What is Power-to-X? A Complete Guide to Renewable Energy Storage and Conversion

What is Power-to-X?

Power-to-X (often abbreviated as P2X) represents a transformative approach to energy production and utilization, bridging the gap between renewable energy generation and the demands of various sectors in the economy. As the world increasingly shifts towards sustainability and seeks to mitigate the impacts of climate change, Power-to-X technologies enable the conversion of surplus electricity—especially from renewable sources like wind and solar—into various energy carriers and chemical products.

This innovative process seeks not only to harness intermittent renewable resources but also to provide pathways for decarbonizing industries that have traditionally depended on fossil fuels. By creating hydrogen, synthetic natural gas (SNG), and a range of liquid fuels, Power-to-X plays a critical role in the transition to a circular economy. It serves as a key enabler of energy security, economic development, and environmental protection.

-

Power-to-X (often abbreviated as P2X) is a term used to describe various technologies that convert surplus electricity, especially from renewable sources like wind or solar, into other useful forms of energy or chemicals. The “X” can stand for different end products, such as hydrogen, synthetic natural gas (SNG), or even liquid fuels. Essentially, it’s a method of storing and using excess renewable electricity when there is more produced than consumed, helping to balance the power grid.

The concept of Power-to-X began gaining traction as renewable energy technologies evolved, particularly in the early 2000s. Countries with substantial investments in wind and solar power started exploring ways to store and utilize excess energy. The growth of Power-to-X technologies has been propelled by increasing awareness of green hydrogen's potential and advancements in electrolysis technology. Supportive policies and climate action plans have further stimulated development.

While Power-to-X technologies are still developing, the momentum towards their adoption is building. Growing recognition of the importance of green hydrogen and synthetic fuels in tackling climate change, combined with technological advancements and supportive policies, indicates a bright future for Power-to-X solutions. However, scaling these technologies to meet broader energy and climate goals will require continued collaboration, investment, and innovation across various sectors and regions.

Power-to-X explained in simple terms.

How Does Power-to-X Work?

Power-to-X technologies utilize renewable electricity to produce various energy products. A foundational technology in this process is electrolysis, where renewable electricity is used to split water (H₂O) into hydrogen (H₂) and oxygen (O₂). The hydrogen produced can be used directly as a clean fuel, in fuel cells, or as a building block for synthesizing other chemicals. This method plays a critical role in the transition to a circular economy and serves as a key enabler of energy security, economic development, and environmental protection.

-

Electrolysis is a process that uses electricity to break down a substance into its basic parts. It typically involves two electrodes—one positive (anode) and one negative (cathode)—placed in a liquid called an electrolyte. When electric current is applied, it causes chemical reactions at the electrodes. For example, in the electrolysis of water, electricity splits water into hydrogen and oxygen gases. This process is important for making clean hydrogen fuel, coating metals with other materials, and purifying metals, making it a key technology for producing energy in a sustainable way.

Electrolysers in Power-to-X Processes

Alkaline Electrolysers: They operate in an alkaline environment, typically using a dilute solution of potassium hydroxide (KOH) as the electrolyte. The key components of an alkaline electrolyser include an anode and cathode separated by an ion-conducting membrane. When a voltage is applied, water molecules at the cathode undergo reduction, resulting in the production of hydrogen gas, while at the anode, water is oxidized, producing oxygen. Alkaline electrolysers are known for their efficiency, scalability, and relatively low cost, making them a viable option for large-scale hydrogen production.

Proton Exchange Membrane (PEM) Electrolysers: Uses a solid polymer electrolyte and operates at higher pressures and efficiencies. PEM electrolysers are known for their high efficiency, rapid response times, and ability to operate at high current densities, which makes them suitable for integration with renewable energy sources like solar and wind. Their compact design and modularity allow for versatile deployment in applications ranging from small-scale hydrogen production to large industrial systems, supporting the transition to a hydrogen economy.

Anion Exchange Membrane (AEM) Electrolysers: AEM electrolysers combine some of the advantages of both alkaline and Proton Exchange Membrane (PEM) technologies, such as the use of non-precious metal catalysts and the potential for high efficiency and lower costs. These electrolysers are particularly attractive for renewable energy integration and hydrogen production, as they can operate under a range of conditions and hold promise for scalable and sustainable hydrogen generation.

Electrolysis the Feedstock for Other Processes: The hydrogen produced through electrolysis can serve as a building block for further chemical synthesis in various PtX pathways. It can be combined with carbon dioxide in processes like methanation to produce methane (Power-to-Gas), or with nitrogen to produce ammonia (Power-to-Ammonia). These products can be utilized as fuels, chemicals, or even stored for later use. Electrolysers serve as the core technology in Power-to-X (PtX) systems, as they are essential for producing green hydrogen from renewable energy sources. This hydrogen acts as a versatile energy carrier that can be utilized in various PtX applications.

-

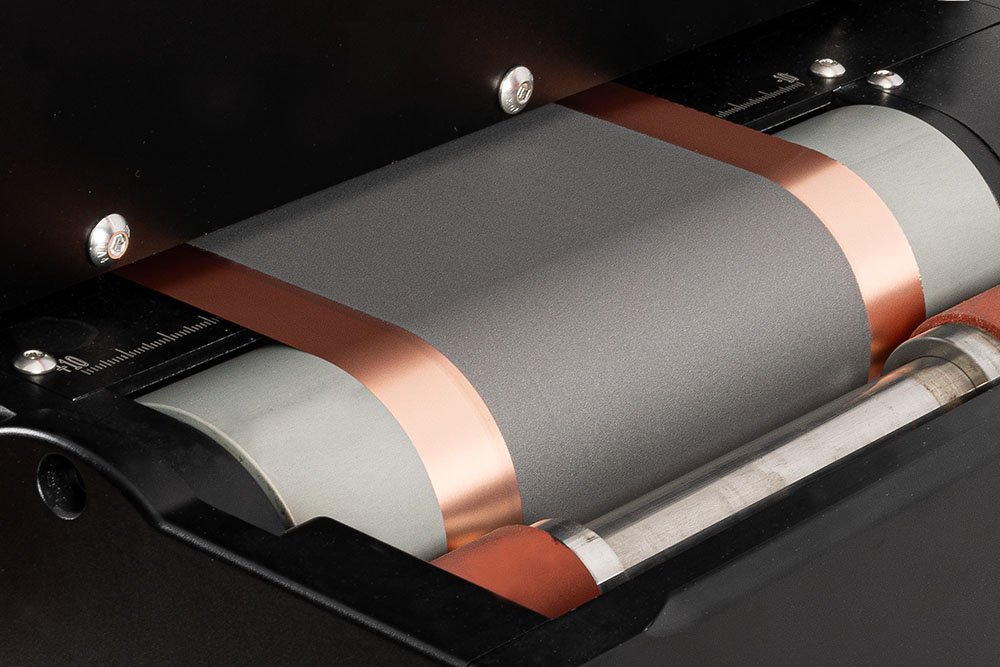

Slot-die Coating of Electrolysers Slot-die coating is often used to apply catalyst layers onto the electrodes of electrolysers. By ensuring a consistent distribution of active materials, it enhances the electrochemical performance and efficiency of the electrodes. This is crucial as the quality and uniformity of the catalyst layer can significantly affect the overall performance of the electrolysis system, including reaction kinetics and gas generation rates. Additionally, slot-die coating allows for scalable production processes that can meet the demands of industrial applications while minimizing material waste. The technique is compatible with various materials, including inks or slurries containing catalysts or other functional additives, making it a versatile option in the fabrication of electrolysis components. This technology helps advance the development of more efficient and cost-effective hydrogen production technologies.

Slot-die coating is used to apply catalyst layers onto the electrodes of electrolysers, ensuring uniform distribution that enhances their electrochemical performance and efficiency.

Applications and Examples of Power-to-X Technology

The applications of Power-to-X are diverse and impactful, spanning across multiple industries, including transportation, heating, and chemical production. From producing green hydrogen for fuel cells to creating synthetic fuels and chemicals, these technologies play a crucial role in decarbonizing traditionally fossil fuel-dependent sectors. In this section, we will explore the key applications of Power-to-X technologies, highlighting how they contribute to energy security, environmental protection, and economic development in the quest for a more sustainable and resilient future.

Power-to-Gas (PtG): In Power-to-Gas (PtG) processes, the hydrogen generated from electrolysis is combined with carbon dioxide (CO₂) captured from the atmosphere or industrial processes through methanation to produce synthetic natural gas (SNG) in the form of methane (CH₄), which can then be injected into existing natural gas grids, used for heating, or served as a fuel for vehicles, effectively helping to store excess renewable energy in the form of gas that can be fed into existing natural gas pipelines.

Power-to-Liquid (PtL): Power-to-Liquid (PtL) technologies refer to a set of processes that convert renewable electricity into liquid fuels, primarily by synthesizing hydrocarbons or alcohols from carbon dioxide and water. This transformation involves using electrolyzers to split water into hydrogen and then combining this hydrogen with captured carbon dioxide through chemical reactions, such as the Fischer-Tropsch synthesis, to produce synthetic fuels like synthetic gasoline, diesel, or kerosene. PtL technologies leverage excess renewable energy, particularly from sources like wind and solar, to address energy storage challenges and create sustainable alternatives to conventional fossil fuels. These liquid fuels can be used in existing infrastructure, including transportation and heating, thus providing a versatile solution for reducing greenhouse gas emissions and improving energy security while facilitating the transition to a carbon-neutral economy.

Power-to-Chemicals (PtC): This technology focuses on producing chemical feedstocks from renewable energy. PtC processes can utilize hydrogen derived from electrolysis to create various chemicals, such as ammonia via the Haber-Bosch process. Ammonia can further be transformed into fertilizers or converted to hydrogen or other chemicals.

Power-to-Heat (PtH): Though less emphasized, PtH technologies convert surplus renewable electricity into heat, which can be used for district heating systems or industrial processes. This can be achieved using electric boilers or heat pumps, providing a way to utilize excess power that might otherwise be wasted.

Power-to-Hydrogen (P2H): This process involves using renewable electricity to split water (H₂O) into hydrogen (H₂) and oxygen (O₂) through electrolysis.

Power-to-Ammonia:This process utilizes renewable hydrogen and nitrogen from the air to produce ammonia, a critical component for fertilizers.

Power-to-Carbon: This emerging area focuses on converting renewable electricity into solid carbon products, which can be used in various industrial applications.

Hydrogen Storage Technologies for Power-to-X:

Hydrogen storage technologies are closely connected to Power-to-X as they play a crucial role in the effective use, distribution, and application of hydrogen produced from renewable energy sources. As hydrogen is a key output of several Power-to-X processes (such as electrolysis), efficient storage solutions are necessary for maximizing the benefits of hydrogen in the energy system.

Compressed Hydrogen Storage: Storing hydrogen in high-pressure tanks.

Liquid Hydrogen Storage: Cooling hydrogen to very low temperatures to liquefy it for storage.

Metal Hydrides or Chemical Hydrides: Storing hydrogen in solid materials, which can release hydrogen upon heating.

The above-mentioned technologies, often interconnected, form the backbone of the Power-to-X framework, allowing for the flexibility and adaptability necessary to transition to a low-carbon future. By facilitating the conversion of renewable energy into various usable forms, power-to-x plays a critical role in decarbonizing multiple sectors of the economy.

Conclusion: The Vital Role of Power-to-X in Energy Transition

Power-to-X technologies represent a groundbreaking approach to harnessing and utilizing renewable energy, offering transformative solutions for a sustainable future. By converting excess renewable electricity into versatile energy carriers and chemical products, Power-to-X not only addresses the challenges posed by intermittent energy sources but also plays a critical role in decarbonizing various sectors of the economy.

From producing green hydrogen and synthetic natural gas to creating sustainable liquid fuels and chemicals, the applications of Power-to-X are diverse and impactful, driving the transition to a circular economy. As we move toward a low-carbon future, the integration of these technologies will be essential in meeting global energy demands while reducing greenhouse gas emissions.

Despite the challenges ahead, including scaling up these technologies and ensuring supportive policies, the potential of Power-to-X to enhance energy security, foster economic development, and protect the environment is undeniable. By continuing to innovate and collaborate across sectors, Power-to-X can emerge as a cornerstone of the energy landscape, paving the way for a more sustainable and resilient future. Embracing these advancements is not just an option; it is imperative for addressing the pressing challenges of climate change and ensuring a cleaner, greener world for generations to come.

Learn More About Power-to-X

Daiyan, Rahman, Iain MacGill, and Rose Amal. "Opportunities and Challenges for Renewable Power-to-X." ACS Energy Letters, vol. 5, no. 12, 2020, pp. 3843-3847. doi:10.1021/acsenergylett.0c02249.

Palys, Matthew J., and Prodromos Daoutidis. "Power-to-X: A Review and Perspective." Computers & Chemical Engineering, vol. 165, 2022, 107948. ISSN 0098-1354. doi:10.1016/j.compchemeng.2022.107948.

Dahiru, Ahmed Rufai, Ari Vuokila, and Mika Huuhtanen. "Recent Development in Power-to-X: Part I - A Review on Techno-Economic Analysis." Journal of Energy Storage, vol. 56, Part A, 2022, 105861. ISSN 2352-152X. doi:10.1016/j.est.2022.105861.

Related Articles

Roll-to-Roll Manufacturing of Batteries: A Revolution in Energy Storage

As the demand for renewable energy solutions and portable electronic devices grows, the need for efficient and scalable battery manufacturing processes has never been more critical.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

Slot-die Heads

Slot-die heads for high-quality coatings. Available in stainless steel, titanium, or PEEK, with widths from 40 mm to 305 mm, ensuring precise thin-film production.