Industrialization of Perovskite Solar Cells: Achievements, Challenges, and Future Prospects

A recent study published in Light: Science & Applications titled "Achievements, Challenges, and Future Prospects for Industrialization of Perovskite Solar Cells" delves into the rapid advancements and ongoing challenges in the development of perovskite solar cells (PSCs). This review provides a comprehensive analysis of the current state of PSC technology, outlines the major obstacles to large-scale production, and offers insights into the future potential of this promising renewable energy technology.

Key Highlights

Impressive Efficiency Achievements: Over the past decade, PSCs have achieved remarkable progress, reaching a certified power conversion efficiency (PCE) of 26.1%. This high efficiency positions PSCs as a strong competitor to established solar technologies.

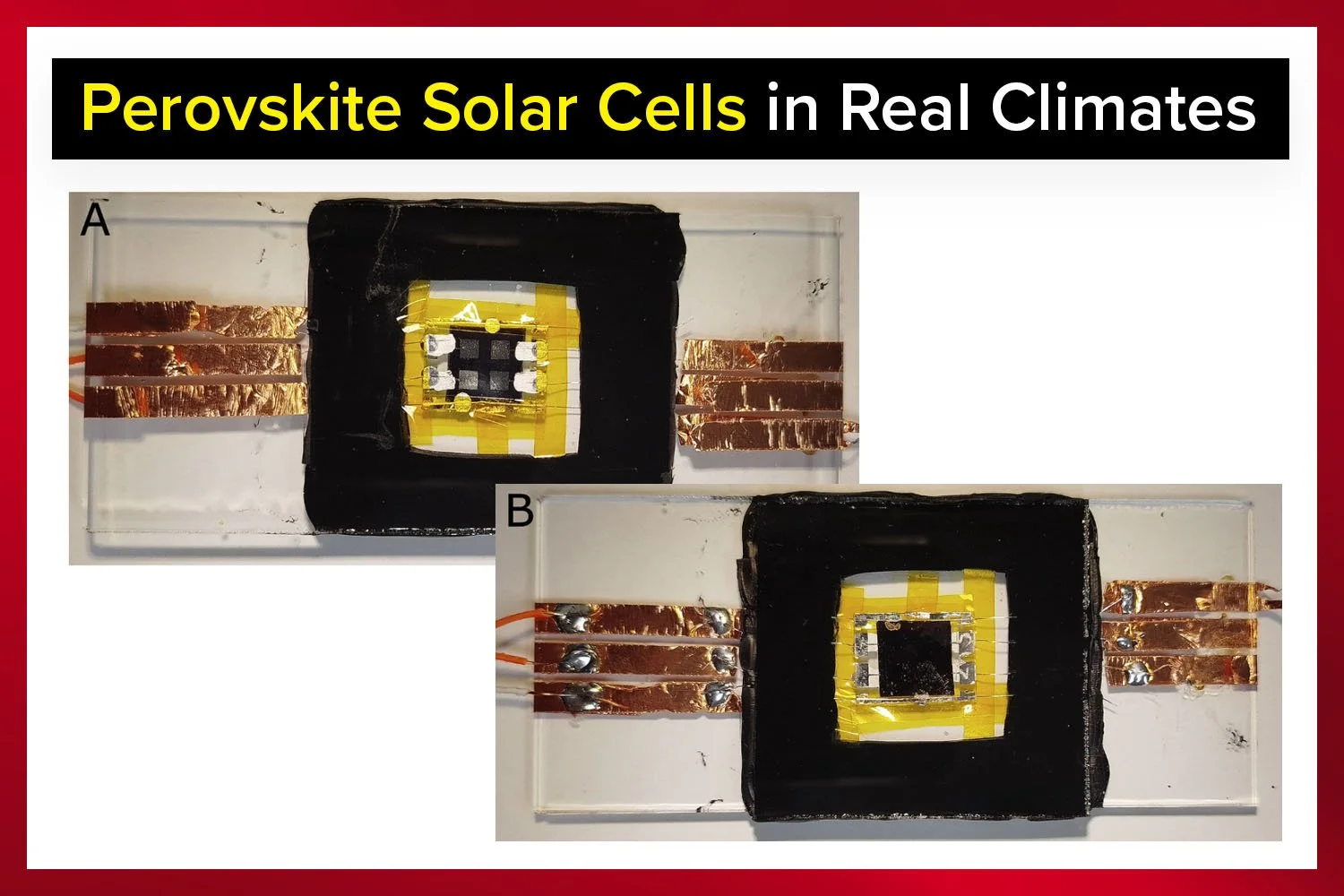

Challenges in Stability and Upscaling: Despite their efficiency, PSCs still face significant hurdles in terms of long-term stability, particularly with respect to thermal and light stability. Additionally, scaling up from laboratory-level devices to large-area perovskite solar modules (PSMs) presents challenges that need to be addressed.

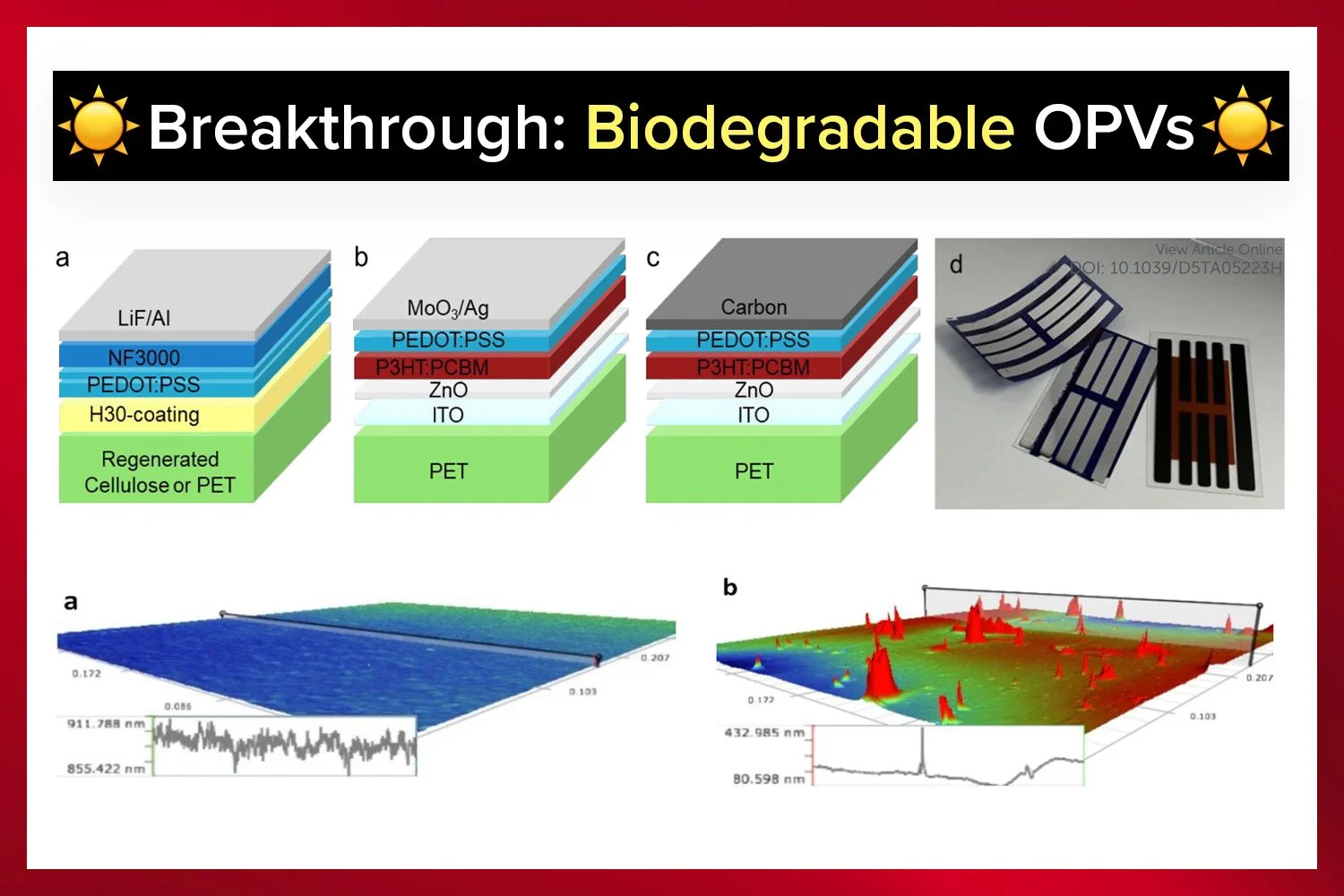

Sustainability Considerations: The study emphasizes the importance of sustainable practices, including the use of green solvents, device recycling, and encapsulation technology to reduce the environmental impact of PSCs during their life cycle.

Future Prospects: With ongoing research and technological improvements, PSCs are expected to see broader applications across various scenarios, offering great potential for integration into diverse environments.

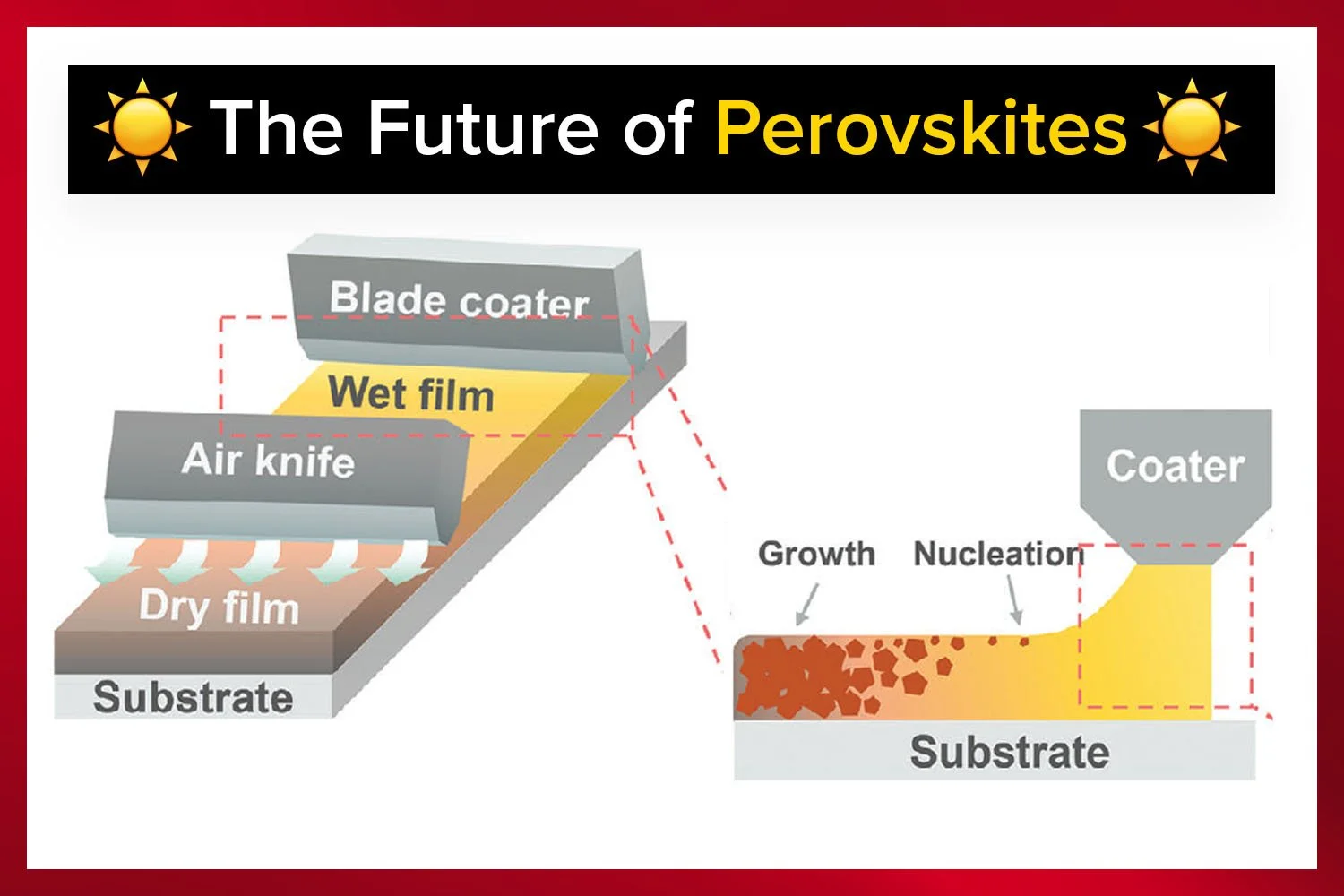

With the Slot-die Coater, it is easy to make solar cells.

Introduction: The Promise of Perovskite Solar Cells

Solar power has become one of the most reliable and renewable energy sources, with significant advancements in photovoltaic (PV) technology over the years. Silicon-based solar cells have dominated the market for decades, but newer technologies like perovskite solar cells are emerging as strong contenders due to their excellent photoelectric properties and potential for higher performance at lower costs.

Perovskite materials, particularly metal halide perovskites, have garnered attention due to their ability to achieve high power conversion efficiencies. Since the first PSCs were developed, their efficiency has risen dramatically, with the latest certified single-junction PSCs reaching an impressive 26.1%. This breakthrough marks a pivotal moment in the industrialization of PSCs.

-

Perovskite solar cells offer several advantages over silicon-based cells, including higher efficiency potential, lower production costs, and flexibility in design. These attributes make PSCs a highly promising technology for the future of solar energy.

Key Challenges in the Industrialization of PSCs

While PSCs show tremendous promise, the road to industrialization is not without its challenges. The review identifies several key areas that require attention for PSCs to become a viable and sustainable technology on a large scale.

1. Stability Issues

One of the most pressing concerns for PSCs is their long-term stability. While encapsulation technologies have helped to address issues related to water and oxygen exposure, PSCs still face challenges related to thermal and light stability. These issues can cause degradation and performance fluctuations, which are significant barriers to large-scale adoption.

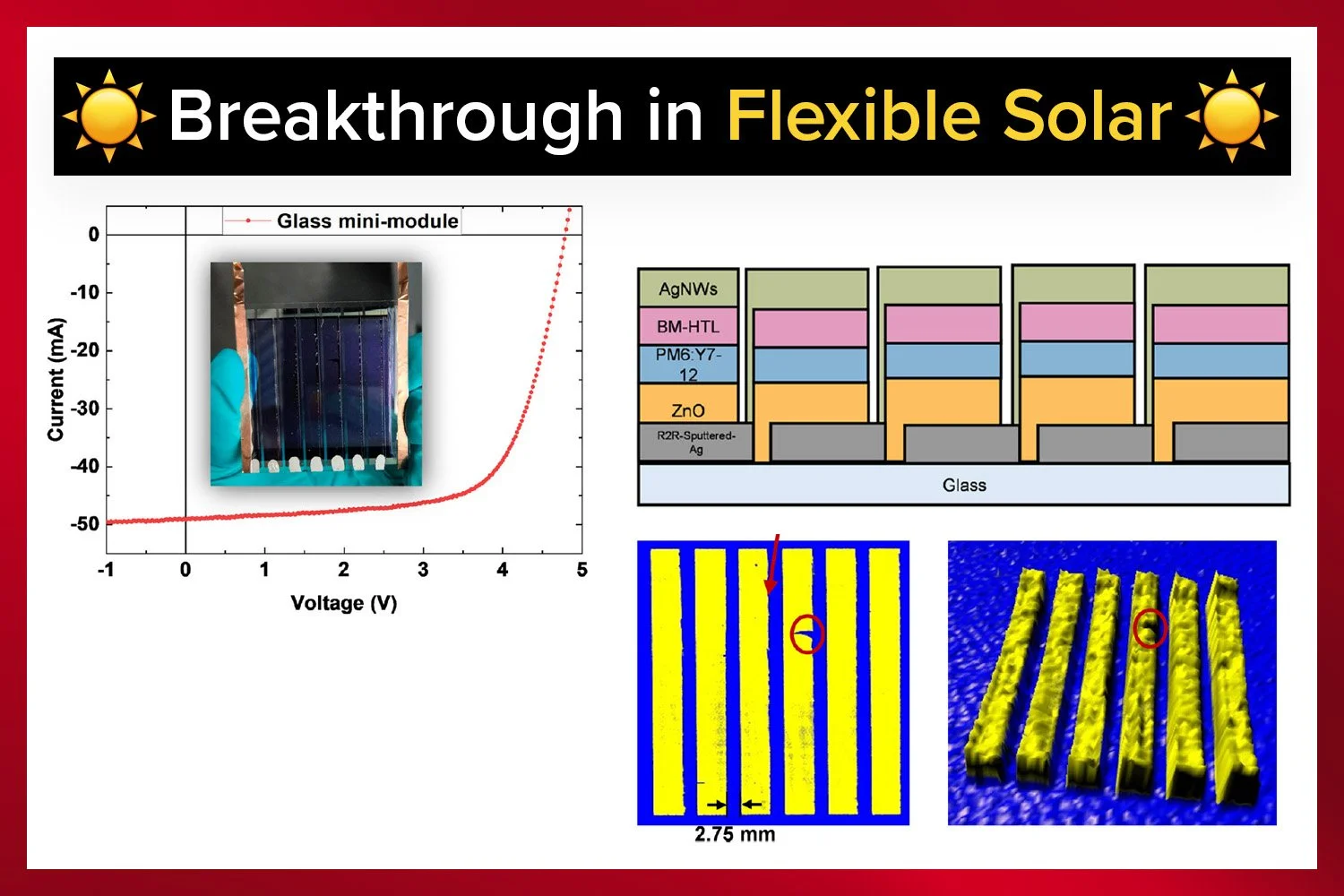

2. Scaling Up Production

Another challenge is upscaling from small-area laboratory devices to large-area perovskite solar modules. The efficiency losses during this transition are significant, and much effort is needed to reduce the performance gap between laboratory-scale devices and their large-area counterparts.

3. Sustainability

As with any emerging technology, sustainability is a key consideration. The study highlights several strategies that can help reduce the environmental impact of PSCs, such as the use of green solvents, effective recycling methods, and encapsulation to protect the materials during their life cycle. However, these practices must continue to evolve to ensure that PSCs are not only a source of clean energy but also environmentally responsible.

Build your own R2R Slot-die Coater machine. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, laminators and more.

Multi-Scenario Applications: Expanding the Reach of PSCs

The versatility of PSCs is another key strength. PSCs can be fabricated in various structures and sizes to suit different applications, from small-scale devices to large solar modules. The study discusses ongoing research aimed at optimizing these fabrication techniques to ensure that PSCs can be deployed in a wide range of scenarios. As research continues, PSCs are expected to be more widely used across various industries, further increasing their potential impact on renewable energy systems.

Conclusion: The Path Forward for PSCs

In summary, perovskite solar cells have made significant strides in terms of efficiency, positioning them as a strong contender in the renewable energy sector. However, their industrialization faces several key challenges related to stability, upscaling, and sustainability. Overcoming these obstacles will require continued research and technological development. The study concludes that with ongoing efforts to improve these areas, PSCs have the potential to play a significant role in the global energy transition, contributing to the widespread adoption of clean, renewable energy.

The findings of this review are critical for guiding the future development of PSCs and ensuring that they can be effectively integrated into various applications in the years to come.

Authors:

Chuang Yang

Wenjing Hu

Jiale Liu

Chuanzhou Han

Qiaojiao Gao

Anyi Mei

Yinhua Zhou

Fengwan Guo

Hongwei Han

Probably the World’s Most Compact R2R Slot-die Coater: A compact, fully integrated roll-to-roll coating platform for laboratories, complete with a mounting system, anodized rollers, a syringe pump, a 65 mm stainless slot-die head and an infrared oven system—delivering unmatched precision and scalability.