What Are Organic Batteries? A Sustainable Alternative Explained

As the world pivots toward renewable energy and cleaner technologies, the demand for sustainable energy storage solutions continues to grow. One emerging contender in this field is organic batteries, a promising innovation offering sustainability, efficiency, and flexibility. These batteries, built from carbon-based compounds, stand to disrupt traditional energy storage by reducing reliance on scarce or toxic materials. This article explores the fundamentals of organic batteries, their working principles, benefits, challenges, and future outlook.

What Are Organic Batteries?

Organic batteries are electrochemical storage devices that rely primarily on organic (carbon-based) molecules instead of traditional metals such as lithium, cobalt, or nickel. These organic compounds are often derived from abundant sources, including biomass or synthetic chemistry, making them far more sustainable in origin and disposal. Organic batteries make use of organic compounds – primarily carbon-based materials – as the active components in electrochemical reactions that generate electrical energy. Unlike traditional batteries, which often rely on scarce metals and heavy metals like lithium and cobalt, organic batteries utilize abundant organic materials, making them a more sustainable and environmentally friendly option

How Do Organic Batteries Work?

The operation of organic batteries is similar to that of conventional batteries, involving electrochemical reactions between an anode and a cathode. When charged, the anode (negative electrode) undergoes oxidation, losing electrons, while the cathode (positive electrode) experiences reduction, gaining electrons. This flow of electrons generates electrical energy that can be harnessed for use. Meanwhile, ions migrate through the electrolyte, which may be a liquid, gel, or solid, to maintain charge balance during the process. Upon discharge, the reverse reactions occur, allowing the stored energy to be released. The composition and configuration of the organic materials can be tailored to enhance performance, providing a sustainable alternative to traditional batteries.

Key Components of Organic Batteries Include:

Cathode: Common organic cathode materials include quinones, conductive polymers (like polyaniline), and organic dyes (like anthraquinone). The reduction process typically involves the reversible acceptance of electrons and protons, leading to the formation of stable intermediates that can facilitate charge storage.

Anode: Organic anodes often comprise materials like lithium organic compounds, such as lithium-coupled redox-active organic compounds. The anode's oxidation during discharge involves the loss of electrons and can be coupled with lithium intercalation/extraction processes.

Electrolytes: Electrolytes in organic batteries can be composed of ionic liquids, gel electrolytes, or organic solvents containing lithium salts. The choice of electrolyte affects ionic conductivity, stability, and operational voltage. Ionic liquids often have high thermal stability and low volatility, enhancing battery safety while maintaining a wide electrochemical stability window.

Composite Materials: Researchers increasingly explore composite materials that combine organic substances with traditional conductive materials, enhancing overall performance.

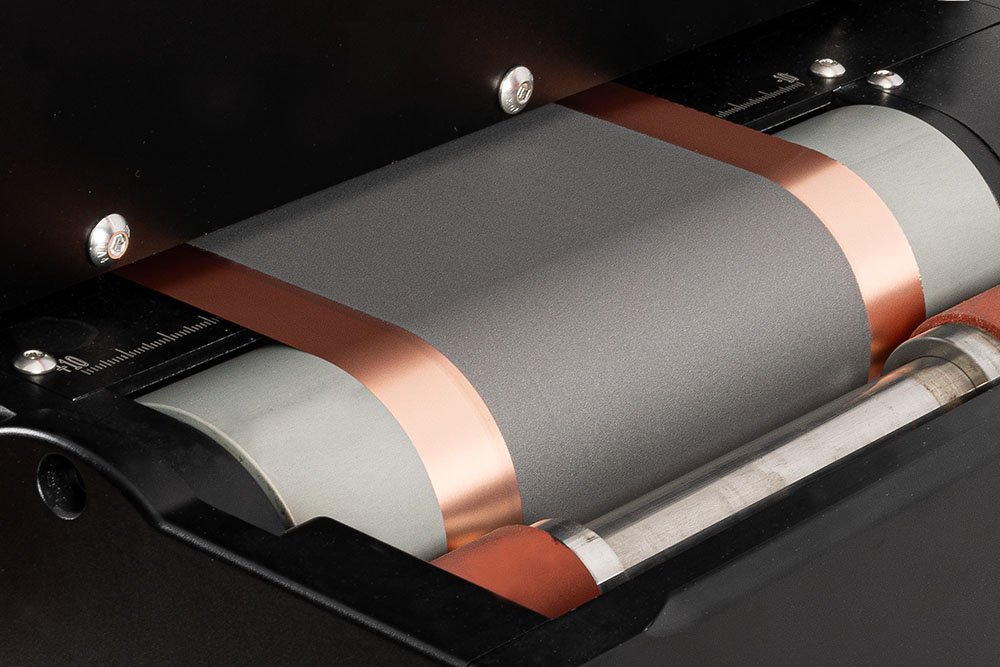

The Laboratory Roll-to-Roll Coater is the ideal coating machine for scaling up to roll-to-roll processing of battery electrode materials or for testing and optimizing battery electrode slurries.

Benefits of Organic Batteries

One of the most compelling reasons for the development of organic batteries is their sustainability. Traditional batteries not only rely on finite raw materials, but also produce toxic waste. In contrast, organic batteries shift the paradigm toward clean, recyclable energy storage.

Sustainability: Organic materials are often derived from renewable resources, making organic batteries a more sustainable choice compared to traditional options. They can potentially reduce reliance on finite resources and heavy metals that can harm the environment.

Environmental Safety: Organic batteries generally pose less risk of pollution and environmental damage, as their components are less toxic and can be more easily disposed of or recycled.

Cost-Effectiveness: While still in development, the utilization of abundant organic materials may lead to reduced manufacturing costs in the long term. This affordability can accelerate the adoption of organic batteries across diverse industries.

Higher Energy Density: Some organic batteries have been shown to provide higher energy density compared to traditional lithium-ion batteries, meaning they can store more energy in a smaller volume.

Current Challenges

Despite the promising advantages, organic batteries are still in the early stages of development and face several challenges:

Performance Issues: Many organic materials may not yet have the same performance characteristics as traditional battery materials, particularly in terms of cycling stability and energy density.

Longevity and Durability: Research is ongoing to enhance the lifespan and reliability of organic batteries in comparison to well-established alternatives.

Market Readiness: While progress is being made, widespread commercialization of organic batteries is still a work in progress, requiring further research and development.

As a result, most organic battery research is still at the laboratory or pilot scale, although significant advancements are being reported regularly

The Road Ahead

The potential for organic batteries is vast, with ongoing research aiming to tackle the current limitations. Collaboration between academic institutions, industry leaders, and startups is essential in transforming the concept of organic batteries into a viable product. For businesses looking to stay ahead of the curve, investing in the development of organic battery technologies could prove beneficial. Not only would this align with the growing demand for sustainable solutions, but it also opens up a range of opportunities for innovation and market differentiation

Emerging applications include:

Grid-level energy storage for renewable sources like solar and wind

Flexible electronics and wearable tech

Smart packaging and disposable IoT sensors

Low-cost backup power for rural or off-grid communities

Investing in organic battery R&D could position companies at the forefront of next-generation energy solutions. It’s not just about environmental impact; it’s also about future-proofing against market and regulatory shifts.

Conclusion

Organic batteries represent a significant advancement in energy storage technology. As research continues and hurdles are addressed, these alternatives poised to revolutionize the way we think about power and energy storage could transform more than just personal electronics; they could redefine entire industries. At Infinity PV, we are at the forefront of renewable energy solutions and are excited about the opportunities that organic batteries present for a sustainable future.

The Slot-die Coater is an excellent choice for researchers focused on developing and optimizing battery electrode slurries at the laboratory scale.

Get Professional Support for Your Battery Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Articles

What are Supercapacitors?

Supercapacitors, also known as ultra-capacitors or electric double-layer capacitors (EDLCs), are energy storage devices that have a higher capacitance than traditional capacitors.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater. A compact, fully integrated R2R coater that fits on a workbench, in a fume hood or a glovebox.