Slot-Die Coating Advances for High-Performance Perovskite Solar Cells: A Study on Interface Roughness

Optimizing Slot-Die Coating for Commercial Solar Cell Production

Overview: Enhancing Solar Cell Efficiency with Slot-Die Coating Technology

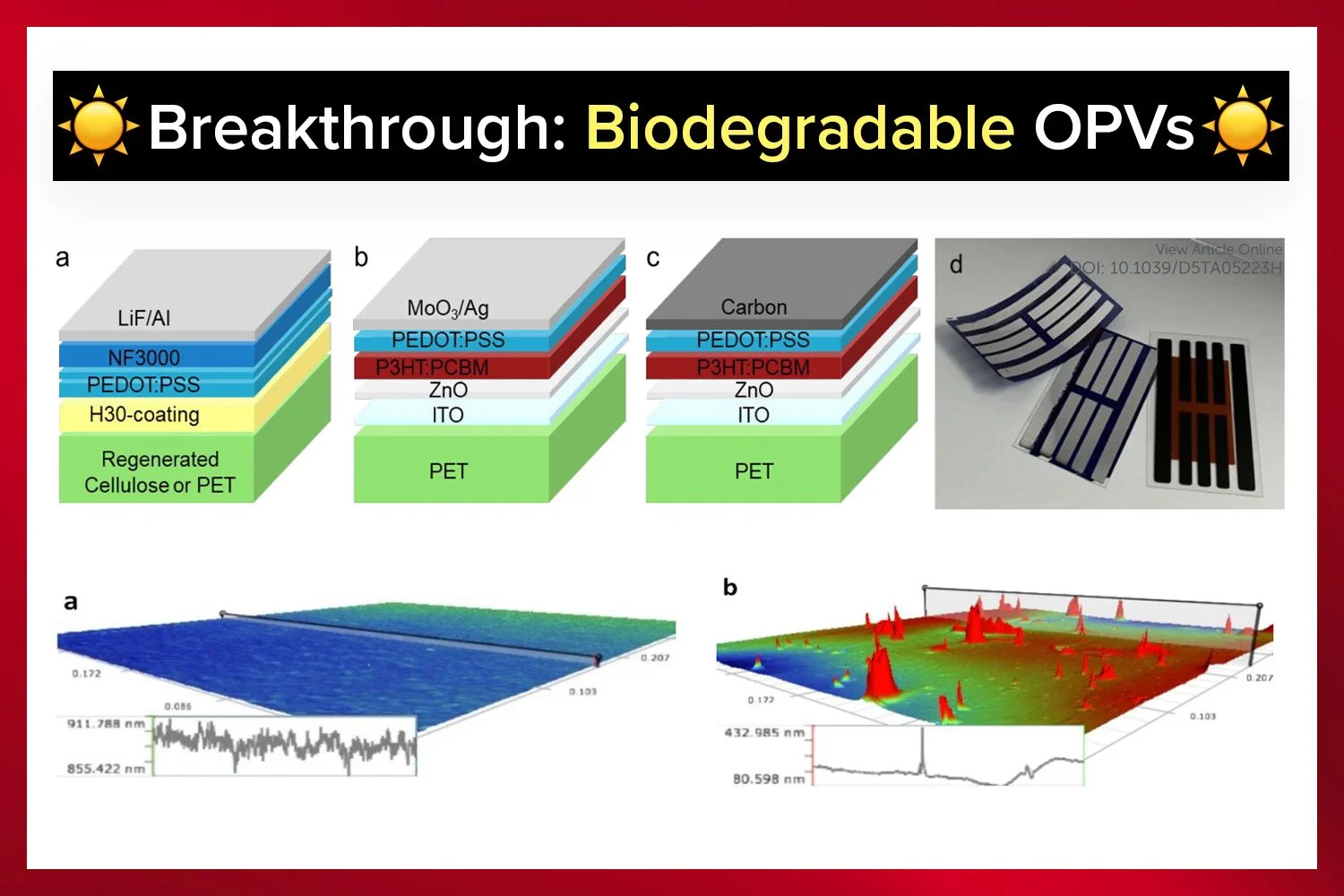

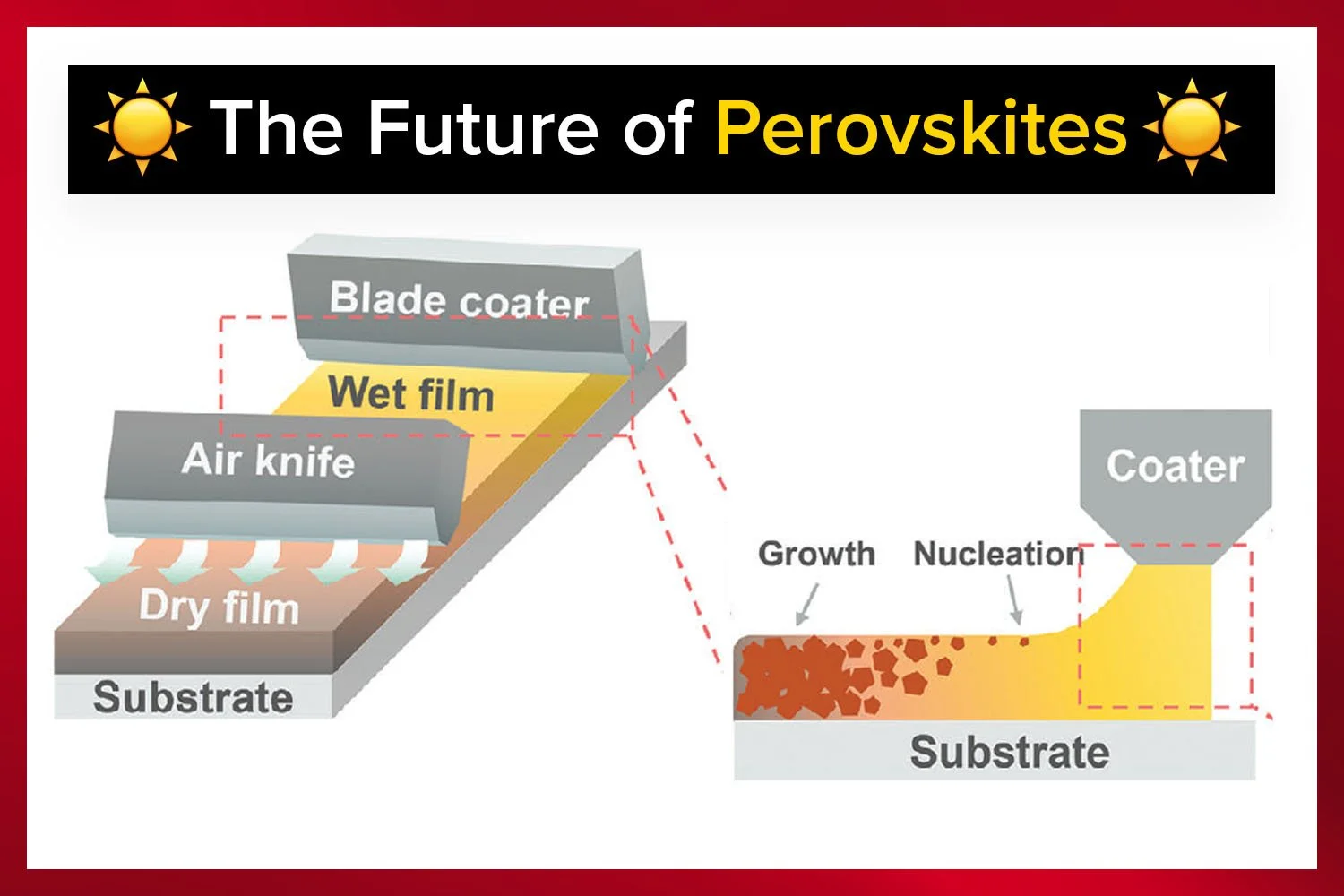

In the pursuit of commercializing perovskite solar cells, the industry is turning to scalable, cost-effective manufacturing techniques. One such method, slot-die coating, is gaining prominence due to its compatibility with large-area, continuous roll-to-roll processing. However, there are challenges to overcome, particularly when it comes to interfacial wettability and surface roughness, which significantly impact film uniformity and solar cell performance.

A recent study titled “Influence of interfacial roughness on slot-die coatings for scaling-up high-performance perovskite solar cells” investigates the correlation between interfacial roughness, wettability, and the overall efficiency of perovskite solar cells produced using slot-die-coating. This study offers a comprehensive understanding of how modifying the roughness of the hole transport layer (HTL) can improve the quality of perovskite films, enhance charge transport, and ultimately lead to high-efficiency perovskite solar cells with long-term stability.

Key Highlights of the Study on Slot-Die Coating and Solar Cell Efficiency

Slot-die coating improves scalability for large-area perovskite solar cells: Slot-die coating is a highly scalable, roll-to-roll process that facilitates mass production of perovskite solar cells, crucial for commercial applications.

Impact of HTL roughness on wettability: Increasing the roughness of the HTL improves wettability, allowing uniform perovskite films to form with fewer defects.

Energy loss reduction at the HTL/perovskite interface: By using slot-die coating-based HTL like NiOx/Me-4PACz, energy losses are significantly suppressed, leading to higher power conversion efficiency (PCE).

Achievement of over 19% efficiency: The study demonstrated that slot-die coating-produced perovskite solar cells can reach an impressive efficiency of 19.17% in unit cells, with long-term stability.

It’s easy to create solar cells using the Slot-die Coater.

The Role of Slot-Die Coating in Perovskite Solar Cell Manufacturing

Understanding Slot-Die Coating and Its Applications

Slot-die coating is a precision-based method that dispenses a controlled amount of ink or solution through a slot-die head onto a substrate, creating a uniform thin film. This technique is especially suitable for solution-processed perovskite solar cells due to its ability to coat large areas with consistent thickness. In comparison to other methods like spin coating, slot-die coating offers scalability and reduced material waste, making it ideal for commercial-scale solar cell production.

Challenges in Slot-Die Coating for Perovskite Solar Cells

While slot-die coating provides a promising route for manufacturing large-area perovskite solar cells, achieving uniform film deposition can be challenging. Problems like micro-cavities, pinholes, and streaks often arise, particularly when the interface between the HTL and perovskite ink has low wettability. The wettability of this interface is influenced by surface chemistry, roughness, and energy, all of which play a pivotal role in the quality of the resulting perovskite layer.

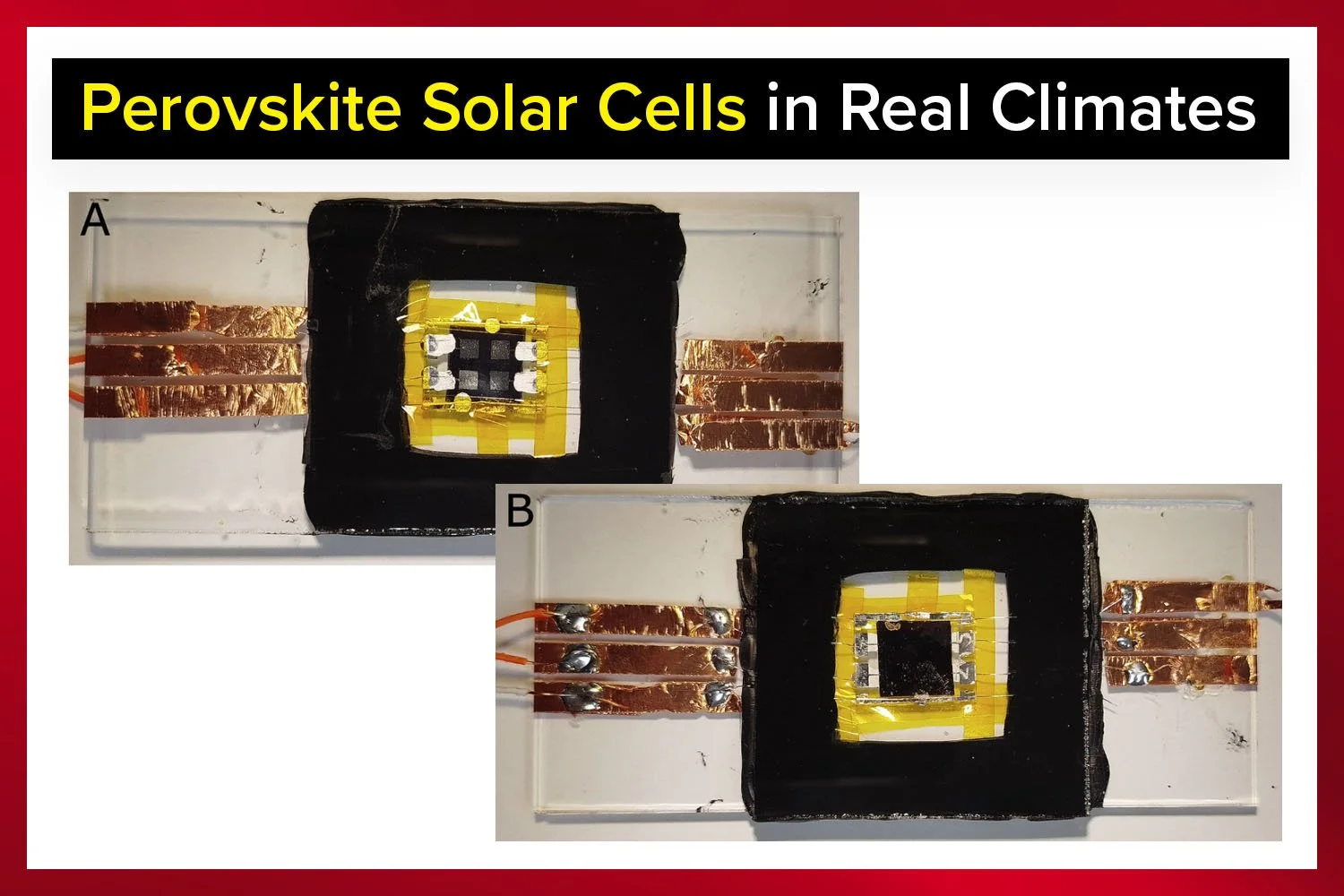

How to test solar cells using a source measure unit and solar simulator.

Optimizing Interfacial Wettability through Slot-Die Coating

Importance of Interfacial Wettability in Perovskite Solar Cells

The interface between the HTL and the perovskite layer is crucial for determining the quality of the perovskite film and the overall performance of the solar cell. Poor wettability can lead to defects such as pinholes, which reduce the efficiency of the perovskite solar cell. In this study, researchers focused on improving the wettability of the HTL by increasing its surface roughness. This modification allowed the perovskite ink to spread more evenly, forming a high-quality film without defects.

Impact of Roughness on HTL Performance

The roughness of the HTL affects the physical interactions between the perovskite ink and the substrate. By increasing the roughness, slot-die coating promotes better ink wetting, which leads to a more uniform perovskite layer. This improvement in film quality is crucial for achieving high-performance perovskite solar cells. In this study, the researchers found that increasing the roughness of NiOx/Me-4PACz HTL significantly enhanced the wettability and improved the overall efficiency of the solar cells.

Slot-Die Coating and Energy Loss Reduction at the HTL/Perovskite Interface

In addition to improving film quality, slot-die coating was also shown to reduce energy losses at the HTL/perovskite interface. The study focused on the use of NiOx/Me-4PACz as the HTL, a material known for its excellent hole transport properties. However, its poor wettability presented challenges in forming a uniform perovskite layer. By applying slot-die coating to deposit this HTL, the researchers were able to suppress energy losses, leading to more efficient charge transport and higher PCE.

Understanding the differences between non-heated and heated slot-die heads is vital for selecting the best option for your specific coating needs. Be sure to read our guide on non-heated vs. heated slot-die heads.

High-Efficiency Results from Slot-Die Coated Perovskite Solar Cells

Achieving Over 19% Efficiency with Slot-Die Coating

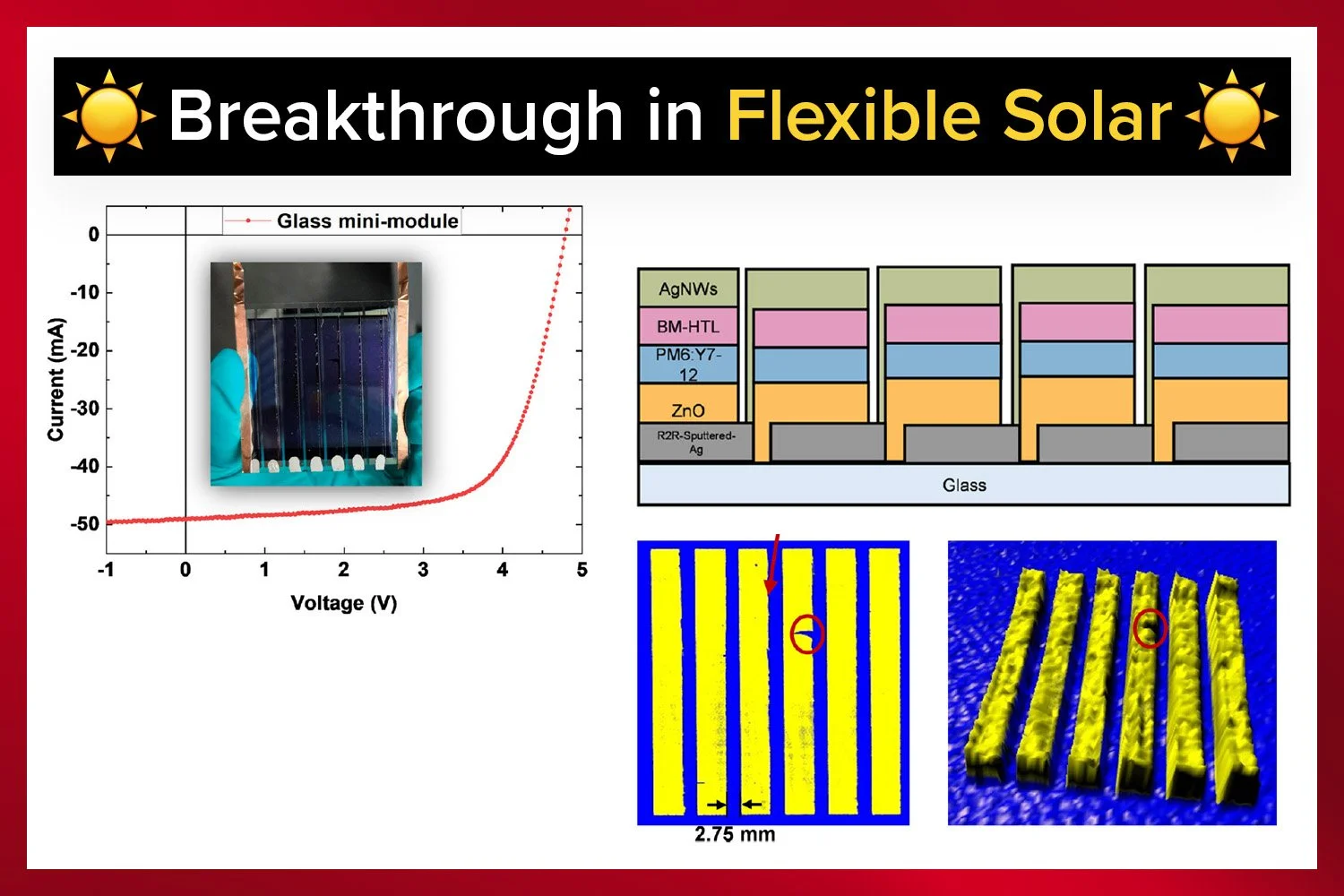

One of the most significant findings of this study was the high efficiency achieved using slot-die coating for both the HTL and perovskite layers. The researchers reported a unit cell efficiency of 19.17%, with lab cell-sized modules reaching up to 17.42%. These results demonstrate the potential of slot-die coating for producing high-performance perovskite solar cells with long-term stability, a critical requirement for commercial solar cells.

Long-Term Stability of Slot-Die Coated Solar Cells

In addition to high efficiency, the study also reported excellent stability for the slot-die-coated perovskite solar cells. The unencapsulated devices maintained over 85% of their initial efficiency after more than 2,000 hours in a nitrogen atmosphere. This level of stability is promising for the future commercialization of perovskite solar cells, as it suggests that slot-die coating can produce durable solar cells with minimal performance degradation over time.

Build your own R2R Slot-die Coater machine. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, laminators and more.

Conclusion: The Future of Slot-Die Coating in Perovskite Solar Cell Manufacturing

This study highlights the immense potential of slot-die coating as a scalable and efficient method for producing high-performance perovskite solar cells. By addressing the challenges associated with wettability and surface roughness at the HTL/perovskite interface, slot-die coating offers a pathway to commercializing perovskite solar cells at a large scale. With the ability to achieve high efficiencies and long-term stability, slot-die-coated perovskite solar cells are well-positioned to become a key technology in the solar energy market.

Future Prospects for Slot-Die Coating in Solar Cell Production

As the solar industry continues to move towards mass production, slot-die coating will likely play an increasingly important role in the manufacturing of perovskite solar cells. Further research into optimizing interface engineering, particularly in terms of surface roughness and energy management, could push the boundaries of what is possible with this technology. Additionally, as slot-die coating techniques evolve, we may see even larger modules with improved efficiencies, driving down the cost of solar energy and accelerating the adoption of perovskite-based solar panels.

Authors

Sushil Shivaji Sangale

Dilpreet Singh Mann

Hyun-Jung Lee

Sung-Nam Kwon

Seok-In Na

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.