Gear Pump

A high-performance positive displacement pump designed to handle a diverse range of fluids with precision.

Gear Pump for R2R Slot-die Coating

The Gear Pump is a high-performance positive displacement pump designed to handle a diverse range of fluids with precision. Utilizing advanced gear technology, it efficiently transfers mechanical energy from the motor to the fluid, ensuring a steady and reliable fluid supply over extended periods. This pump excels in both low and high flow rate applications, making it a versatile choice for various industrial processes. Its robust design accommodates non-Newtonian fluids, broadening its applicability across different liquid types.

Featuring a 5-inch color touchscreen, the Gear Pump offers intuitive control, allowing for easy adjustments to ink delivery even during operation. The included computer interface provides comprehensive control and seamless data logging, enabling straightforward integration of multiple pumps for automated gradient and dilution experiments.

Applications:

Ink Dosage

Chemical Processing

Medical and Pharmaceutical Industries

Adhesive Dispensing

Food and Beverage Industry

Specifications:

Pump Type: Internal Gear Pump

Flow Rate: 0.05 - 288 ml/min

Max System Pressure: 8 bar (1160 psi)

Viscosity Range: 0.3 – 1000 mPas

Liquid Temperature Range: -5°C to 60°C

Particle Size: <10 μm

Key Features

5" Touch Screen for Easy Operation

Exceptional Resistance to Corrosion, Oxidizing and Reducing Media, Acids, and Bases

High dosage precision CV < 1 % at low volumes

Broad viscosity range

Low pulsation delivery, low shear stress rotary micro annular gear technology

High differential pressures achievable even for low viscosity liquids

Easy Maintenance

Adjustable flow rate by changing RPM

Compatible with the Laboratory Roll-to-Roll Coater

Setups Featuring the Gear Pump

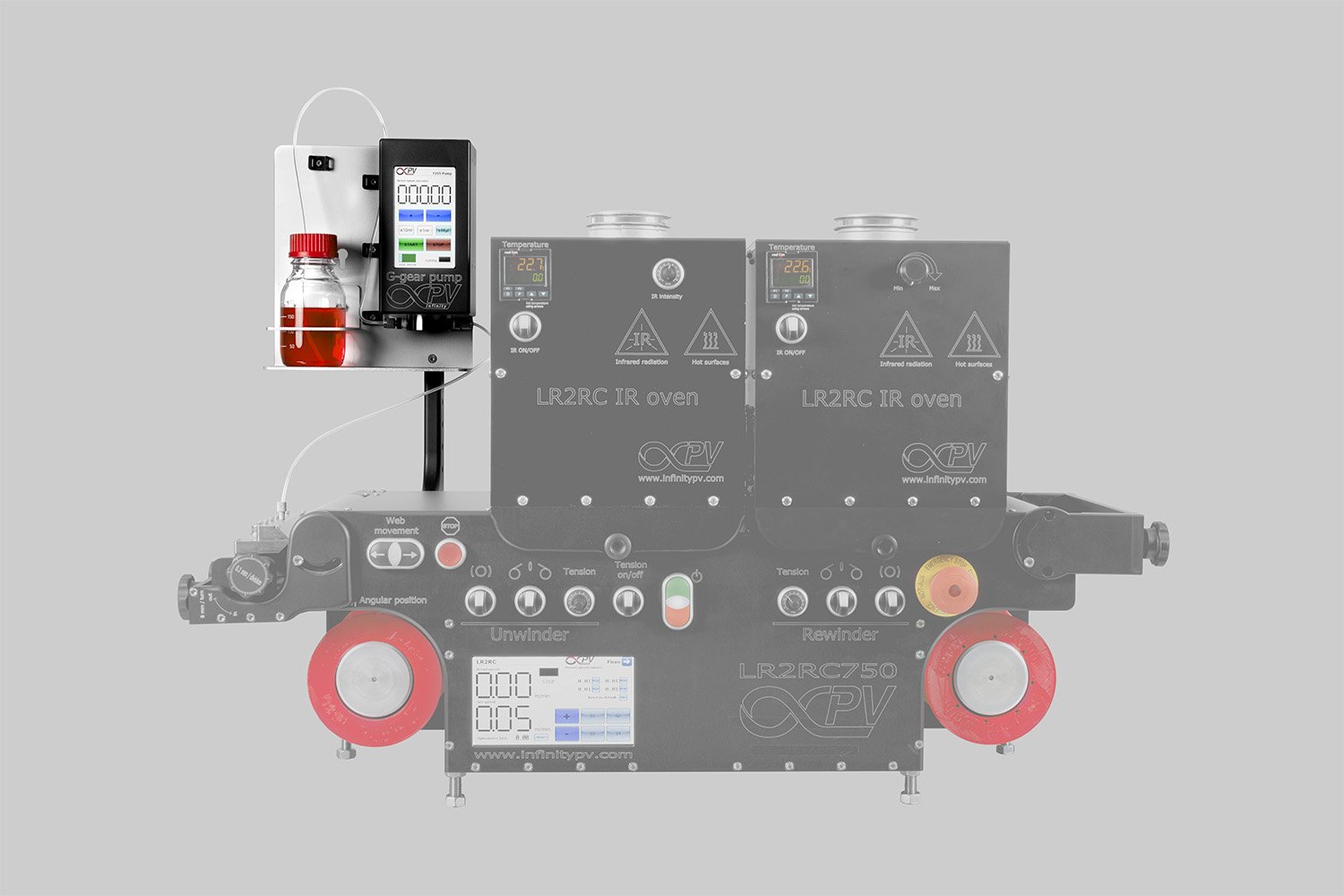

The Gear Pump mounted on an LR2RC750 platform featuring a Simple Mounting System, stainless steel Slot-die Head, two IR Ovens and Nip Roller.

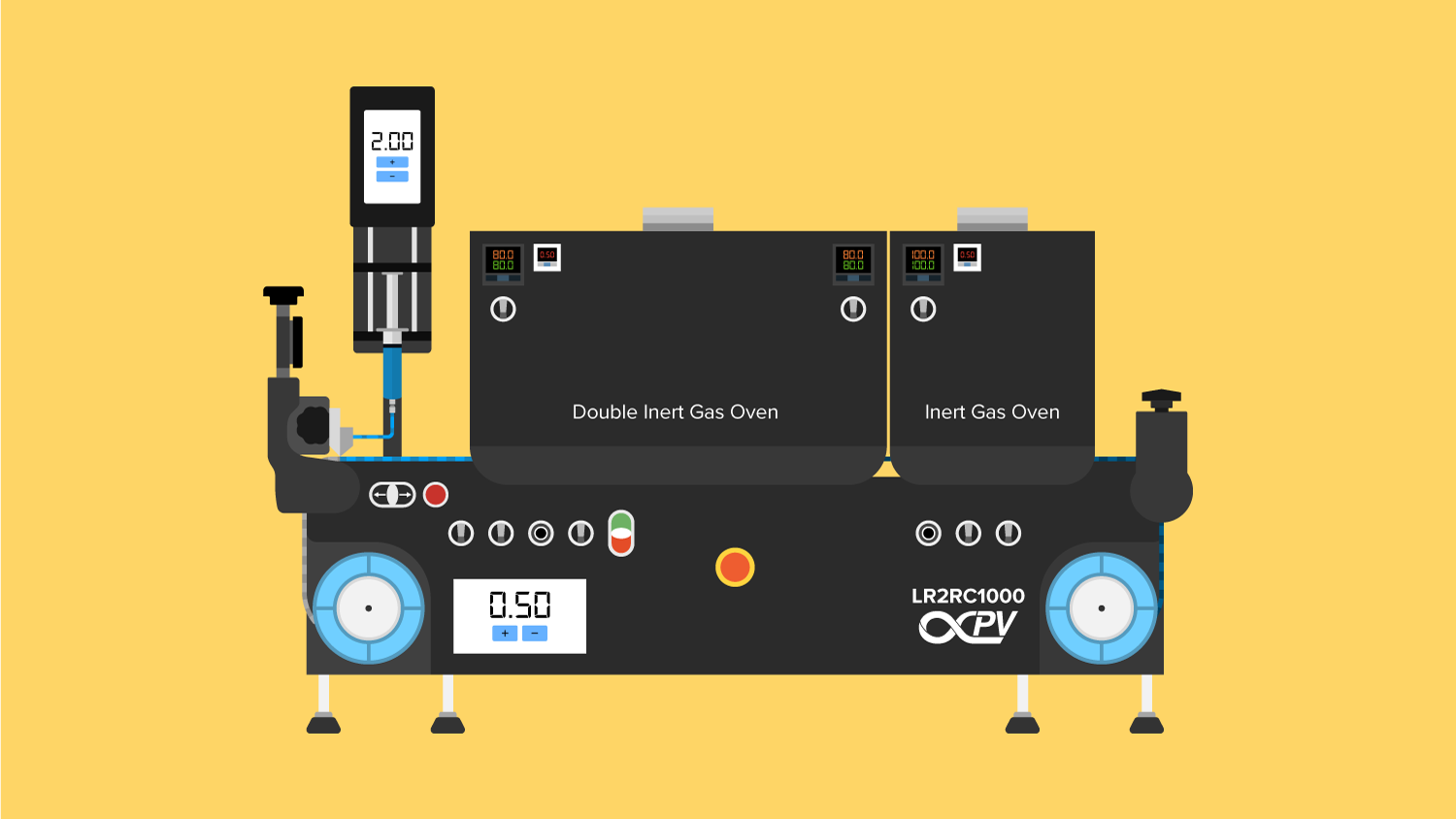

The Gear Pump mounted on an LR2RC1000 platform featuring an Advanced Mounting System, Snap Off and a Nip Roller.

Guide: How to Choose the Right Pump for Slot-Die Coating

Selecting the ideal pump for slot-die coating is essential to ensure precision and consistency. This guide explores different pump options, including syringe, gear, and peristaltic pumps, detailing how each supports efficient ink delivery for producing high-quality coatings in applications like solar cells, batteries, and printed electronics.

Download Brochure

Explore the capabilities of the Laboratory Roll-to-Roll Coater by downloading our detailed brochure. This document provides an in-depth overview of the coater’s customizable features, technical specifications, and broad range of applications. Discover how our advanced technology can enhance your research and production processes.

Video: What is the Laboratory Roll-to-Roll Coater?

The Laboratory Roll-to-Roll Coater is a compact, high-precision lab coater that transforms the way thin functional films are processed. It offers modular customization to fit different needs, scalable efficiency for small-scale production, and a user-friendly design with easy-to-remove components. Ideal for applications like batteries, fuel cells, and solar cells, it allows you to customize a system that’s perfect for your needs.

Probably the World’s Most Compact R2R Slot-die Coater

The LR2RC500 Bundle is a compact, fully integrated roll-to-roll coating platform for laboratories, complete with an advanced mounting system, anodized rollers, a jumbo syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.