Slot-Die Coating vs. Slurry Coating: Which Coating Method is Best for Your Thin-Film Applications?

In the ever-evolving world of manufacturing, coating technologies play a pivotal role in the production of high-performance materials. From batteries and solar cells to advanced displays and flexible electronics, the choice of coating method can significantly impact the quality, efficiency, and cost of production. Among the various coating techniques available, slot-die coating and slurry coating stand out for their unique benefits and specific applications.

Slurry Coating

Slurry coating, characterized by its versatility and simplicity, involves applying a liquid slurry onto a substrate using methods such as doctor blade, spray, dip, or roll-to-roll coating. It offers a cost-effective solution but can face challenges in achieving uniform thickness and precision.

Slot-die Coating

On the other hand, slot-die coating is renowned for its precision and consistency. This method uses a die with a narrow slot to control the application of slurry with high accuracy, making it ideal for applications requiring uniformity and minimal waste. Though it demands a higher initial investment and careful maintenance, slot-die coating is often preferred for high-quality thin films, including those used in batteries and advanced displays.

In this article, we will explore the key differences between slurry and slot-die coating, examining their respective advantages, disadvantages, and suitable applications. Whether you're evaluating these methods for a specific project or aiming to understand their broader implications, this guide will provide valuable insights into selecting the right coating technique for your needs.

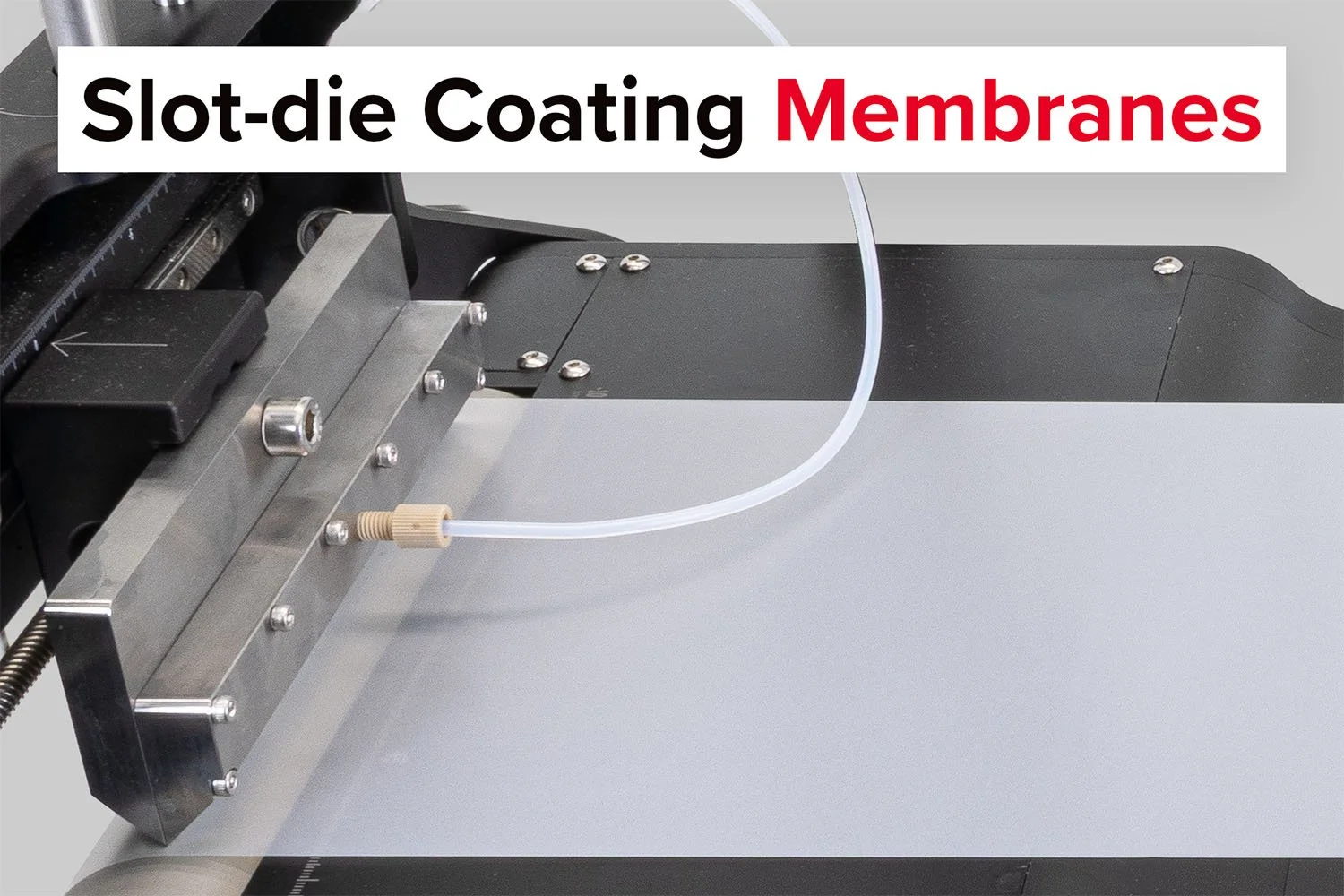

A visual representation of the slot-die coating process.

What is Slot-die Coating?

Slot-die coating is a highly precise and versatile technique widely used in the roll-to-roll (R2R) manufacturing of thin films for various advanced technologies, such as batteries, solar cells, and flexible electronics. This method involves dispensing a liquid coating material through a narrow slot onto a continuously moving substrate, allowing for exceptional control over the thickness and uniformity of the applied film. The slot-die system can be finely tuned by adjusting parameters such as the flow rate of the coating material, the speed of the substrate, and the gap between the slot-die and the substrate surface. Get a thorough understanding of slot-die coating.

Advantages of Slot-die Coating:

Uniformity: Offers high uniformity and consistency in coating thickness.

Precision: Precise control over the coating parameters, such as thickness and width.

Scalability: Suitable for both small-scale and large-scale production.

Material Efficiency: Minimizes waste by precisely controlling the amount of slurry dispensed.

Disadvantages of Slot-die Coating:

Complexity: Requires precise control and monitoring of parameters such as flow rate, substrate speed, and slurry viscosity.

Cost: Generally higher initial investment in equipment compared to simpler coating methods.

Maintenance: Regular maintenance needed to prevent clogging and ensure consistency.

Applications of Slot-die Coating:

Widely used in battery manufacturing for electrode coatings due to its precision and uniformity.

Suitable for applications requiring high-quality thin films, such as OLED displays, solar cells, and advanced coatings.

Slot-die heads for high-quality coatings. Available in stainless steel, titanium, or PEEK, with widths from 40 mm to 305 mm, ensuring precise thin-film coating.

What is Slurry Coating?

Slurry coating is a fundamental process in the roll-to-roll (R2R) manufacturing landscape, particularly valued for its versatility and ability to handle complex, thick coatings. This technique involves applying a slurry—a suspension of solid particles dispersed in a liquid carrier—onto a moving substrate. The slurry typically contains a mixture of active materials, binders, and solvents, which are spread across the substrate using methods such as knife-over-roll or dip coating. After application, the coated substrate undergoes drying to remove the solvent, leaving behind a solid, functional film.

Slurry coating, often referred to simply as "coating," involves the application of a liquid slurry onto a substrate. This can be achieved through various methods, such as doctor blade coating, spray coating, dip coating, or roll-to-roll coating.

Advantages of Slurry Coating:

Versatility: Can be adapted to various coating techniques and substrates.

Simplicity: Generally simpler setup and operation.

Cost-Effective: Equipment may be less expensive and easier to maintain.

Disadvantages of Slurry Coating:

Uniformity: Achieving consistent thickness and uniformity can be challenging, especially over large areas.

Control: Less precise control over coating thickness compared to slot-die coating.

Material Waste: Potentially more material waste due to overspray or excess slurry.

Applications of Slurry Coating:

Commonly used for thin-film coatings, adhesives, and applications where high precision is not as critical.

Can be used in laboratory settings for small-scale experiments and initial development stages.

A slurry coater coating a thin-film battery on a roll-to-roll lab coater.

Conclusion - Slurry Coating or Slot-die Coating?

The choice between slurry coating and slot-die coating depends on the specific requirements of the application:

Slurry Coating is often chosen for its simplicity, flexibility, and lower cost, making it suitable for less critical applications or initial material tests.

Slot-Die Coating is preferred for applications where uniformity, precision, and material efficiency are critical, such as in high-quality battery electrode manufacturing and other advanced thin-film applications.

Selecting the appropriate method involves considering factors like desired coating quality, production scale, and budget. For high-performance batteries and other demanding applications, slot-die coating usually offers significant advantages over general slurry coating methods.

Further Reading

Slot-Die Coating Explained: Basics, Benefits, and Applications

Comprehensive Guide to Fuel Cells: Types, Applications, Benefits, and Drawbacks

Solid-State Lithium-Ion Batteries: Advantages, Production, and Future Prospects

Contact Us

For more information or to discuss your specific project needs, feel free to contact us. We offer a range of products and services tailored to meet the demands of modern manufacturing, including high-precision slot-die coating systems and versatile slurry coaters.

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.