Image 1 of 3

Image 1 of 3

Image 2 of 3

Image 2 of 3

Image 3 of 3

Image 3 of 3

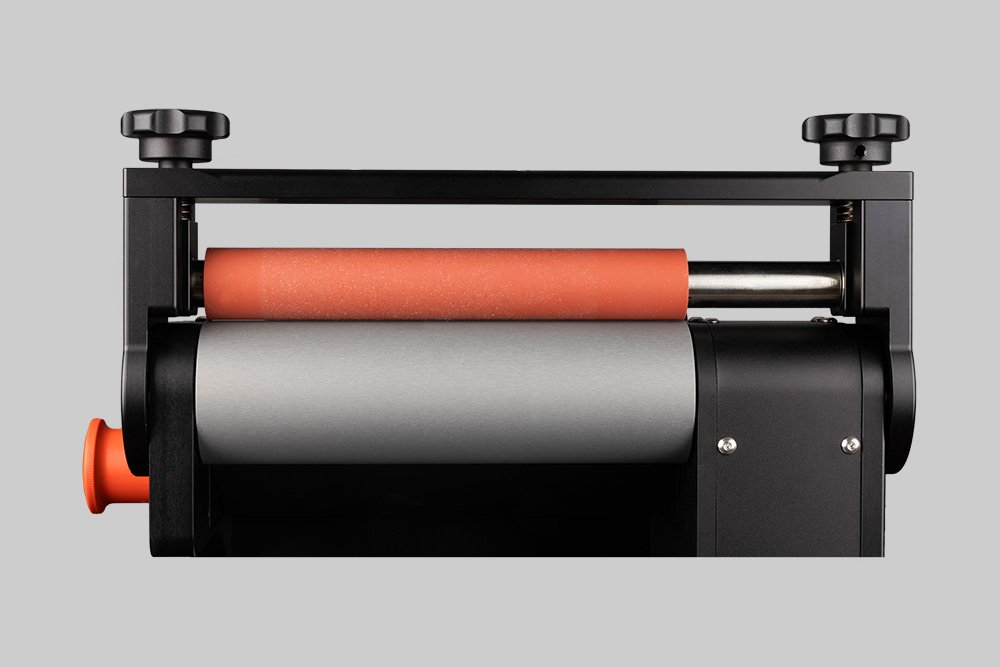

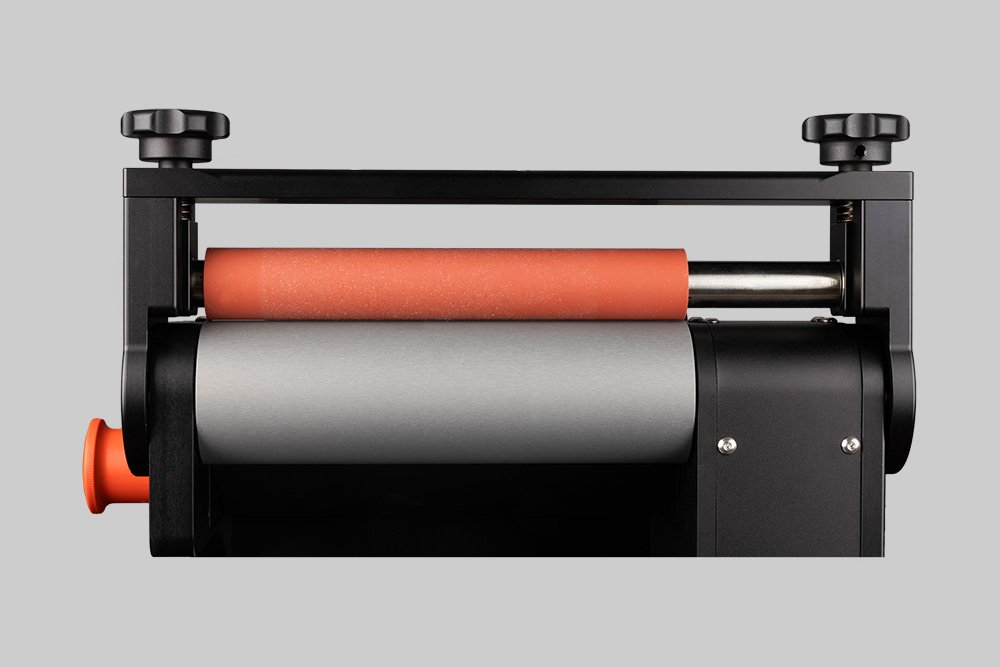

Manual Nip Roller and Simple Laminator

The nip roller enhances web control by pressing the web onto the roller, increasing friction and optimizing web movement and speed. Includes both manual control of nip pressure and tilt.

The nip roller enhances web control by pressing the web onto the roller, increasing friction and optimizing web movement and speed. Includes both manual control of nip pressure and tilt.

The nip roller enhances web control by pressing the web onto the roller, increasing friction and optimizing web movement and speed. Includes both manual control of nip pressure and tilt.

The basic configuration includes a full rubber roller with manual adjustment for both nip pressure and tilt. For more advanced needs, options include adjustable nip rollers with automated nip engagement, precise pressure control, and specific pressure points. Additionally, the system can function as a simple laminator, making it ideal for manual packaging of devices with minimal effort.

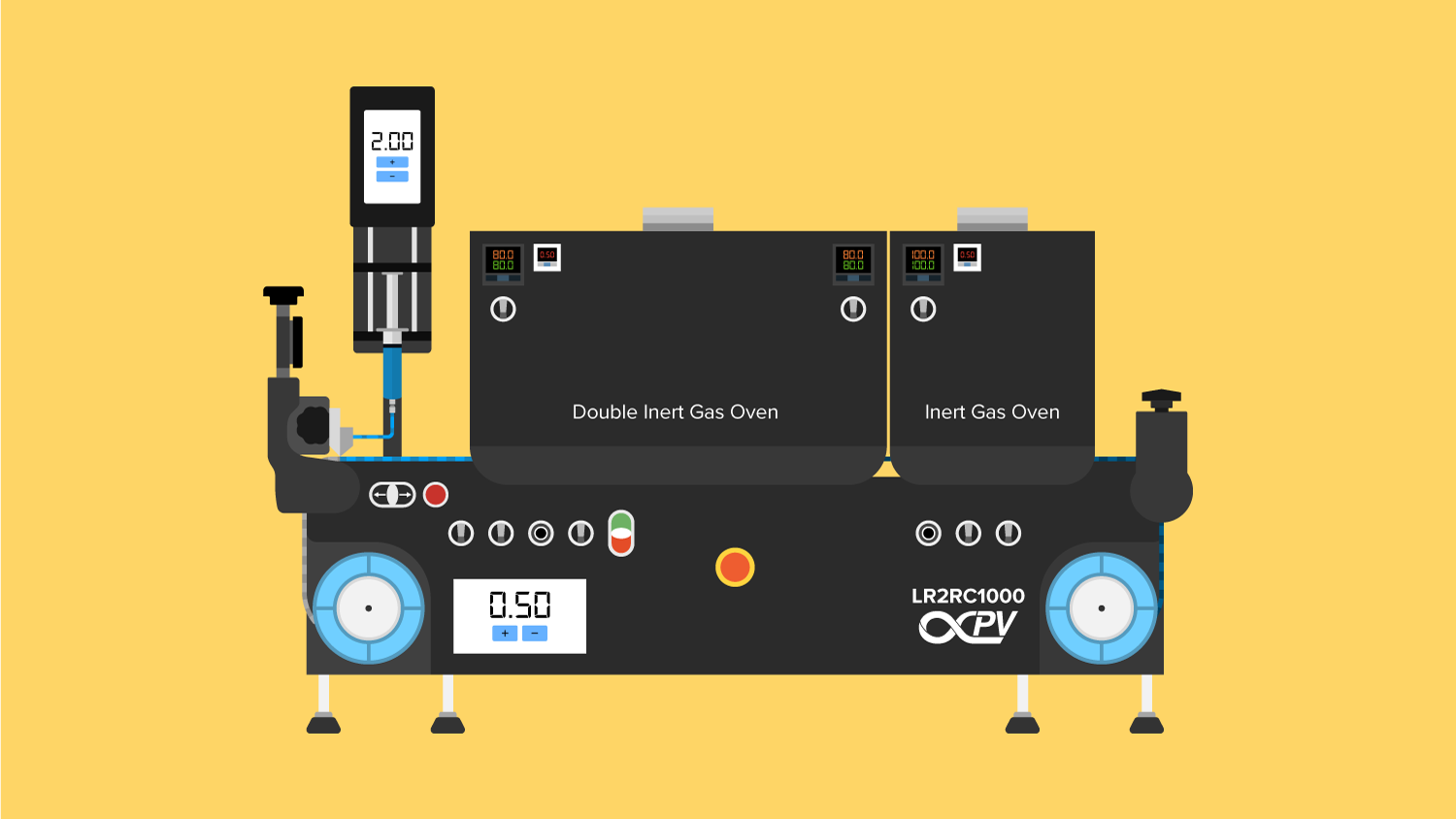

Modular Customization with the Laboratory Roll-to-Roll Coater

The Laboratory Roll-to-Roll Coater is a high-precision, compact solution for processing thin functional films in both lab and small pilot-scale environments. Its versatile modular design supports slot-die coating, slurry coating, and flexographic printing, and accommodates various coating components including slot-die heads, laminators, air knives, edge guides, plasma and corona treatment systems, and drying and curing ovens. The Laboratory Roll-to-Roll Coater can fit seamlessly into existing lab spaces, gloveboxes, or fume hoods without additional infrastructure. Capable of handling hundreds of meters of foil, it provides scalability and efficiency for applications such as thin film batteries, fuel cells, printed solar cells, OLEDs, sensors, adhesives. Designed for user convenience and built to international safety standards, the Laboratory Roll-to-Roll Coater is a flexible and economical choice for advancing thin-film technology. Customize your system today to meet your specific needs.

Key Features

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Choose from a variety of lengths and widths, with numerous components available.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

Modular Drying/Curing System: Accommodates various drying and curing methods.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

Technical Specifications

Operating Power: Single phase (240VAC) for smaller models; three-phase (400VAC) for larger models.

Drying/Curing Length: From 250 mm (LR2RC500) to 1250 mm (LR2RC1500).

Web Width: Up to 200 mm (standard), up to 310 mm (wide models).

Web Speed: 0.05-2.8 m/min (forward and reverse).

Spindles: Automatic compressed air spindles for 3-inch core diameters, adjustable cones for smaller cores in LR2RC500.

Applications

Printed Solar Cells (OPV, Perovskite, DSSC, Tandem)

Adhesives and Sealants

Medical Devices (Biocompatible and Drug-eluting Layers)

Packaging Materials

All Laboratory Roll-to-Roll Coater Platforms

Coating and Printing Components

Video: What is the Laboratory Roll-to-Roll Coater?