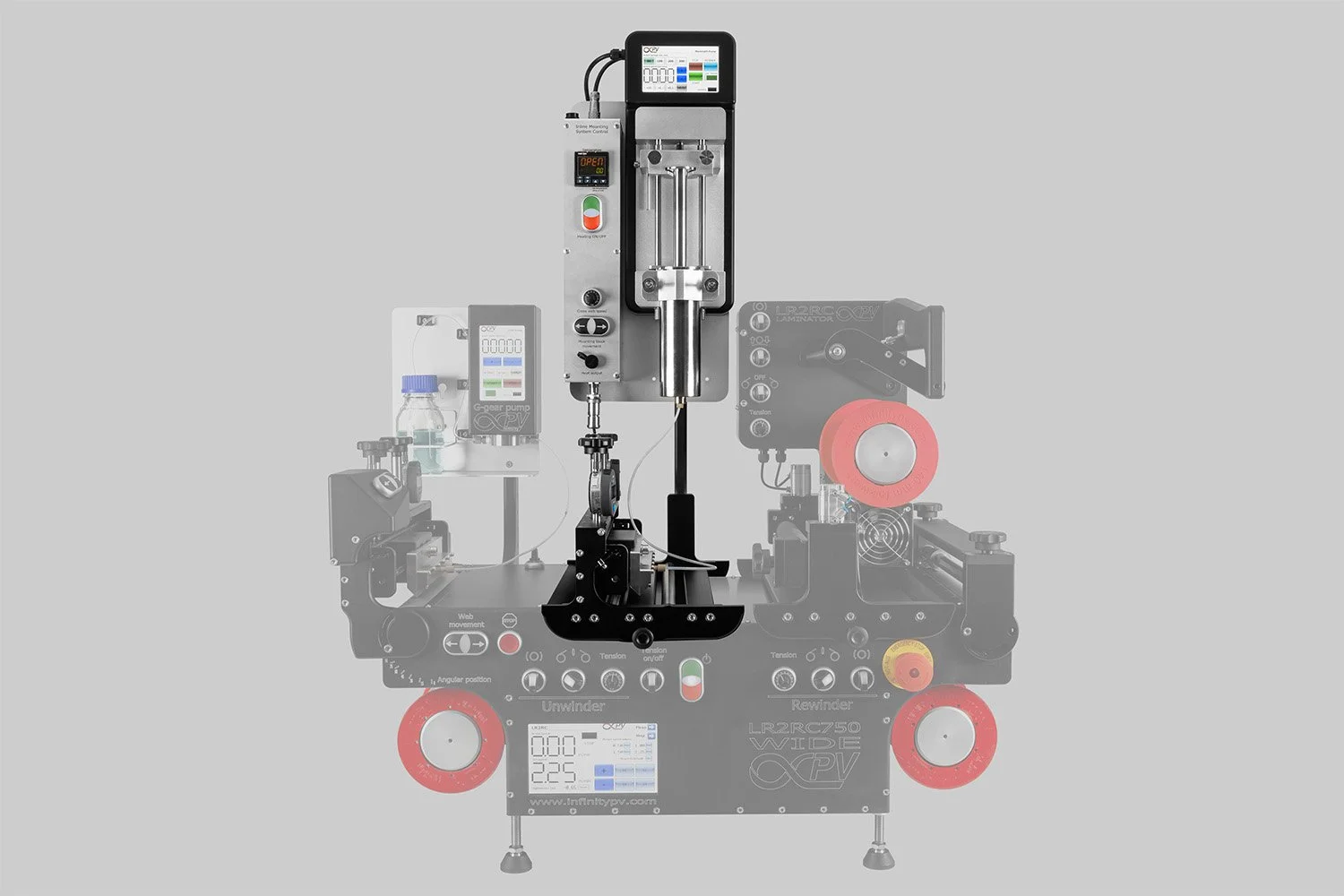

Gear Pump for the Laboratory Roll-to-Roll Coater

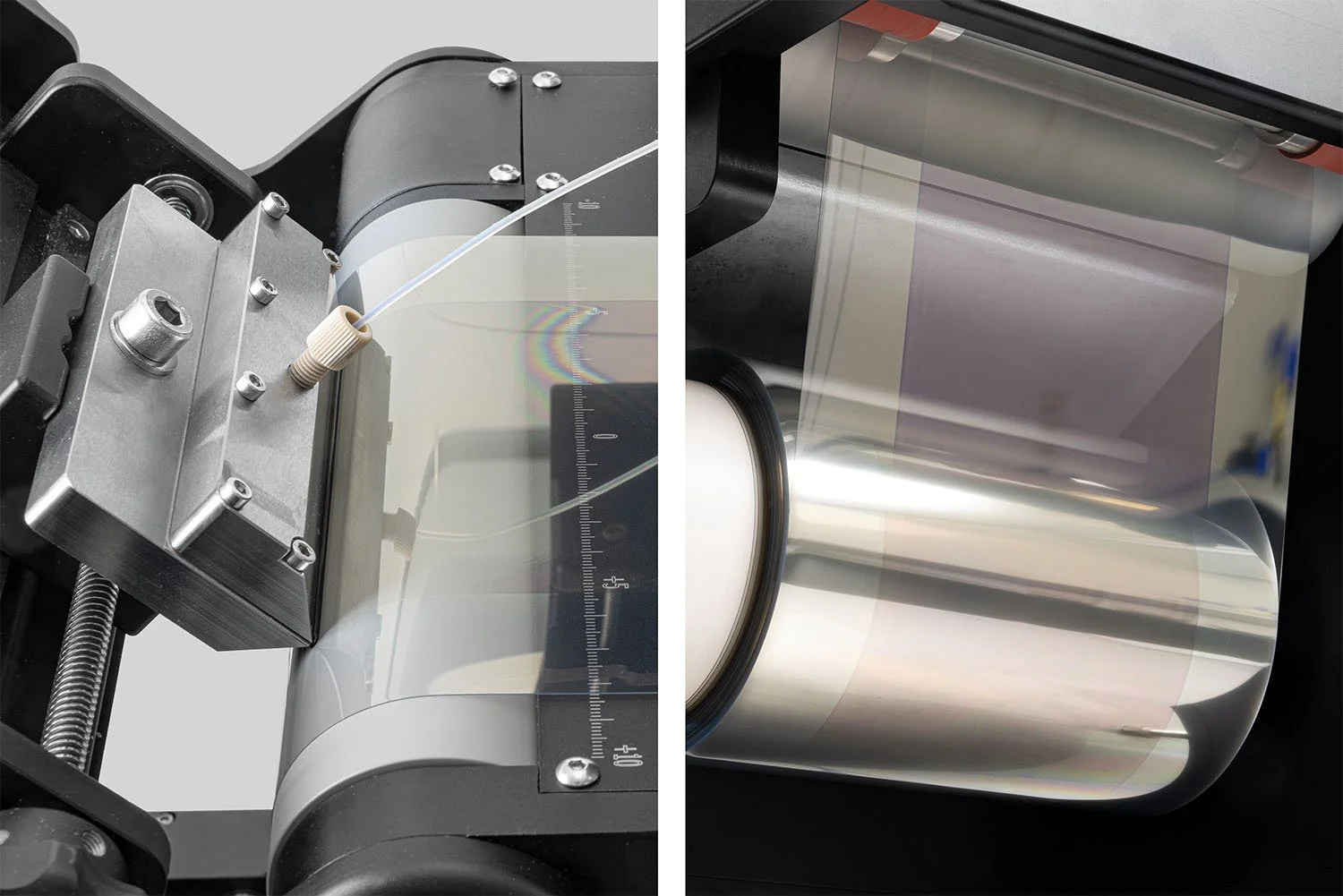

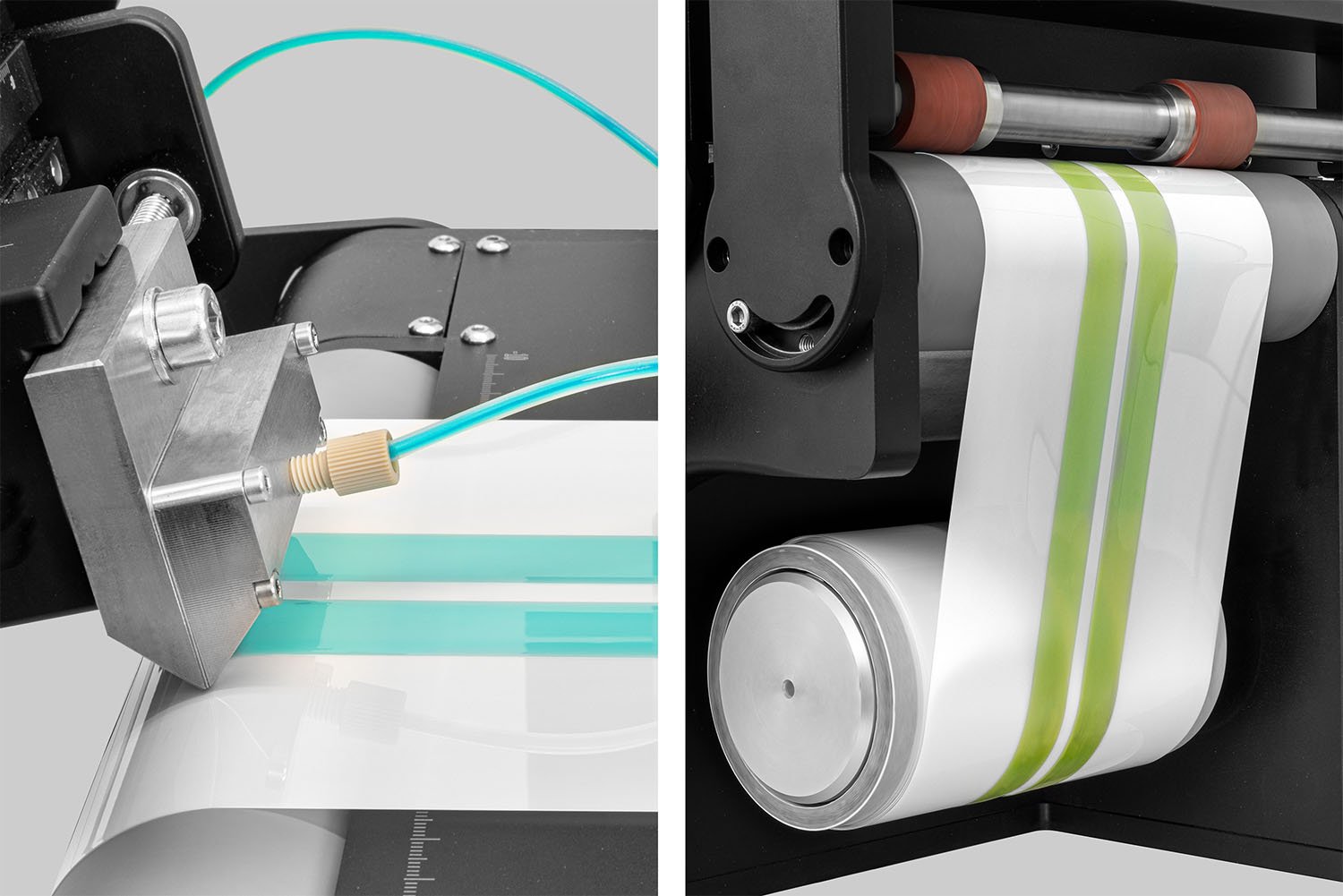

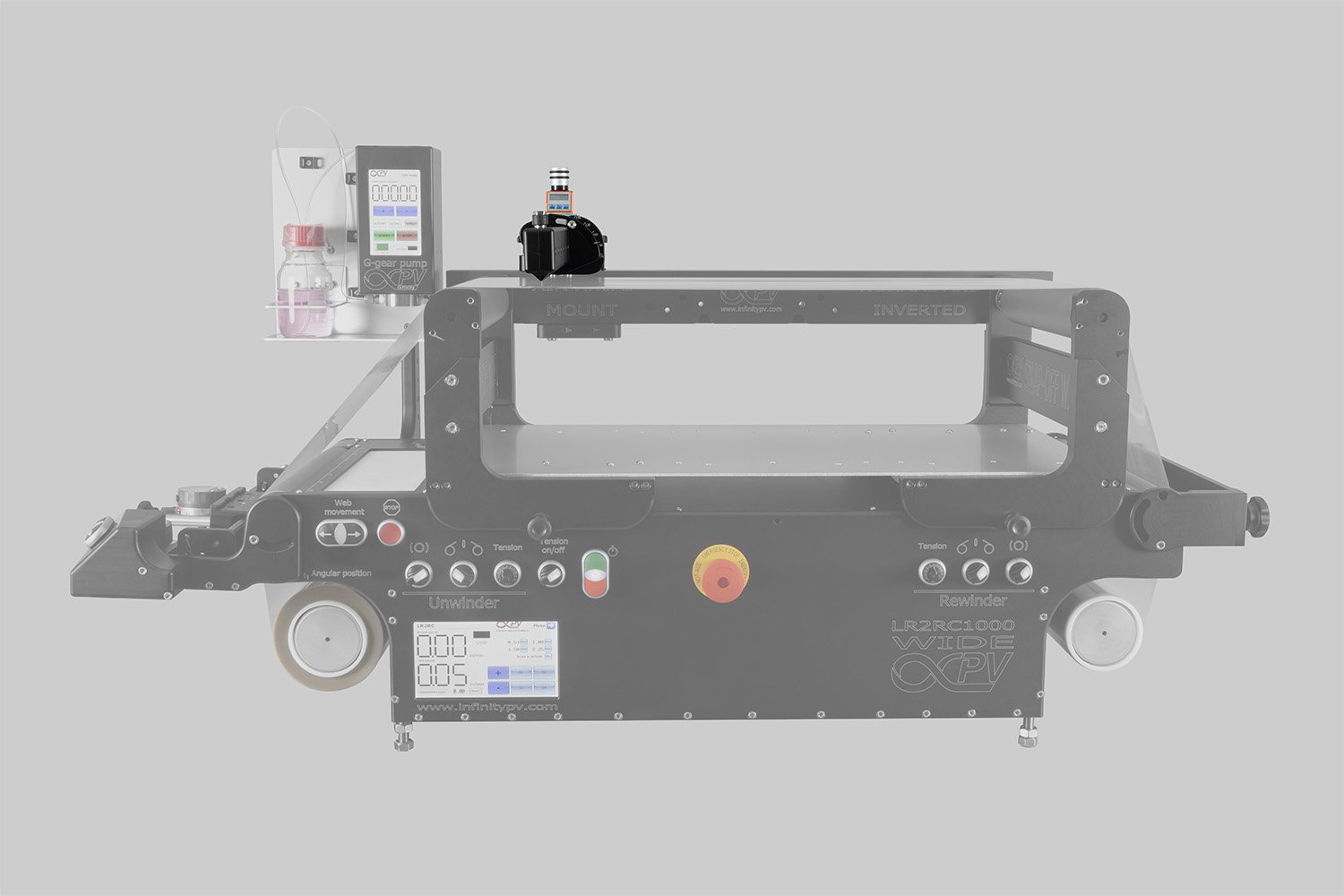

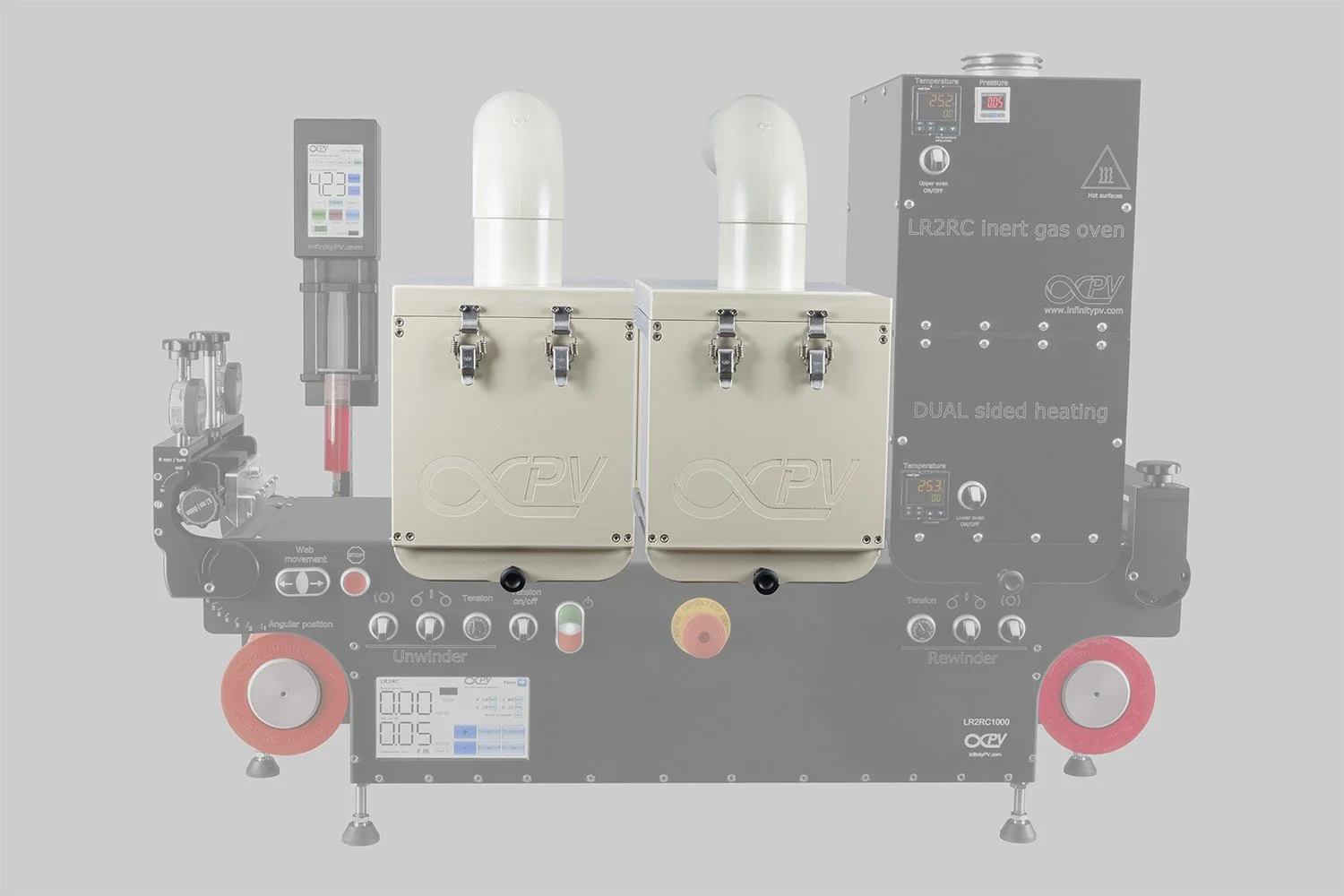

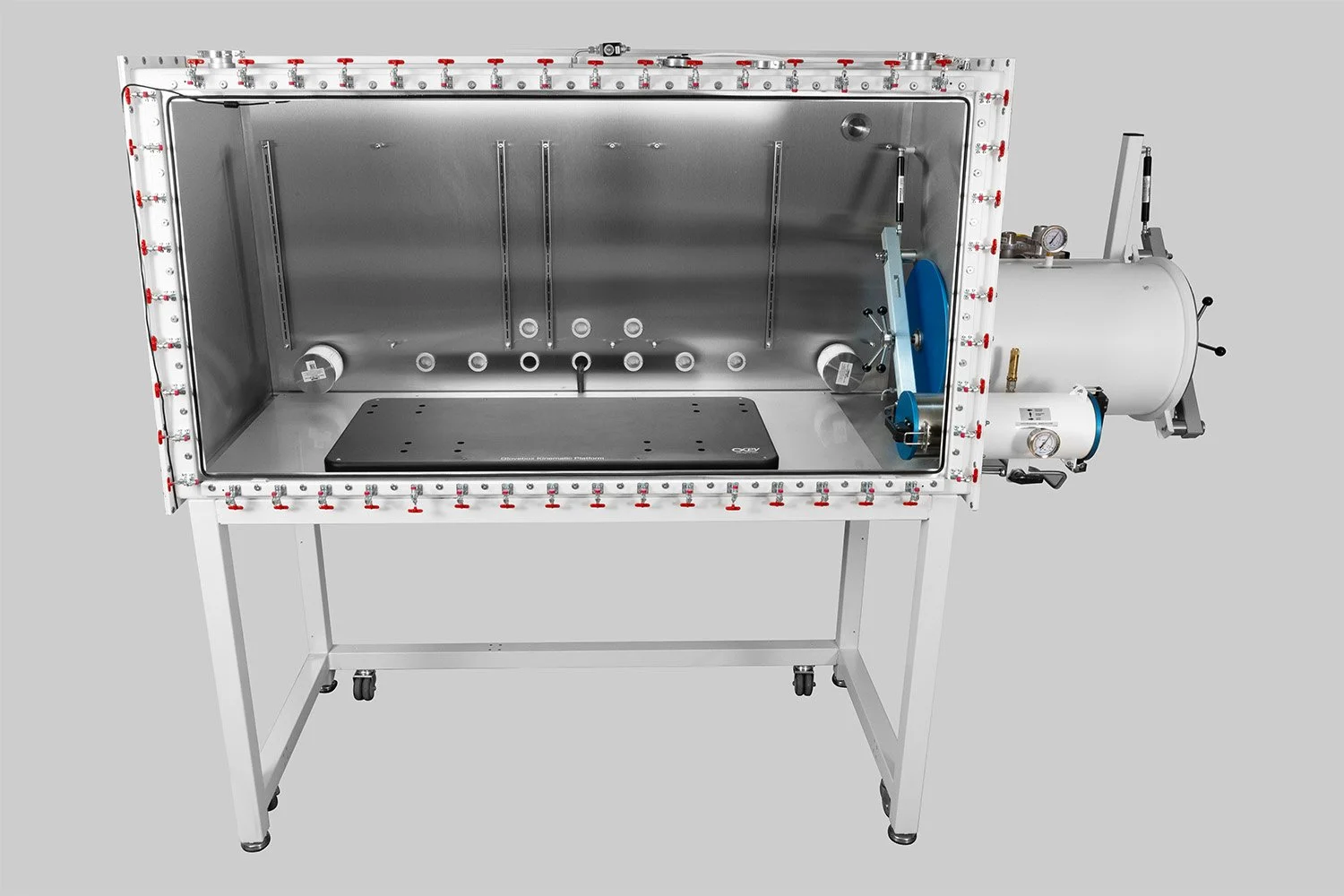

The Gear Pump is designed to seamlessly integrate with the Laboratory Roll-to-Roll Coater, a versatile and compact system for precise thin-film processing in lab and pilot-scale environments. Our modular components allow you to customize your coater for a wide range of applications including batteries, medtech, fuel cells, printed solar cells, sensors and more. Built for easy installation and interchangeability, these components help you optimize performance while maintaining flexibility and scalability.