What Are Solar Cells and How Do They Work?

Solar cells, or Photovoltaics (PVs), convert light directly into electricity. What makes this technology groundbreaking is not only that it transforms light into energy but also how it has changed our perspective on energy production and its integration into society. Humankind is tied to energy resources, from rural homes to broadcast towers in remote areas. Solar cells have sparked the idea of small scale off grid electricity generation, instead of relying on centralized distribution. Ideally, it is possible to get all necessary power from solar energy without needing a connection to the power grid.

Figure 1. Solar Energy Distribution to Various Applications

Basic Principle: Converting Light into Electricity

The conversion of light into a form of energy is not an unfamiliar concept, as it mirrors the process of photosynthesis. Where photosynthesis use the energy of light, to drive electrochemical reactions, a solar cell device uses the energy to generate charges when exposed to light – charges that can be extracted to generate electrical power.

A basic solar cell consists of a semiconductor material sandwiched between two electrodes, one for positive charges (holes) and the other for negative charges (electrons). Additional layers can be included to improve efficiency and stability. The working principle of a simple solar cell device involves:

Absorption of incident light and the creation of excited charge carriers.

Collection of holes and electrons at positive and negative electrodes

Generation of electricity via separated charges flowing through an external circuit.

Figure 2. How Solar Panels Generate Electricity

The process of generating electric current from light is called the photovoltaic effect. Electrons and holes are typical charge carriers, free to move when they have sufficient energy and a driving force. This movement requires semiconductors, which can be made of materials such as silicon, perovskites, or organic compounds.

-

Semiconductors are materials that exhibit conductive properties between that of a conductor (e.g. copper) and that of an insulator (e.g. glass). Semiconductors are used in a variety of electronic components such as diodes, transistors and solar cells. In such components/devices the advantage of doping the semiconductors are employed, giving the semiconductors unique properties to facilitate or block the transport of electrons and holes under various conditions. A diode acts like a one-way gate for electric current, while a transistor serves as a switch or amplifier, both relying on the specialized behavior of semiconductors. A solar cell has diode like properties.

In silicon solar cells doping of one side facilitates the transport of electrons and the other the transport of holes, and it is thus the doping of silicon that drives the extraction of charges in a silicon solar cell.

Similar architectures, although achieved by different means, are the driving force for all solar cells – the goal is to set up a configuration where electrons and holes are created upon exposure to light, and then having one side of the cell being preferable to transport of electrons and the other side preferable to transport of holes.

Types and Generations of Solar Cells

Engineering semiconductors to harness sunlight efficiently is the key factor for the photovoltaic technology. Semiconductors are materials that fall between electrical insulators and conductors. They can be single elements or compounds, and their conductivity can be modified, creating immense potential for different applications. The most used semiconductor in solar cell technology is silicon, but solar cells can also be made from organic materials or a combination of inorganic elements such as gallium arsenide or cadmium telluride. As solar cell research/technology has evolved, the discovery of new semiconductor materials for solar cells and new ways of manufacturing have emerged. The evolvement is typically looked upon as 3 “generations” of solar cells, each with their own special focus, strengths and tradeoffs.

1st Generation: Crystalline (single or multi-) Silicon Solar Cells (c-Si)

2nd Generation: Thin-Film Solar Cells (CdTe, GaAs, amorphous Silicon)

3rd Generation: Organic Solar Cells, Perovskite Solar Cells, Dye-Sensitized Solar Cells, Quantum Dot Solar Cells and Tandem Solar Cells

So far the market leader is the first generation silicon solar cells with 97% of production where the second generation thin film based solar cells follow as second, with 2,5%. Most of the third-generation solar cell types such as perovskite solar cells and organic solar cells are still in the research stage. From research laboratories to commercial applications, there are many factors like cost, environmental impact or physical attributes that play an important role for both society and application potential. Figure 3 gives an overview of the 3 generations.

Figure 3. Generations of Solar Cells. Adapted and redrawn based on (Davis, 2024)

1st Generation:

First generation solar cells are based on silicon wafers, mainly using monocrystalline or multi-crystalline silicon. Single crystalline silicon (c-Si) solar cells as the most common, known for their high efficiency (~27% research record) and long-term durability. On the downside they are energy-intensive to manufacture, sensitive to purity and defects, the wafers are brittle, and the final panels are heavy to handle.

2nd Generation:

Second generation of solar cells are based on thin film application, easing the work with different substrates such as plastic. Thin-film solar cells, like amorphous silicon (a-Si), cadmium telluride (CdTe) and copper indium gallium selenide (CIGS), are lightweight and flexible, which offers variety of applications such as operations in space, though they typically offer lower efficiencies (~23% research record) and shorter lifetimes. While they require fewer raw materials and less energy for production, CdTe contains toxic cadmium, raising concerns about disposal, and CIGS uses scarce elements like indium and gallium, which have environmental costs associated with mining.

With the sheet based Slot-die Coater, it is easy to make solar cells.

3rd Generation:

Third generation solar cells are driven by the goal of lowering cost through new materials, lowering production energy and fast manufacturing methods such as roll-to-roll processing. Among the advanced materials can be mentioned organic compounds, dye-sensitized or perovskites. These materials can be designed to reach certain aspects for better efficiency or stability at potentially low costs. They offer versatility in terms of tunability, and light absorption compared to silicon solar cells. Organic solar cells (OSCs) are carbon-based, lightweight and flexible, but they currently have lower efficiencies (up to 19% on research) and shorter lifetimes making them hard to commercialize. Perovskite solar cells are rapidly improving, with efficiencies exceeding 26% on research, and are cost-effective to produce. But, as organic solar cells, they face challenges with stability and they furthermore have potential negative environmental issues related to the fact that they contain lead. Dye sensitized solar cells use light-absorbing dye molecules to convert light into electricity with low-cost and flexible advantages. However, their efficiencies (~13% research record) are still not suitable for commercialization. Quantum dot solar cells share similarities with dye sensitized solar cells in structure and it is also low cost in production. They have achieved remarkable efficiency (~19% research record), however low light absorption is a significant problem.

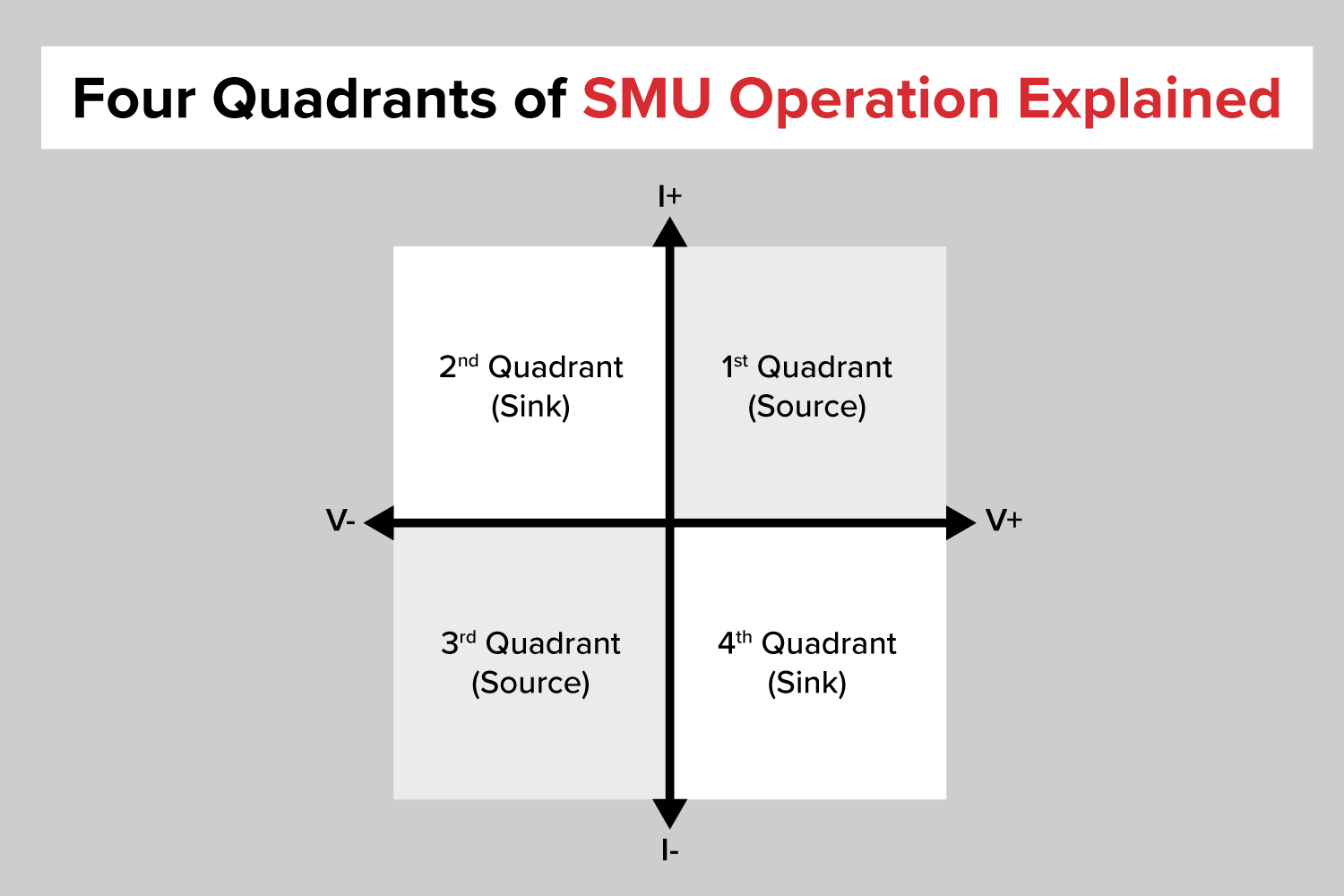

How to test solar cells using a source measure unit and solar simulator.

Lastly, the concept of tandem solar cells is very interesting, as they can combine different technologies into one by stacking multiple layers, that each function as individual solar cells which absorb different regions of light in the solar spectrum, thereby boosting overall efficiency since more light can be absorbed. These layers can be made of different materials such as silicon, organic or perovskite compounds, to complement each other’s properties.

Conclusion

As solar cell technologies continue to evolve, they will create new potentials of how we produce and use energy in a fundamental way. From a currently silicon dominated market to emerging third-generation innovations, the future of solar cells looks promising. Improvements in key factors such as efficiency, stability and sustainability are essential to realize their full potential. If these advancements remain on track, solar energy might not only satisfy our increasing energy needs but also lead us to a cleaner and more sustainable future.

Learn More About Solar Cells:

Akinoglu, B. G., Tuncel, B., & Badescu, V. (2021). Beyond 3rd generation solar cells and the full spectrum project. Recent advances and new emerging solar cells. Sustainable Energy Technologies and Assessments, 46, 101287.

Luque, A., & Hegedus, S. (Eds.). (2011). Handbook of photovoltaic science and engineering. John Wiley & Sons. (APA style)

Pastuszak, J., & Węgierek, P. (2022). Photovoltaic cell generations and current research directions for their development. Materials, 15(16), 5542.

About the Author

Ümran Işıl Biçer is a Marie Curie PhD fellow at infinityPV, contributing to the Marie Skłodowska-Curie EIFFEL project. She received her bachelor’s degree from Middle East Technical University in Turkey and completed her master’s through the Erasmus Mundus MaMaSELF program, studying at Ludwig Maximilian University of Munich and the University of Montpellier, with her thesis conducted at the University of Helsinki. She is pursuing a PhD in the development of non-fullerene acceptors for organic solar cells, focusing on scalable roll-to-roll printing methods to improve solar cell efficiency and stability.

Compact solar simulator (390–700 nm) with six tunable LEDs, Class A uniformity, and excellent temporal stability. Ideal for small to medium solar cells and controlled illumination experiments.