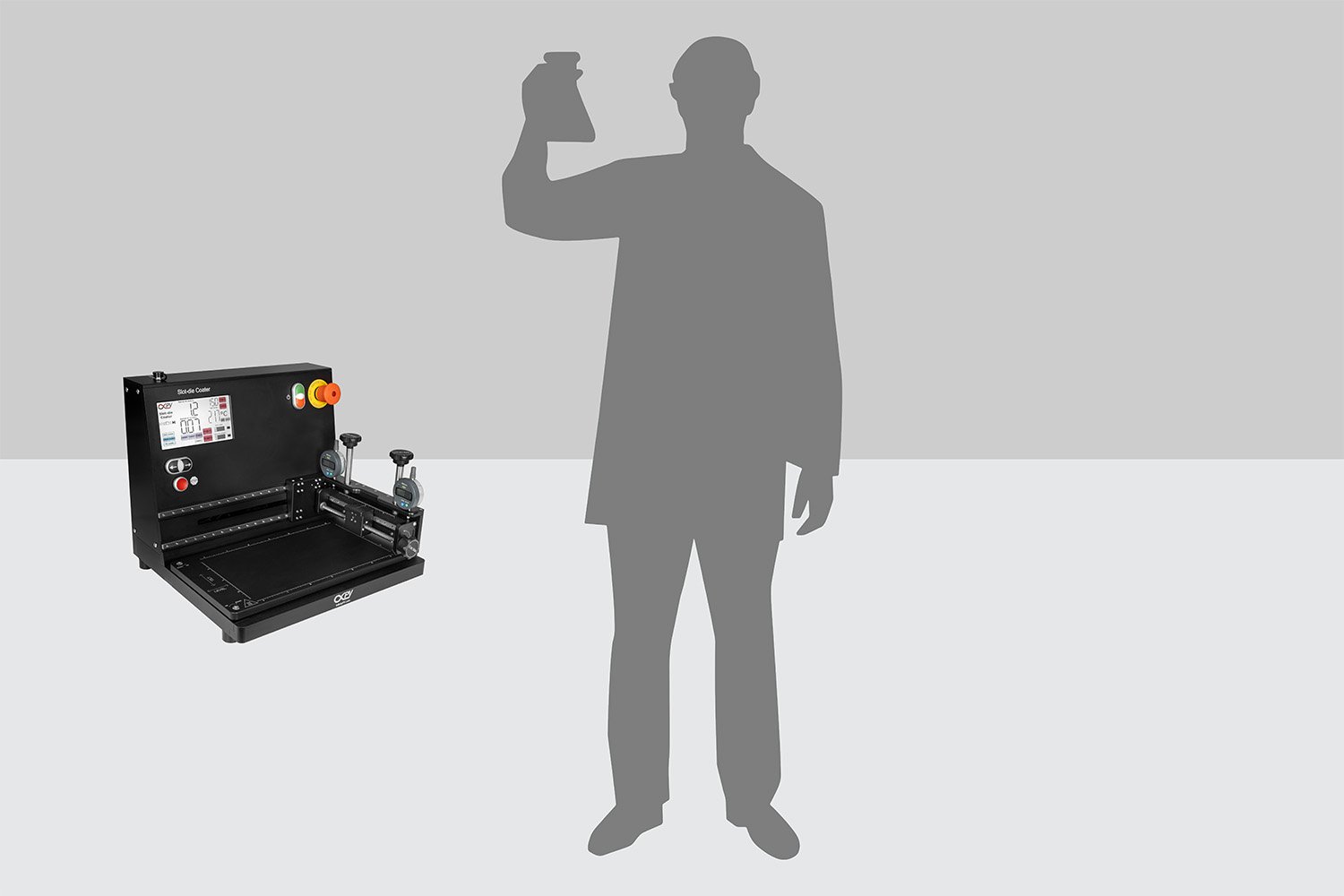

Slot-die Coater Platform

A compact sheet coater for advanced thin-film applications that offers precision and reliability for R&D in areas like printed batteries, solar cells, fuel cells, OLEDs, and sensors.

A compact sheet coater for advanced thin-film applications that offers precision and reliability for R&D in areas like printed batteries, solar cells, fuel cells, OLEDs, and sensors.

A compact sheet coater for advanced thin-film applications that offers precision and reliability for R&D in areas like printed batteries, solar cells, fuel cells, OLEDs, and sensors.

The Slot-Die Coater is designed to meet the stringent needs of advanced thin-film applications. Offering exceptional coating uniformity, it delivers precise thickness control, perfect for both organic and inorganic materials. This cutting-edge coater ensures outstanding results for a wide range of applications, including printed batteries, solar cells, fuel cells, OLEDs, and sensors.

Why Slot-Die Coating Is the Ideal Choice for Thin Films

Slot-die coating stands out for its exceptional uniformity, precise thickness control, and scalability. It accommodates a variety of liquid formulations, making it perfect for nanometer-to-micrometer-scale films and ensuring consistent, high-quality results for various applications. Its efficiency and adaptability make it the go-to choice for precision and reproducibility in R&D.

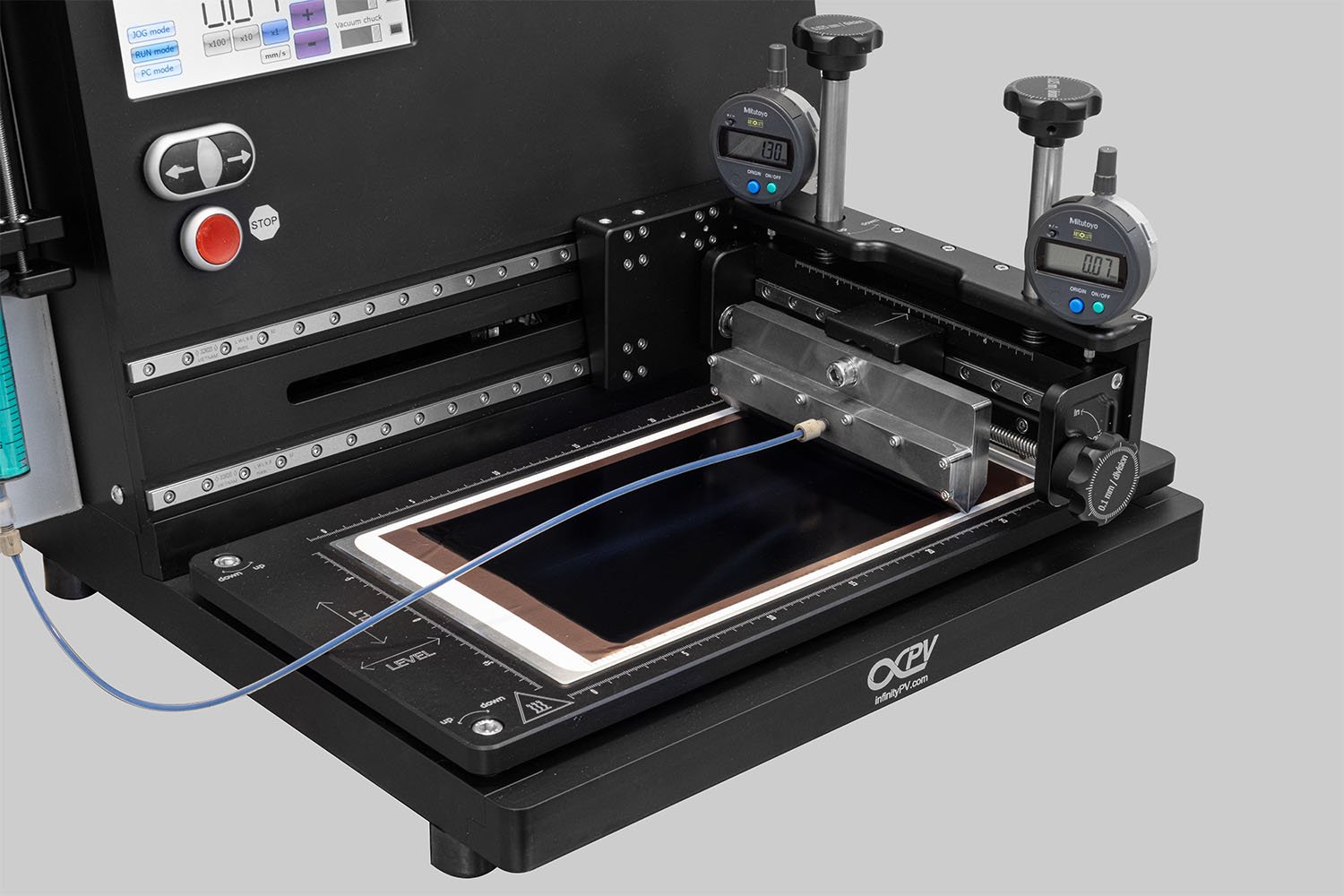

Engineered for Precision: Vacuum Chuck for Substrate Alignment

The coater features a diamond-milled microporous vacuum chuck, ensuring precise alignment and secure holding of both rigid substrates and flexible foils. This design guarantees uniform coatings across large areas, providing reliable results with every use.

Integrated Drying for Maximum Efficiency

Simplify your workflow with an integrated heated vacuum chuck, combining coating and drying into one compact unit. Offering precise temperature control, it ensures uniform drying, improving film quality while saving lab space.

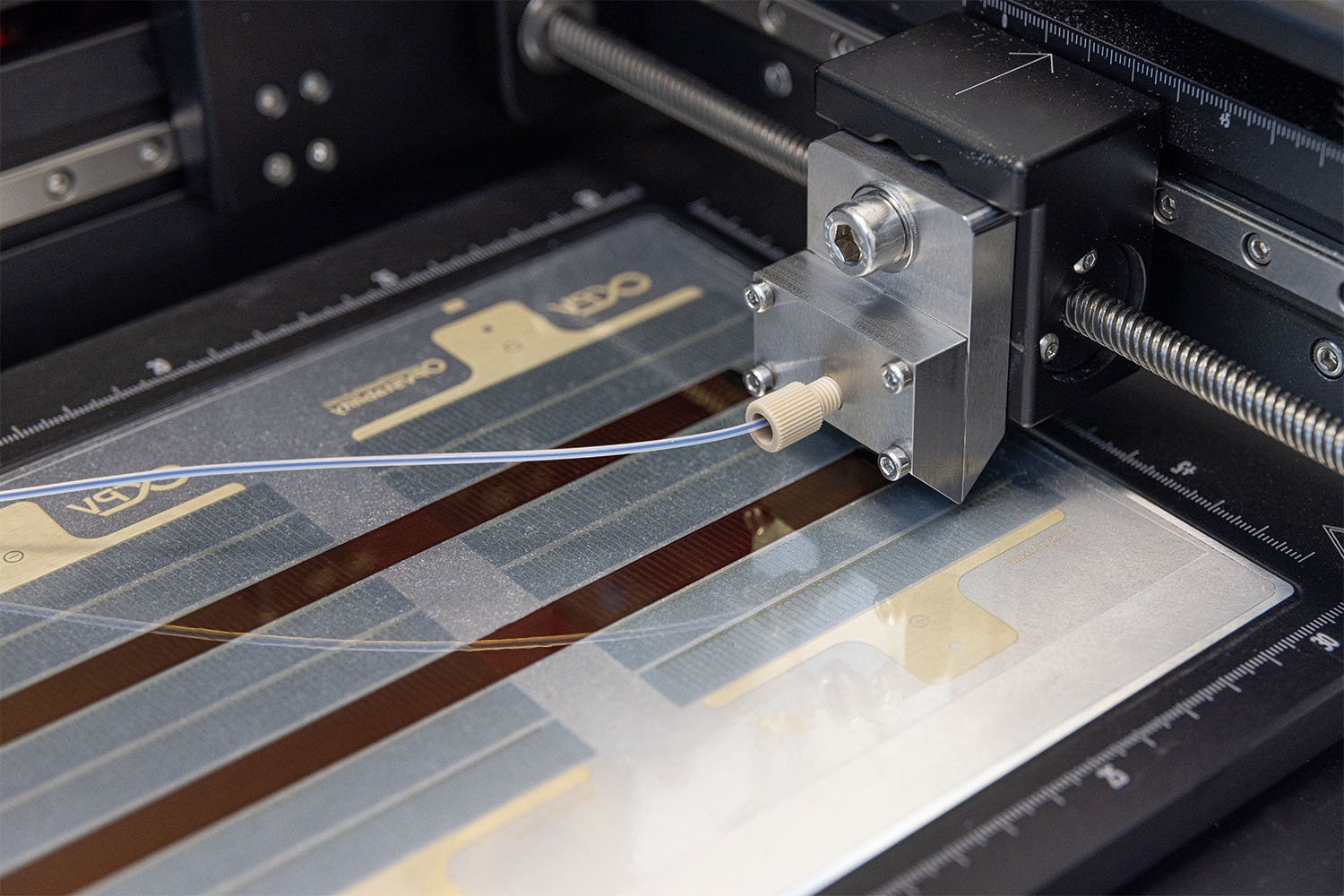

Optimized Ink Delivery with Precision Syringe Pump

Achieve ultimate control over your coating process with the infinityPV Syringe Pump. It provides precise flow rate adjustments for optimal ink delivery, perfect for both organic and inorganic formulations. Tailor your setup for the unique demands of your R&D projects.

Key Features

Quick Set-Up and Easy Operation

Modular Design with interchangeable components

Cantilever Structure for convenient substrate handling

Heated Vacuum Chuck for precise alignment and drying

Micrometer Adjustments for head-to-substrate gap

Integrated Syringe Pump for precise ink delivery

Versatile Coating/Printing Options: Slot-Die, Bar, Knife, Pen, and Flexo

Compact Design: Compatible with glovebox and fumehood

CE Certified & CSA/UL Compliant for global use

Technical Specifications

Operating Power: 110-240 VAC

Coating Speed: 1.2–33 mm/sec

Vacuum Chuck Temperature Range: RT–90 °C

Size: 340 x 420 x 400 mm (WxDxH)

Weight: 22.5 kg

Height Adjustment Resolution: 1 μm

Control Interface: Touchscreen and physical buttons for easy operation

Option for Heated Slot-die Head