Slot-Die & Roll-to-Roll News in Thin-Film Batteries

Discover the latest news, developments, and applications in slot-die coating technology. From precision coating techniques and equipment updates to real-world use cases in solar cells, batteries, fuel cells, pharmaceuticals, and more, we share the knowledge and progress that drive this versatile and scalable method forward.

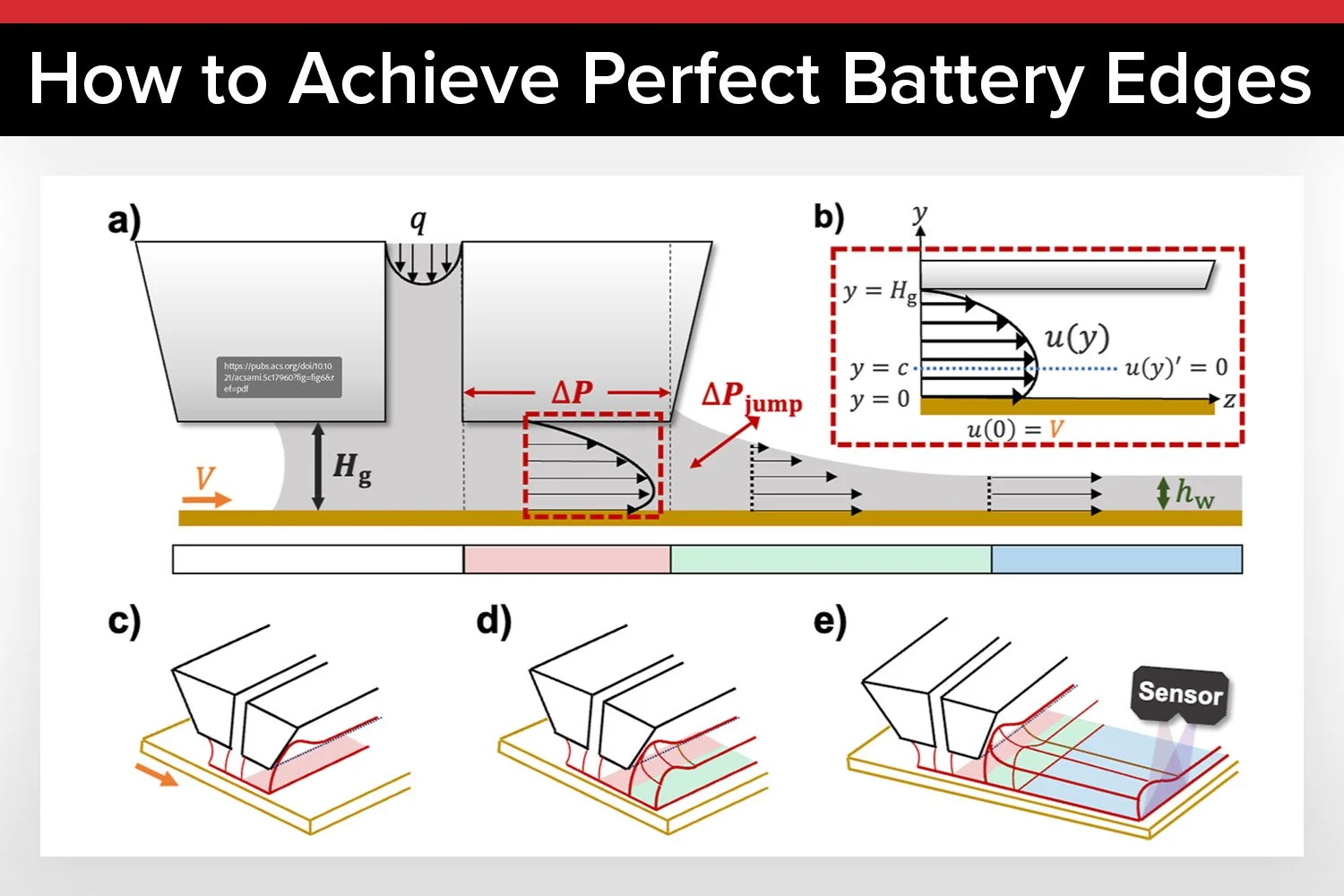

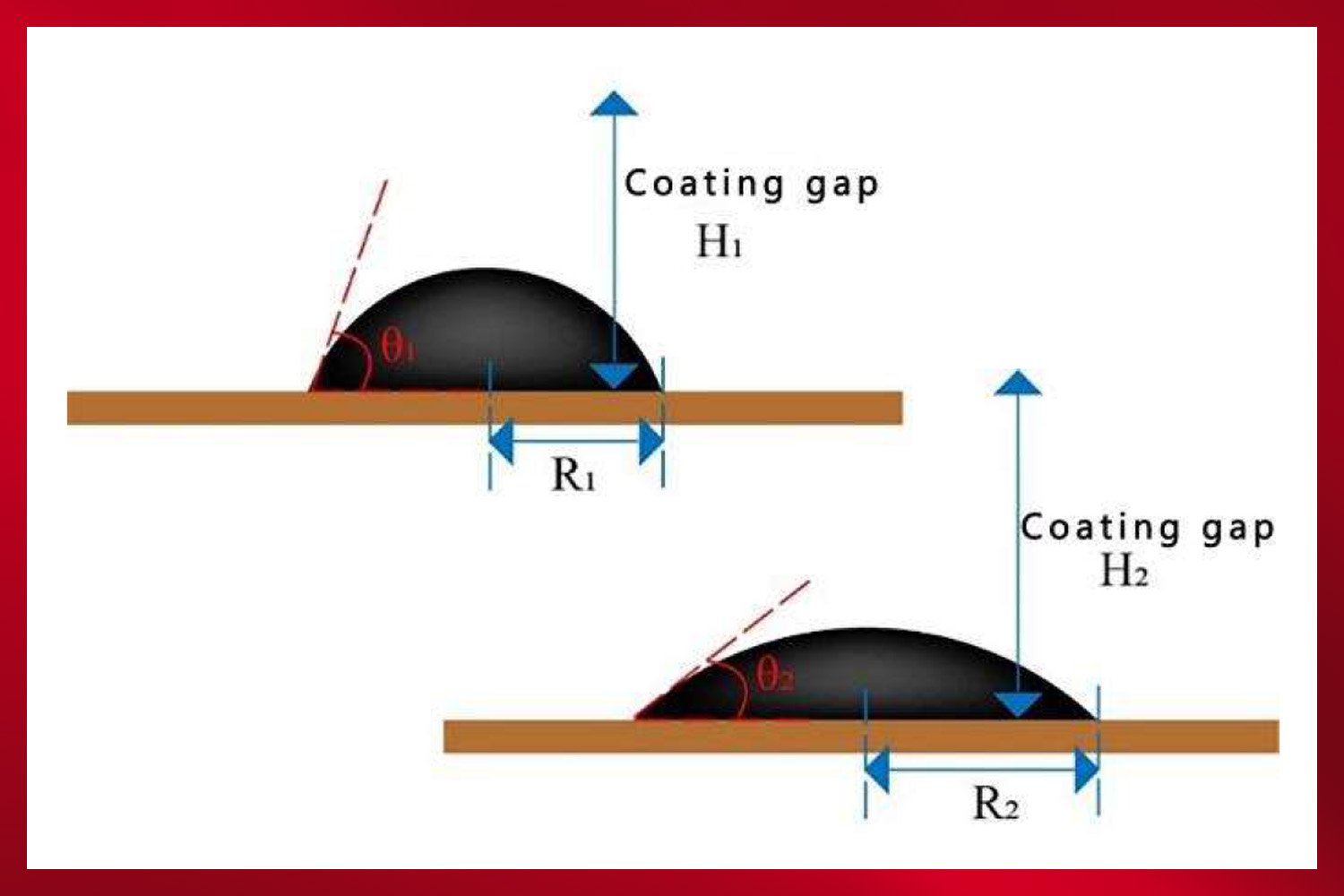

Learn the simple rule for perfect edges, why it matters for thick electrodes, and how it could transform battery manufacturing for electric vehicles and beyond.

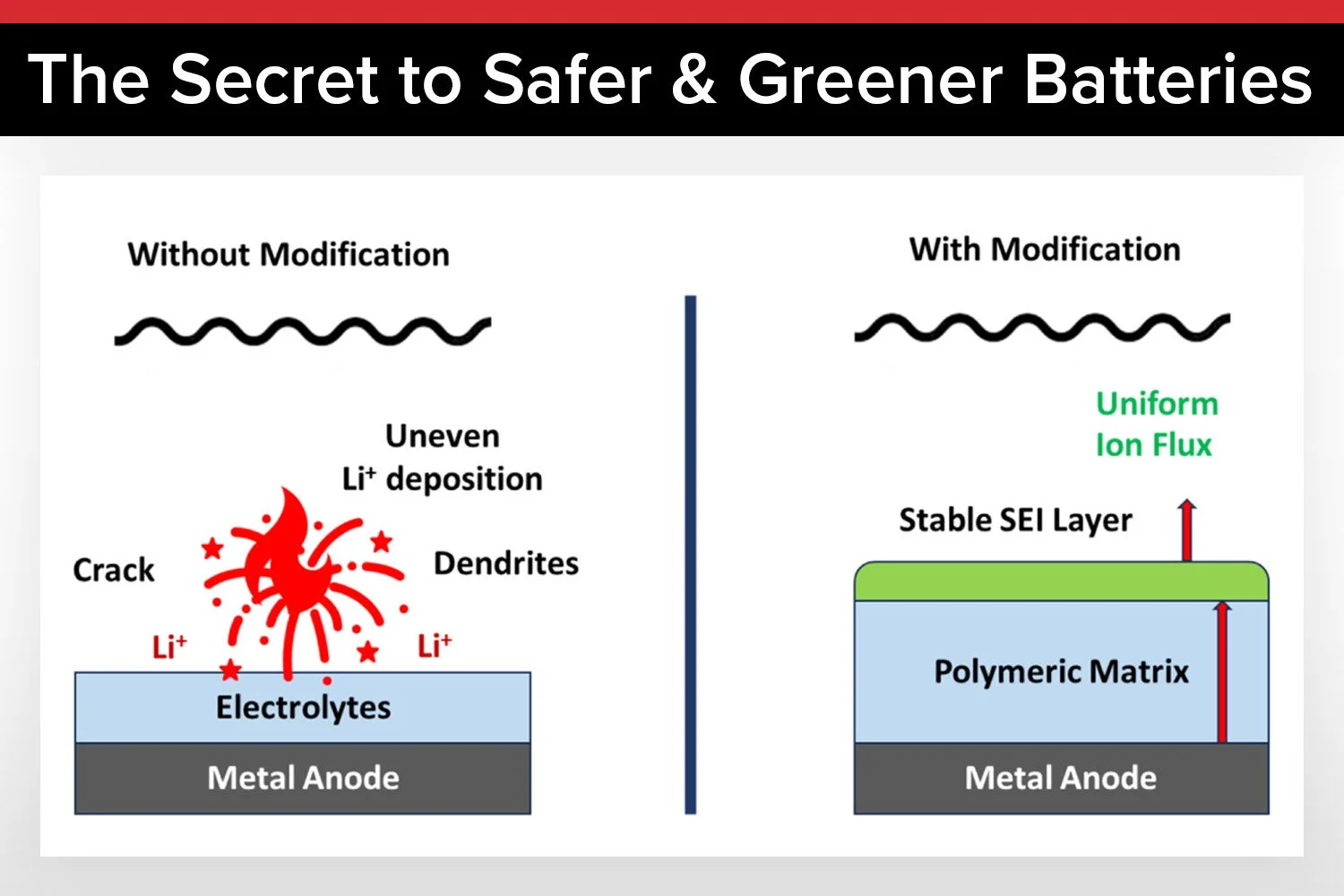

Discover how single-ion conducting biopolymer electrolytes are transforming the battery industry by suppressing dendrites, improving safety, and offering a sustainable alternative to traditional materials.

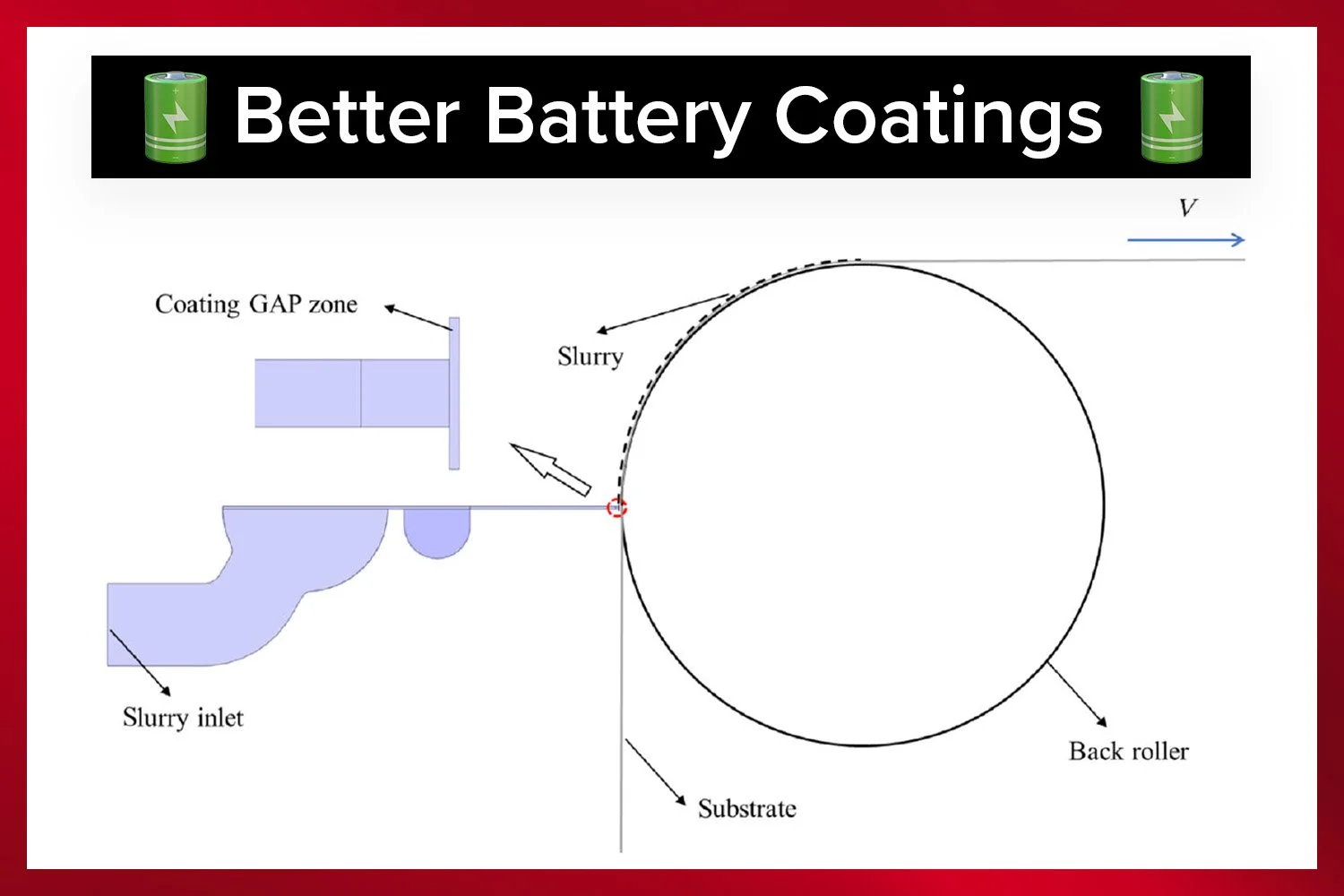

New research shows how advanced simulations reveal the causes of wet film defects in slot-die coating and help improve lithium-ion battery electrode manufacturing.

Researchers developed a roll-to-roll coating method that creates dendrite-free zinc anodes with 99.9% efficiency and long lifetimes, paving the way for scalable and safer aqueous zinc batteries.

A new study shows how tailoring FEC electrolyte additives stabilizes dry-processed silicon anodes and Ni-rich cathodes, achieving high efficiency and long cycle life for next-generation EV batteries.

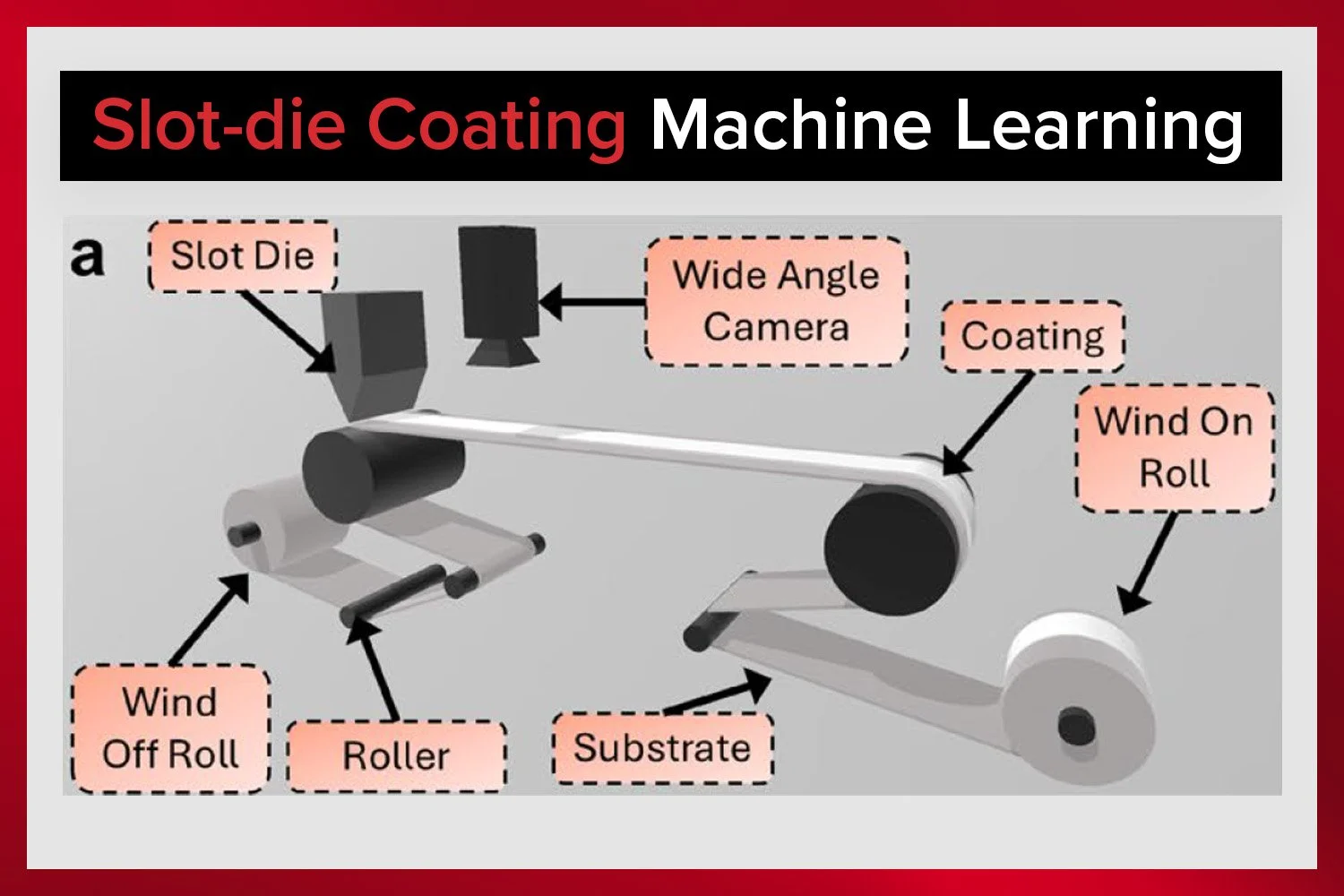

A new study shows how machine learning can optimize roll-to-roll slot die coating, delivering record coating uniformity, reducing waste.

A new perspective article explores the risks of poor battery quality at scale and outlines how manufacturers can improve safety, reliability, and sustainability in the race to electrify.

A recent study reveals that high shear dispersion in slurry preparation significantly enhances lithium-sulfur battery performance by creating denser cathodes and improving cycle life in pouch cells.

This article presents a smart new way to make electric vehicle batteries last longer. It combines two ideas: balancing battery cells so they charge evenly, and using machine learning to predict how much life the battery has left.

A new fuzzy logic controller developed at KIT helps reduce scrap and improve flexibility in lithium-ion battery slot die coating, offering a smarter way to scale sustainable battery production.

This article reviews a landmark study showing how roll-to-roll methods and electrode design improvements can scale battery manufacturing, cut costs, and boost energy density without new materials.

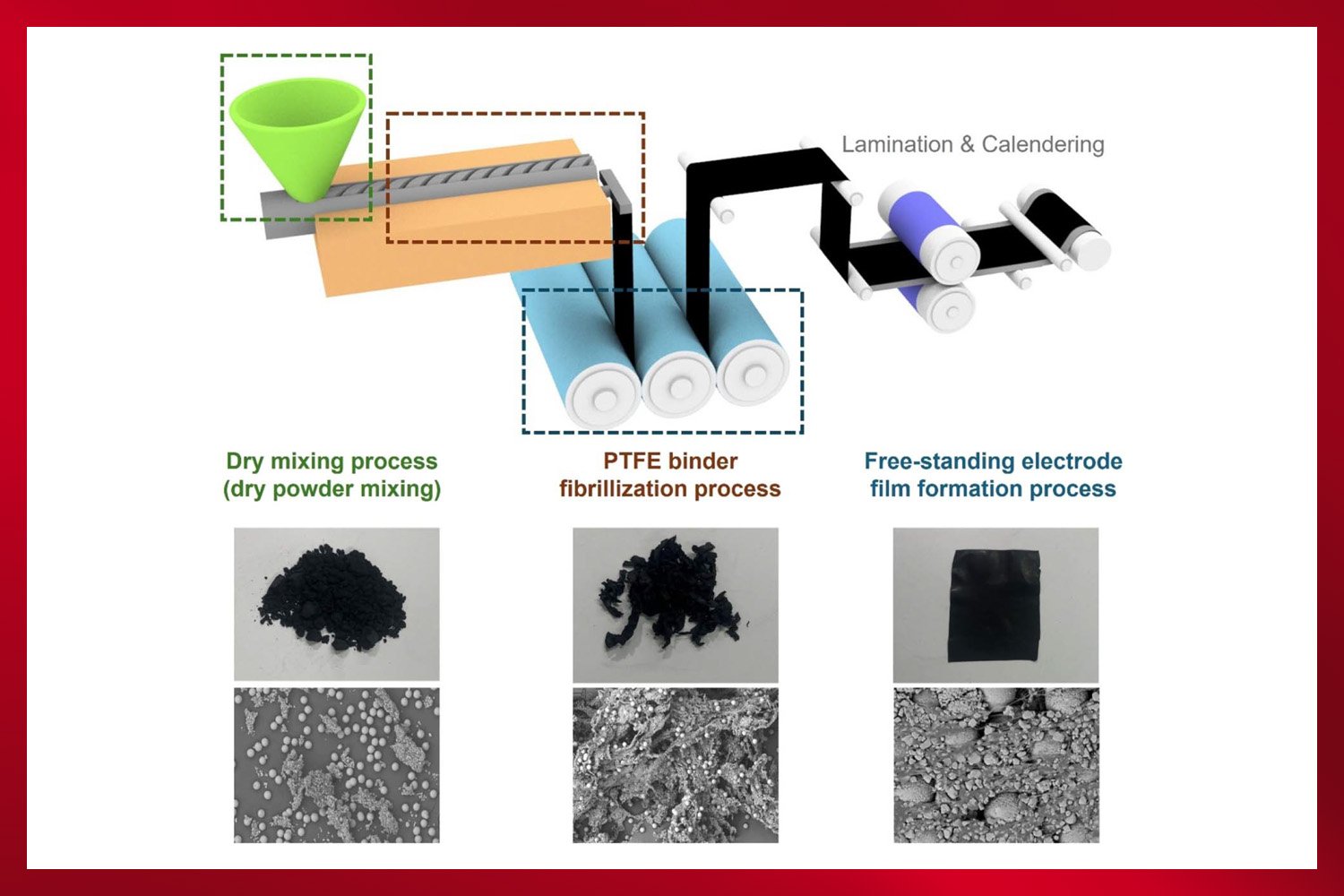

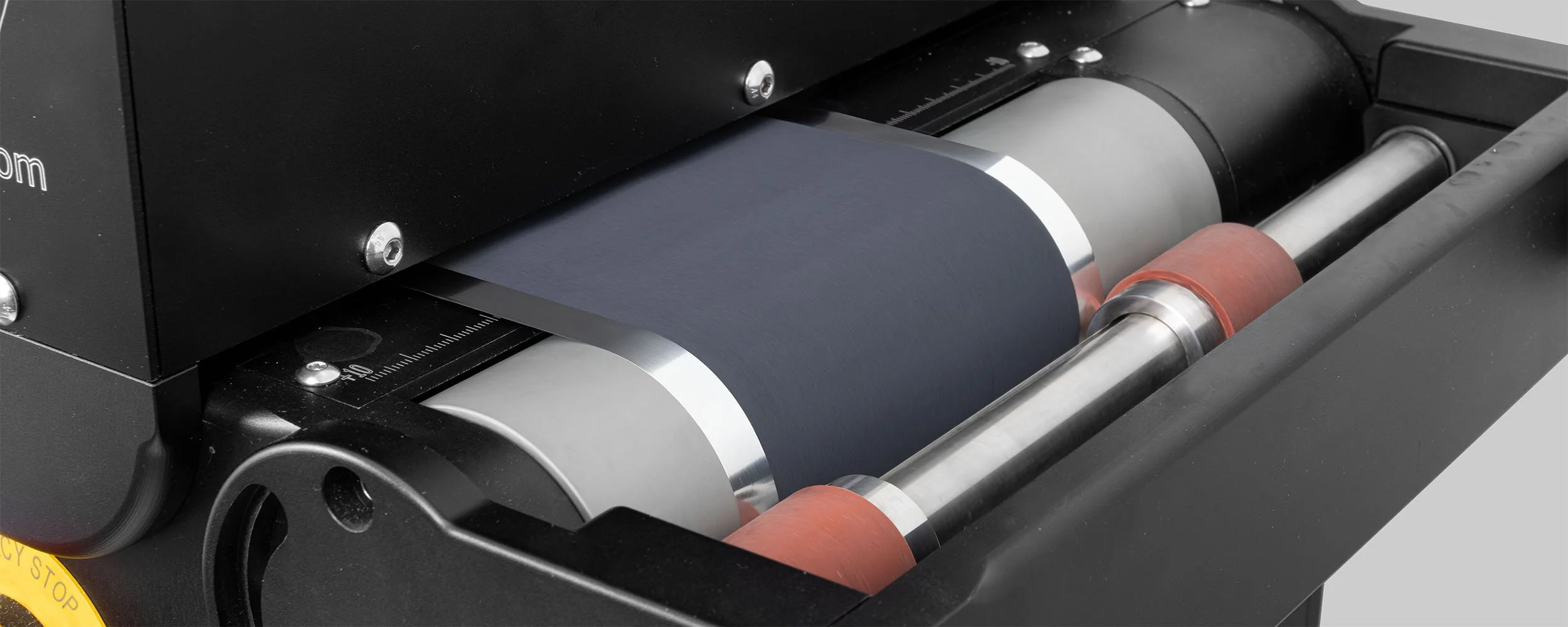

A new study shows how calender gap and roller speed influence the film formation in semidry electrode production for lithium-ion batteries, improving efficiency and performance.

Discover how cutting-edge manufacturing equipment is driving cost efficiency, sustainability, and innovation in lithium-ion battery gigafactories, based on a recent review by researchers from Concordia University.

Discover how chromatic confocal sensors enhance drying process control in lab-scale roll-to-roll battery electrode manufacturing with real-time thickness and roughness data.

A new study shows how heated substrates improve slot-die coating stability and reduce defects in lithium-ion battery electrode films—ideal for lab-scale R2R engineers.

A new study explores how the flow properties of battery electrode slurries affect manufacturing outcomes and performance, offering insights for process optimization.

Discover how a new study predicts coated layer thickness in roll-to-roll processes using meniscus shape analysis and machine learning.

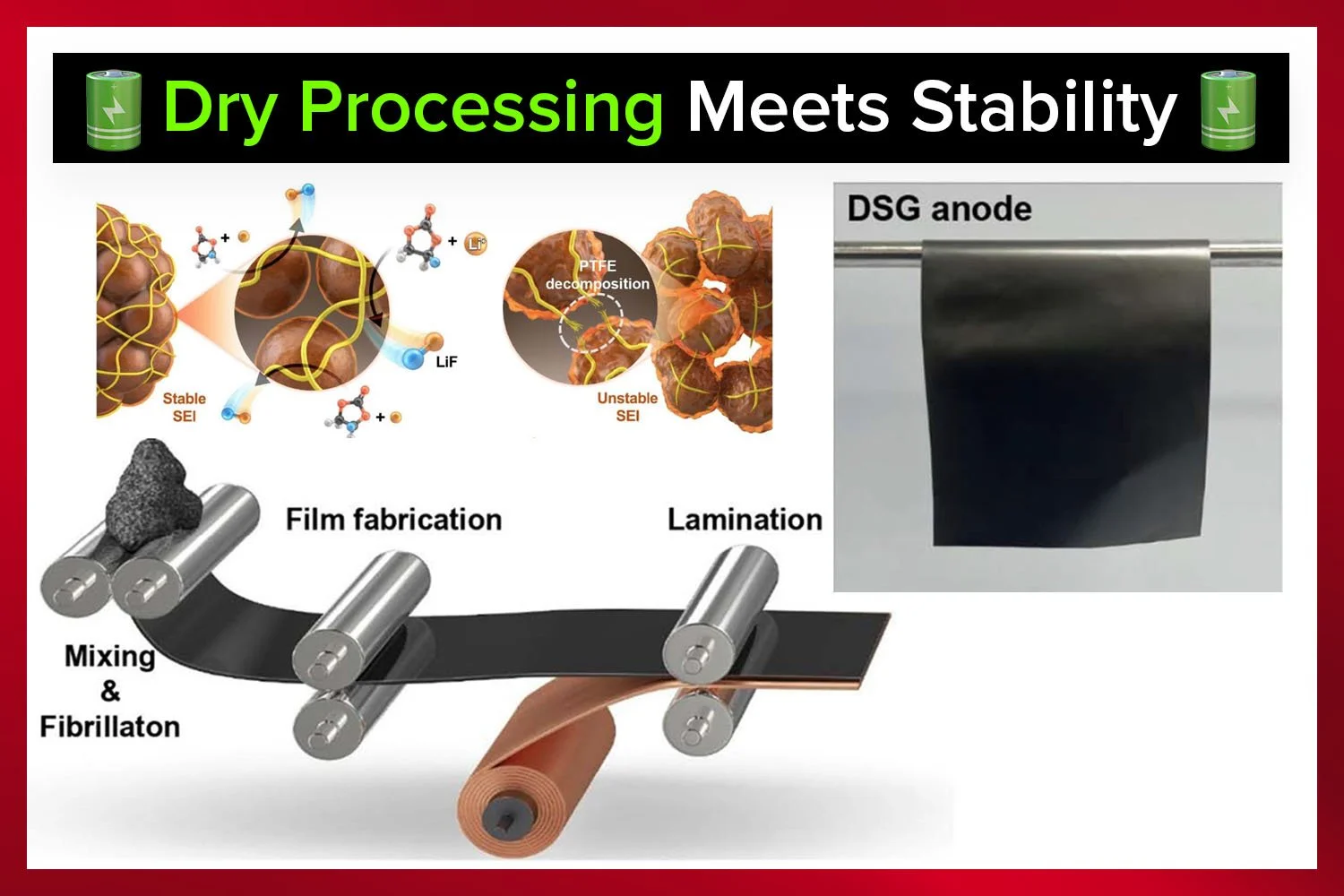

A recent study highlights the roll-to-roll dry coating process as a scalable, sustainable alternative to conventional battery electrode manufacturing, addressing key challenges in energy density, cost, and environmental impact.

Researchers have developed and validated a model that predicts lithium battery electrode coating thickness with high accuracy, helping manufacturers reduce waste and optimize performance.

Traditional lithium-ion battery manufacturing relies on energy-intensive slurry-based processing. However, innovations like dry processing, radiation curing, and 3D printing are transforming electrode production—offering higher efficiency, lower costs, and improved sustainability.

Organic batteries offer a sustainable alternative to lithium-ion technology. A new study explores their mechanisms, advantages, and challenges in energy storage applications.

Researchers have developed groundbreaking methods for fabricating high-precision microstructures using a modified Continuous Liquid Interface Production (CLIP) process.

A recent study explores the optimization of simultaneous two-layer coatings for lithium-ion battery (LIB) anode electrodes, incorporating primer layers to improve mechanical properties and coating stability.

Discover how AI-driven diagnostics are transforming battery technology, from electric vehicles to energy storage systems.

We Are Ready to Help You

With decades of experience in printed electronics, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project. Contact us to discuss how we can support your solar cell development.

Slot-die Heads for High-Performance Precision Coating

Whether you're working on batteries, pharmaceuticals, solar cells, or other thin-film technologies, this video guides you through the full process of using infinityPV’s slot-die heads—from assembly and mounting to precision adjustment, coating, and cleaning. Available in stainless steel, titanium, and PEEK, and in widths from 40 to 305 mm, these slot-die heads are engineered for accuracy, repeatability, and compatibility with all infinityPV platforms.

We Are Trusted by the World’s Top Scientists

How researchers used the infinityPV LBIC to achieve record-high performance in ITO-free, roll-to-roll processed organic solar modules.

How researchers pushed perovskite efficiency from 19.1% to 20.5% and retained 98% output after 1500 hours of outdoor testing using SMU.

Researchers achieved record efficiencies of 17.6% for flexible perovskite solar cells using the Research Laboratory Coater from infinityPV.