Slurry Coater

Precision Slurry Coating for Next-Generation Thin Films: Consistent Quality, Uniform Application.

Slurry Coating for Advanced Thin Film Production

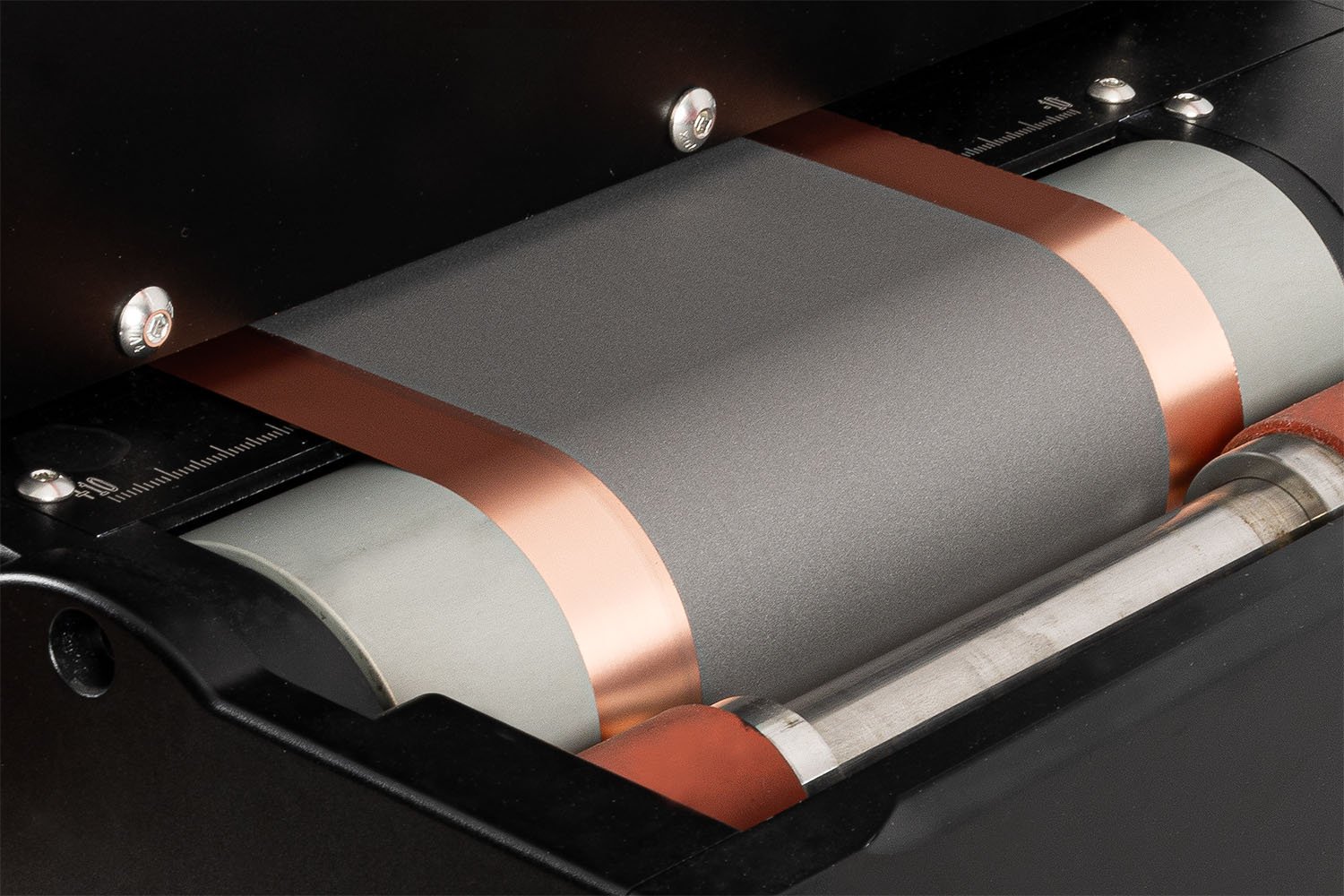

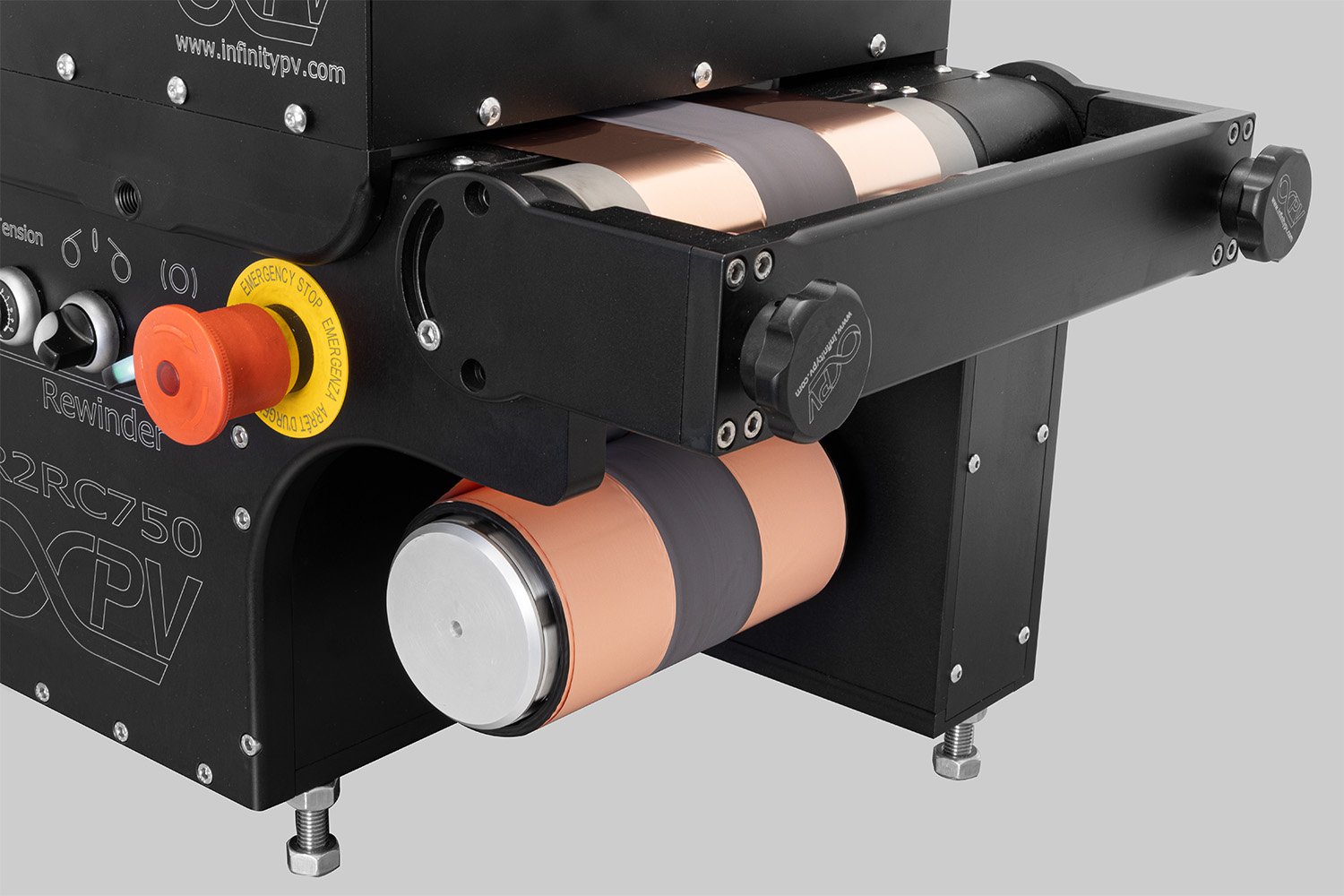

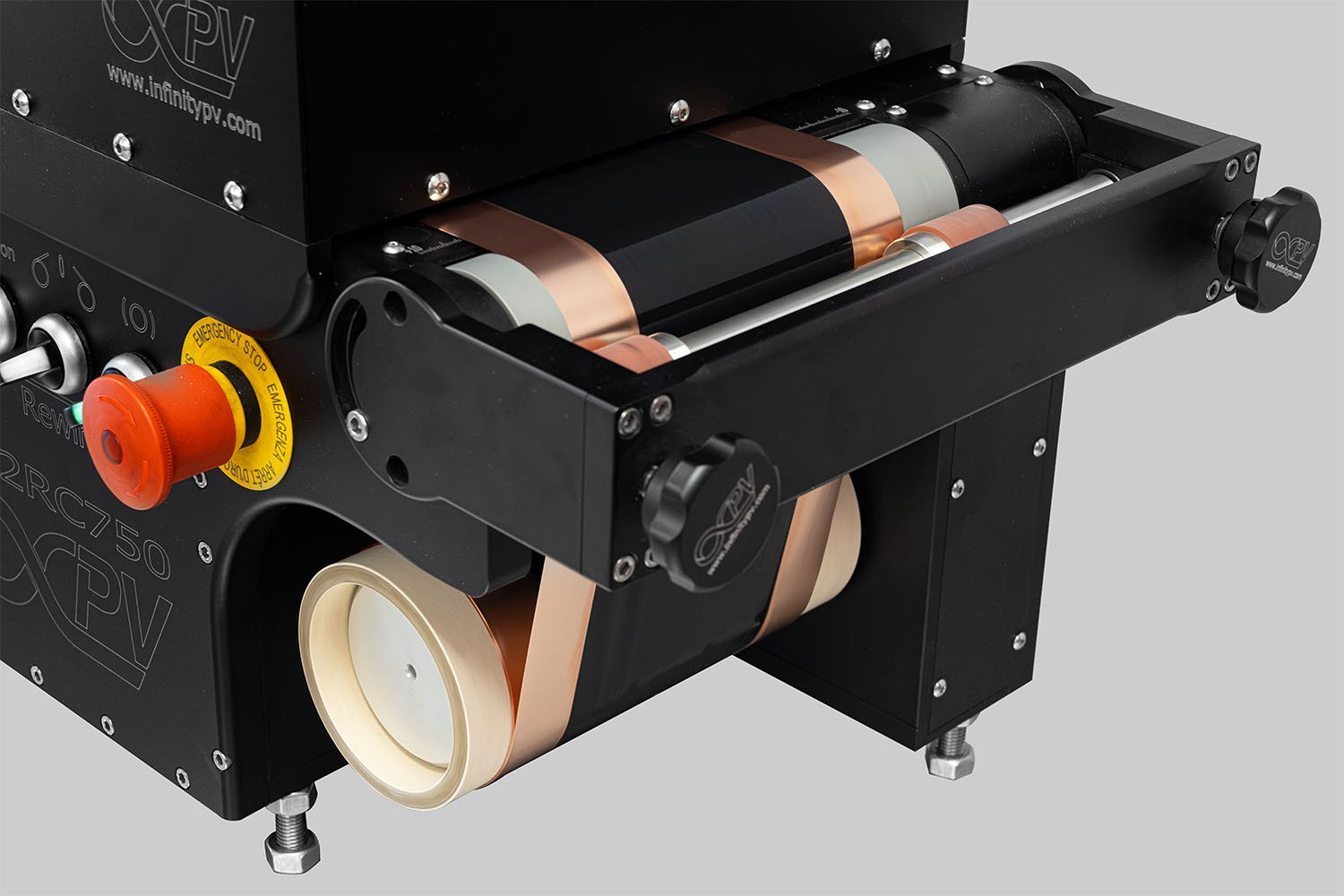

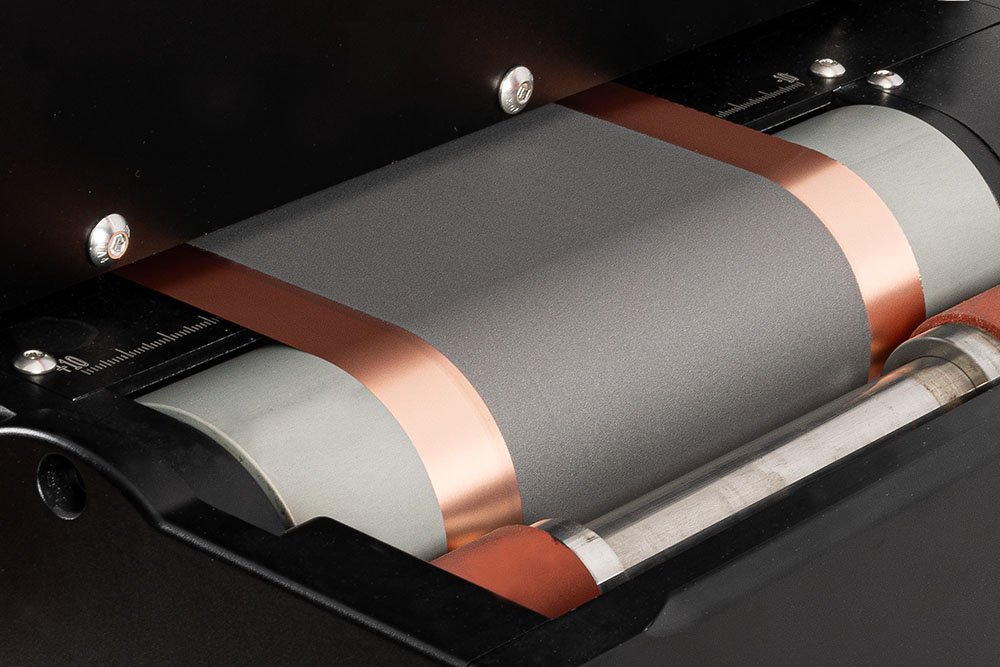

The Slurry Coater is a fundamental wet film forming tool for the Laboratory Roll-to-Roll Coater platform, enabling lab scale production of advanced functional thin films. This includes thin film batteries, fuel cells and printed solar cells. The Slurry Coater is used for applying a viscous mixture (ideal for non-newtonian liquids and suspensions) in the form of a slurry, accurately and uniformly, onto a substrate, ensuring consistent quality and performance. With continuous mixing of the slurry during processing, accomplished as the coating takes place over the backing roller of the Laboratory Roll-to-Roll Coater, sedimentation of particles in the ink is prevented. Dosing of ink can be controlled via the Laboratory Roll-to-Roll Coater pumping systems and it is possible to keep the ink under inert conditions.

Key Features

Designed for Slurry Coating

Made from POM and Stainless Steel (316L)

100 mm Coating Width

Works With Thin Substrates (5-25 um)

Simple Adjustment of the Substrate - Knife Gap

Precise Ink Delivery from the Laboratory Roll-to-Roll Coater Pumping System

Option for Inert Conditions

Slurry Coater for Uniform Lab-Scale Wet Film Coating

How Does the Slurry Coater Work?

The Slurry Coater is a fundamental wet film forming tool for the Laboratory Roll-to-Roll Coater platform enabling lab scale production of advanced functional thin films.

With its modular oven systems, the Laboratory Roll-to-Roll Coater secure efficient drying of the processed thin films using hot-air, inert gas, infrared or UV-curing.

Slurry Coating vs. Slot-die Coating

The slurry coater offers efficient coating with non-newtonian inks and inks with particles that may have a high density and a tendency to sediment through its simple technology. In contrast the slot-die coating provides a versatile and scalable solution. The slurry coater excels in uniform coating application for slurries, ideal for industries requiring consistency. On the other hand, slot-die coating offers flexibility and control, making it suitable for applications where varying thickness and materials are needed.

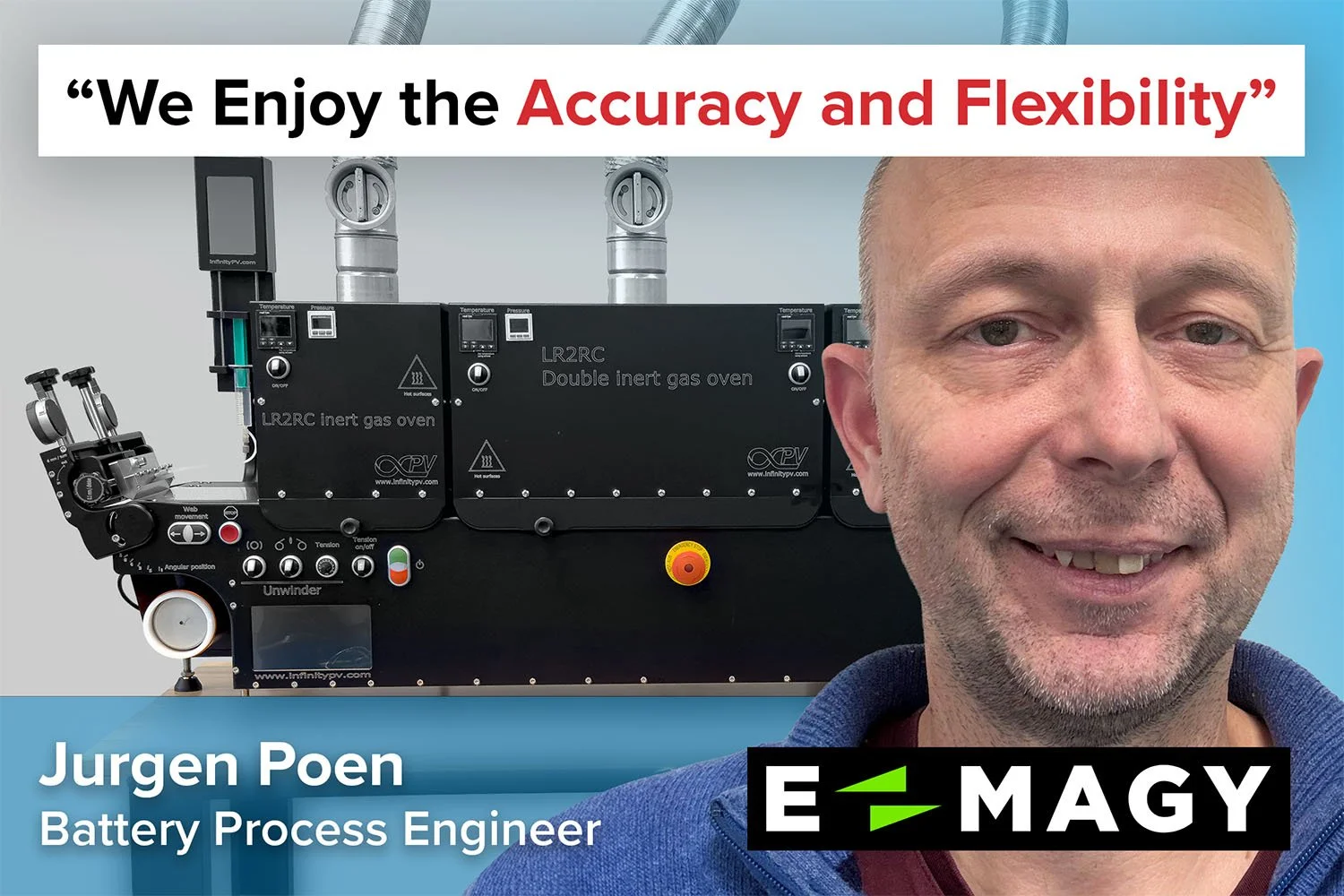

We Are Trusted by the World’s Top Scientists

Build Your Own R2R Lab Coater

With its modular design, the Laboratory Roll-to-Roll Coater empowers you to customize your system with the components you need. Choose between slot-die heads, slurry coaters, air knives, ovens, knife cutters, laminators, laser systems and more.

Related Products

Laboratory Roll-To-Roll Coater

A compact high precision laboratory roll-to-roll coating machine that transforms the way thin functional films are printed and coated.

Syringe Pumps

Discover the precision and versatility of infinityPV syringe pumps, engineered to seamlessly integrate into our cutting-edge coating and printing equipment.