Exploring Slot-Die Coating of Niobium Pentoxide: A Scalable Solution for Enhancing Perovskite Solar Cell Stability and Performance

Overview

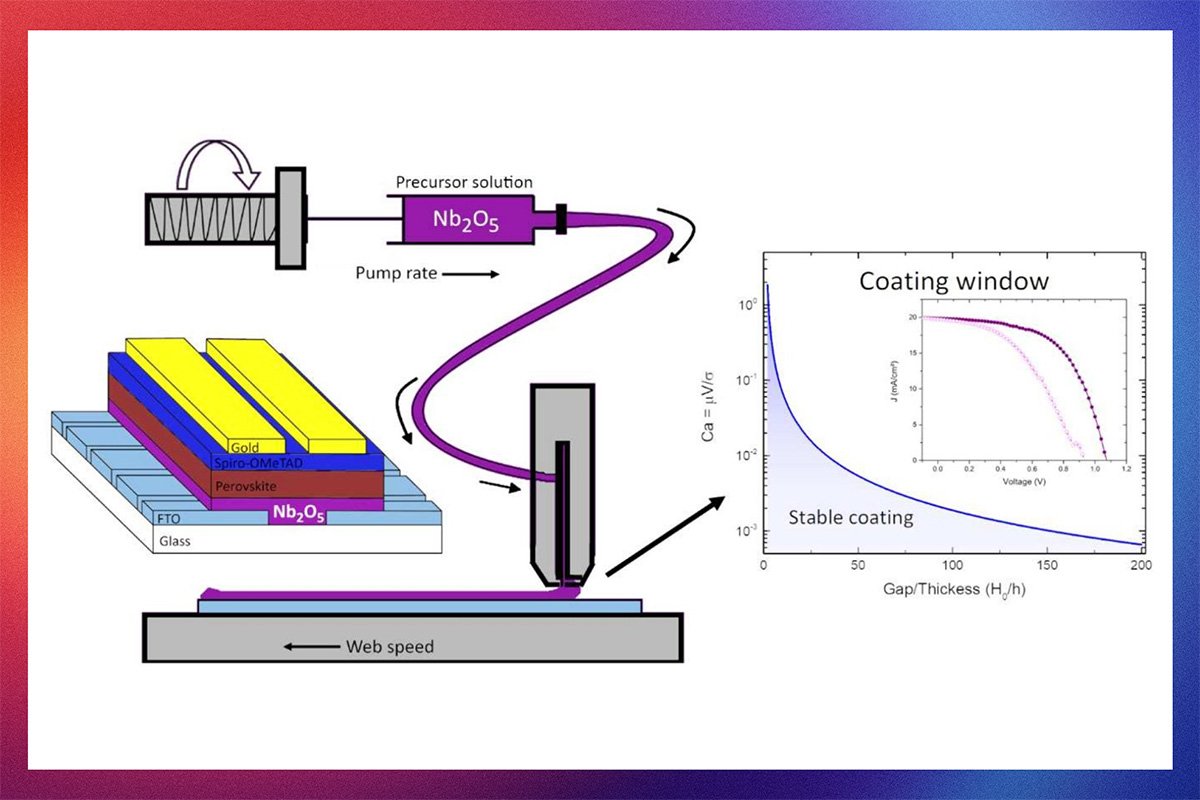

This study investigates the innovative use of slot-die coating for depositing niobium pentoxide (Nb₂O₅) as an electron transport layer (ETL) in perovskite solar cells, a technique not previously explored in existing literature. Niobium pentoxide is recognized for its favorable properties, such as stability, transparency, and appropriate energy level alignment, making it a suitable candidate for addressing the stability challenges in perovskite solar cells. The research emphasizes optimizing slot-die coating parameters to produce high-quality, scalable films that can be seamlessly integrated into industrial production processes.

Key Highlights

Innovative Approach: This study is the first to employ slot-die coating for niobium pentoxide layers in perovskite solar cells, demonstrating a scalable, solution-based deposition method that aligns with industrial production needs. Slot-die coating allows for the continuous deposition of thin films over large areas, making it ideal for commercial applications.

Optimization of Parameters: The research examines critical parameters of the slot-die coating process, including solution concentration, pump rate (Q), and web speed (V). By adjusting these factors, the study achieved a balance between the solution flow and substrate speed, leading to films with controlled thickness and uniform coverage. This precise control is essential for optimizing the electron-selective properties of the niobium pentoxide layers.

Performance Insights: Devices utilizing optimally coated niobium pentoxide layers demonstrated efficiencies of up to 12%. The study employed current density versus voltage scans and transient analysis to assess device performance. Notably, the transient analysis identified an optimal delay time of approximately 200 ms for integrating current–voltage measurements, which helps stabilize the device’s operation by reaching an equilibrium state. This detailed analysis provided valuable insights into the dynamic phenomena that affect device performance, such as charge transport and recombination processes.

Introduction to Solar Cell Technologies

Generations of Solar Cells:

First Generation: Based on silicon technology, these cells are widely used but are limited by high production costs.

Second Generation: Includes thin-film technologies like Copper Indium Gallium Selenide (CIGS), CdTe (cadmium telluride), and GaAs, which offer reduced costs and improved flexibility.

Third Generation: Emerging technologies such as dye-sensitized and perovskite solar cells. Perovskite cells, in particular, have gained significant attention due to their rapidly improving power conversion efficiencies. However, these cells face stability issues and performance inconsistencies related to the size and deposition methods of their layers.

Challenges in Perovskite Solar Cells: Despite their potential, perovskite solar cells struggle with long-term stability and the formation of defects at the interfaces between different layers, particularly between the electron transport layer (ETL) and the perovskite absorber. These defects can cause performance degradation and hysteresis in current–voltage characteristics, leading to efficiency losses. Historically, materials like titanium dioxide (TiO₂) and tin dioxide (SnO₂) have been used as ETLs, but they exhibit drawbacks such as UV-induced degradation and processing challenges.

Niobium Pentoxide as an Electron Transport Layer

Advantages of Nb₂O₅: Niobium pentoxide has emerged as a promising ETL material due to its high stability, resistance to UV degradation, and suitable energy band alignment, which promotes efficient electron transport while blocking holes. Unlike TiO₂, Nb₂O₅ does not catalyze the degradation of the perovskite layer, thus offering a more stable interface. Its deposition can be achieved through various methods, but scalable techniques like slot-die coating have the potential to meet industrial demands.

Previous Methods and Limitations: Traditional deposition methods, such as spin coating, sputtering, electron beam (EB), and atomic layer deposition (ALD), have shown varying levels of success with Nb₂O₅ but often face limitations in scalability, cost-effectiveness, or operational complexity. For instance, while sputtering and ALD can produce high-performance layers, they are generally expensive and less suitable for large-scale applications. Similarly, spin coating, though effective, poses challenges in uniformity and scalability for large-area coatings.

Slot-Die Coating as a Scalable Solution: Slot-die coating addresses the limitations of other methods by providing a continuous, scalable, and cost-effective way to deposit thin films. This technique is widely used in the coating of perovskite and Spiro-OMeTAD layers but has not been extensively explored for metal oxides like Nb₂O₅ until this study. By carefully controlling the slot-die coating parameters, the research demonstrates that it is possible to produce niobium pentoxide films with the desired thickness and coverage quality, enhancing the overall device performance.

Conclusions

The study successfully demonstrates that slot-die coating can be used to deposit niobium pentoxide as an ETL in perovskite solar cells, achieving efficiencies of up to 12% under optimal conditions. The ability to finely tune the coating parameters allows for the production of high-quality films that are suitable for large-scale applications, offering a significant advancement in the scalability of perovskite solar cell manufacturing.

Future Directions: The findings suggest that further optimization of slot-die coating parameters and a deeper understanding of transient behaviors in these devices could lead to even greater efficiencies and stability. Exploring additional dopants or multi-layer structures could also enhance the performance of niobium pentoxide ETLs, paving the way for more robust and commercially viable perovskite solar cells.

This study highlights the potential of slot-die coating as a transformative technology for the production of perovskite solar cells, aligning with the industry's goals of achieving high efficiency, stability, and scalability in solar energy solutions.

Authors:

Lucas Jorge Affonço

Silvia Fernandes

João Pedro Ferreira Assunção

Janardan Dagar

Carlos Graeff

José Carlos da Silva da Silva

Eva Unger

Learn More About Slot-die Coatng

How to Select the Right Slot-Die Head

Selecting the appropriate slot-die head is crucial for optimizing the performance of your coating processes in various applications.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

Source Measure Units

The infinityPV Source Measure Units offer cutting-edge technology for precise solar cell characterization and research, redefining precision and efficiency in testing.