Slot-die Coater Customizer

1. Platform

The Slot-die Coater has a small foot print and present an open platform that is easily adaptable to all the great experiments that have not been carried out yet. You can fit them almost everywhere in the lab, in the fume cupboard, on the bench and in the glovebox.

A compact sheet coater for advanced thin-film applications that offers precision and reliability for R&D in areas like printed batteries, solar cells, fuel cells, OLEDs, and sensors.

A compact sheet coater for advanced thin-film applications that offers precision and reliability for R&D in areas like printed batteries, solar cells, fuel cells, OLEDs, and sensors.

2. Mounting System

Depending on the mounting system, the coating position can be adjusted either manually using adjustment knobs or electronically with motorized controls operated via software.

Manual positioning of the slot-die head, bar coater, knife coater or flexo roller. Included with the base Slot-die Coater.

The advanced mounting system features manual adjustment with digital micrometers to ensure precise head-to-substrate distance control.

Software control of the coating position with 3-axis motion control (side registration, up/down, fwd/rev).

3. Base Plate

The Slot-die Coater includes an integrated hot plate for drying thin films and offers options such as a standard hot plate (up to 100 °C), high-temperature hot plate (up to 140 °C), or heated vacuum chuck (up to 100 °C). The vacuum chuck provides precise workholding with minimal deformation and features a diamond-milled surface for uniform coating and drying.

The Slot-die Coater includes an integrated hot plate for convenient drying of processed thin films directly on the unit. The system features a standard hot plate capable of reaching temperatures up to 100 °C, ensuring efficient drying during your coating process.

Upgrade from the standard hot plate, which reaches up to 100 °C, to the high-temperature hot plate capable of reaching 140 °C. This enhanced option provides greater flexibility, optimizing your thin-film coating applications.

Upgrade from the standard hot plate to the heated vacuum chuck, capable of reaching up to 100 °C. This advanced feature provides precise workholding for thin foils and substrates, minimizing deformation during coating and printing.

4. Syringe Pump

The syringe pumps feature a color touchscreen for precise ink flow control, a USB interface for full control and data logging, and compatibility with our free software for easy setup of simple or complex experiments. They support smooth ink delivery for R&D and can be combined for automated gradient or dilution tasks

Experience precision with syringe pumps, available in Standard (0-20 mL) and Jumbo (0-60 mL) variants.

5. Coating and Printing

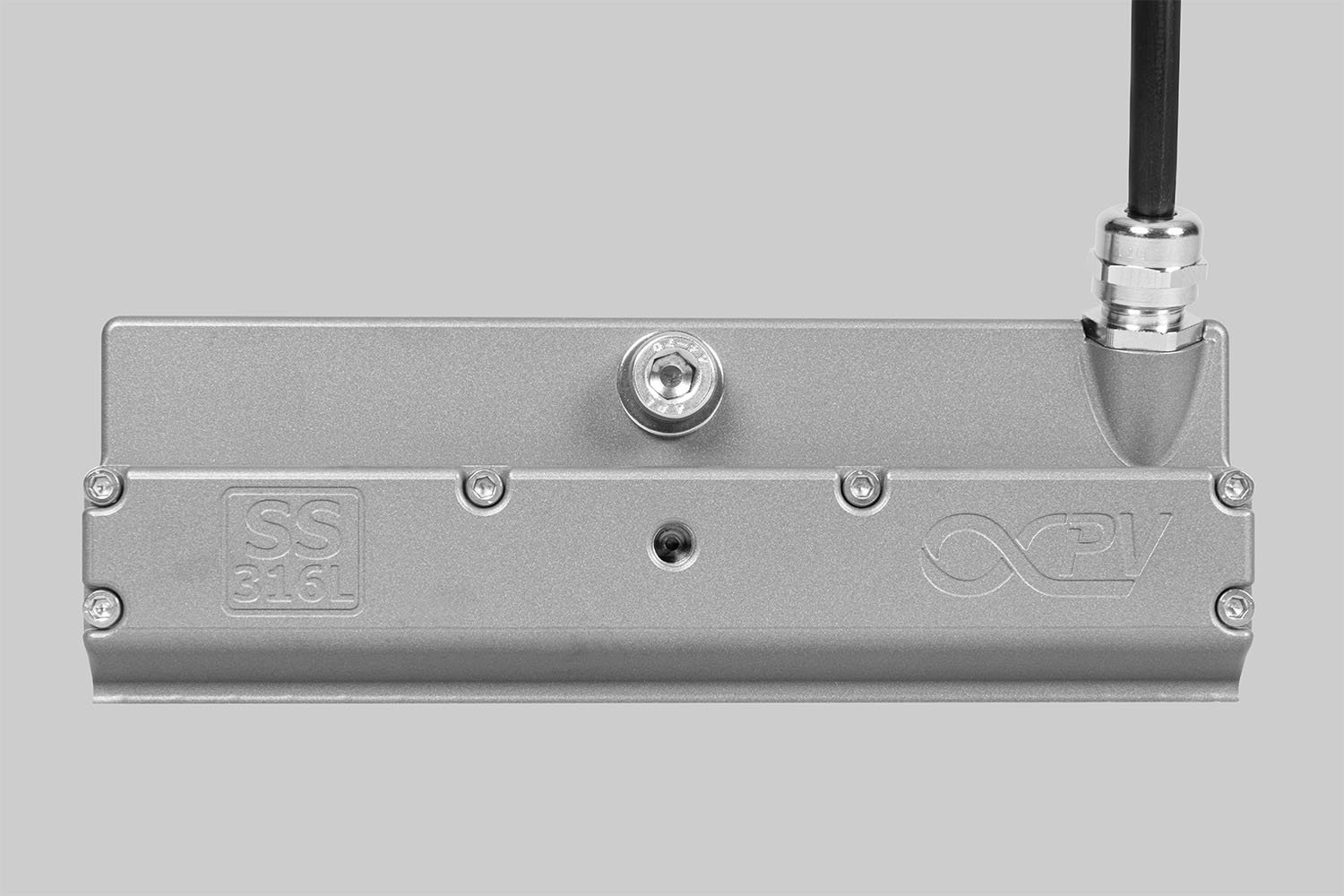

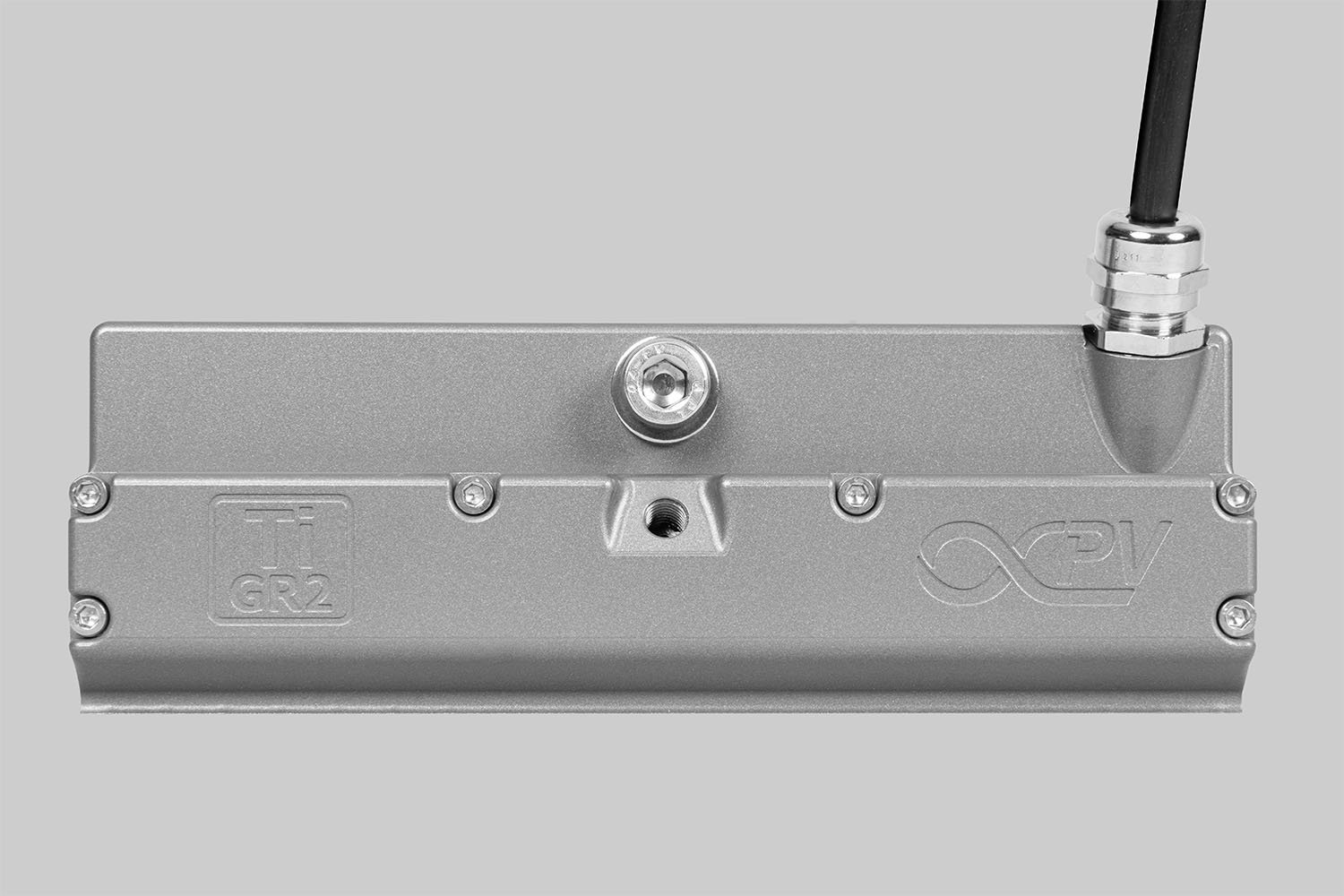

The Slot-die Coater supports slot-die heads (available in PEEK, Stainless Steel and Titanium), a Knife Coater, Bar Coater and multiple Air Knives. The slot-die heads offer precise coatings for both small details and large surfaces. Heated versions are also available in stainless steel and titanium.

If you need a customized slot-die head tailored to your specific requirements, our expert team is ready to collaborate with you to design and manufacture a solution that meets your exact needs.

Engineered for precise temperature regulation and superior slot-die coating performance, this advanced controller guarantees uniform film thickness and enhances product quality, ensuring optimal results with every use.

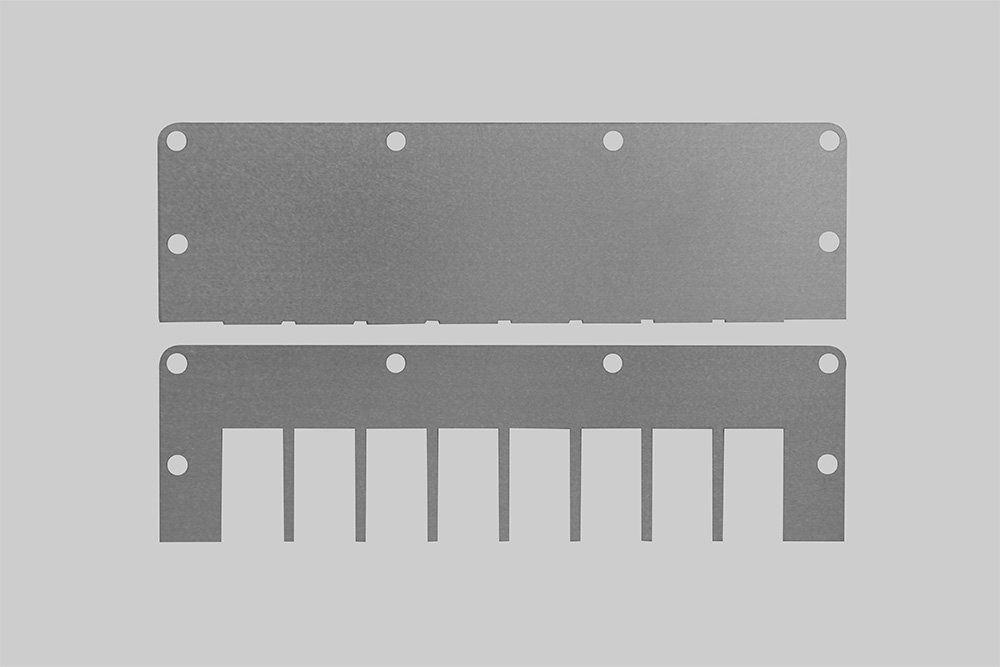

Optimize your slot-die coating systems with our custom shim kits, designed to meet your specific needs and applications.

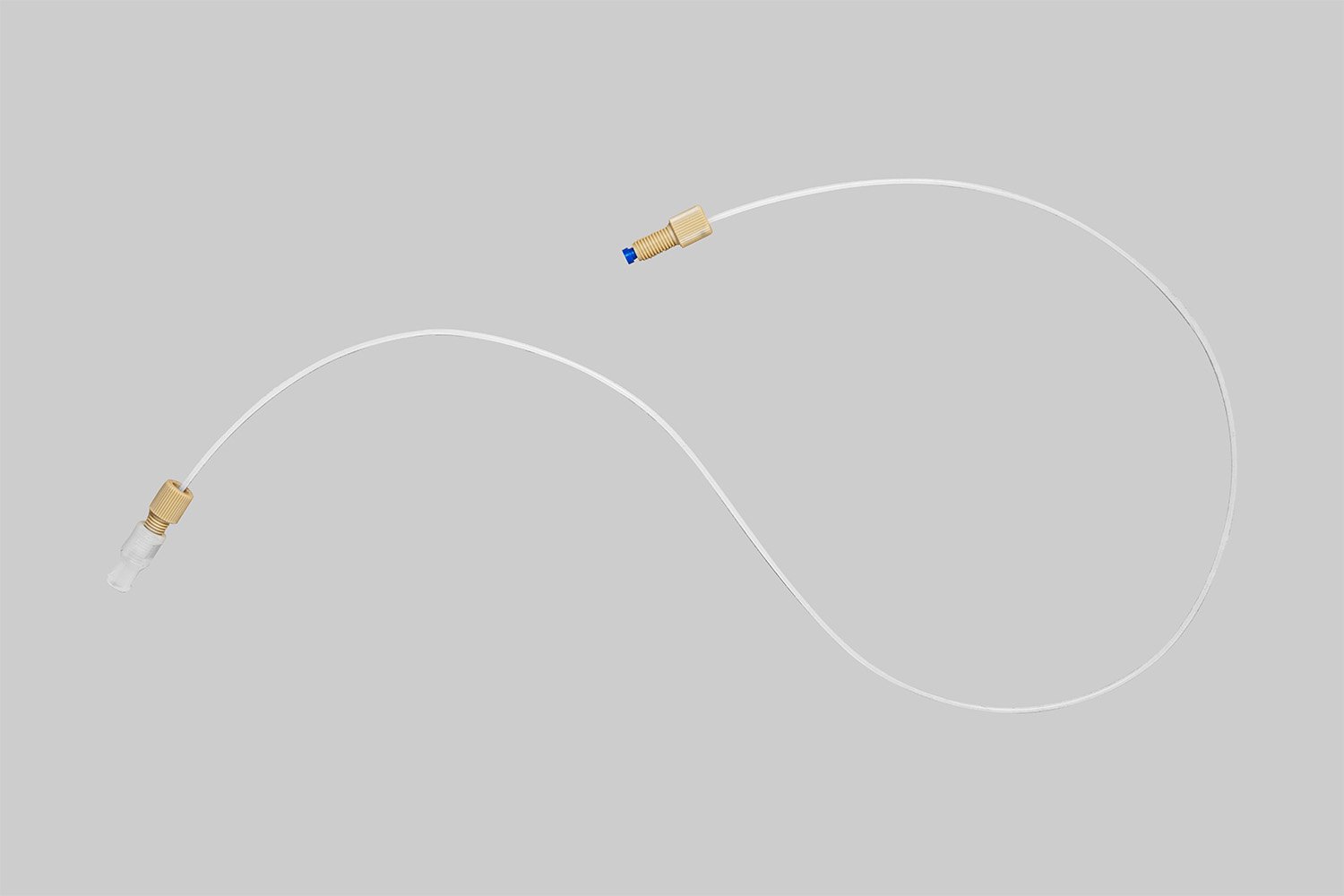

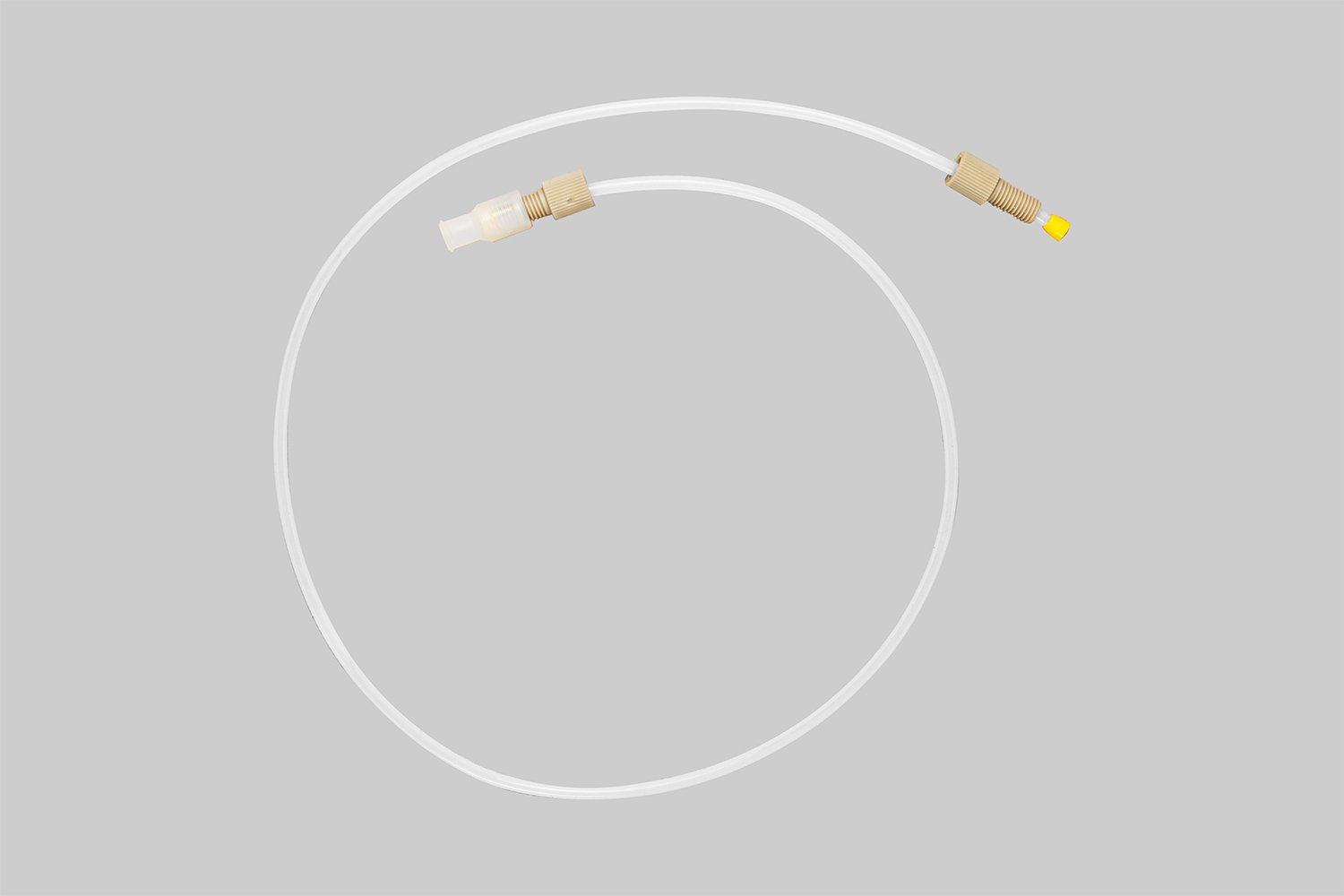

Includes 60 cm of Teflon tubing with a 0.50 mm diameter for low-viscosity inks, and PEEK female Luer lock connectors for secure and reliable connections.

Includes 60 cm of Teflon tubing with a 1.6 mm diameter for high-viscosity inks, along with PEEK female Luer lock connectors to ensure secure connections.

Optimize the drying and quenching of coated thin films with the air knife. Designed for materials like perovskites, it offers precise control with adjustable angles, distances, and customizable air blade widths.

With micrometer screws and a digital display, the Air Knife Pro allows for fine-tuning the air knife position, giving you reliable control that’s ideal for applications requiring consistent, repeatable results.

The knife coater unit has a knife blade in anodized aluminum with a high precision ground edge, resulting in a coating width of 30 mm.

Bar Coater for thin films: The spring-loaded system compensates for minor alignment inaccuracies. Simply push one of the five bars (10, 25, 50, 100, or 250 microns) into the holder to achieve various wet thicknesses.

The simple flexographic roller system can be used for printing many types of materials when preparing single devices among others the back silver for inverted geometry device.

6. Get a Quotation

Congratulations on customizing your Slot-die Coater! You are now ready to receive a quotation. If you are uncertain about your platform or component choices, please contact us. We’d be delighted to assist you.