How Do Organic Batteries Work? A Deep Dive into the Latest Research

A recent article titled published How Do Organic Batteries Work? Theoretical and DesignPrinciples of Electrode Materials for All-Organic Batteries explores the theoretical and design principles of electrode materials for all-organic batteries. The research highlights the advantages, challenges, and mechanisms behind organic batteries as a sustainable alternative to conventional lithium-ion batteries.

Key Highlights

Organic Batteries as a Sustainable Alternative: Organic electrode materials eliminate the need for scarce and geopolitically sensitive metals like lithium, cobalt, and nickel.

Redox Activity in Organic Materials: Organic materials store energy through rearrangements of covalent bonds and electron delocalization rather than metal-based oxidation states.

Advantages Over Conventional Batteries: Organic batteries offer high flexibility, potential for transparency, and a wide range of design possibilities.

Types of Organic Battery Configurations: Three primary configurations exist—dual-ion, cation-rocking chair, and anion-rocking chair systems—each with unique advantages.

Mechanistic Benefits: Faster ion transport in amorphous organic materials leads to improved charge and discharge rates compared to crystalline inorganic materials.

Challenges in Practical Applications: Issues such as solubility of organic active materials and optimization of full-cell designs remain key hurdles to commercialization.

Role of Artificial Intelligence: AI and machine learning are increasingly being used to screen organic molecules for potential use in batteries.

The Laboratory Roll-to-Roll Coater provides a straightforward and efficient solution for coating solid-state lithium-ion batteries.

The Fundamentals of Organic Batteries

Organic batteries operate on the same fundamental principles as conventional batteries but use carbon-based molecules instead of metal oxides. Unlike lithium-ion batteries, which rely on the intercalation of lithium ions within a crystalline structure, organic batteries utilize redox-active groups (RAGs) that enable electron transfers without the constraints of a rigid lattice.

The study explains that the redox reaction in organic electrode-active materials involves the redistribution of delocalized electrons within the organic structure. This process reduces the reorganization energy and enhances ion mobility, leading to faster charge and discharge rates.

Types of Organic Battery Configurations

The study classifies organic battery configurations into three categories:

Dual-Ion Batteries: These utilize an n-type organic material at the negative electrode and a p-type organic material at the positive electrode. Both anions and cations participate in charge compensation.

Cation-Rocking Chair Batteries: In this setup, two n-type organic materials are used, allowing cations (e.g., lithium ions) to shuttle back and forth between the electrodes.

Anion-Rocking Chair Batteries: These use two p-type organic materials, meaning only anions participate in ion transfer, allowing for metal-free electrolytes.

Each configuration has specific advantages and drawbacks. While dual-ion systems can achieve high working potentials, they require an excess of electrolyte salt. On the other hand, rocking-chair configurations simplify electrolyte composition but can be challenging to optimize for energy density.

-

Organic batteries rely on abundant elements like carbon, hydrogen, and nitrogen, eliminating the need for rare metals like lithium and cobalt, which have high environmental and geopolitical risks

Overcoming Challenges in Organic Batteries

The main challenge hindering the commercialization of organic batteries is the solubility of organic electrode materials in the electrolyte, which can lead to capacity loss over multiple charge cycles. The study explores several strategies to mitigate this issue:

Polymerization: By integrating redox-active groups into polymers, solubility can be minimized, improving long-term stability.

Salification: The introduction of ionic groups into organic molecules enhances stability and prevents dissolution.

Separator and Electrolyte Modifications: Developing solid-state or highly concentrated electrolytes can reduce unwanted solubility.

Despite these advances, achieving a balance between stability, cost, and performance remains a key challenge for researchers.

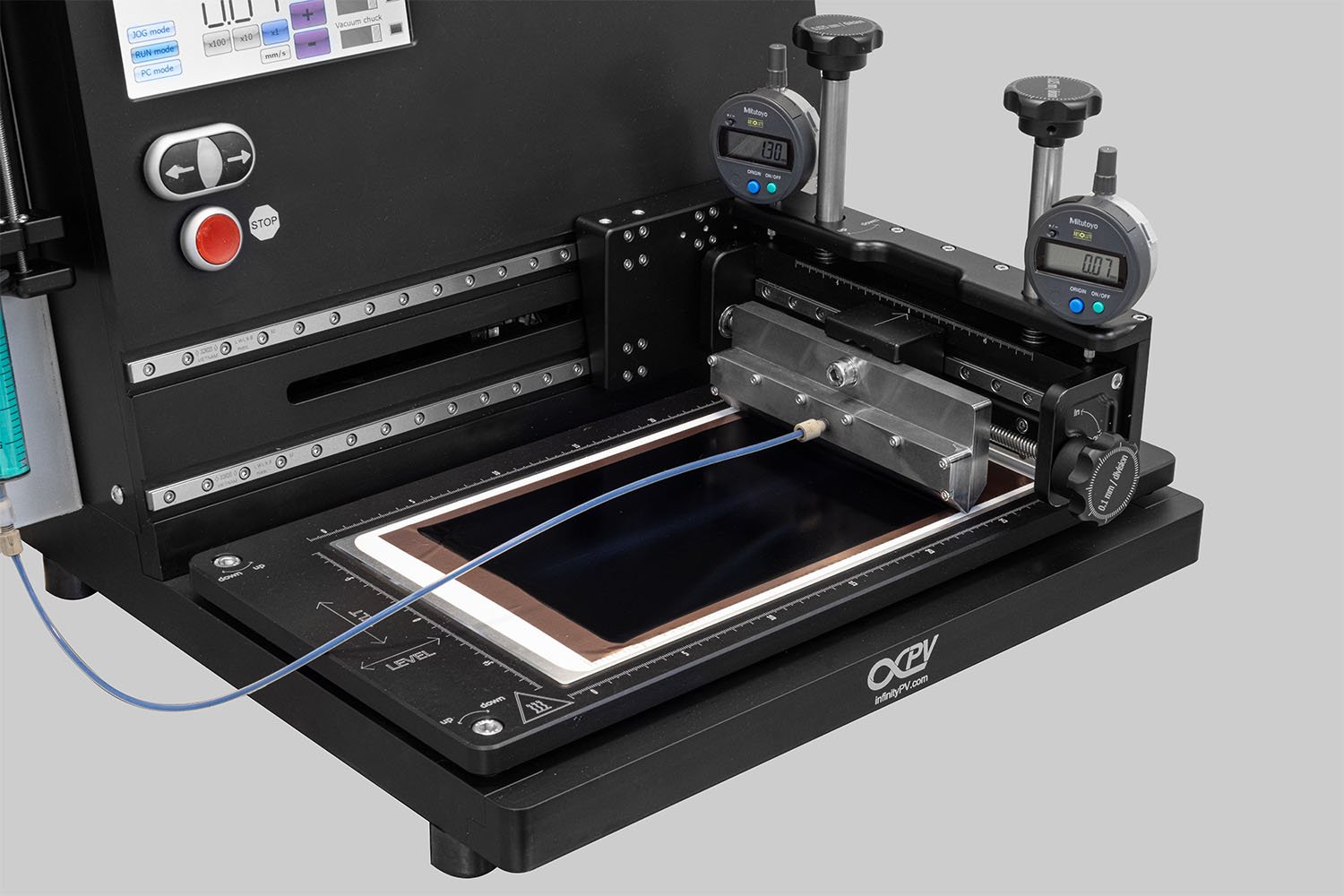

Battery coating has never been easier with the precision and efficiency of the Slot-die Coater.

The Role of Artificial Intelligence in Organic Battery Design

The study also highlights how AI and machine learning are being used to accelerate material discovery. By screening millions of molecules using density functional theory (DFT) models and AI-driven analysis, researchers can identify promising candidates for organic electrode materials with optimized redox potential, stability, and processability.

One notable breakthrough mentioned in the study is the use of AI to identify 459 potential organic molecules for battery applications out of a dataset of 20 million candidates. Such advancements are expected to significantly shorten the development cycle for new battery technologies.

Conclusion

The research provides a comprehensive understanding of how organic batteries function, the advantages they offer, and the challenges that need to be addressed. While organic batteries are not yet a commercial competitor to lithium-ion technology, ongoing developments in material stability, electrolyte optimization, and AI-driven discovery are rapidly advancing the field.

With the growing demand for sustainable energy storage, organic batteries could play a crucial role in reducing reliance on scarce metals and enabling new applications such as flexible and transparent energy storage devices.

Authors

Robin Wessling

Philipp Penert

Birgit Esser

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Products

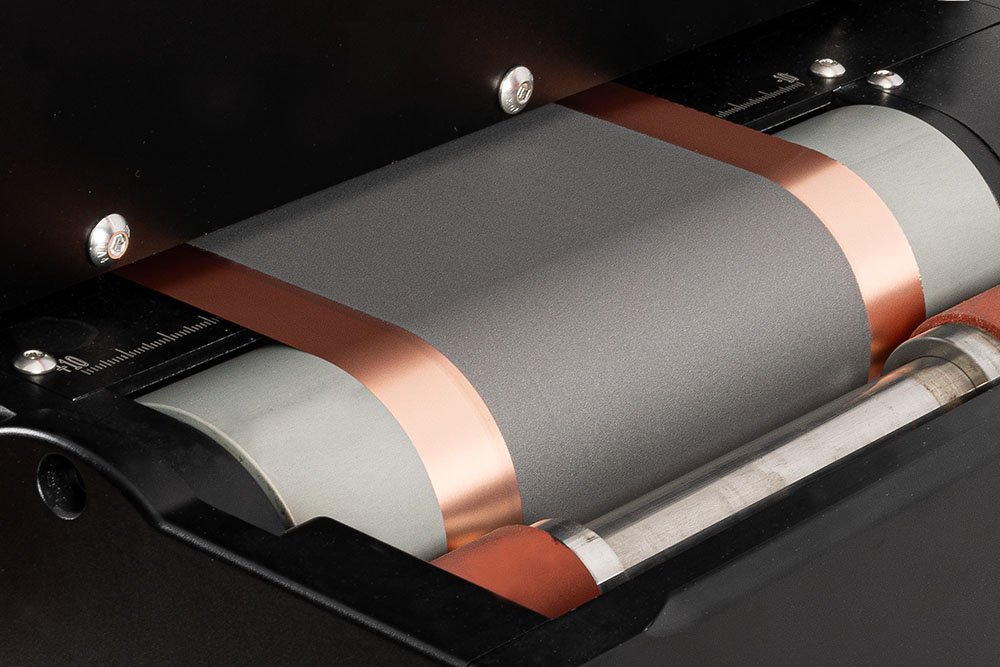

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater, featuring a syringe pump, a 65 mm slot-die head, and an infrared oven for precise lab coating.