Slot-die Coater

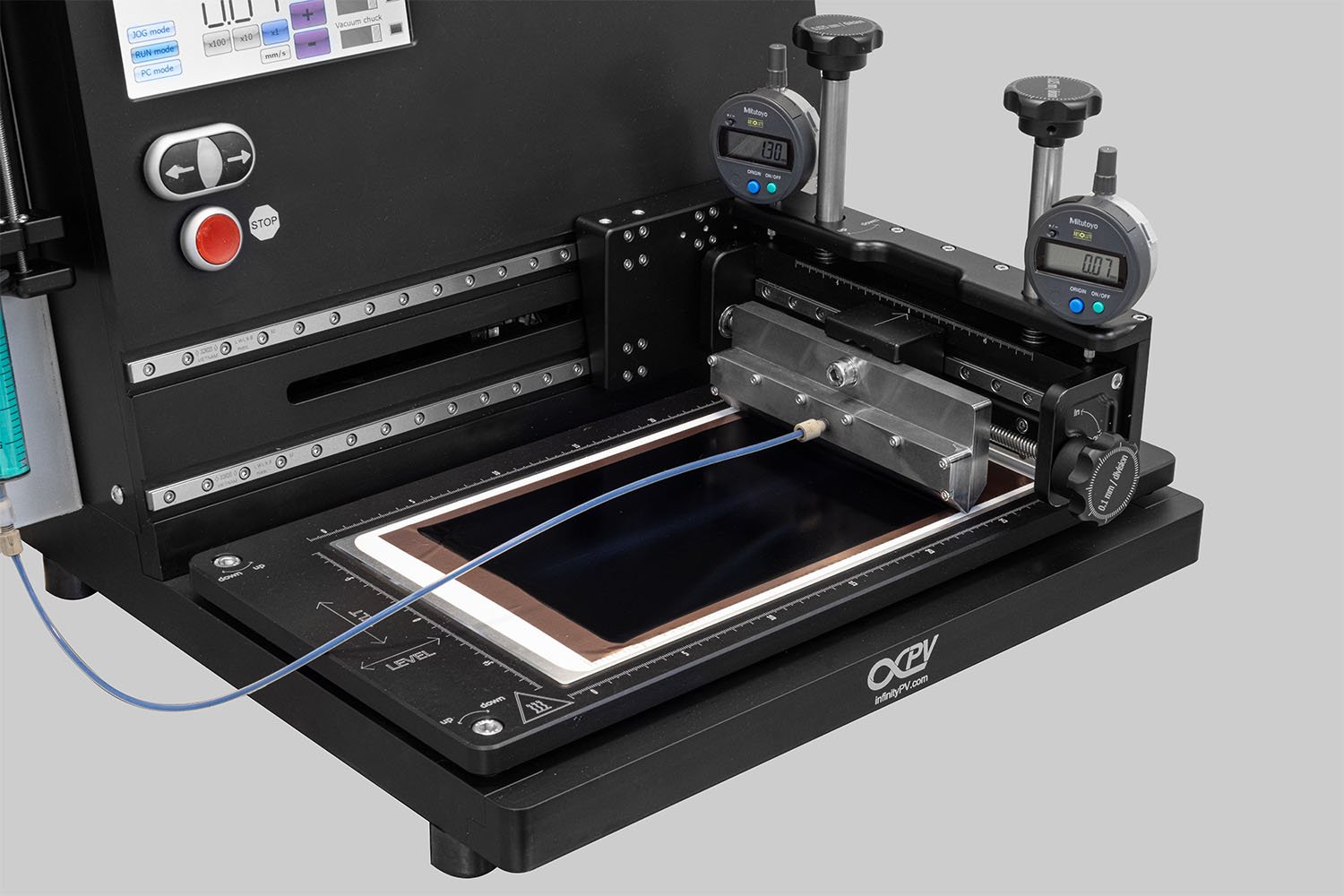

A state-of-the-art, compact sheet coater designed for precise and consistent slot-die coating of thin-films.

State-of-the-Art Slot-die Coater for Advanced Thin-Film Applications

Take your thin-film research to the next level with the Slot-die Coater from infinityPV. Designed to meet the rigorous demands of R&D, this cutting-edge sheet coater delivers precision and reliability for applications including printed batteries, solar cells, fuel cells, MedTech, and more. Whether working with organic or inorganic materials, our Slot-die Coater ensures exceptional coating uniformity, empowering researchers to achieve breakthrough results.

Why Slot-Die Coating Is the Ideal Choice for Thin Films

Slot-die coating stands out for its exceptional uniformity, precise thickness control, and scalability. Perfectly suited for nanometer-to-micrometer-scale films, this technique accommodates a wide variety of liquid formulations, ensuring consistent, high-quality results for diverse applications. Its efficiency and adaptability make it the go-to solution for researchers striving for precision and reproducibility.

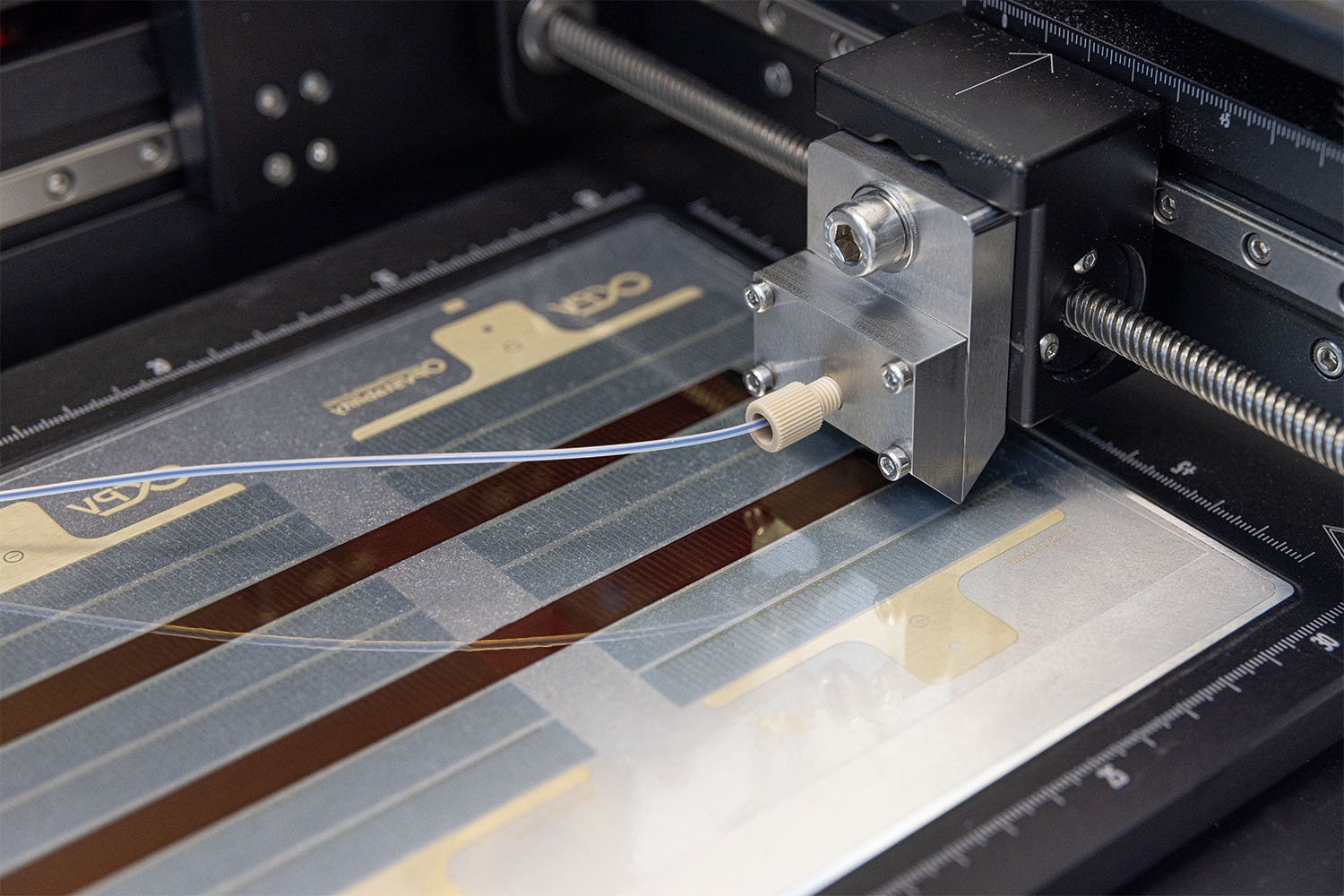

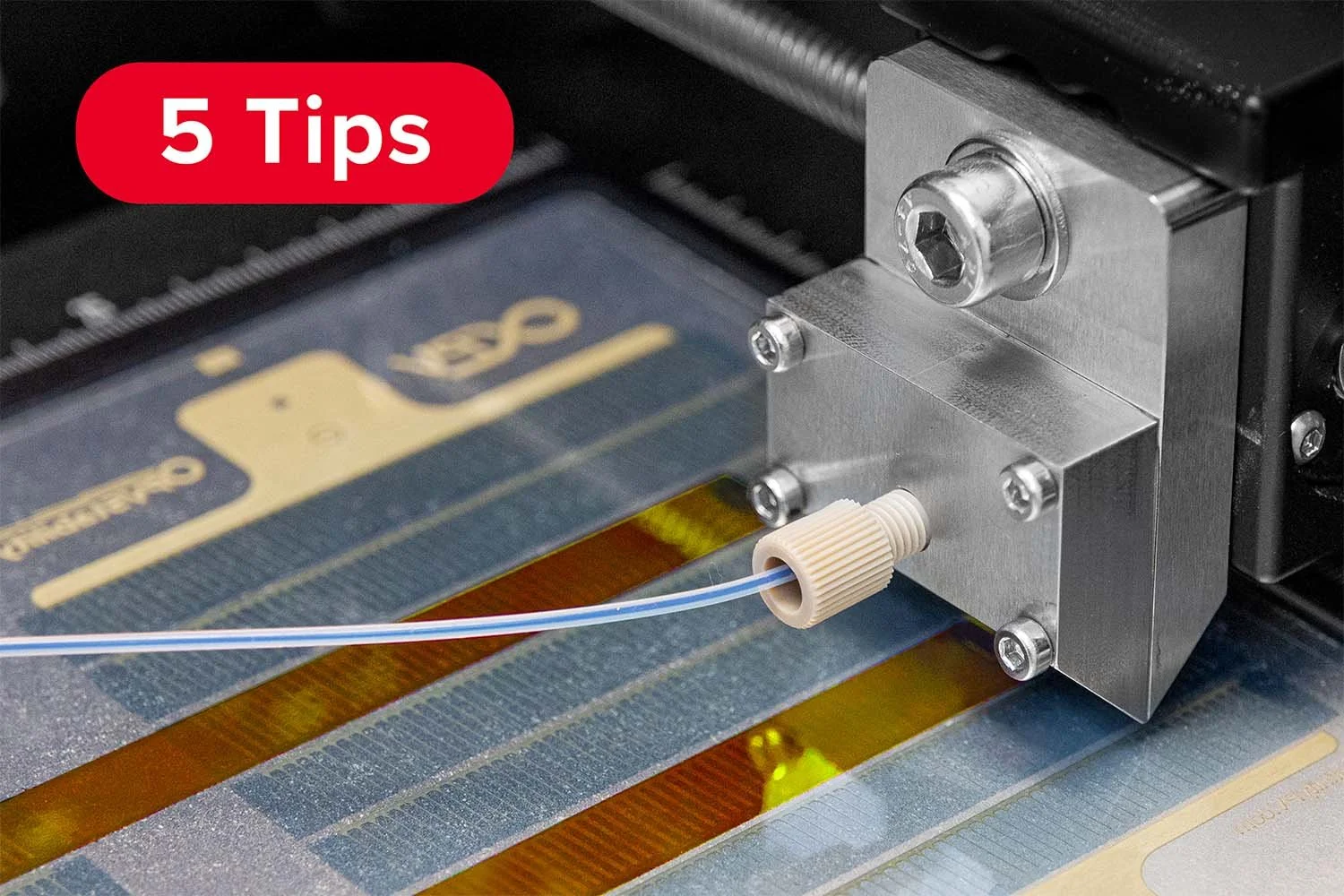

Engineered for Precision: Vacuum Chuck for Substrate Alignment

Uniform thin-film coatings begin with proper substrate alignment. The Slot-die Coater features an ultra-smooth, diamond-milled microporous vacuum chuck that securely holds both rigid substrates and flexible foils. This innovative design ensures precision coating across large areas, guaranteeing reliable performance with every use.

Integrated Drying for Maximum Efficiency

Simplify your workflow with the Slot-die Coater’s heated vacuum chuck, which seamlessly integrates coating and drying into one compact unit. With precise temperature control, this feature ensures uniform drying, improving film quality while saving valuable lab space. Streamline your thin-film processing with this efficient all-in-one solution.

Optimized Ink Delivery with Precision Syringe Pump

Achieve unmatched control over your coating process with the infinityPV Syringe Pump. Offering precise flow rate adjustments, it ensures optimal ink delivery for both organic and inorganic formulations. This versatile pump is essential for tailoring your setup to meet the unique demands of your research and development projects.

Try Slot-die Coater with Your Own Foils — No Obligations

Experience the Slot-die Coater in action with your own foils and solutions. Spend a day in our professional lab, operate the coater yourself, and take real results home — no obligations, just opportunities. Learn more.

Key Features

Quick Set-Up and Easy Operation

Modular Design with interchangeable components

Cantilever Structure for convenient substrate handling

Heated Vacuum Chuck for precise alignment and drying

Micrometer Adjustments for head-to-substrate gap

Integrated Syringe Pump for precise ink delivery

Versatile Coating/Printing Options: Slot-Die Coating, Bar Coating, Knife Coating, Pen, and Flexo Printing

Compact Design: Compatible with glovebox and fumehood

CE Certified & CSA/UL Compliant for global use

Technical Specifications

Coating Width: 100 x 280 mm (Mini) | 160 x 280 mm (Pro)

Coating Speed: 1.2 – 33 mm/sec

Size: 440 x 360 x 400 mm (Mini) | 440 x 420 x 400 mm (Pro)

Weight: 22 kg (Mini) | 24 kg (Pro)

Operating Power: 110-240 VAC

Hot Plate Temperature Range: RT – 140 °C

Vacuum Chuck Temperature Range: RT – 100 °C

Slot-die Head Adjustment Resolution: 1 μm

Control Interface: Touchscreen and physical buttons for easy operation

Option for Heated Slot-die Head

Watch How Easy It is to Get Results

Making Uniform Thin-films Using the Slot-die Coater

Making Solar Cells on the Slot-die Coater

Making Batteries Using the Slot-die Coater

Platforms

Customize your Slot-die Coater to meet your exact needs. Choose your platform, integrate precision syringe pumps, and select from various coating tools, including slot-die heads for uniform thin films, bar coaters, knife coaters, and flexo printers. Build the perfect system for your applications with ease.

Coating Area: 100 x 280 mm

A compact sheet coater for advanced thin-film applications that offers precision and reliability for R&D in areas like printed batteries, solar cells, fuel cells, OLEDs, and sensors.

Coating Area: 160 x 280 mm

A compact sheet coater for advanced thin-film applications that offers precision and reliability for R&D in areas like printed batteries, solar cells, fuel cells, OLEDs, and sensors.

Components

Customize your Slot-die Coater to meet your exact needs. Choose your base plate, integrate precision syringe pumps, and select from various coating tools, including slot-die heads for uniform thin films, bar coaters, knife coaters, and flexo printers. Build the perfect system for your applications with ease.

The infinityPV slot-die heads offer unparalleled performance across various materials and size. Available in PEEK, Stainless and Titanium in standard widths of 40 mm, 65 mm, 115 mm, 165 mm, 195 mm and 305 mm. View video.

Engineered with precision and innovation in mind, our slot-die heads offer unparalleled performance across various materials and size. Available in Stainless Steel and Titanium in standard widths of 40 mm, 65 mm, 115 mm and 165 mm. View video.

If you need a customized slot-die head tailored to your specific requirements, our expert team is ready to collaborate with you to design and manufacture a solution that meets your exact needs. View video.

The Slot-die Coater includes an integrated hot plate for convenient drying of processed thin films directly on the unit. The system features a standard hot plate capable of reaching temperatures up to 100 °C, ensuring efficient drying during your coating process.

Upgrade from the standard hot plate, which reaches up to 100 °C, to the high-temperature hot plate capable of reaching 140 °C. This enhanced option provides greater flexibility, optimizing your thin-film coating applications.

Upgrade from the standard hot plate to the heated vacuum chuck, capable of reaching up to 100 °C. This advanced feature provides precise workholding for thin foils and substrates, minimizing deformation during coating and printing.

Bar Coater for thin films: The spring-loaded system compensates for minor alignment inaccuracies. Simply push one of the five bars (10, 25, 50, 100, or 250 microns) into the holder to achieve various wet thicknesses.

The knife coater unit has a knife blade in anodized aluminum with a high precision ground edge, resulting in a coating width of 30 mm.

The simple flexographic roller system can be used for printing many types of materials when preparing single devices among others the back silver for inverted geometry device.

Optimize the drying and quenching of coated thin films with the air knife. Designed for materials like perovskites, it offers precise control with adjustable angles, distances, and customizable air blade widths.

With micrometer screws and a digital display, the Air Knife Pro allows for fine-tuning the air knife position, giving you reliable control that’s ideal for applications requiring consistent, repeatable results.

Experience precision with syringe pumps, available in Standard (0-20 mL) and Jumbo (0-60 mL) variants.

Manual positioning of the slot-die head, bar coater, knife coater or flexo roller. Included with the base Slot-die Coater.

The advanced mounting system features manual adjustment with digital micrometers to ensure precise head-to-substrate distance control.

Software control of the coating position with 3-axis motion control (side registration, up/down, fwd/rev).

Engineered for precise temperature regulation and superior slot-die coating performance, this advanced controller guarantees uniform film thickness and enhances product quality, ensuring optimal results with every use.

Makes it easy to position and handle your coating equipment in gloveboxes or other confined spaces, allowing smooth movement and secure locking in the precise position you need.

Peer-Reviewed Studies Featuring the Slot-die Coater

Upgrade Your Slot-Die Coater with Roll-to-Roll Capability

Create the R2R Hybrid Coater. Start by configuring the Slot-die Coater to match your thin-film needs, then choose and configure the compatible Laboratory Roll-to-Roll Coater. Once ready, dock the Slot-die Coater on top for a fully integrated setup.

Slot-die Coater

Customize the Slot-die Coater with the options and the components that is needed for processing your thin film technologies.

Laboratory Roll-to-Roll Coater

The Laboratory Roll-to-Roll Coater's modular design allows users to customize the system according to their specific requirements.

R2R Hybrid Coater

Dock the Slot-die Coater Pro onto the Laboratory Roll-to-Roll Coater platform and get the most advanced equipment in lab-scale thin film processing.

We Are Ready to Help You

With decades of experience in slot-die coating, our team is here to provide in-depth guidance on choosing the right system for your needs. Whether you're exploring advanced production methods or need help fine-tuning your setup, we offer expert advice tailored to your project.

Frequently Asked Questions

-

The infinityPV Slot-Die Coater is designed for high-precision thin-film research. It features a heated vacuum chuck for substrate alignment, an integrated syringe pump for precise ink delivery, and a modular design that allows easy customization.

-

Our Slot-Die Coater is ideal for R&D in printed batteries, perovskite and organic solar cells, fuel cells, OLEDs, flexible electronics, sensors, and other thin-film applications.

-

Coating Width: 100 x 280 mm (Mini) | 160 x 280 mm (Pro)

Coating Speed: 1.2 – 33 mm/sec

These parameters allow for flexible coating setups in various research environments.

-

Yes, the compact design of the infinityPV Slot-Die Coater makes it compatible with both gloveboxes and fume hoods, making it suitable for sensitive materials and controlled atmospheres.

-

Yes, the Slot-Die Coater includes a hot plate that enables uniform drying of thin films. The temperature range varies depending on the configuration, with options extending up to 140°C.

-

infinityPV offers slot-die heads in PEEK, stainless steel, and titanium, available in standard widths from 40 mm to 165 mm. Heated slot-die heads are also available for applications requiring precise temperature control.

-

Slot-die coating is a precision thin-film deposition technique used to create uniform coatings across various substrates. It is widely used in research and industrial applications for solar cells, batteries, OLEDs, sensors, and printed electronics.

-

Slot-die coating offers superior uniformity, precise thickness control, and high material efficiency. Unlike spin coating or dip coating, it minimizes material waste and is easily scalable from laboratory to industrial production.

-

Slot-die coating provides higher precision and better material utilization than spray coating, which can lead to overspray and waste. Compared to blade coating, slot-die technology offers better control over film thickness and is more suited for high-throughput production.

Technical Specifications

Slot-die Coater

| Item | Technical Parameter | Remarks |

|---|---|---|

| Dimensions (WxDxH) | Slot-die Coater Mini: 440 x 360 x 400 mm Slot-die Coater Pro: 440 x 420 x 400 mm | Depends on final configuration |

| Weight | Slot-die Coater Mini: 22 kg Slot-die Coater Pro: 24 kg | Depends on final configuration |

| Coating Area | Slot-die Coater Mini: 100 x 280 mm Slot-die Coater Pro: 160 x 280 mm | |

| Coating Speed | 1.2 – 33 mm/sec | |

| Operating Power | 110 - 240 VAC | Depends on final configuration |

| System | Touch Screen | Depends on final configuration |

| Control | Manual Adjustment PC Control | Depends on final configuration |

| Base Plate Temperature | Hot Plate: RT – 140 °C Vacuum Chuck: RT – 100 °C | |

| Thin Film Processing Options | Slot-die Coating Heated Slot-die Coating Knife Coating Bar Coating Simple Flexo Printing | |

| Slot-die Coating Width | 5 mm – 150 mm | Patterned or full coating |

| Slot-die Head Position | 12 o’clock | |

| Height Adjustment (Head to Substrate) | 5 mm | |

| Sideways Travel Length | Slot-die Coater Mini: 100 mm Slot-die Coater Pro: 160 mm | |

| Slot-die Head Material | Stainless Steel (M315 and 316L) PEEK Titanium | |

| Tubing and Connector Material | PTFE (Tubing) and Peek (Connector) |

Syringe Pump

| Item | Technical Parameters | Remarks |

|---|---|---|

| Pump Control | Touch Screen Computer Control | |

| Ink Flow | 0.01 ml – 9.99 ml | |

| Ink Volume | Standard Pump up to 20 ml syringe Jumbo Pump up to 60 ml syringe. | |

| Option for Mixing/Gradient Experiments | Combine up to 4 pumps for advanced mixing and gradients experiments | |

| Power Supply | 24 V | Powered from Slot-die Coater |

| Thin Film Processing Options | Slot-die coating, heated slot-die head, knife coating, bar coating, simple flexo printing |

Coating and Printing Components

| Item | Technical Parameters | Remarks |

|---|---|---|

| Heated Slot-die Heads | ||

| Temperature Range | RT-100 ◦C. | |

| Slot-die Head Material | Stainless Titanium | |

| Slot-die Coating Width | 10 mm – 150 mm | Patterned or full coating |

| Flexo Printer | ||

| Printing Width | 25 mm wide standard 1-junction 10 mm wide stripes sleeve | |

| Printing Thickness | 1.5-50 m3m2 | |

| Printing Pattern | Slanted Stripes | Customized patterns obtainable |

| Bar Coater | ||

| Coating Width | 36 mm | |

| Coating Thickness | The nominal thickness obtainable with each bar: #1 = 10 micron #2 = 25 micron #3 = 50 micron #4 = 100 micron #5 = 250 micron | |

| Coating Thickness Adjustment | Changing Bars | |

| Bar Coater Material | The bars are made of Stainless Steel | |

| Knife Coater | ||

| Coating Width | 30 mm | |

| Coating Thickness | Up to 750 microns | |

| Coating Thickness Adjustment | Manually | |

| Knife Coater Material | Stainless (the Knife) and Alloy |

Which Slot-die Head Do YOU Need?

Your coating process is only as good as the head that delivers it. Whether you’re developing batteries, solar cells, fuel cells, pharmaceuticals, or something else, selecting the right slot-die head is critical for quality, efficiency, and cost-effectiveness. In our guide, we break down how to evaluate your needs and help you understand which size and material slot-die head suits your application best.