Mammoth Syringe Pump

Delivering precise, programmable flow control for high-volume coating applications.

Unmatched Precision for High-Volume Coating Applications

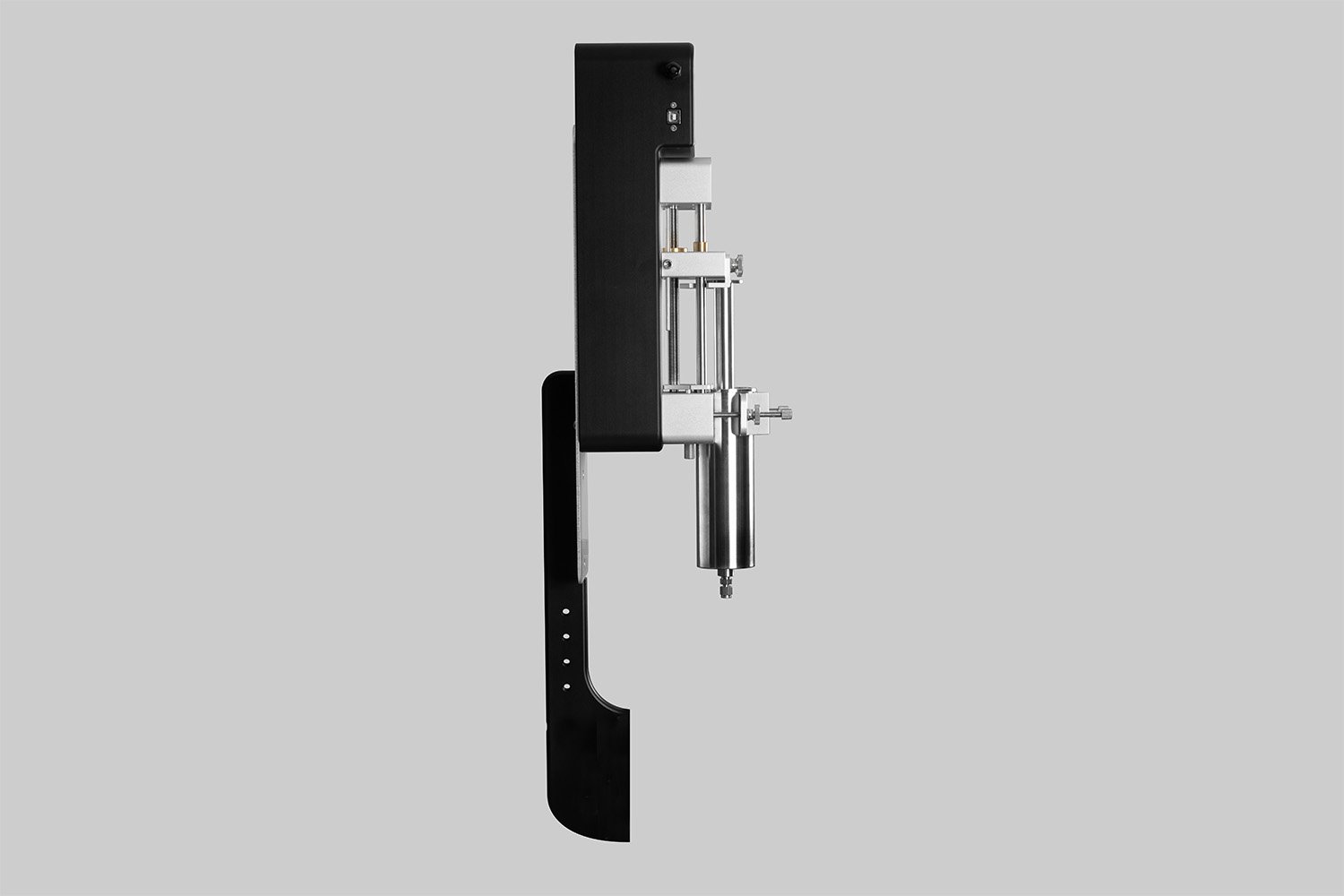

The infinityPV Mammoth Syringe Pump is engineered to set a new benchmark in precision and reliability for high-volume coating applications. At its core is a robust 300 ml stainless steel (316) syringe, designed to withstand corrosive materials while ensuring effortless cleaning and maintenance. This combination of durability and efficiency makes the Mammoth Syringe Pump a trusted tool across a spectrum of demanding industries.

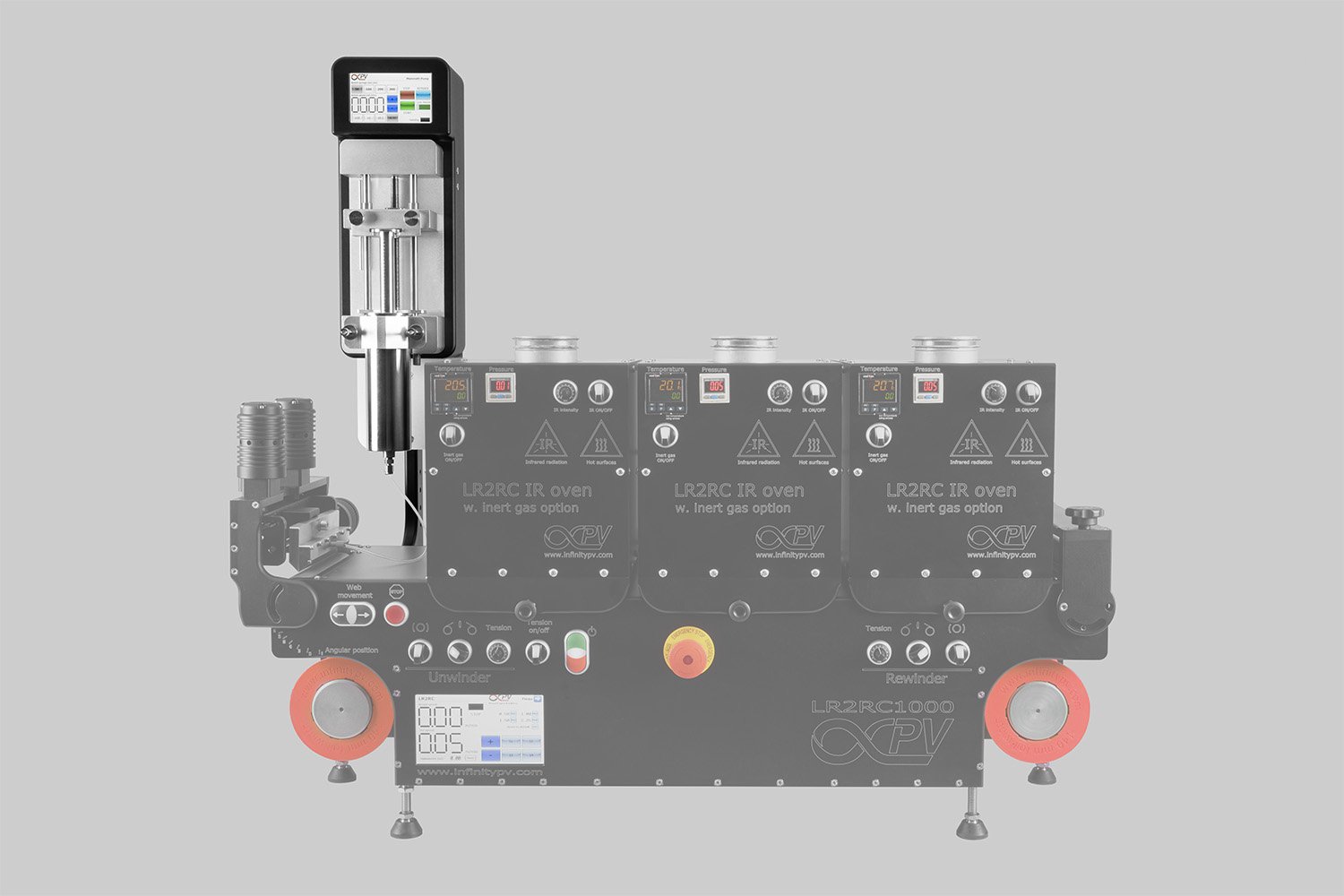

Delivering exceptional accuracy and control, the Mammoth Syringe Pump ensures consistent coating thickness and quality, which are vital for experimental integrity and production excellence. Whether working with low-viscosity inks or dense battery slurries, the pump handles diverse materials with precision and consistency. It integrates seamlessly with the infinityPV Laboratory Roll-to-Roll Coater, offering a complete solution for advanced coating processes. This compatibility ensures optimized workflows and precision delivery for applications such as slot-die coating and other roll-to-roll processes.

The intuitive 5-inch touchscreen interface puts complete control at your fingertips, allowing users to program, monitor, and fine-tune operations effortlessly. Multi-pump operation further enhances workflow efficiency, enabling simultaneous processes or complex compound delivery systems. With its cutting-edge programmability and versatility, the Mammoth Syringe Pump adapts to the unique challenges of every application.

Built with reliability at its foundation, the Mammoth Syringe Pump ensures long-term performance with minimal maintenance, making it an indispensable asset for laboratories and industrial setups alike.

Fey Features

Unmatched Precision: Accurate flow control for consistent coating quality

Material Versatility: Suitable for a wide range of viscosities and materials

Durable Design: Stainless steel syringe for corrosion resistance and longevity

Ease of Use: Intuitive touchscreen interface for seamless programming and monitoring

Programmability: Flexible delivery rates tailored to unique workflows

Enhanced Efficiency: Multi-pump compatibility for simultaneous or complex processes

Reliable Performance: Low-maintenance operation for long-term durability

Technical Specifications

Syringe Volume: 300 ml Stainless Steel (316)

Flow Rate Range: 0.01 ml/min – 99.99 ml/min

User Interface: 5-inch touchscreen

Material Compatibility: Polymers, battery slurries, inks, adhesives

Connectivity: Computer interface for advanced control

Integration: Compatible with the Laboratory Roll-to-Roll Coater

Applications:

Printed Electronics: Solar cells, batteries, fuel cells, and electrolysers

Medical and Pharmaceutical: Precise fluid dispensing and adhesive applications

Industrial Coatings: Laminating, slot-die coating, and adhesive dispensing

Food and Beverage Industry

Setups Featuring the Mammoth Syringe Pump

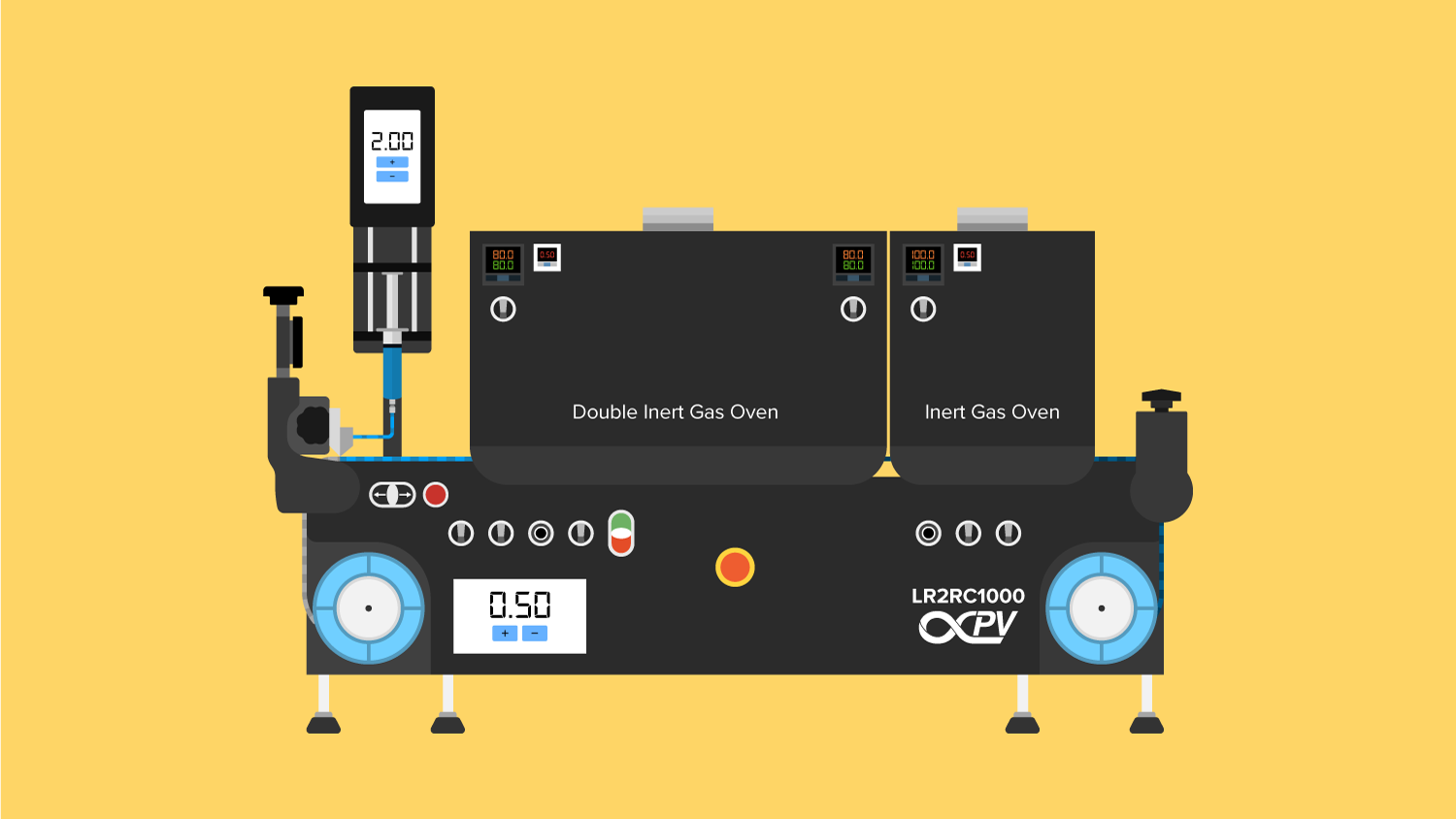

The Mammoth Syringe Pump mounted on an LR2RC1000 platform featuring a PC Controlled Mounting System, stainless steel Slot-die Head, three IR Ovens and a Nip Roller.

The Mammoth Syringe Pump mounted on an LR2RC1000 platform featuring a PC Controlled Mounting System, stainless steel Slot-die Head, Roll-to-Roll Laminator, UV-LED Oven, Knife Cutter and a Nip Roller.

Multi-Pump Setup With the Jumbo Syringe Pump

The Jumbo Syringe Pump is available in multi-pump setups, offering versatility for coating, printing, and fluid delivery needs. These setups are ideal for applications requiring precise control of multiple fluids, such as ink formulations, solvents, or additives. Whether for multi-fluid coating, gradient experiments, dilution protocols, high-volume production, or automated delivery, the multi-pump configurations ensure accurate, repeatable results.

How to Choose the Right Pump for Slot-Die Coating: A Complete Guide

Choosing the right pump for slot-die coating is crucial for achieving precise and consistent results. Our guide covers various pump types, including syringe, gear, and peristaltic pumps, and explains how each contributes to efficient ink delivery, ensuring high-quality coatings for applications such as solar cells, batteries, and printed electronics.

Probably the World’s Most Compact R2R Slot-die Coater

The LR2RC500 Bundle is a compact, fully integrated roll-to-roll coating platform for laboratories, complete with an advanced mounting system, anodized rollers, a jumbo syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.

Video: What is the Laboratory Roll-to-Roll Coater?

The Laboratory Roll-to-Roll Coater is a compact, high-precision lab coater that transforms the way thin functional films are processed. It offers modular customization to fit different needs, scalable efficiency for small-scale production, and a user-friendly design with easy-to-remove components. Ideal for applications like batteries, fuel cells, and solar cells, it allows you to customize a system that’s perfect for your needs.