Slot-die Heads

From precision coating in laboratory settings to seamless industrial-scale production, our heads deliver unmatched performance

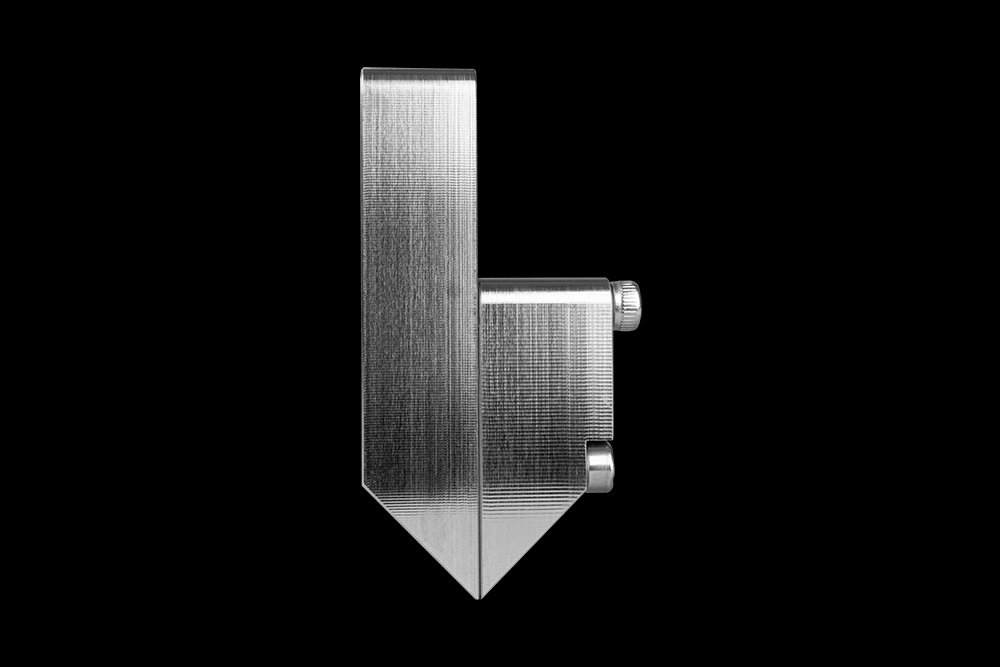

Standard and Customized Slot-die Heads

Our standard slot-die heads are meticulously crafted to meet industry demands, offering superior performance and reliability. However, we understand that your specific requirements may vary. That's why we also offer customizable options tailored to your unique needs.

Our standard and most sold slot-die head:

Stainless Steel (M315 Heavy): Budget friendly and will solve the task in 95% of all cases.

We also offer slot-die heads in three other materials:

PEEK (Ultra-Lightweight): Ideal for applications where weight is a critical factor.

Stainless Steels (316L Heavy): Known for their durability and resilience.

Titanium (Lightweight): Combining strength with lightweight properties for optimal performance.

In addition to these standard materials, we also provide various alloys such as aluminum-magnesium. Furthermore, we have the capability to manufacture heads in specialty materials like inconel and teflon upon request.

40 mm Head (10/13 mm Working Width)

65 mm Head (50 mm Working Width)

115 mm Head (100 mm Working Width)

165 mm Head (150 mm Working Width)

195 mm Head (180 mm Working Width)

305 mm Head (195 mm Working Width)

Slot-die Heads from infinityPV

Engineered with precision and innovation in mind, our slot-die heads offer unparalleled performance across various materials and size. Available in PEEK, Stainless Steel (315/316L) and Titanium in standard widths of 40 mm, 65 mm, 115 mm, 165 mm, 195 mm and 305 mm, these heads accommodate a wide range of working widths, allowing for precise coatings ranging from minute details to expansive surfaces.

Designed for versatility, our slot-die heads feature optimized dead volumes suitable for laboratory, pilot, and industrial-scale applications. Whether you're working with microliters or milliliters, our heads deliver consistent and reliable performance across a variety of coating scenarios.

Practicality is at the forefront of our design. With only two parts, our slot-die heads simplify assembly, disassembly, and cleaning processes, enhancing efficiency and reducing downtime. Whether you're operating at low pressure with low-viscosity inks or seeking rapid positioning on automated coating platforms, our lightweight PEEK heads offer ease of use without compromising precision.

We prioritize accessibility and convenience. We maintain a comprehensive stock of standard heads and shim kits, ensuring quick availability for your projects. Additionally, our team specializes in crafting custom shims tailored to your unique specifications, providing personalized solutions to meet your specific coating requirements.

Experience the reliability and performance of infinityPV slot-die heads — an essential tool for achieving precise and efficient coatings in diverse applications.

Key Highlights

Available in PEEK, Stainless Steel and Titanium

Standard Available in Widths of:

40 mm (10/13 mm Working Width)

65 mm (50 mm Working Width)

115 mm (100 mm Working Width)

165 mm (150 mm Working Width)

195 mm (180 mm Working Width)

305 mm (280 mm Working Width)

Light Weight

No Gaskets

Few Parts

Very Simple to Assemble and Disassemble

Easy to Clean and Maintain

From Single Stripes to Many

From Narrow to Wide Coating Width

Easy Design of Shims and Meniscus Guides

Very Low Dead Volume is Possible

Available with Electrical Heating

Temperature Controller for Heated Slot-die Heads

Fits all Our Coating and Printing Platforms

Fitting Kits and Shim Kits

All of our slot-die heads necessitate fitting kits and shim kits for optimal operation. Our range of small laboratory-scale heads is available in various materials and standard widths, including 40 mm, 65 mm, 115 mm, 165 mm, 195 mm, and 305 mm. These dimensions accommodate working widths ranging from a single 10 mm or 13 mm stripe to 50 mm, 100 mm, 150 mm, 180 mm, and 280 mm, respectively. We keep standard heads and shims in stock and offer custom shim fabrication for our clients. Plus, we can tailor slot-die heads and kits to your specific needs.

Fitting Kits

Our fitting kits come preassembled with hoses and fittings, simplifying the connection of your slot-die head to a syringe for ink feeding. Crafted from high-quality materials, the fitting kit ensures durability and can be reused multiple times

Shim Kits

By adjusting the thickness of the shim, you can finely tune the gap between the slot-die lips, influencing the amount of material deposited onto the substrate during the coating process. Shims play a crucial role in achieving precise and uniform coatings.

How to Select the Correct Slot-die Head

Selecting the right slot-die head involves considering various options and decisions. To guide you through this process, we’ve compiled a list of questions. Please review them and answer them as well as you can to ensure that you choose the most suitable product for your needs.

Are you coating at high speed (>2 m min¹) or low speed (< 2 m min⁻¹)?

Is your ink material high viscosity (>100 mPas) or low viscosity (0.6-100 mPas)?

Does your ink exhibit Newtonian, thixotropic or rheopexic behavior?

Do you need to pump ink at high pressure?

Is your ink homogenous or inhomogenous (i.e. it contains particles)?

If it contains particles, are they magnetic?

Is the chemistry of your ink mild (i.e. organic solvents) or extreme

(i.e. strongly corrosive or redox active)?

Is your ink very costly or is it available in volume?

Do you need to coat lines or do you need to apply an even coat over

the entire working width?

What coated width do you need (working width)?

Do you have geometrical constraints surrounding your coating platform

(i.e. inverted coating or narrow space)?

Do you need to heat or cool your ink during coating?

Do you need constant agitation of your ink to maintain homogeneity?

Do you have a requirement for very high precision?

Is the budget for you application limited?

Do you need a general-purpose multiple use slot-die head or will it be

dedicated to one process and only one ink?

By answering these questions, you’ll discover that decisions regarding materials, dead volume, feed ports, connections, lip design, precision, special functions, and more have already been addressed. Generally, our budget-friendly option will meet your requirements, but occasionally, there may be situations where low-cost solutions are not available.

Selection Guide

| PEEK | M315 Stainless | 316L Stainless | Titanium | |

|---|---|---|---|---|

| 40 mm Head (10/13 mm Working Width) |

✓ |

✓ |

||

| 65 mm Head (50 mm Working Width) | ✓ | ✓ | ✓ | ✓ |

| 115 mm Head (100 mm Working Width) |

✓ |

✓ |

✓ | ✓ |

| 165 mm Head (150 mm Working Width) | ✓ | ✓ | ✓ | ✓ |

| 195 mm Head (180 mm Working Width) | ✓ | ✓ | ✓ | ✓ |

| 305 mm Head (280 mm Working Width) | ✓ | ✓ | ||

| Heated 65 mm Head (50 mm Working Width) | ✓ | ✓ | ✓ | |

| Heated 115 mm Head (100 mm Working Width) | ✓ | ✓ | ✓ | |

| Heated 165 mm Head (150 mm Working Width) | ✓ | ✓ | ✓ | |

| Heated 195 mm Head (180 mm Working Width) | ✓ | ✓ | ✓ | |

| Light Weight | ✓ | ✓ | ✓ | ✓ |

| Heat Conducting | ✓ | ✓ | ✓ | |

| Thermally Insulating | ✓ | |||

| Low Heat Capacity | ✓ | |||

| Corrosion Resistant | ✓ | ✓ | ✓ | ✓ |

| Precision Ground | ✓ | ✓ | ✓ | |

| Cost | Medium | Low | High | High |

Videos

Organic Solar Cells: Fast Roll-to-Roll (R2R) Printing and Coating

How to Print Solar Cells With The Research Laboratory Coater (RLC)

Related Products

Laboratory Roll-To-Roll Coater

A compact high precision laboratory roll-to-roll coating machine that transforms the way thin functional films are printed and coated.

Research Laboratory Coater

The creative starting point where films can be made using your materials and inks through a wide choice of deposition techniques.