Revolutionizing Battery Diagnostics with AI: Enhancing Durability, Reliability, and Efficiency

Overview

As battery technology becomes a cornerstone in sectors like electric vehicles (EVs) and large-scale energy storage, the demand for advanced diagnostics has never been greater. A recent study published in Materials Today Advances highlights how artificial intelligence (AI) is revolutionizing battery diagnostics, moving beyond traditional model-based approaches to achieve real-time monitoring and more accurate health assessments. Unlike conventional methods that rely heavily on physical models and need frequent recalibration, AI-driven diagnostics leverage machine learning (ML) to deliver data-driven insights that enhance battery durability, reliability, and efficiency across various applications. This study provides a fresh look at how AI is transforming battery technology, addressing both the opportunities and challenges of integrating AI into battery management systems, and exploring the future potential for even smarter, AI-powered solutions. By doing so, it offers a compelling roadmap for how AI can help us build more resilient, efficient batteries to power the energy systems of tomorrow.

Key Highlights

AI-Driven Diagnostics: AI models analyze vast data sets (voltage, temperature, impedance) in real time to provide accurate predictions and assess battery health without frequent recalibration.

Physics-Informed Learning: Integrating scientific knowledge about battery behavior with AI offers new ways to manage complex battery systems.

Challenges of AI: The "black box" nature of deep learning models presents interpretability and transparency issues, which are critical in safety applications.

Future Technologies: Innovations like explainable AI (XAI), cloud computing, and digital twins promise more transparent, accessible, and efficient battery diagnostics.

How AI is Transforming Battery Diagnostics: A Deeper Look

The Importance of Battery Diagnostics

Battery diagnostics is essential for any application where durability and reliability are crucial. In electric vehicles, for instance, accurate health assessment can prevent unexpected battery failures, reduce operational interruptions, and extend battery life. The same applies to stationary energy storage, which needs to ensure uninterrupted performance to support grid stability. Traditional diagnostics methods, which rely on physical models, struggle to keep up with the data demands and complexity of modern battery systems. This is where AI steps in, providing a more adaptable, data-driven approach.

AI vs. Traditional Diagnostics: The Key Differences

Traditional battery diagnostics rely on physical models that need to be recalibrated frequently to maintain accuracy. This recalibration process is time-intensive and may not be responsive enough for modern energy applications. AI diagnostics, on the other hand, use machine learning models to extract patterns from large data sets. These models analyze variables such as voltage, current, temperature, and impedance, enabling real-time health assessments and continuous adaptation to new data.

By utilizing AI, companies can avoid the need for constant recalibration and gain more reliable diagnostics. The machine learning approach provides a more holistic view of battery health and allows for predictive analytics that help prevent issues before they occur.

Discover how roll-to-roll (R2R) manufacturing is transforming battery production. Learn about its efficiency, scalability, and advantages for flexible, lithium-ion, and solid-state batteries.

The Role of Physics-Informed Learning in Battery Diagnostics

In recent years, a new approach called physics-informed learning has emerged, combining AI's data-processing capabilities with foundational scientific knowledge about battery behavior. This technique is especially useful for diagnosing complex, multiscale battery systems that are difficult to manage with traditional AI alone.

What is Physics-Informed Learning?

Physics-informed learning integrates prior knowledge from observational, empirical, physical, or mathematical insights into AI algorithms. For batteries, this could mean embedding principles about electrochemical processes directly into the learning model. By doing so, AI can make more accurate predictions even in challenging scenarios, like when data is incomplete, irregular, or noisy. This hybrid approach not only boosts the AI’s accuracy but also enhances its reliability, which is vital for safety-critical applications such as EVs and grid storage.

Advantages of a Hybrid AI Approach

By integrating physics-based insights, AI models are better equipped to handle real-world complexities in battery diagnostics. This hybrid method improves the model's ability to account for variables and boundary conditions that could otherwise lead to errors in purely data-driven systems. The result is a more robust, reliable diagnostic tool that aligns closely with the physical realities of battery behavior.

Challenges in AI-Powered Battery Diagnostics

The "Black Box" Problem

While AI brings immense potential to battery diagnostics, it comes with certain challenges. One of the primary issues is the "black box" nature of many AI models, particularly deep learning models. In simple terms, these models can be difficult to interpret, which poses a problem in applications where safety is crucial. Users need to understand why and how an AI model reaches its conclusions to trust its outputs fully.

Data Quality and Computational Demands

AI diagnostics are highly dependent on the quality and volume of data. Poor or incomplete data can lead to inaccurate predictions, while larger data sets improve AI performance but demand significant computational resources. For companies without access to high-performance computing, deploying advanced AI diagnostics can be challenging. Additionally, AI models require continual updates and data to stay effective, which can create barriers for smaller organizations or applications with limited data access.

Read our article to explore the benefits of solid-state lithium-ion batteries, including enhanced safety, higher energy density, and faster charging.

Future Outlook: Overcoming Barriers and Exploring New Technologies

Despite the current challenges, the future of AI in battery diagnostics looks promising. Researchers and developers are focusing on ways to make AI more transparent, accessible, and efficient. Here’s what the future may hold:

Explainable AI (XAI) for Transparency

To address the black box issue, explainable AI (XAI) aims to make AI models more interpretable. XAI techniques improve visualization, making it easier to understand why an AI model has made certain predictions. For battery diagnostics, XAI would mean that users can clearly see the data and reasoning behind health assessments, boosting confidence in AI-driven decisions.

Cloud Computing and Edge Computing for Efficiency

AI-based diagnostics typically require significant data storage and processing capabilities, which can be costly to maintain on local systems. Cloud computing and edge computing offer solutions by enabling data processing in the cloud, reducing the need for local resources. Edge computing, in particular, brings processing closer to where the data is generated (like within EVs or energy storage systems), enhancing data speed and reducing latency.

Digital Twins: Virtualizing Battery Diagnostics

Digital twins — virtual replicas of physical battery systems — are emerging as valuable tools in AI-driven diagnostics. These models can simulate real-world conditions, allowing developers to test AI algorithms under varied scenarios without risking physical assets. Digital twins can be used to improve battery safety, efficiency, and lifespan by running virtual diagnostics and analyzing potential issues before they impact actual battery systems.

Emerging Technologies for Smarter Diagnostics

Looking further ahead, innovations like AIOps (AI for IT operations), lifelong machine learning, and cloud-based digital twins promise even greater efficiency and adaptability in battery diagnostics. These technologies will allow for smarter, self-updating systems that continuously learn and adapt to changing conditions, pushing the limits of what's possible in battery health management.

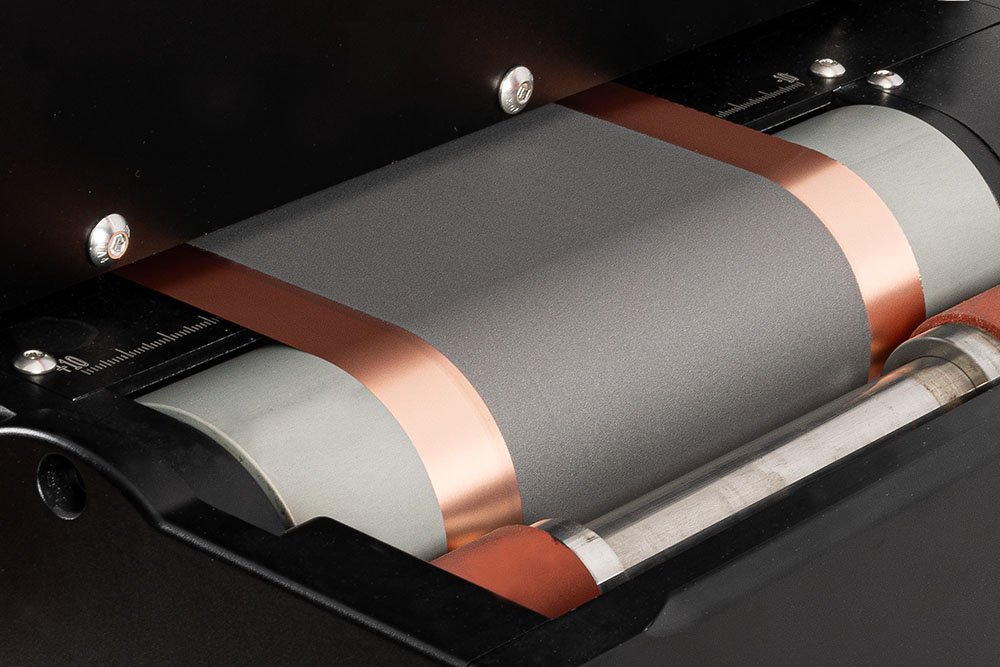

The Laboratory Roll-to-Roll Coater is the perfect machine for thin-film battery production and testing. Compact yet powerful, it’s ideal for precision-coating tasks in both lab and pilot-scale environments, with modular options for customized, application-specific setups.

Conclusion

The advent of AI in battery diagnostics has paved the way for more accurate, reliable, and cost-effective health assessments, with applications in EVs, grid storage, and beyond. Traditional model-based diagnostics are gradually giving way to data-driven approaches, as machine learning enables real-time health assessments and predictive maintenance. Physics-informed learning further enhances AI's potential, allowing it to integrate scientific knowledge for a more holistic understanding of battery behavior.

While challenges such as model transparency and data requirements remain, the future is bright. Innovations like explainable AI, cloud computing, and digital twins promise to make AI diagnostics more accessible and trustworthy. With continued advancements, AI is set to revolutionize battery technology, providing a foundation for safer, more efficient, and longer-lasting batteries.

Future Outlook: Towards a New Era of Battery Diagnostics

As AI continues to evolve, battery diagnostics will likely see further integration with cutting-edge technologies. New partnerships between academia and industry will be key, ensuring research findings translate into practical solutions. By fostering an open ecosystem for knowledge sharing and iteration, these collaborations can propel innovation and accelerate the shift toward smarter battery diagnostics.

The rapidly growing volume of battery data will also drive the development of more computationally efficient AI models. Future research will likely focus on building interpretable, physics-informed, and resource-efficient machine learning algorithms, ensuring that AI diagnostics remain scalable and adaptable. By bridging these technical and practical gaps, AI will play a crucial role in the global transition to cleaner, more reliable energy solutions.

Final Thoughts

AI-powered diagnostics represent a leap forward in battery technology, promising benefits for electric vehicles, grid storage, and countless other applications. As we continue to refine these tools and integrate them with broader technological trends, battery systems will become smarter, safer, and more resilient. Embracing AI for battery diagnostics is more than a technical shift — it’s a pivotal step towards a sustainable energy future.

Authors:

Jingyuan Zhao, University of California, Davis

Xudong Qu, Hubei University of Arts and Science

Yuyan Wu, Stanford University

Michael Fowler, University of Waterloo

Andrew F. Burke, University of California, Davis

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

Research Laboratory Coater

A versatile, compact system for producing high-quality films using multiple deposition techniques like slot-die coating and flexo.