What are Supercapacitors?

Supercapacitors, also known as ultra-capacitors or electric double-layer capacitors (EDLCs), are energy storage devices that have a higher capacitance than traditional capacitors. They are capable of storing and discharging energy quickly, making them suitable for applications that require rapid bursts of energy or quick charge and discharge cycles.

How Do Supercapacitors Work?

Supercapacitors operate by storing electrical energy through the separation of charges within their structure, which consists of two electrodes, an electrolyte, and a separator. When a voltage is applied, positive and negative ions in the electrolyte migrate to the oppositely charged electrodes, forming an electric double layer at each electrode surface. This separation of charge creates an electric field that stores energy. Supercapacitors can also utilize pseudocapacitance, where electrochemical reactions enhance charge storage by allowing ions to interact more effectively with the electrode materials. The rapid movement of ions enables supercapacitors to charge and discharge quickly, providing high power density and long cycle life, making them ideal for applications that require quick bursts of energy, such as in electric vehicles, renewable energy systems, and consumer electronics.

-

Capacitors are passive electronic components that store electrical energy in an electric field. They consist of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field develops, and charge accumulates on the plates, allowing the capacitor to store energy.

Supercapacitors vs. Lithium-ion Batteries

Supercapacitors works in some ways just as a battery, but Supercapacitors and for example lithium-ion batteries differ in several key aspects related to their energy storage capabilities and operational characteristics. Supercapacitors excel in power density, allowing for rapid charge and discharge cycles, which makes them ideal for applications requiring quick bursts of energy, such as in regenerative braking systems or fast charging scenarios. In contrast, lithium-ion batteries offer higher energy density, enabling them to store more energy in a smaller volume, which is preferable for applications requiring sustained energy output, such as powering electric vehicles and portable electronics. Additionally, supercapacitors have a much longer cycle life, often exceeding a million charge/discharge cycles with limited degradation, while lithium-ion batteries typically last for several thousand cycles before their capacity diminishes significantly. However, lithium-ion batteries operate at higher voltages and generally provide a more stable energy output over time, making them better suited for longer-term energy storage. Overall, the choice between supercapacitors and lithium-ion batteries depends on the specific application requirements regarding power, energy capacity, cycle life, and cost.

Undecided with Matt Ferrell: Supercapacitors explained - the future of energy storage?

Applications of Supercapacitors

Supercapacitors are used in a wide array of applications due to their ability to deliver and store energy rapidly. In the transportation sector, they power hybrid and electric vehicles by assisting with regenerative braking and providing quick acceleration boosts. In renewable energy systems, supercapacitors help stabilize electrical grids and store excess energy from sources like solar and wind for quick release. They are also found in consumer electronics, offering fast charging and backup power for devices such as smartphones and cameras. Additionally, supercapacitors play a critical role in industrial applications, telecommunications, medical devices, electric bikes, and smart grid technologies, where quick bursts of energy or reliable backup power are essential. Their versatility and efficiency make them valuable in various technological domains.

Automotive: In hybrid and electric vehicles, supercapacitors are used for regenerative braking systems to capture and store energy that can be released during acceleration.

Electronics: They provide backup power for electronic devices, ensuring reliable operation during short power interruptions.

Renewable Energy: Supercapacitors are employed in energy storage systems to stabilize power supply from intermittent sources like wind and solar.

Industrial: They are used in applications requiring rapid bursts of power, such as in elevators, cranes, and uninterruptible power supplies (UPS).

Development of Supercapacitors

The development of supercapacitors is progressing rapidly, with ongoing research and innovation aimed at addressing their limitations and expanding their applications. Overall, the development of supercapacitors is dynamic and multifaceted, with significant advancements occurring in materials, design, integration, and scaling. Research is addressing performance challenges and expanding the horizons for supercapacitor applications, making them an increasingly important part of future energy storage solutions. As technology progresses, supercapacitors are likely to see broader adoption, contributing to innovations in energy management and storage across various industries.

Joy of Electronics: How to Make a Professional Supercapacitor at Home

-

Slot-die coating is a high-precision method used to apply thin, uniform layers of materials onto substrates. It involves extruding the coating material through a narrow, elongated slot in a slot-die head, which evenly distributes the coating across the moving substrate below. This technique is valued for its ability to achieve consistent film thickness and high-quality coatings with minimal waste, making it ideal for applications in industries such as electronics, photovoltaics, and packaging. Learn more about slot-die coating.

How Are Supercapacitors Produced Today?

Material Selection:

Electrodes: Identifying and preparing high-surface-area materials, such as activated carbon, graphene, or other carbon materials.

Electrolyte: Choosing an appropriate electrolyte, which can be aqueous, organic, or ionic liquid, depending on the desired performance characteristics.

Separator: Selecting a suitable porous separator material that allows ionic conductivity while preventing electrical shorting between the electrodes.

Electrode Fabrication:

Preparation of Electrode Slurry: The active material (e.g., activated carbon) is mixed with a binder (such as polyvinylidene fluoride) and conductive additives (like carbon black) to create a homogenous slurry.

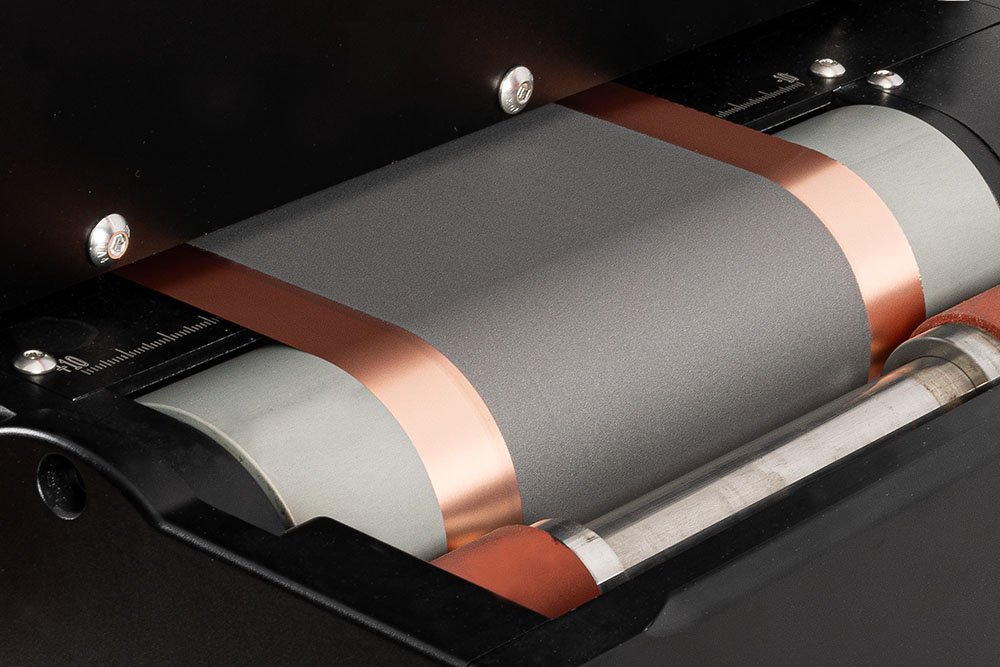

Slot-Die Coating: This step involves using the slot-die coating technique to uniformly apply the prepared slurry onto a substrate (typically conductive foils like aluminum or copper). The precision of slot-die coating ensures an even layer with controlled thickness, which is crucial for the performance of the supercapacitor.

Drying: After coating, the electrodes are dried using ovens to remove any solvents from the slurry, ensuring that the active materials are securely adhered to the substrate.

Electrode Assembly:

Layering: The dried electrodes are layered with a separator that has been saturated with electrolyte. This can be done in various configurations, such as stacking or winding (for cylindrical supercapacitors).

Sealing: The assembled electrodes and separator are sealed within a casing that protects the components and contains the electrolyte.

Electrolyte Filling:

The electrolyte is added to the assembled cells, which can be done through ports or directly if the assembly allows for it before final sealing.

Formation and Testing:

Formation: The supercapacitors undergo a formation process, where they are charged and discharged to stabilize the electrodes and optimize the electrochemical performance.

Testing: The completed supercapacitors are subjected to rigorous testing for capacitance, internal resistance, leakage current, and other performance metrics to ensure they meet required specifications.

Final Packaging:

Once tested and verified, the supercapacitors are packaged for distribution, ready to be integrated into various applications.

-

Slot-die coating is one of the techniques used in the processing of supercapacitors, particularly for the application of electrode materials onto substrates. This method is especially beneficial in the production of large-area and uniform coatings, which is critical for the performance of supercapacitors.

Advantages

High Precision: Achieves precise control over film thickness and uniformity.

Cost-Effectiveness: Reduces waste of materials compared to traditional coating methods.

Adaptability: Suitable for a wide range of materials and thickness requirements.

Automation: Can be easily automated for large-scale production.

Market Trends and Future Outlook

The supercapacitor market is experiencing growth due to increased demand for energy storage solutions in various sectors. Key trends include:

Growing Adoption in Electric Vehicles: As the automotive industry moves towards electrification, the use of supercapacitors for regenerative braking and power management is expected to rise.

Expanding Use in Renewable Energy: The need for energy storage solutions in renewable energy systems is driving market growth.

Technological Advancements: Continuous research and development are leading to better-performing and more cost-effective supercapacitors, broadening their application scope.

Regulatory Support: Increasing emphasis on energy efficiency and sustainability is likely to boost market demand.

Build your own R2R Slot-Die Coater and start producing supercapacitors with precision and efficiency.

Conlusion

Supercapacitors represent a versatile and advanced energy storage solution with unique advantages in power density, rapid charge/discharge cycles, and durability. While they face challenges such as lower energy density and higher cost, ongoing innovations are enhancing their performance and expanding their applications. As technology progresses, supercapacitors are likely to play a crucial role in various sectors, from automotive and electronics to renewable energy and industrial applications, offering new possibilities for energy storage and management.

Learn More About Supercapacitors

Wang, T., Pan, R., Martins, M.L., et al. "Machine-Learning-Assisted Material Discovery of Oxygen-Rich Highly Porous Carbon Active Materials for Aqueous Supercapacitors." Nature Communications, vol. 14, no. 1, 2023, article 4607. doi:10.1038/s41467-023-40282-1.

Baptista, Joana Monteiro, et al. "State-of-the-Art Materials for High Power and High Energy Supercapacitors: Performance Metrics and Obstacles for the Transition from Lab to Industrial Scale – A Critical Approach." Chemical Engineering Journal, vol. 374, 2019, pp. 1153-1179. doi:10.1016/j.cej.2019.05.207.

Olabi, A.G., Mohammad Ali Abdelkareem, Tabbi Wilberforce, and Enas Taha Sayed. "Application of Graphene in Energy Storage Device – A Review." Renewable and Sustainable Energy Reviews, vol. 135, 2021, article 110026. doi:10.1016/j.rser.2020.110026.

The Electric Viking: Experts say Ultramicro Supercapacitor are "Game-Changing Energy Storage"

Undecided with Matt Ferrell: Revisiting the Supercapacitor - The Wait for Graphene is Over

Related Articles

Roll-to-Roll Manufacturing of Batteries: A Revolution in Energy Storage

As the demand for renewable energy solutions and portable electronic devices grows, the need for efficient and scalable battery manufacturing processes has never been more critical.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

Slot-die Heads

Slot-die heads for high-quality coatings. Available in stainless steel, titanium, or PEEK, with widths from 40 mm to 305 mm, ensuring precise thin-film production.