Groundbreaking Hydrogel System Significantly Improves Solar Cell Efficiency Through Passive Cooling

A recent study published in Advanced Materials Technologies explores an innovative hydrogel system designed to passively cool solar cells. The research introduces a thermoresponsive hydrogel capable of reducing solar panel temperatures by 23 °C, leading to a 12.3% increase in power conversion efficiency (PCE). This study provides valuable insights into an energy-efficient and cost-effective method for improving solar cell performance, particularly in hot climates where high temperatures can significantly degrade photovoltaic (PV) efficiency.

Key Highlights

High temperatures reduce solar cell efficiency, with performance losses of up to 18% at 65–70°C.

The study introduces thermoresponsive poly(N-isopropylacrylamide) (PNIPAM) hydrogels.

The optimal hydrogel composition (PNIPAM with 15% polyacrylamide) achieved a high swelling ratio and rapid water release rate.

The hydrogel reduced silicon PV cell temperatures from 70°C to 47°C .

Power conversion efficiency increased from 12.2% to 13.7%, a relative improvement of 12.3%.

The required hydrogel weight was 90% lower than conventional phase change materials (PCMs).

The study highlights the potential for hydrogel-based cooling in sustainable energy solutions.

The hydrogel is lightweight, easy to apply, and does not require electricity to function, making it an attractive alternative to active cooling systems.

The Challenge: Heat-Induced Efficiency Loss in Solar Cells

Solar panels are highly susceptible to performance losses due to heat. As temperatures increase, the open-circuit voltage of photovoltaic (PV) cells decreases, reducing overall efficiency. Studies have shown that PV efficiency can drop by approximately 0.45% per degree Celsius increase in temperature. At 65 °C, solar cells can lose up to 18% of their efficiency. This issue is particularly concerning as global temperatures rise, making cooling solutions imperative for maximizing renewable energy output. Traditional cooling solutions, such as water circulation or air cooling, often require additional power, increasing operational costs and reducing net energy production.

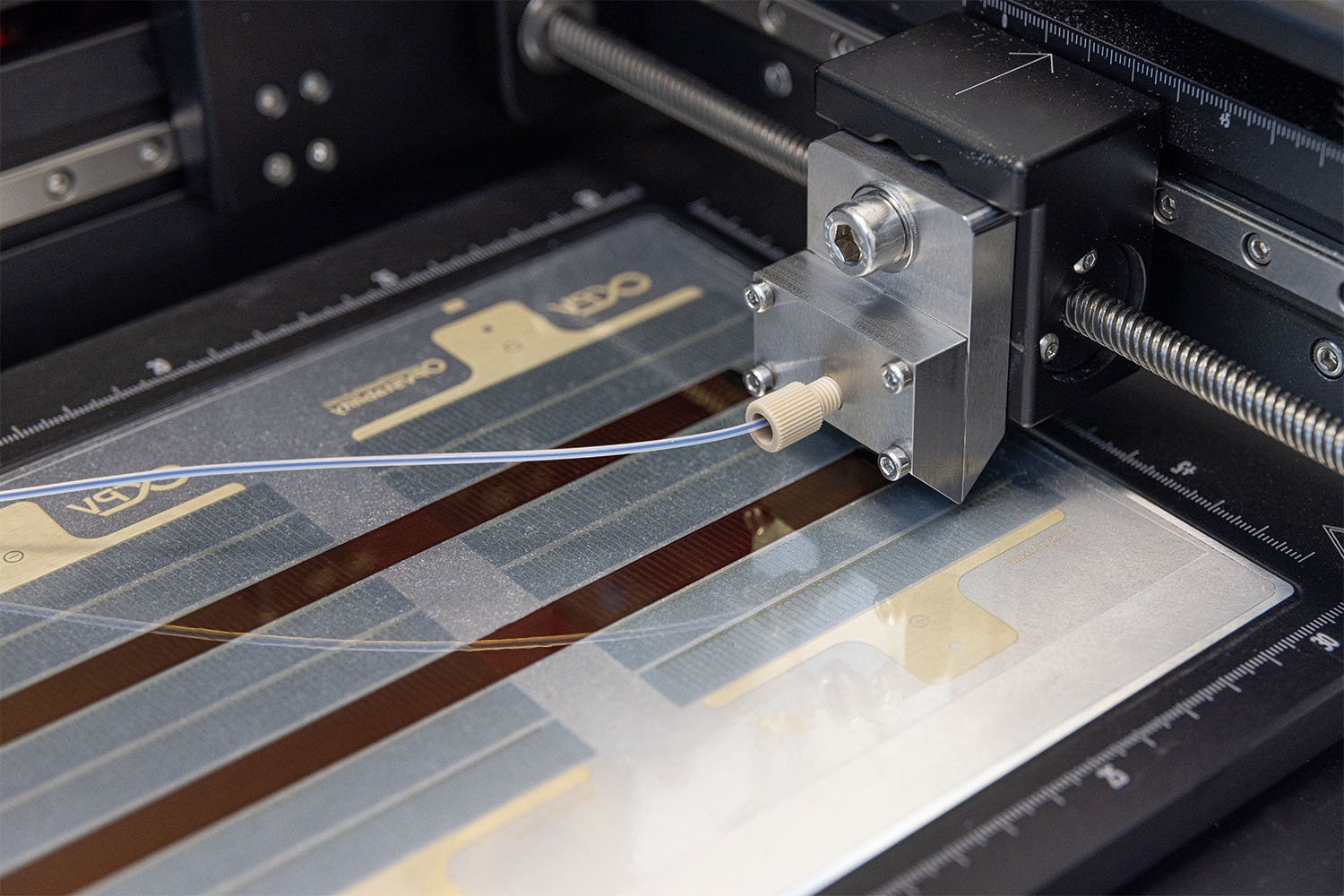

Use a precision slot-die coater to make flexible solar cells.

The Study: Hydrogel-Based Passive Cooling Approach

The researchers investigated a passive cooling method using hydrogels that absorb and release water to dissipate heat. The key material used in this study was PNIPAM, a thermoresponsive polymer that contracts and releases water when temperatures exceed 32–33 °C. By incorporating polyacrylamide (PAM), poly(vinyl alcohol) (PVA), or polyethylene glycol (PEG), the team optimized the hydrogel's cooling performance.

Experimental Methods

Hydrogels were synthesized and tested for water absorption, water release rates, and cooling efficiency.

Differential thermal analysis (DTA) was conducted to quantify cooling power and heat dissipation rates.

Solar panels were tested under simulated sunlight to measure temperature reductions and efficiency improvements.

Hydrogels were applied to the backside of the solar panels to evaluate real-world application feasibility.

Various compositions of hydrogels were compared to determine the most effective cooling agent.

-

Higher temperatures increase carrier recombination rates in solar cells, leading to lower open-circuit voltage and reduced power output.

Results: High Efficiency with Minimal Material Use

The best-performing hydrogel, PNIPAM/PAM (15% PAM), exhibited a swelling ratio of 30 and a specific cooling power of 1.86 W/g. When applied to silicon PV cells, this hydrogel lowered the temperature from 70 °C to 47 °C, resulting in a relative increase in PCE of 12.3%.

Crucially, this hydrogel required only 5.1 kg per square meter of PV panels, significantly less than the 50 kg/m² needed for traditional phase change materials. This reduction in weight and material use makes the hydrogel system a practical and scalable solution for solar energy applications.

Comparison with Other Cooling Methods

Passive cooling methods are gaining interest due to their energy efficiency and low maintenance requirements. Compared to phase change materials, the hydrogel system offers several advantages:

Lower weight: PCMs typically require up to 50 kg per square meter, while the hydrogel system needs only 5.1 kg.

Greater temperature reduction: The hydrogel system reduces temperatures by 23 °C, whereas PCMs usually achieve reductions of 10–15 °C.

Ease of application: Hydrogels can be applied as a coating or layer without requiring specialized encapsulation.

Sustainability: Unlike some PCMs, which may degrade over time, hydrogels are environmentally friendly and non-toxic.

Build your own R2R Slot-die Coater machine. Choose between slot-die heads, flexographic printers, slurry coaters, air knives, drying and curing units, laminators and more.

Significance and Future Applications

This study demonstrates that hydrogel-based passive cooling is a viable and effective solution for mitigating heat-induced losses in solar panels. The findings have significant implications for renewable energy efficiency, particularly in hot climates. Further research may explore:

Enhancing long-term stability and reusability of hydrogels.

Scaling up the application for commercial solar farms.

Investigating self-regenerating hydrogels that reabsorb water from humidity.

Developing hybrid cooling systems that combine hydrogels with radiative cooling technologies.

Conclusion

By introducing a lightweight, cost-effective hydrogel system for passive cooling, this study offers a promising solution for improving solar energy efficiency. With the potential to significantly reduce operational temperatures and boost power output, hydrogel cooling technology could become a crucial component in the future of solar energy. Given its scalability and minimal material requirements, this system could revolutionize the way solar panels are maintained and optimized for maximum efficiency.

Authors

Teerapat Lapsirivatkul

Supissra Boon-in

Daniel Crespy

Pichaya Pattanasattayavong

Get Professional Support for Your Coating Needs

Need help with slot-die coating, coating machines, or any related applications?

Contact infinityPV’s experts today for professional guidance and support.

Related Products

Laboratory Roll-to-Roll Coater

A compact and modular high precision roll-to-roll slot-die coater that transforms the way thin functional films are printed and coated.

LR2RC500 Bundle

Probably the world’s most compact R2R slot-die coater, featuring a syringe pump, a 65 mm slot-die head, and an infrared oven for precise lab coating.