Robotization of solar cell fabrication

infinityPV is a high technology company that manufactures flexible plastic solar cells. The actual solar cell film is produced efficiently through roll-to-roll production in endless lanes. However, the transition from a roll of a large number of solar modules to discreetly cut and properly treated solar cells is a major challenge and a key to commercial success.

The Project

Innovation Fund Denmark supports the development of a robotized line for the after treatment of solar cells through its Innobooster initiative. The project includes vision control, laser cutting, handling of foils as well as contacting and testing of solar cells (see illustration to the right).

infinityPV believes that a production of solar cells require the highest degree of automation and has implemented UR5 robots from Universal Robots for this purpose. A vision system allows for position registration as well as optical quality control. The robot is interfased with a laser cutter allowing seperation of the individual solar cells / modules. Busbar tape is applied using a custom 3d printed tape dispenser operated by the robot, and IV testing is done directly by the robot, allowing solar cells to be sorted.

During the project the following features were developed, tested, and evaluated.

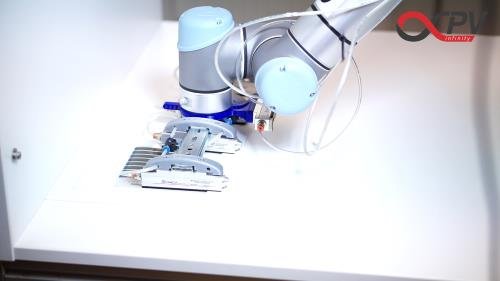

Robotic system implementation

A UR5 robot was implemented and safety parameters explored. A mobile robot platform was developed allowing the robot to interface various stations (e.g. the laser cutter). The robot was programmed to include a program selector allowing easy setup for different foil designs, pickup sequences, garbage pickup, and more.

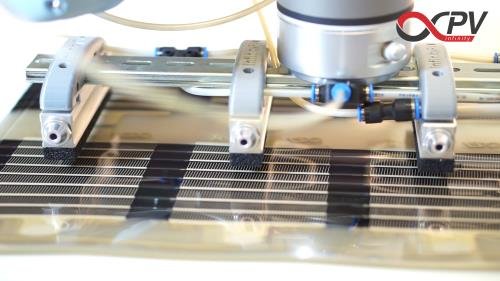

Solar foil handling

Various suction cups and foam suction planes were tested. A vacuum sensor was installed allowing the robot to continuously detect when items are picked up. This allows the robot to register samples in a pile, detect when a pile was empty, and detect pile the height.

Vision system

A vision system was implemented allowing the solar foil to be located based on contrast images. The system allows sub millimeter pickup precision with the robot.

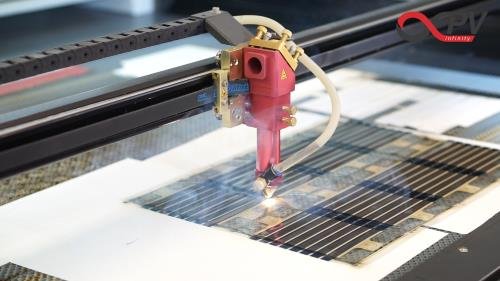

Laser cutter

The UR5 robot was interfaced with a BRM Lasers laser cutter, allowing the robot to activate the laser cutter and detect when the cutting process was done.

Busbar tape

Using a custom 3d printed tape dispenser and spool holder as well as a custom vacuum gripper, the robot can pick custom tape length, separate the tape liner, and cut the tape. Then placement of the tape was controlled using the vision system.

Solar foil test

A simple system with contact pins was utilized to test the solar cells after the busbar tape was implemented. This allows for quality control of the products.

Future perspectives

infinityPV is dedicated to the Industry 4.0 philosophy. We believe that automation and data exchange in manufacturing technologies is a critical for the future of organic solar cell manufacture. Our future goals include implementation of several collaborating robots allowing complex tasks to be completed, full process and manufacturing data logging, and more.