LR2RC1000 Battery Coater

With a substrate processing width of up to 305 mm, you are well-equipped to initiate pilot-scale production of your battery technology.

With a substrate processing width of up to 305 mm, you are well-equipped to initiate pilot-scale production of your battery technology.

With a substrate processing width of up to 305 mm, you are well-equipped to initiate pilot-scale production of your battery technology.

Accelerate Solar Cell Innovation Today

The LR2RC Battery Coater 1000 not only enhances your ability to experiment and refine printed batteries but also provides a pathway to scale your research into potential commercial applications. Investing in these advanced features can significantly improve your research efficiency and outcomes.

What’s Included:

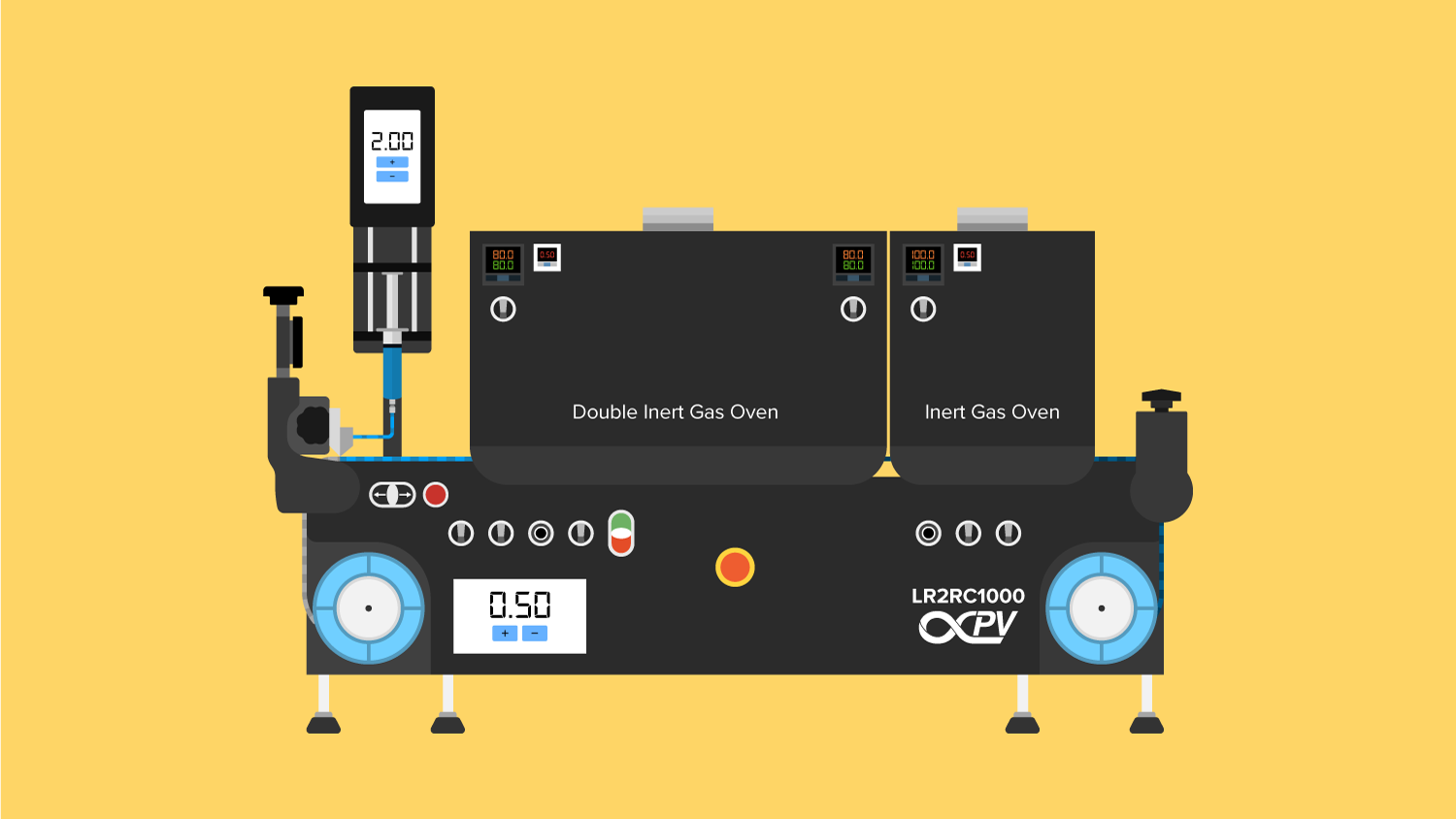

LR2RC1000 Wide Platform: Featuring anodized aluminum rollers, web tension control, spindles with adjustable conical bobbin holders, touch screen interface, and easy-to-use operation buttons.

Advanced Mounting System: Manual adjustment with digital micrometers units for two-point head to substrate distance readout.

Mammoth Syringe Pump: Provides precise and consistent ink delivery, ideal for research applications.

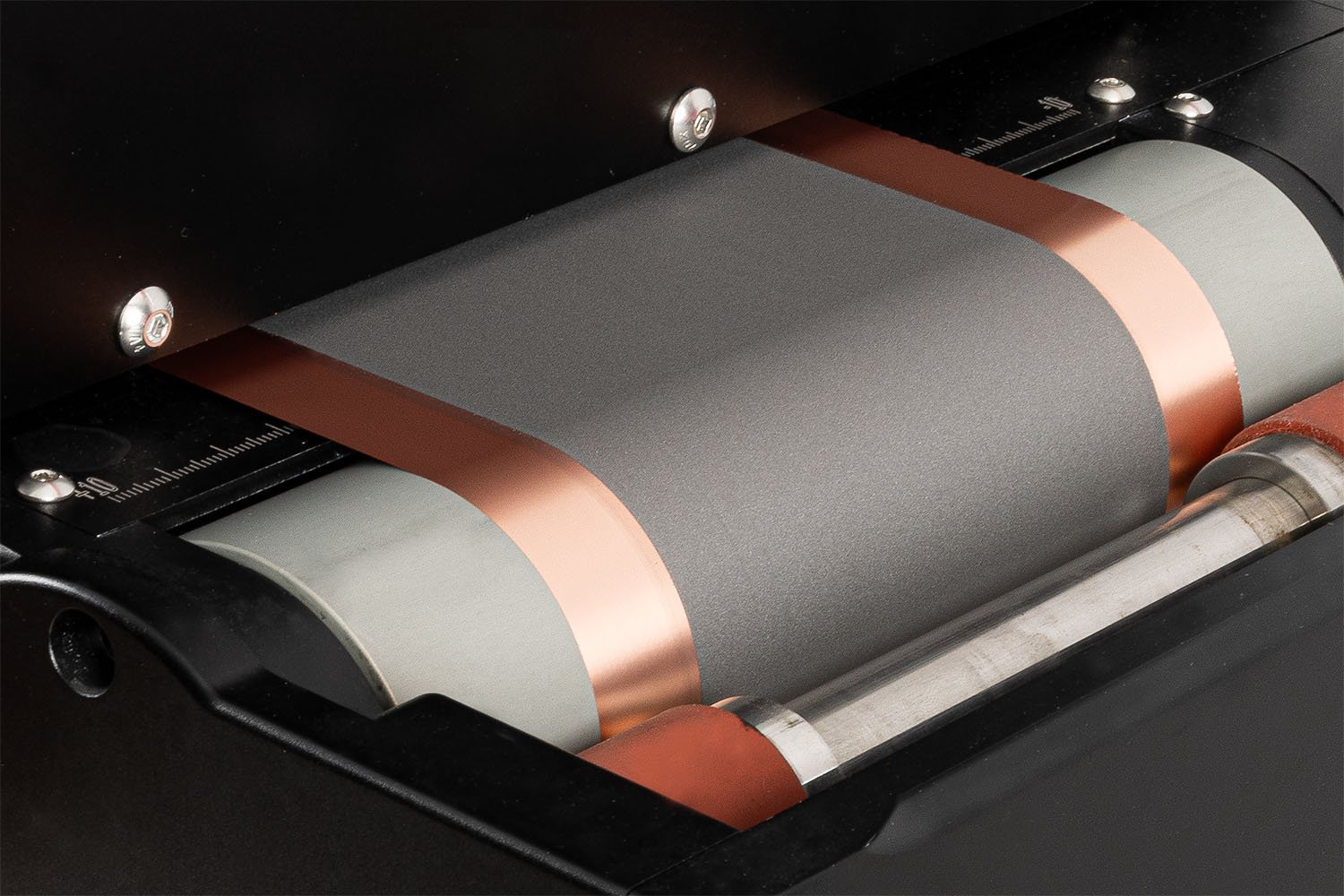

305 mm Stainless Slot-die Head (280 mm Working Width) incl. Shim Kit

Fitting Kits: High viscosity versions included.

Corona Surface Treater: Enables effective surface treatment of substrates.

Edge Guide: For high precision alignment of the substrate.

Inert Gas Oven and Double Inert Gas Oven: For effective drying and curing at a lab scale, enabling quick setup and adjustments to meet your specific needs.

Adjustable Nip Roller: Tailor your setup for various substrate handling requirements.

Key Features

Compact Size: Fits in laboratories without additional infrastructure.

Customizable: Choose from a variety of lengths and widths, with numerous components available.

Easy and Fast Exchangeable Modular Components: Includes printing and coating units, drying and curing systems, foil pretreatment, laminators, trimming knives, and more.

Modular Drying/Curing System: Accommodates various drying and curing methods.

Software Control Option: Advanced control options for precision and repeatability.

Web Tension Control: Ensures consistent quality across runs.

CE Certified - CSA/UL Compliant: Meets international safety standards.

Technical Specifications

Operating Power: Three-phase (400VAC) for larger models.

Drying/Curing Length: 1,25 m

Web Width: Up to 305 mm

Web Speed: 0.05-2.8 m/min (forward and reverse).

Why Choose the LR2RC Battery Coater 1000?

Comprehensive Capabilities: The combination of advanced components (like slot-die head, Edge guide, pump, corona, and oven systems) allows you to conduct a wide range of experiments, from double sided slot-die coating to preprocessing of Cu foil, all in one system.

Scalability: Designed for roll-to-roll (R2R) applications, this system facilitates the transition from lab-scale experiments to larger-scale production, crucial for commercial viability of printed batteries.

Cost-Effective Research: By integrating multiple functions and reducing the need for additional equipment, this system can help lower overall research and development costs while maximizing efficiency.

Customizable and Modular: With modular components, the setup can be easily adapted to fit your specific requirements, making it the ideal platform for diverse applications.