Roll-to-Roll Laminator

With the Roll-to-Roll Laminator, encapsulation or addition of a protecting liner becomes possible and readily scalable in R2R processing.

With the Roll-to-Roll Laminator, encapsulation or addition of a protecting liner becomes possible and readily scalable in R2R processing.

With the Roll-to-Roll Laminator, encapsulation or addition of a protecting liner becomes possible and readily scalable in R2R processing.

Revolutionize Your Lab with the Roll-to-Roll Laminator

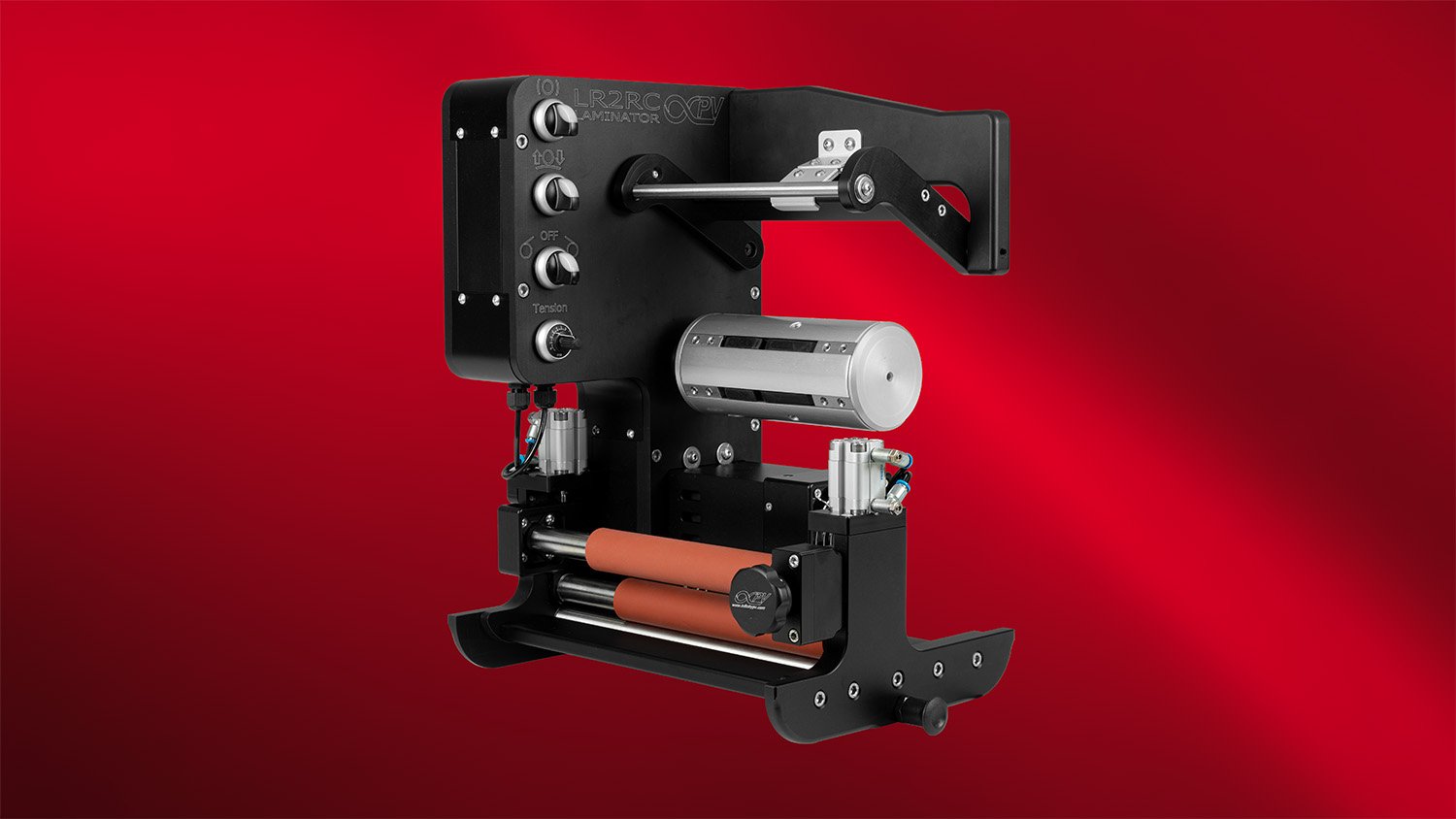

The Roll-to-Roll Laminator is a versatile component that integrates seamlessly into the Laboratory Roll-to-Roll Coater platform. This advanced laminator is designed to facilitate efficient encapsulation and the application of protective liners in R2R processing, supporting various adhesives, including PSA, hotmelt, and UV-curable types. Whether you're working on thin films for batteries, sensors, or other advanced materials, the Roll-to-Roll Laminator ensures high-quality lamination that can be easily scaled for pilot production.

Video: How Does the Roll-to-Roll Laminator Work?

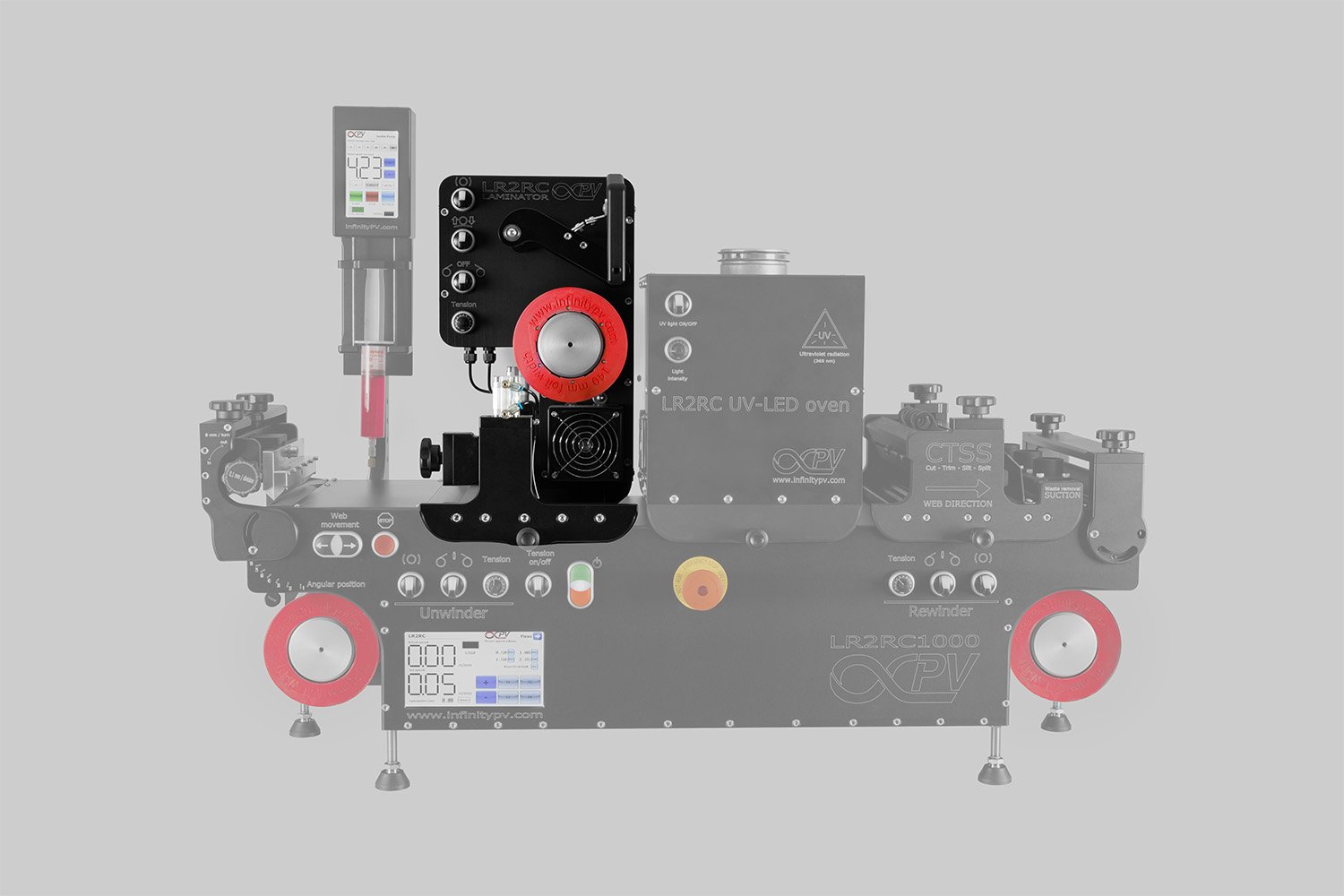

Modular Customization with the Laboratory Roll-to-Roll Coater

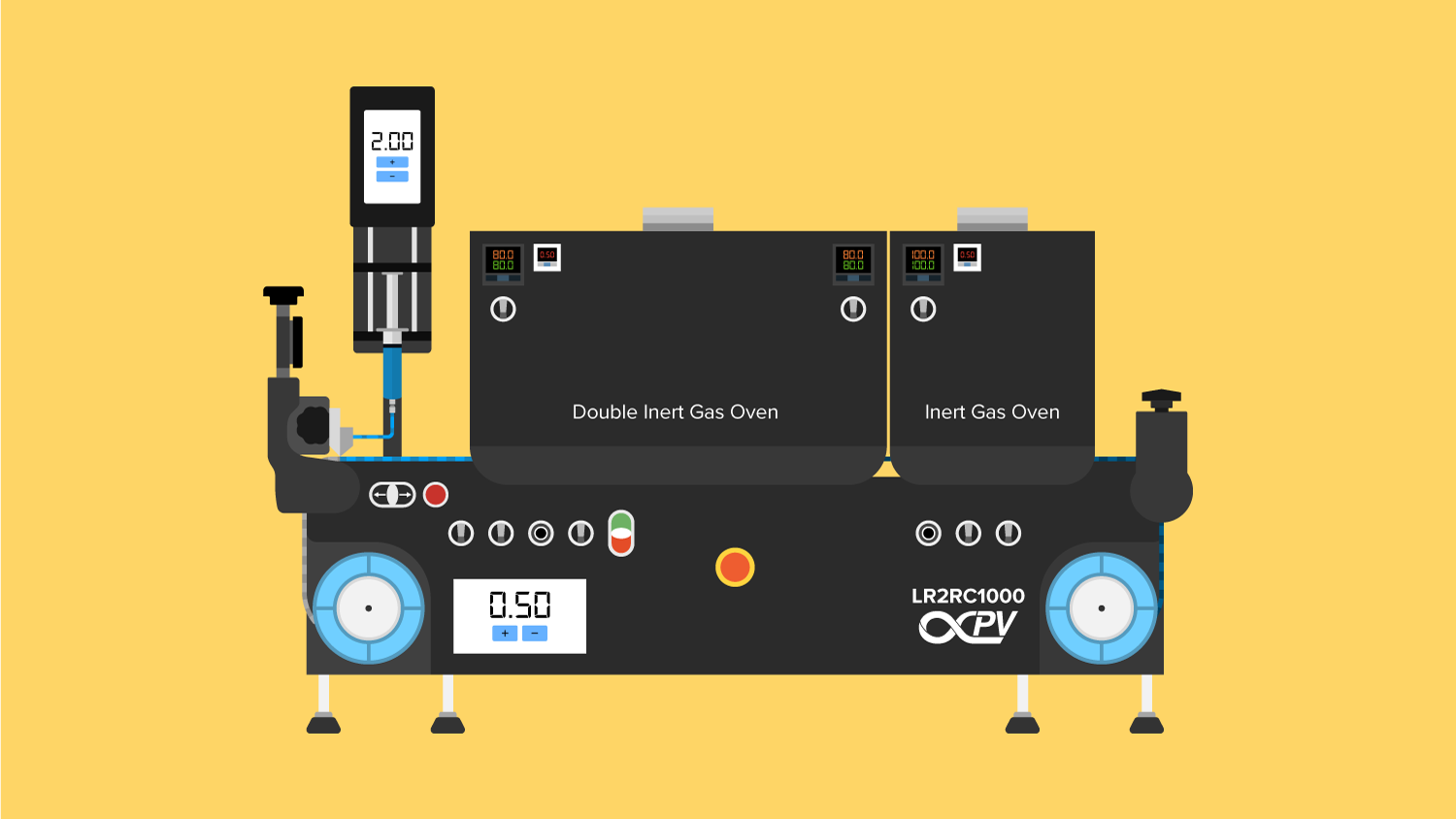

The Laboratory Roll-to-Roll Coater is a high-precision, compact solution for processing thin functional films in both lab and small pilot-scale environments. Its versatile modular design supports slot-die coating, slurry coating, and flexographic printing, and accommodates various coating components including slot-die heads, laminators, air knives, edge guides, plasma and corona treatment systems, and drying and curing ovens. The Laboratory Roll-to-Roll Coater can fit seamlessly into existing lab spaces, gloveboxes, or fume hoods without additional infrastructure. Capable of handling hundreds of meters of foil, it provides scalability and efficiency for applications such as thin film batteries, fuel cells, printed solar cells, OLEDs, sensors, adhesives. Designed for user convenience and built to international safety standards, the Laboratory Roll-to-Roll Coater is a flexible and economical choice for advancing thin-film technology. Customize your system today to meet your specific needs.

All Laboratory Roll-to-Roll Coater Platforms

Coating and Printing Components

Video: What is the Laboratory Roll-to-Roll Coater?

Key Features

Precision Tension Control: Maintains consistent quality across all runs.

Compressed Air Nip: Ensures smooth and accurate lamination.

3-Inch Core Spindle

High Precision Grinded Roller: Delivers superior alignment and finish.

Adjustment Roller: Guarantees precise foil alignment.

Web Width Options: Available in up to 200 mm (standard) or 305 mm (wide model).

Applications

Printed Solar Cells (OPV, Perovskite, DSSC, Tandem)

Adhesives and Sealants

Medical Devices (Biocompatible and Drug-eluting Layers)

Packaging Materials