Solid-State Lithium-Ion Batteries: Advantages, Production, and Future Prospects

Solid-State Lithium-Ion Batteries in Brief

Solid-state Li-ion batteries are advanced energy storage devices that are gaining significant attention in the field of battery technology. These batteries use a solid-state electrolyte instead of a liquid or gel electrolyte, which offers several advantages over traditional Li-ion batteries.

Why Solid-State Lithium-Ion Batteries

One of the main advantages of solid-state Li-ion batteries is improved safety. By eliminating the flammable liquid electrolyte, the risk of leakage, overheating, and thermal runaway is greatly reduced. This makes solid-state Li-ion batteries less prone to explosions and fires, which is crucial for applications in electric vehicles and portable electronics.

Another benefit of solid-state Li-ion batteries is their higher energy density. The use of solid-state electrolytes allows for the utilization of higher energy materials and facilitates the development of thinner electrode layers, resulting in a higher energy storage capacity per unit volume. This leads to longer battery life and increased range for electric vehicles, as well as longer operational time for portable devices.

Solid-state Li-ion batteries also exhibit better cycle life compared to traditional Li-ion batteries. The solid-state electrolyte enables more stable electrochemical reactions, reducing the degradation of active materials during charge and discharge cycles. This results in longer-lasting batteries that maintain their capacity and performance over a greater number of cycles.

Additionally, solid-state Li-ion batteries have the potential for faster charging and discharging rates. The solid-state electrolyte provides a more efficient pathway for ion transport, reducing internal resistance and enabling rapid charging without compromising battery performance. This is particularly important for electric vehicles, where fast charging is desired to minimize downtime during long trips.

Battery Generation Podcast: Why we're not seeing solid-state batteries right now - Prof. Rupp | Battery Podcast

Still Challenges to Overcome

However, despite these advantages, there are still challenges to overcome in the development of solid-state Li-ion batteries. One major hurdle is the development of solid-state electrolytes with high ionic conductivity at room temperature. Researchers are actively working on finding suitable materials that exhibit both high ionic conductivity and good stability.

Overall, solid-state Li-ion batteries have the potential to revolutionize the battery industry by offering enhanced safety, higher energy density, longer cycle life, and faster charging capabilities. With further advancements in materials and manufacturing techniques, solid-state Li-ion batteries could power the next generation of electric vehicles, portable electronics, and renewable energy systems.

How are Solid-State Li-ion batteries Produced

The production of solid-state Li-ion batteries involves several steps:

1. Electrolyte Fabrication:

The first step is to produce the solid-state electrolyte material. This typically involves mixing different elements or compounds to create a homogeneous mixture. Various techniques such as solid-state synthesis, chemical vapor deposition, or sol-gel methods can be used to produce the desired solid-state electrolyte material.

2. Electrode Fabrication:

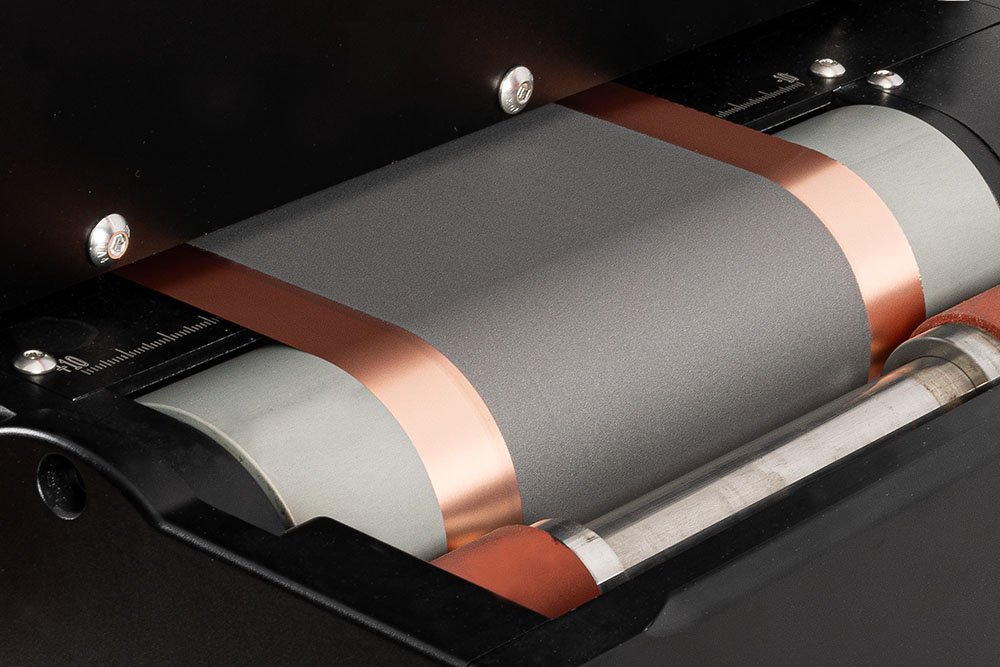

The next step is to fabricate the electrodes. This involves preparing the active material, which is typically a lithium intercalation compound such as lithium cobalt oxide or lithium iron phosphate. The active material is mixed with conductive additives and a binder material to form a slurry. The slurry is then roll-to-roll coated, using slot-die coating or slurry coating, onto a current collector, often made of aluminum for the cathode and copper for the anode and dried to form a solid electrode layer.

3. Battery Assembly:

Once the electrolyte and electrodes are ready, the battery can be assembled. The assembly typically involves stacking alternating layers of cathode, electrolyte, and anode. The number of layers and the specific arrangement may vary depending on the design of the battery. The layered structure is then compressed under suitable pressure to ensure good contact between the electrodes and the electrolyte.

4. Sealing and Packaging:

After the battery assembly, the solid-state Li-ion battery needs to be sealed and packaged to protect it from external elements. The sealing process typically involves welding or bonding the battery components together to create an airtight enclosure. The battery may also be encapsulated in protective materials, such as polymer films, to prevent damage from impacts or moisture.

5. Testing and Quality Control:

Once the batteries are packaged, they undergo various tests to ensure their performance and safety. These tests may include measuring the capacity, voltage, and impedance of the battery, as well as conducting various safety tests such as thermal cycling and short circuit tests. Quality control measures are implemented to identify and troubleshoot any defects or inconsistencies in the production process.

autoevolution: Nissan Shows Production Process for Its All-Solid-State Battery Prototypes

Worth to Keep in Mind

It's worth noting that the production process for solid-state Li-ion batteries is still being actively researched and optimized. As new materials and manufacturing techniques are developed, the production methods may vary, and new steps may be introduced to enhance the performance and efficiency of solid-state Li-ion batteries.

Other New Battery Technologies

Lithium-sulfur batteries

Cobalt-free lithium-ion batteries

Sodium-ion batteries

Iron-air batteries

Zinc-based batteries

Graphene batteries

More About Solid-State Lithium-Ion Batteries

Articles

Janek, J., Zeier, W.G. Challenges in speeding up solid-state battery development. Nat Energy 8, 230–240 (2023). https://doi.org/10.1038/s41560-023-01208-9

Frith, J.T., Lacey, M.J. & Ulissi, U. A non-academic perspective on the future of lithium-based batteries. Nat Commun 14, 420 (2023). https://doi.org/10.1038/s41467-023-35933-2

Lee, YG., Fujiki, S., Jung, C. et al. High-energy long-cycling all-solid-state lithium metal batteries enabled by silver–carbon composite anodes. Nat Energy 5, 299–308 (2020). https://doi.org/10.1038/s41560-020-0575-z

Schnell, J., Günther, T., Knoche, T., Vieider, C., Köhler, L., Just, A., Keller, M., Passerini, S. & Reinhart, G. All-solid-state lithium-ion and lithium metal batteries – paving the way to large-scale production, J. Power Sources, 382 (160-175) (2018). https://doi.org/10.1016/j.jpowsour.2018.02.062.

Websites

Energy Monitor. (2023). Are solid-state batteries finally ready to live up to the hype? [online] Available at: https://www.energymonitor.ai/tech/energy-storage/are-solid-state-batteries-finally-ready-to-live-up-to-the-hype/?cf-view

Built In. (n.d.). New Battery Technologies. [online] Available at: https://builtin.com/hardware/new-battery-technologies

Related Pages

Processing Equipment

We offer comprehensive solutions for printed electronics manufacturing, from small-scale prototyping to large-scale Roll-to-Roll production