LabelTEC Corona Surface Treater Wide

Enables effective surface treatment of polymer-based materials, enhancing their wettability through electrical discharge.

Enables effective surface treatment of polymer-based materials, enhancing their wettability through electrical discharge.

Enables effective surface treatment of polymer-based materials, enhancing their wettability through electrical discharge.

Polymer substrates, due to their naturally low surface energy, often suffer from poor adhesion to inks, glues, and coatings. For optimal adhesion, the surface energy of the substrate must be increased to just above that of the material being applied.

Corona surface treatment with LabelTEC by Tantec effectively enhances surface adhesion properties, making it ideal for pretreating conductive and non-conductive narrow webs. This system can treat one or both sides of the web and accommodates widths from 100-500 mm, with production speeds reaching up to 150 m/min.

Technical Specifications

Mains Voltage and Frequency: 230 VAC 50/60 Hz

Output Voltage/Power: Choose from 200W / 1000W / 2000W

Output Frequency: Up to 30 kHz

Mains Cable: Supplied with connector

Control Interface: Connector supplied

Operator Display: HMI remote

Treatment Width (mm): From 100 – 500 mm

Side for Treatment: 1 or 2 sides

Speeds: Up to 150 m/min

Electrodes: Ceramic

Modular Customization with the Laboratory Roll-to-Roll Coater

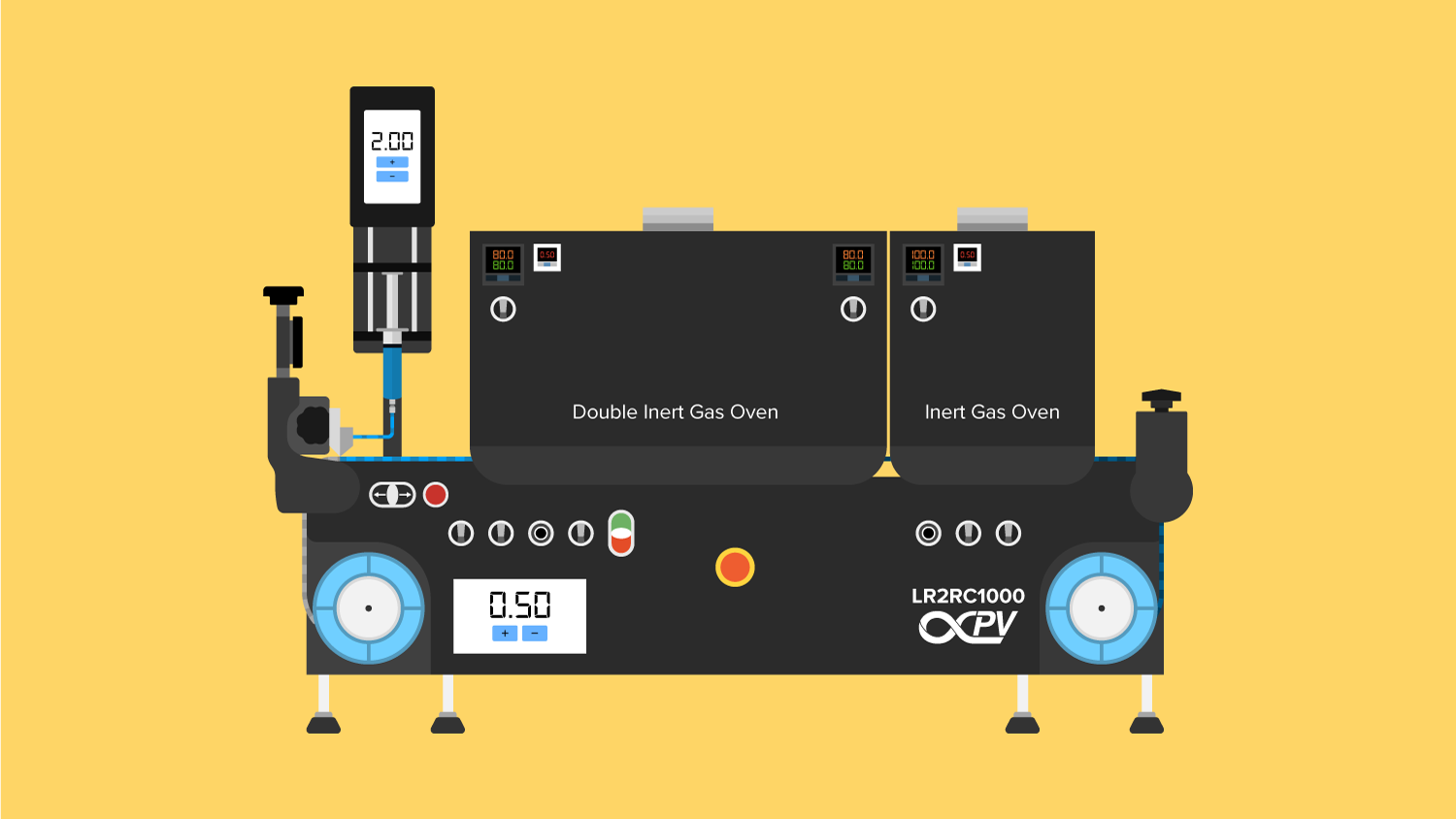

The Laboratory Roll-to-Roll Coater is a high-precision, compact solution for processing thin functional films in both lab and small pilot-scale environments. Its versatile modular design supports slot-die coating, slurry coating, and flexographic printing, and accommodates various coating components including slot-die heads, laminators, air knives, edge guides, plasma and corona treatment systems, and drying and curing ovens. The Laboratory Roll-to-Roll Coater can fit seamlessly into existing lab spaces, gloveboxes, or fume hoods without additional infrastructure. Capable of handling hundreds of meters of foil, it provides scalability and efficiency for applications such as thin film batteries, fuel cells, printed solar cells, OLEDs, sensors, adhesives. Designed for user convenience and built to international safety standards, the Laboratory Roll-to-Roll Coater is a flexible and economical choice for advancing thin-film technology. Customize your system today to meet your specific needs.

Key Features

Compact Size: Fits in laboratories, gloveboxes, or fume hoods without additional infrastructure.

Customizable: Choose from a variety of lengths and widths, with numerous components available.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

Modular Drying/Curing System: Accommodates various drying and curing methods.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

Technical Specifications

Operating Power: Single phase (240VAC) for smaller models; three-phase (400VAC) for larger models.

Drying/Curing Length: From 250 mm (LR2RC500) to 1250 mm (LR2RC1500).

Web Width: Up to 200 mm (standard), up to 310 mm (wide models).

Web Speed: 0.05-2.8 m/min (forward and reverse).

Spindles: Automatic compressed air spindles for 3-inch core diameters, adjustable cones for smaller cores in LR2RC500.

Applications

Printed Solar Cells (OPV, Perovskite, DSSC, Tandem)

Adhesives and Sealants

Medical Devices (Biocompatible and Drug-eluting Layers)

Packaging Materials